Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "Improve hydrodesulfurization activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

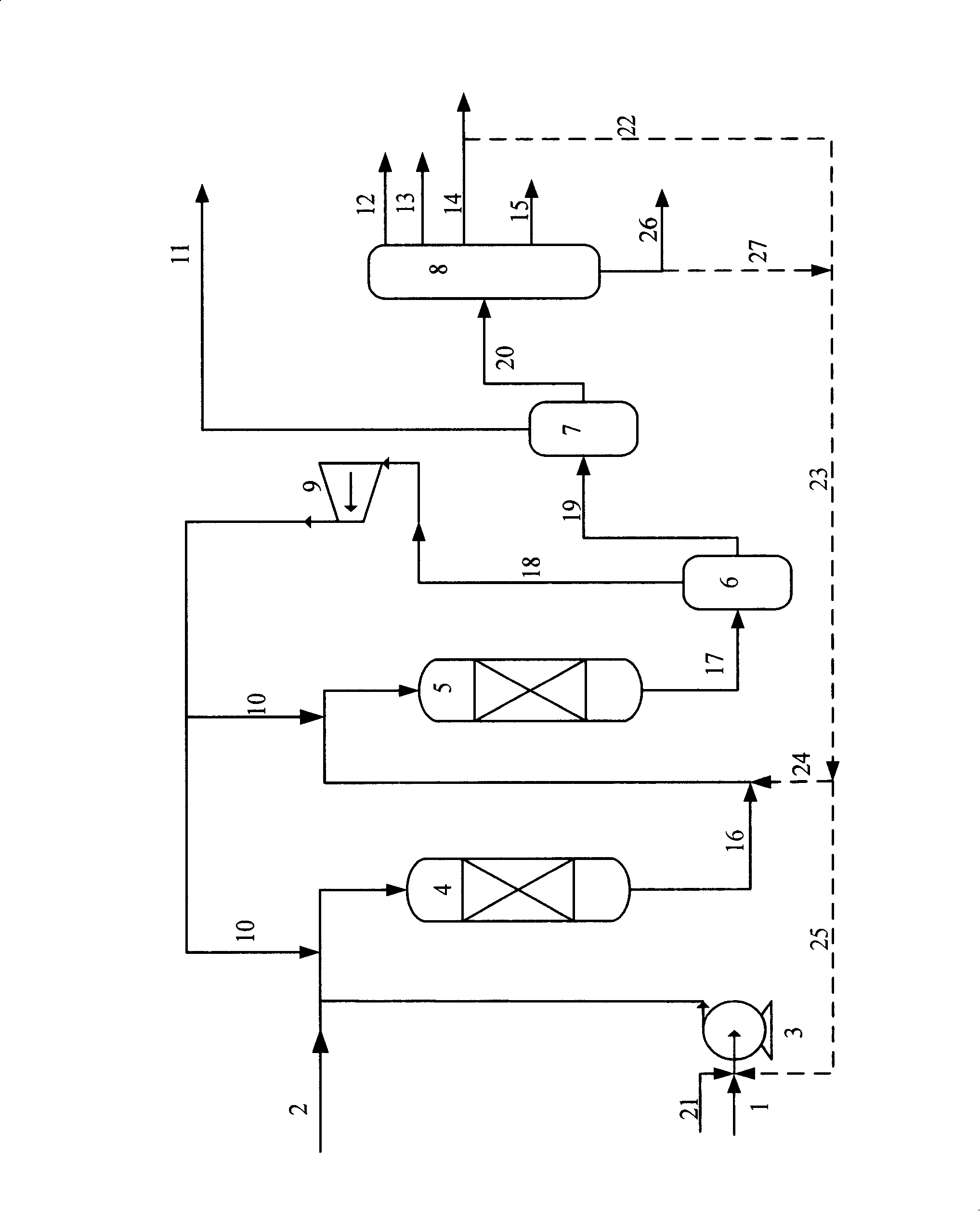

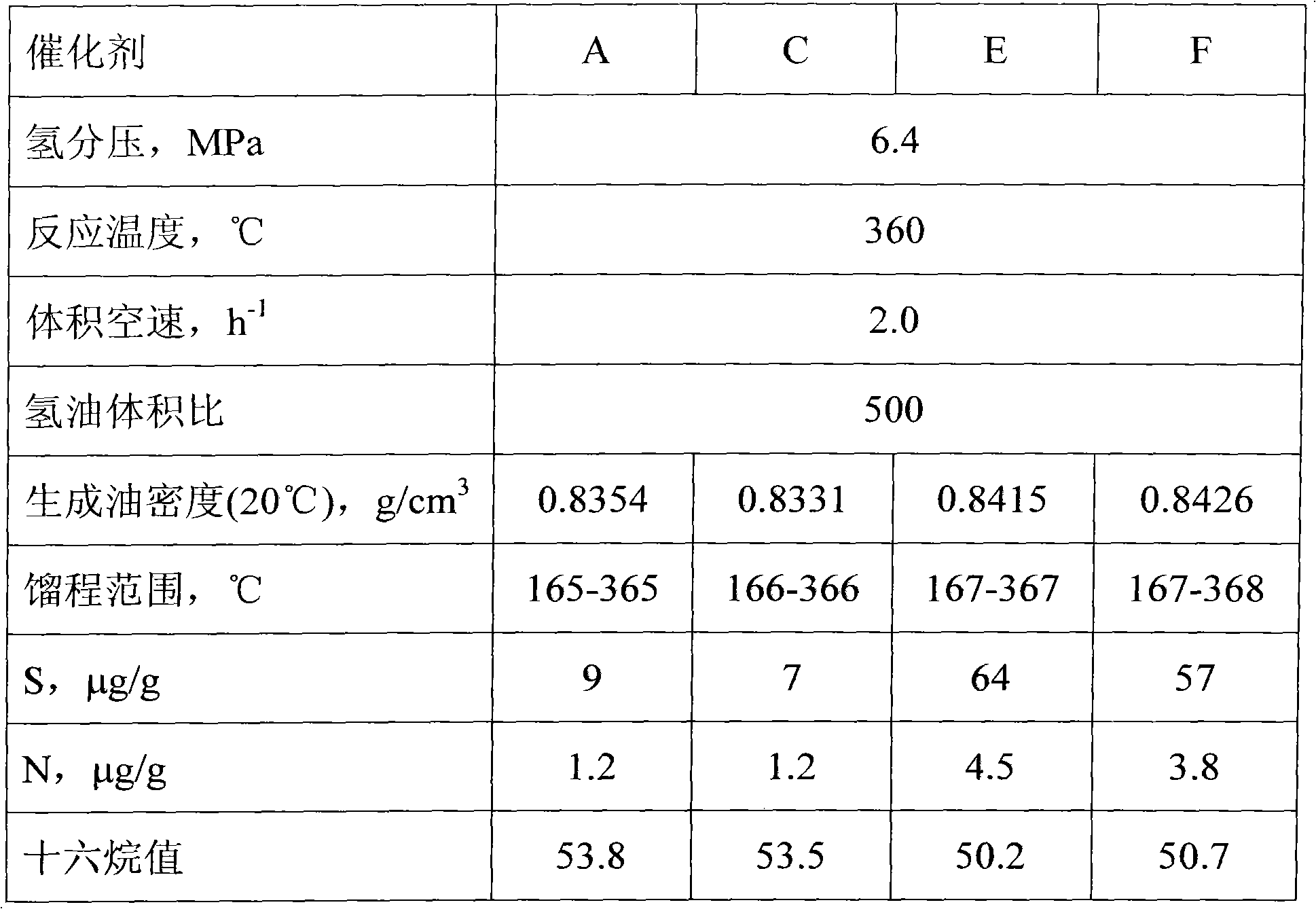

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

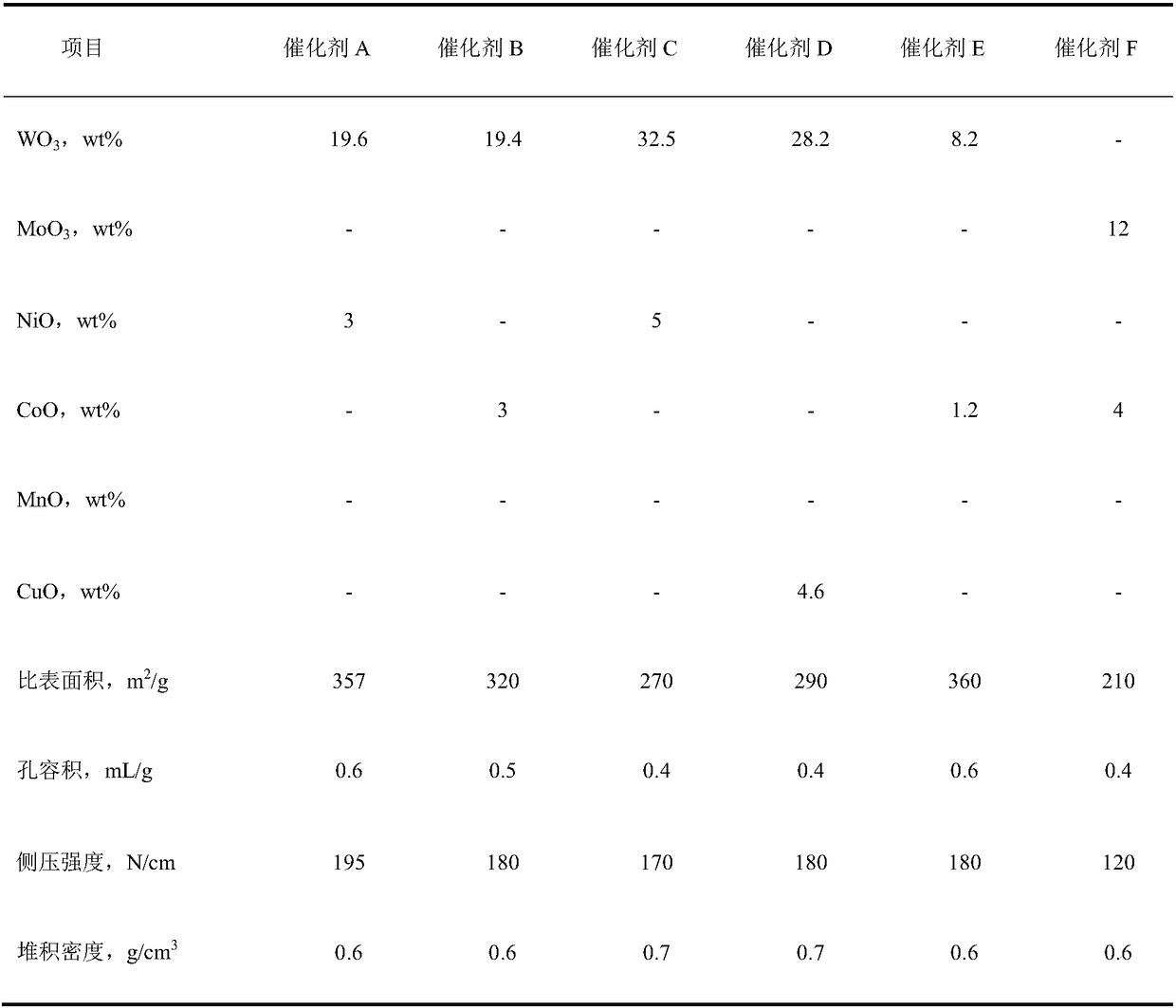

Refined catalyst for fraction oil hydrogenation and its preparing method

ActiveCN1648214AImprove hydrodesulfurization activityRefining to eliminate hetero atomsCobaltTungsten

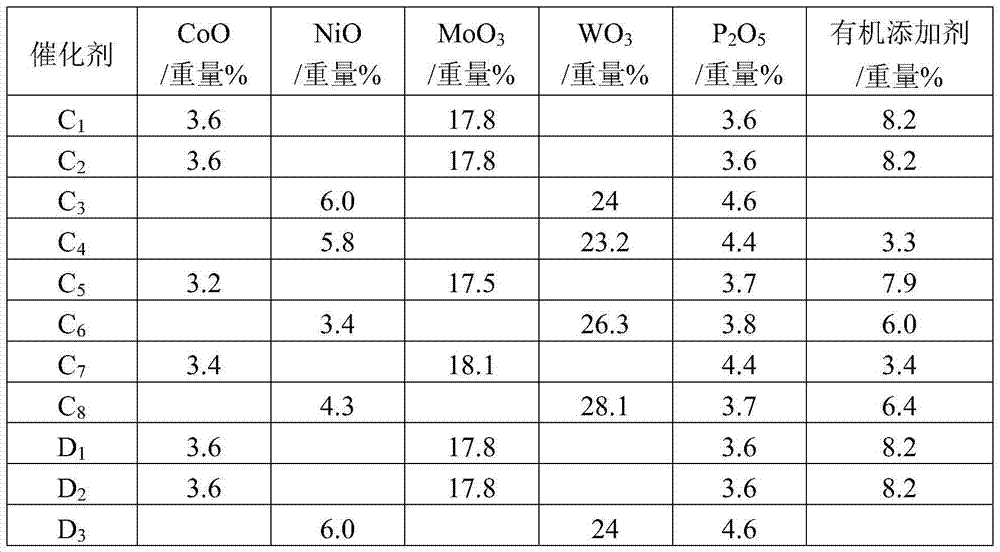

The fraction oil hydrorefining catalyst contains metal components Mo and / or W and Ni and / or Co, C and alumina; and features that its C and alumina is formed mixture carrier with C and alumina in the weight ratio of 1 / 99-1 / 4. Compared with available catalyst, the present invention has even high fraction oil hydrodesulfurizing activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impregnating solution of hydrogenation catalyst, its preparation method, hydrogenation catalyst and preparation method thereof

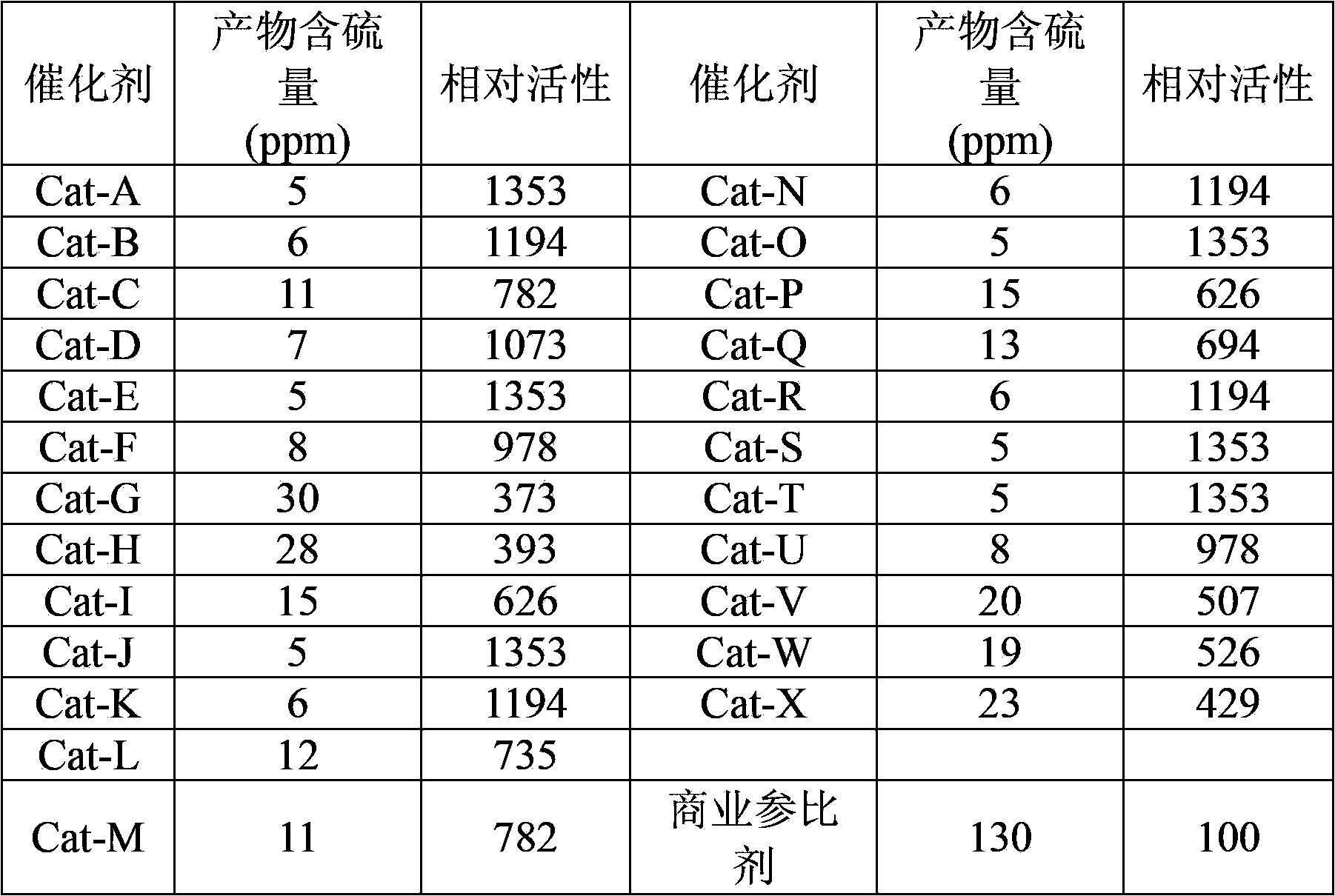

ActiveCN103055956AImprove hydrodesulfurization activityHigh activityMolecular sieve catalystsCatalyst activation/preparationHydrodesulfurizationDecane

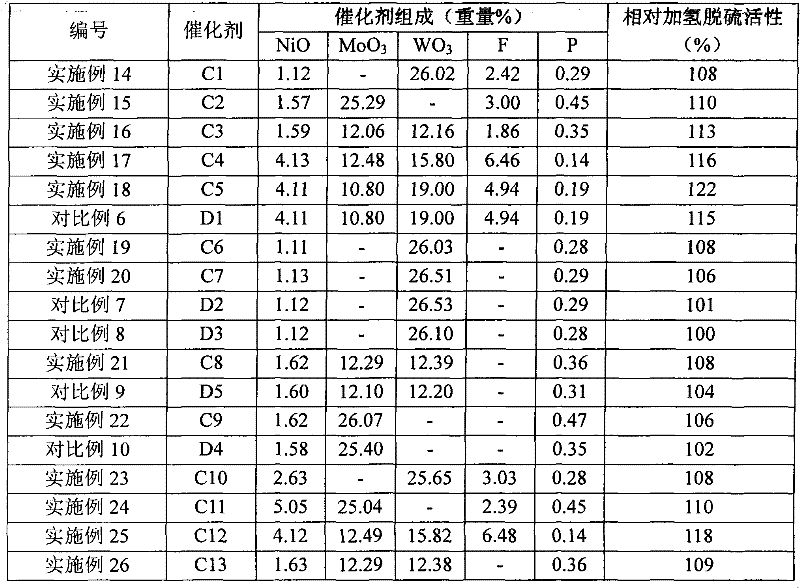

The invention provides an impregnating solution of a hydrogenation catalyst and its preparation method. The method includes: preparing a VIII-th group metal compound and a first organic complexing agent into an aqueous solution A; preparing a VIB-th group metal compound into an aqueous solution B; and mixing the aqueous solution A and the aqueous solution B. Specifically, the ligand of the first organic complexing agent at least contains the coordination atom N. The invention also provides a hydrogenation catalyst and a preparation method thereof. Compared with current catalysts, the hydrogenation catalyst provided in the invention has high hydrodesulfurization activity. For example, a mixed solution of n-decane with a 4, 6-dimethyldibenzothiophene (4, 6-DMDBT) content of 0.59wt% is adopted as the raw material, and hydrodesulfurization activity contrast evaluation is performed on the catalyst provided in the invention and a contrast catalyst. In terms of a contrast catalyst activity of 100, the hydrodesulfurization activity of the catalyst provided in the invention can reach 120.

Owner:CHINA PETROLEUM & CHEM CORP +1

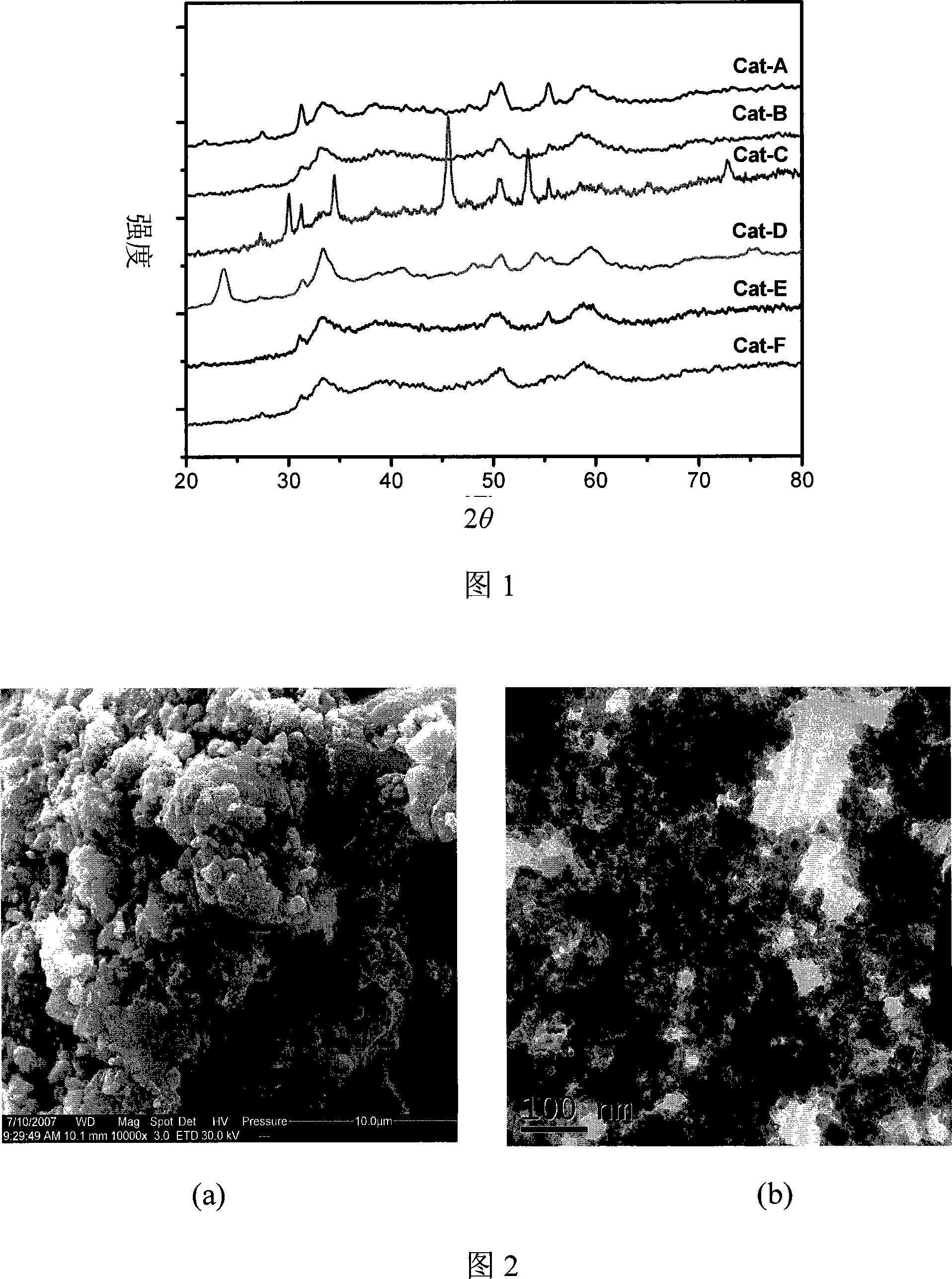

Multi-metal noumenon catalyzer for hydrodesulphurization of diesel oil, producing method and application of the same

InactiveCN101153228ARaw materials are simple and cheapEasy to operateRefining to eliminate hetero atomsHydrodesulfurizationSolvent

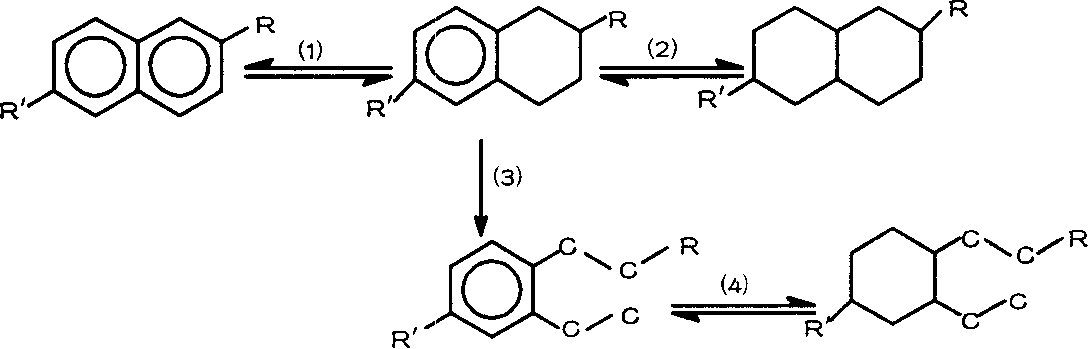

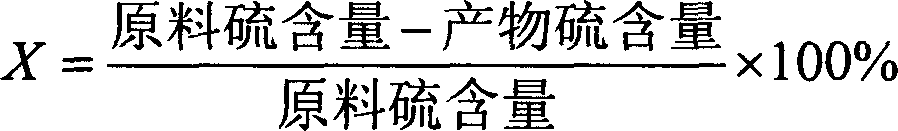

A polymetallic bulk catalyst for diesel oil hydrodesulfurization is provided. The particle diameter of the present invention is 10-100 nm, and the present invention consists of a species of VIII metal and two species of VIB metal, wherein, the mole ratio of the VIII metal and the VIB metal is 1:9-9:1, while the mole ratio of two species of VIB metal is 1:5-5:1. The preparation method is that: a) the basic carbonate of VIII metal is led to dissolve in solvent to form suspension liquid; b) two species of metal salts of the VIB metal are led to dissolve in the solvent, and surfactant is added into the solvent, stirred and heated to 50-250 DEG C; c) the suspension liquid in step a is added into the solvent in step b and led to react in reflux for 4-25 hours under 50-250 DEG C; d) the product obtained in step c is filtered, washed and dried to obtain target product. The catalyst of the present invention is used in the ultra-deep hydrodesulfurization of diesel oil and shows extremely high hydrodesulfurization activity. Under the same operating conditions, the activity of the present invention is 5.9 times as much as industrial reference agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

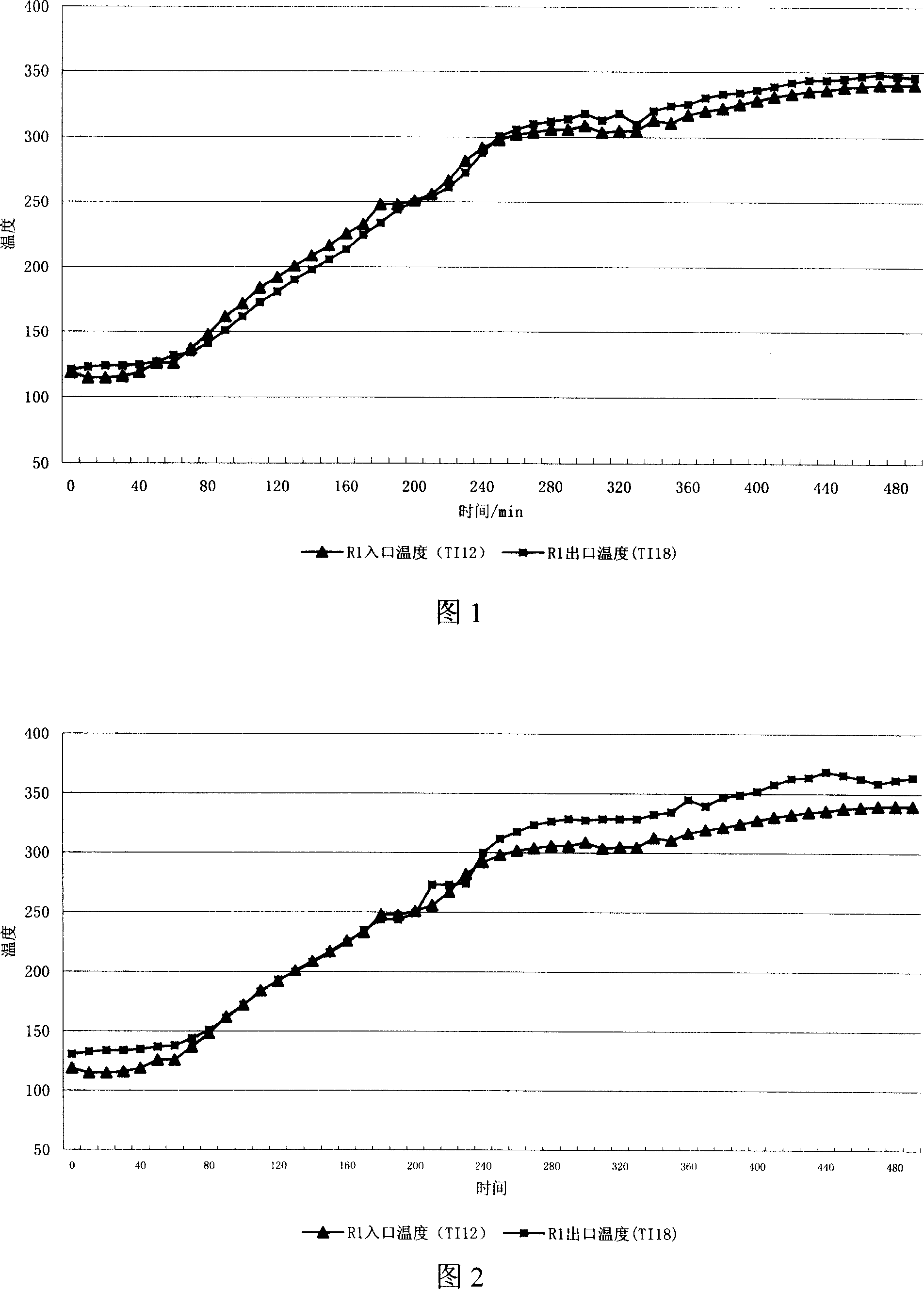

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrothermal deposition preparation of load type single metal hydrogenation catalyst

ActiveCN101298043BImprove and increase dispersionImprove hydrodesulfurization activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsOrganic acidPtru catalyst

The present invention provides a preparation method for a load type hydrogenation catalyst with high activation by hot water deposition. The saline solution of the reactive metal of VIB family is taken as a precursor, an inorganic acid solution as a precipitator and an organic acid as a dispersant; the metallic oxide particles are generated by a liquid deposition reaction in a hydrothermal condition; the organic acid is used for avoiding the conglobation of the oxide particles as well as reducing mutual effects between the oxide and a carrier; the high reaction activation and strong penetrability of subcritical water is utilized to evenly disperse active components on the carrier. The method is particularly suitable for preparing a W / gamma-Al2O3 catalyst, the prepared W / gamma-Al2O3 catalyst has high dispersion degree, relatively weak mutual effects between the active components and the carrier and higher desulfurization activation compared with a catalyst which has same content of active components and is prepared by a conventional pore volume saturation soaking method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

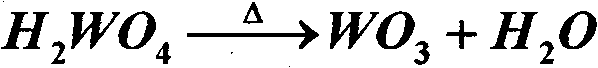

Method for preparing tungsten phosphide catalyst

InactiveCN102921441AGood stabilityImprove hydrodesulfurization activityPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryTungsten

The invention discloses a method for preparing a tungsten phosphide catalyst, and relates to a method for preparing the catalyst. The method for preparing the tungsten phosphide catalyst comprises the following steps of: smashing amorphous phosphotungstate at room temperature, uniformly mixing the amorphous phosphotungstate and gamma-Al2O3, pressing, screening, reducing particles of a certain mesh number in 923K hydrogen flow for 4 hours, and carrying out passivating in nitrogen flow with 0.5 percent of O2 at the room temperature for 2 hours. The tungsten phosphide catalyst is relatively high in stability; the hydrodesulfurization activity is extremely high; and the hydrodesulfurization rate of thiophene is reduced.

Owner:SHAANXI HI TECH ENERGY DEV

Hydrocatalyst and its preparing process

InactiveCN1356378AImprove hydrodesulfurization activityHigh activityHydrocarbon oils refiningNaphtha reformingActive componentSulfur

A hydrocatalyst for decreasing S and olefine contents in poor gasoline and increasing its octane value is prepared from the metallic active component which is two or three of MoOe, CoO and NiO and the carrier prepared from TiO2, modified ZSM-5 molecular sieve and adhesive.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

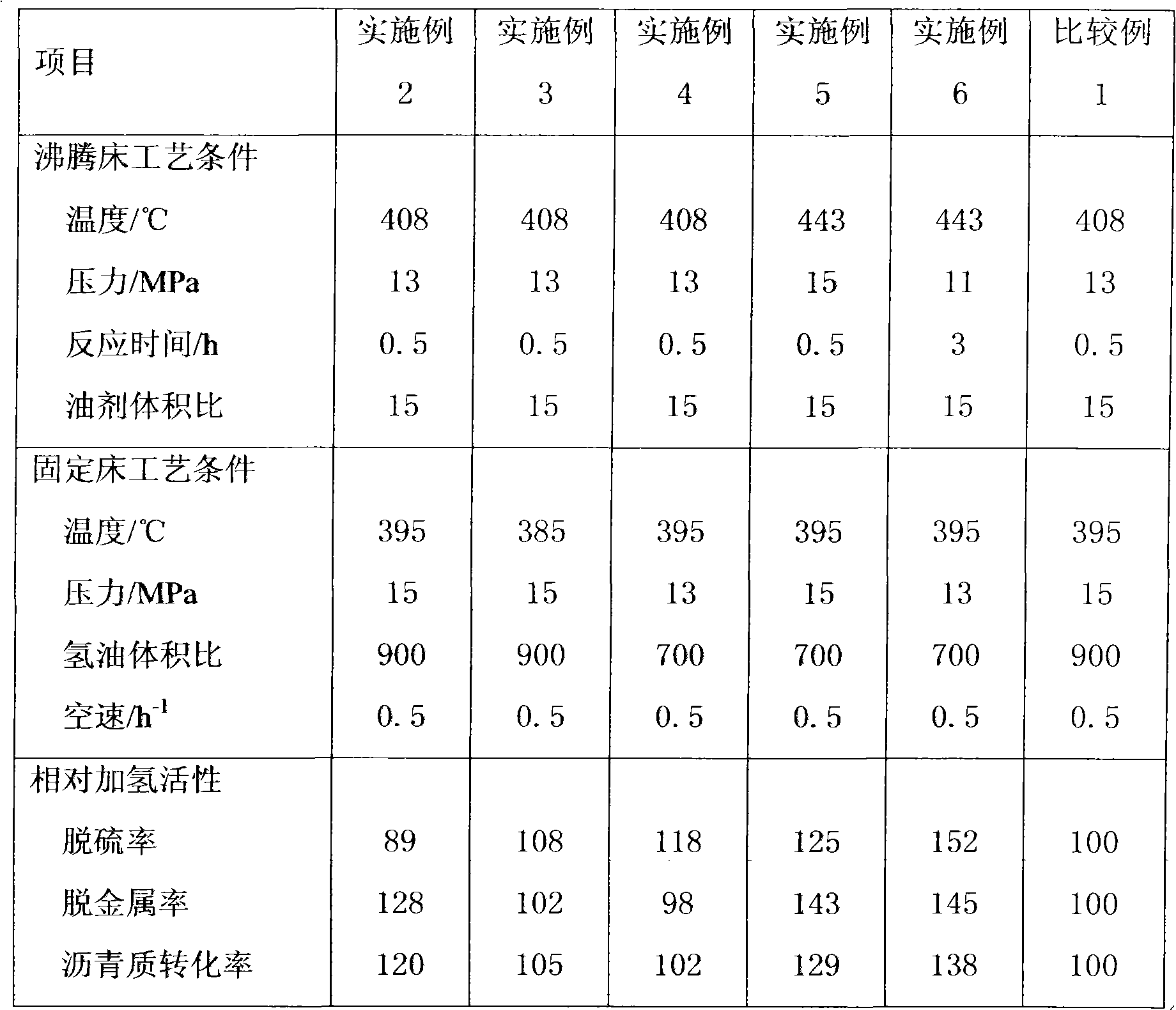

Heavy raw material boiling bed hydrogenation treatment method

ActiveCN102443414ALarge apertureStrong metal capacityHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenSlag

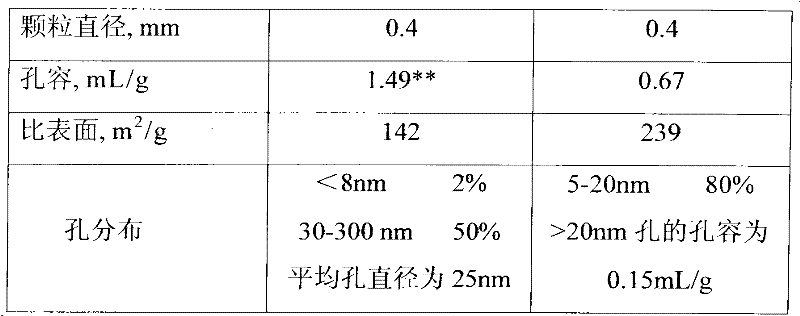

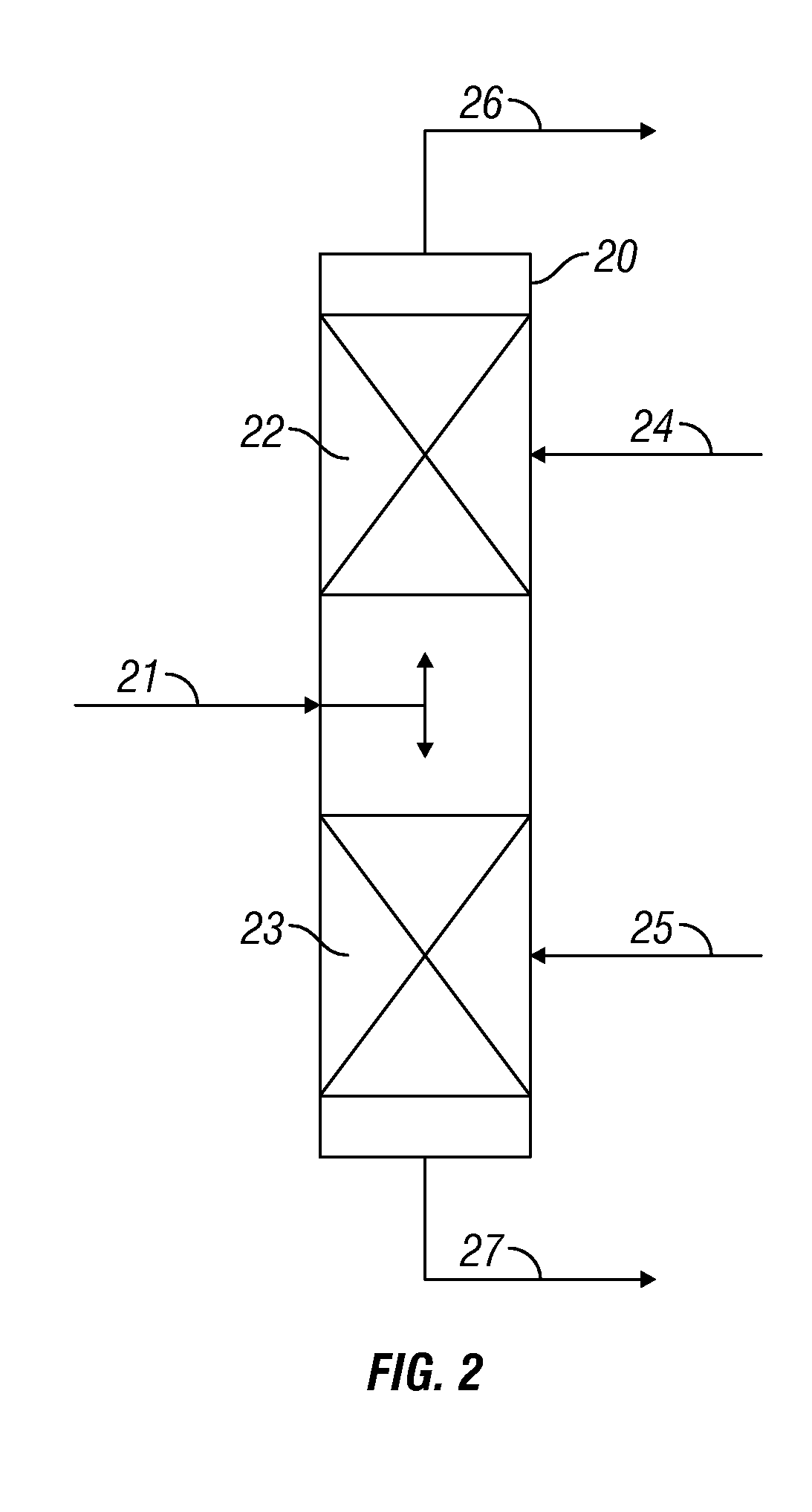

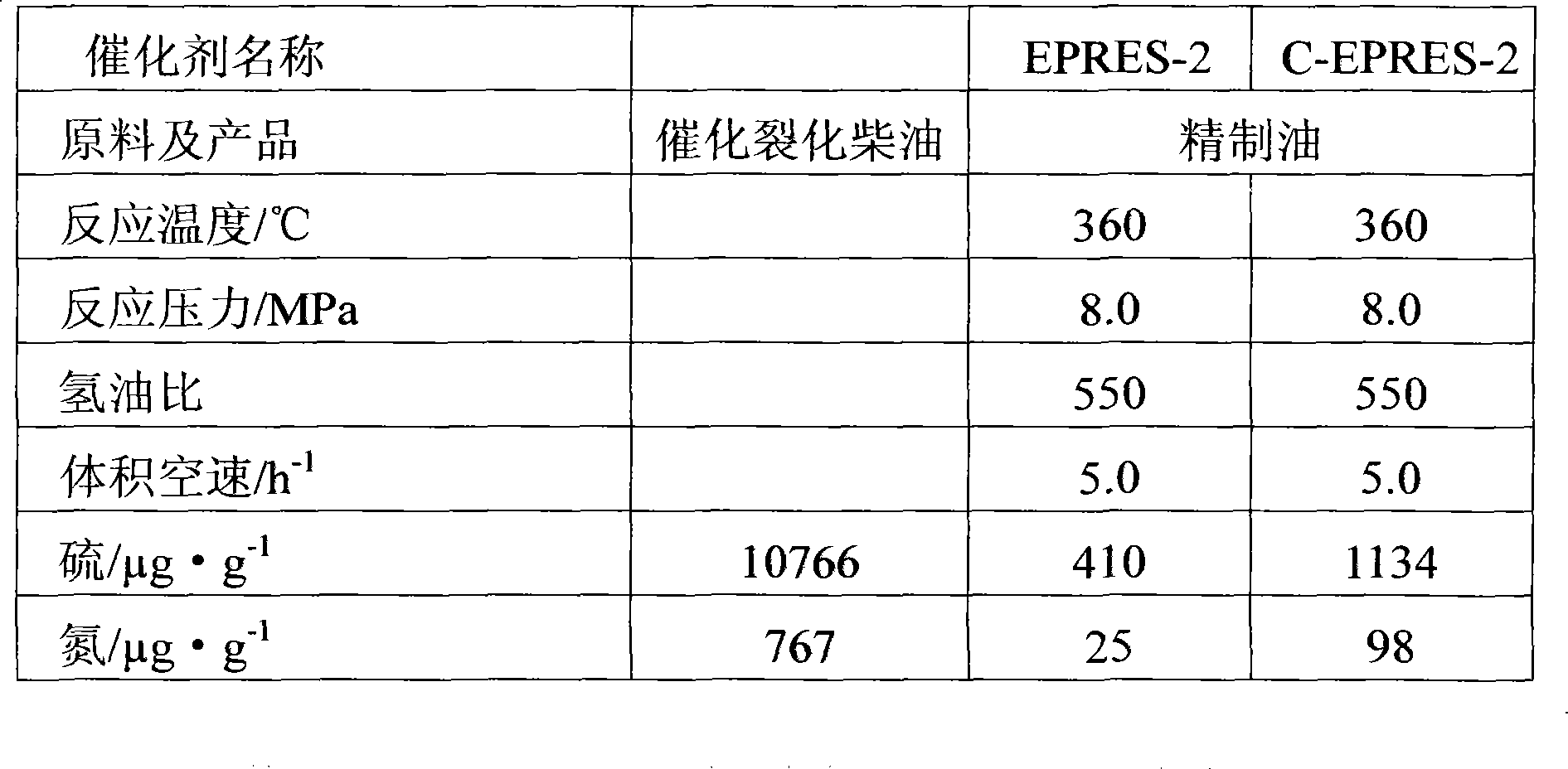

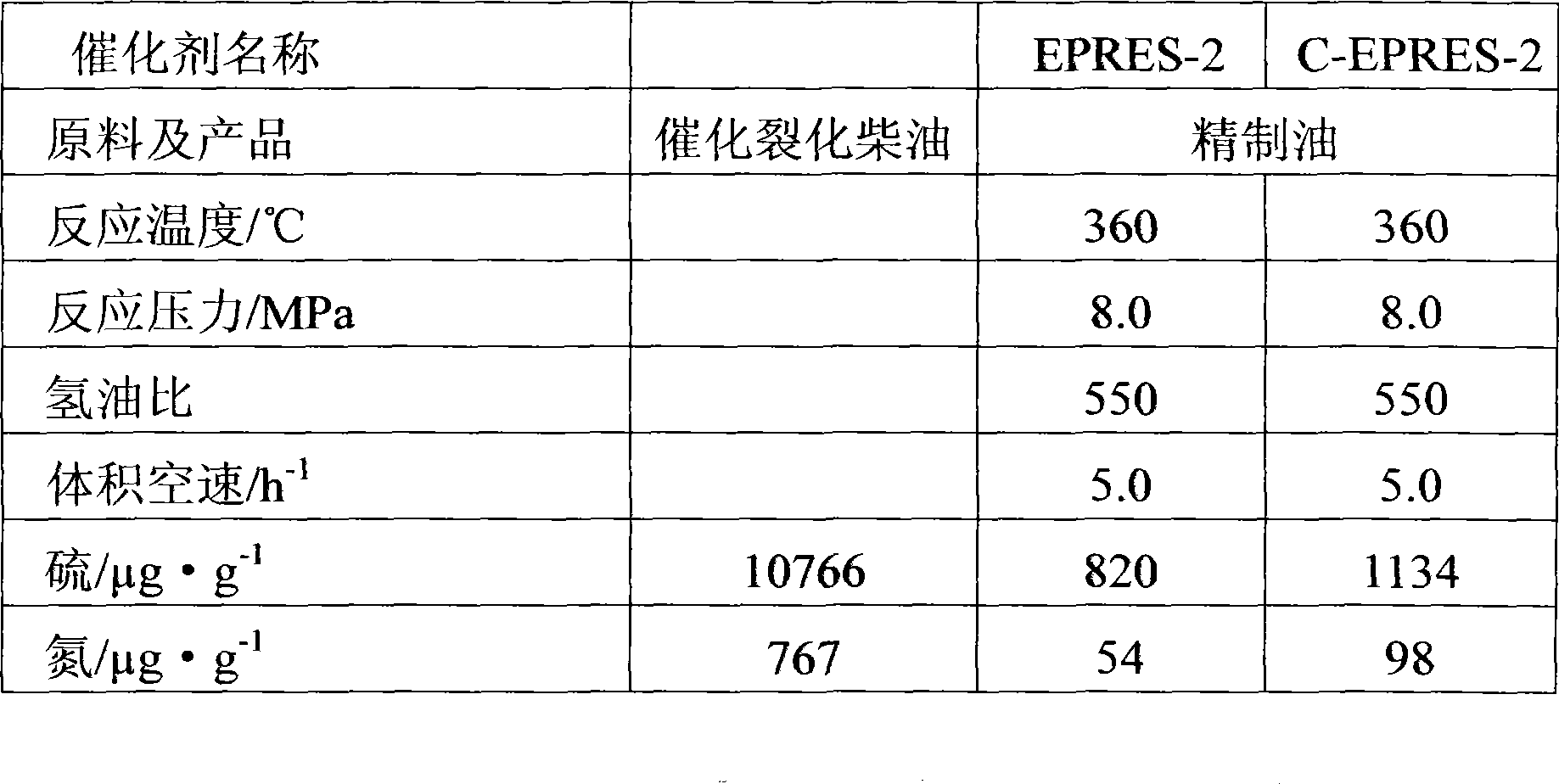

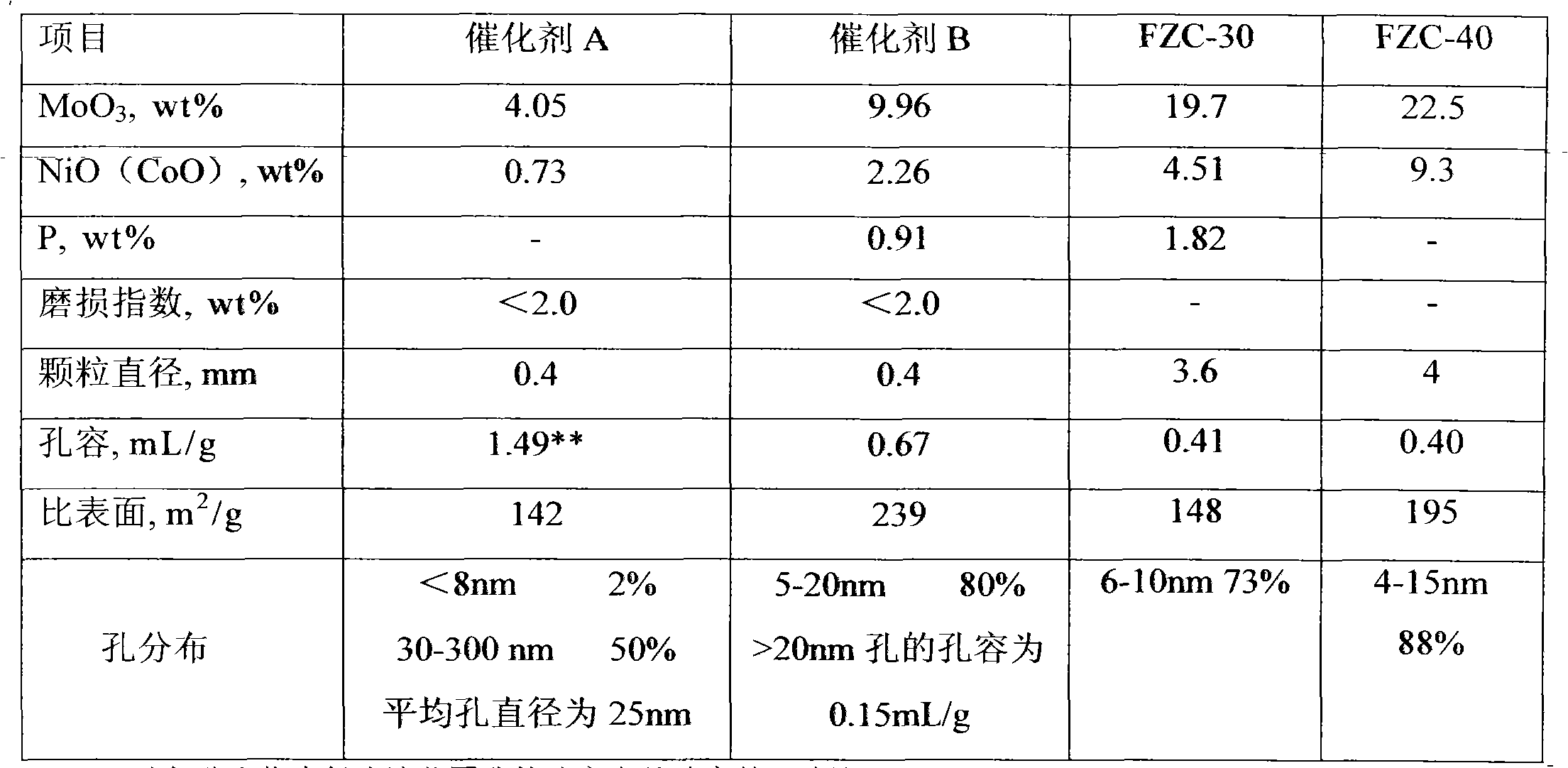

The invention relates to a heavy raw material boiling bed hydrogenation treatment method. A boiling bed hydrogenation treatment reactor is used, the heavy oil raw material oil and hydrogen gas enter a reactor from the bottom, the reaction is carried out under the heavy raw material oil hydrogenation treatment condition, materials after the reaction are discharged out from the reactor from the top, a mixed catalyst of at least two catalysts is used in the boiling bed hydrogenation treatment reactor, and the mixed volume is 1:(0.1-10). One catalyst has the properties that the specific surface is 80 to 200 mm<2> / g, the several-hole diameter can be 15 to 30nm, and holes with the hole diameter being 30 to 300nm account for 35 percent to 60 percent of the total hole volume. The other catalyst has the properties that the specific surface is 180 to 300 mm<2> / g, and holes with the hole diameters being 5 to 20nm at least account for 70 percent of the total hole volume. The method has the advantages that the operation performance of the boiling bed slag oil hydrogenation treatment process can be effectively improved, and the hydrogenation activity level and the operation flexibility are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the selective hydrodesulfurization of a gasoline feedstock containing high levels of olefins

InactiveUS20090223866A1Improve hydrodesulfurization activityLow phosphorus contentRefining to eliminate hetero atomsDistillationHydrodesulfurization

A process for selective hydrodesulfurization of a sulfur and olefin-containing hydrocarbon feedstock boiling in the naphtha or gasoline boiling range utilizing a particularly defined high activity hydrodesulfurization (HDS) catalyst composition comprising a cobalt component, a molybdenum component and little or no phosphorus, prepared on a special alumina support containing a low concentration of silica and having a high surface area of at least 280 m2 / g. In another aspect the process involves separating the feedstock into a light and a heavy fraction, followed by selectively hydrodesulfurizing the heavy fraction using a particularly defined high activity HDS catalyst and hydrodesulfurizing the light fraction with a particularly defined high selectivity HDS catalyst. The process also includes performing the separation into fractions and the selective hydrodesulfurization of the fractions in a distillation column reactor utilizing different particularly defined HDS catalysts.

Owner:CHEM RES & LICENSING CO

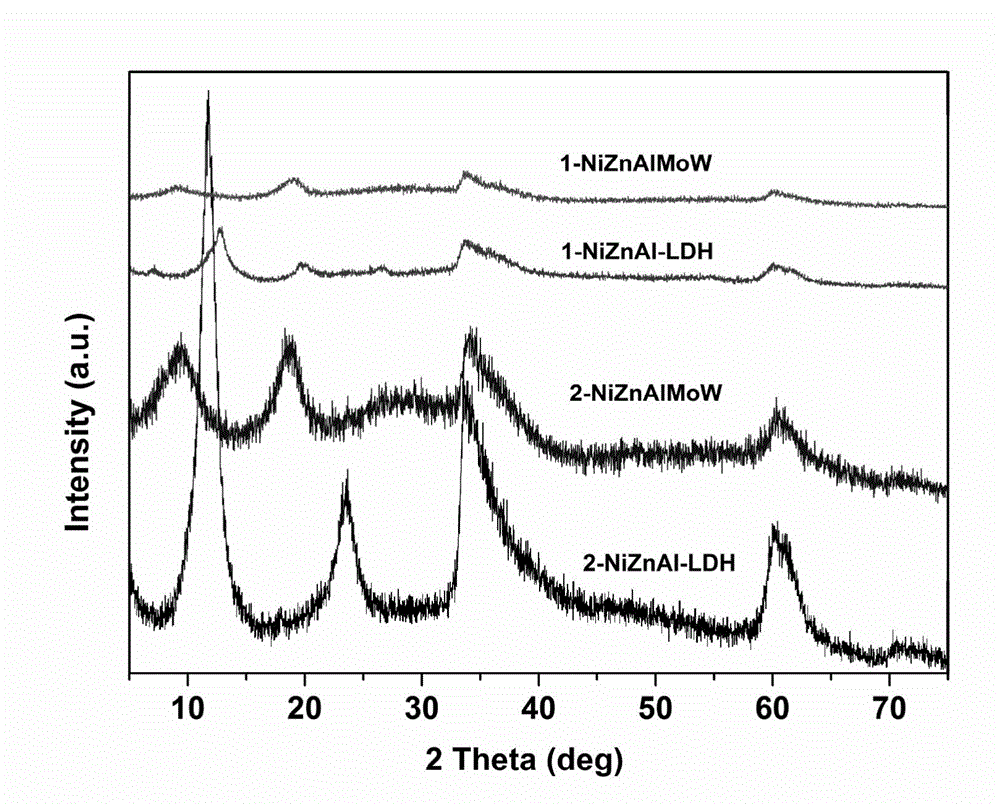

Ultra-deep hydrogen desulfurization multi-metal body catalyst with a stratified structure as well as preparation method and application thereof

ActiveCN103657672AEasy to operateGood dispersionHeterogenous catalyst chemical elementsGaseous fuelsHydrogenHydrodesulfurization

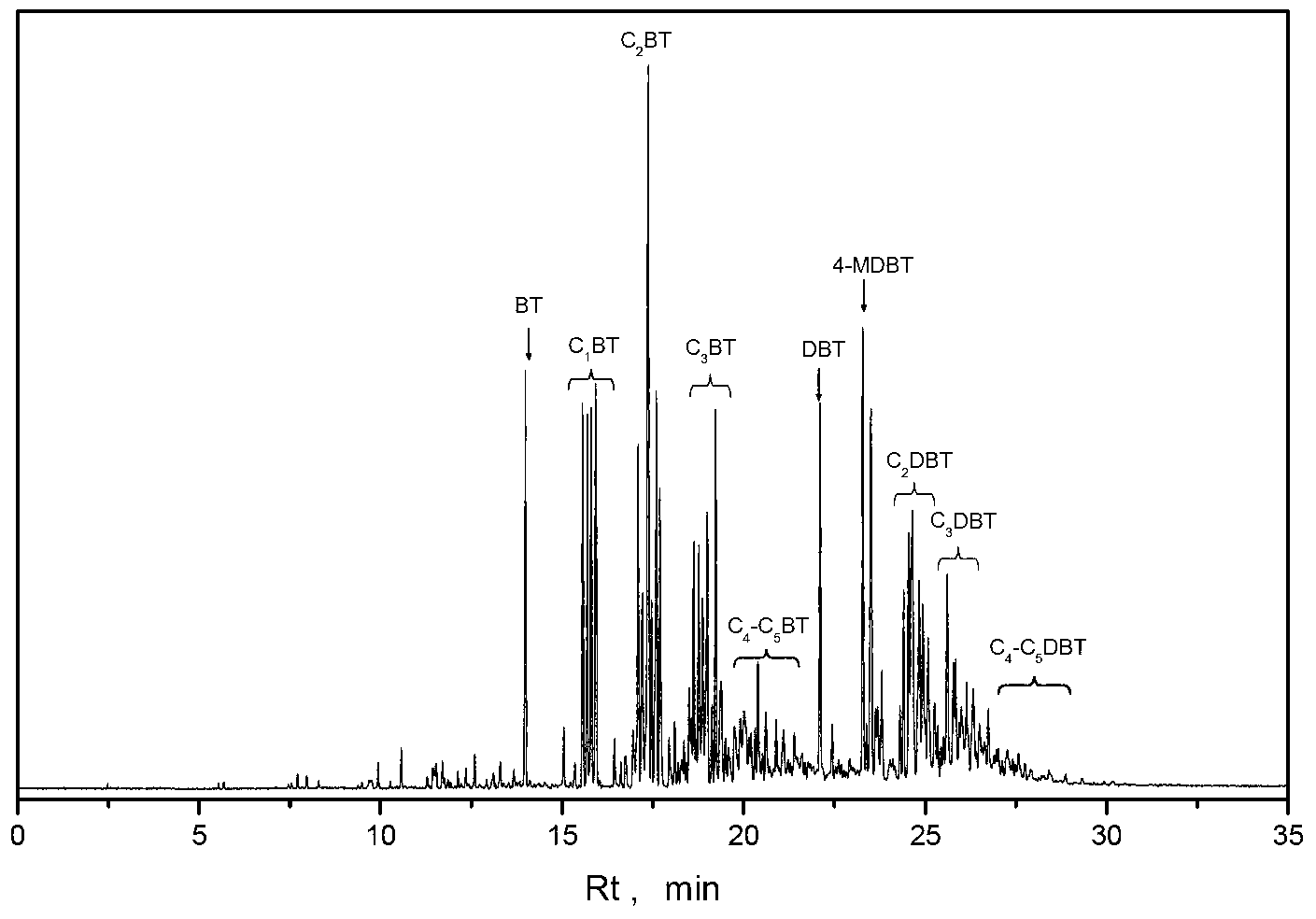

The invention relates to an ultra-deep hydrogen desulfurization multi-metal body catalyst with a stratified structure. In the ultra-deep hydrogen desulfurization multi-metal body catalyst, metals include at last one VIII-group metal, at least one <+2>-valence metal and at least two VIB-group metals. The catalyst is characterized in that, counted by oxides and based on the catalyst, the catalyst comprises the following components by weight percent: 1%-50% of VIII-group metal, 1%-50% of <+2>-valence metals and 5%-60% of two VIB-group metals. The invention further discloses a preparation method and application of the catalyst. The catalyst is applied to the hydrogen desulfurization of diesel distillate containing 4,6-dimethyldibenzothiophene and expresses an ultra-high hydrogen desulfurization activity. According to the catalyst, the ultra-deep desulfurization is realized and the cost of the body catalyst is lowered.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Treatment method before application of hydrogenation catalyst

ActiveCN1861257AImprove sulfur retentionHigh activityCatalyst activation/preparationRefining to eliminate hetero atomsOrganic solventOxidation state

A process for treating the hydrocatalyst before it is used features that the organic solvent and sulfur-contained substance are introduced to the oxidation-state hydrocatalyst for higher activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrofining catalyst containing molybdenum and/or tungsten and nickel and/or cobalt and its preparation process

InactiveCN1566280AImprove hydrodesulfurization activityHigh desulfurization activityRefining to eliminate hetero atomsHydrodesulfurizationUltrasound Radiation

The invention discloses a hydrofining catalyst containing molybdenum and / or tungsten and nickel and / or cobalt, wherein the catalyst comprises a heat-proof inorganic oxide carrying agent and molybdenum and / or tungsten or tungsten and nickel and / or cobalt loaded on the carrying agent, wherein the catalyst is prepared through immersing the heat-proof inorganic oxide carrying agent with dipping solution containing molybdenum and / or tungsten and nickel and / or cobalt compound. The catalyst prepared by the process provided by the present invention has higher hydrogenation desulfurization activity than the conventional catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

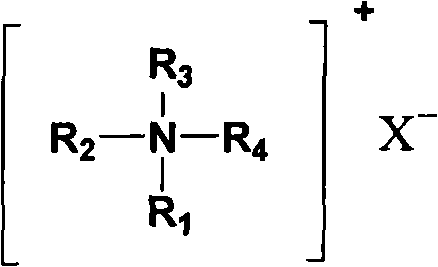

Hydrogenation catalyst, preparation method and application thereof as well as hydrofining method

ActiveCN102451721AImprove hydrodesulfurization activityIncrease productivityPhysical/chemical process catalystsRefining to eliminate hetero atomsPetroleumAmmonium

The invention provides a hydrogenation catalyst, a preparation method and application thereof as well as a hydrofining method. The preparation method comprises the following steps: sequentially loading a first compound and a second compound on a carrier, wherein the first compound is heteropoly acid and / or heteropoly acid salt taking VIB group metal as a coordination atom, and the second compound is a nonmetal oxysalt taking VIII group metal as a cation and / or an anaerobic salt taking VIII group metal as a cation. The method also comprises the following steps: between the first compound loading and second compound loading, allowing the carrier loaded with the first compound to be in contact with NH3; or between the first compound loading and second compound loading, loading quaternary ammonium salts and / or amines on the carrier loaded with the first compound. The hydrogenation catalyst prepared by the method provided by the invention has higher hydrodesulfurization activity, and is suitable for being used as a catalyst in the hydrofining of petroleum distillates or coal liquefaction distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

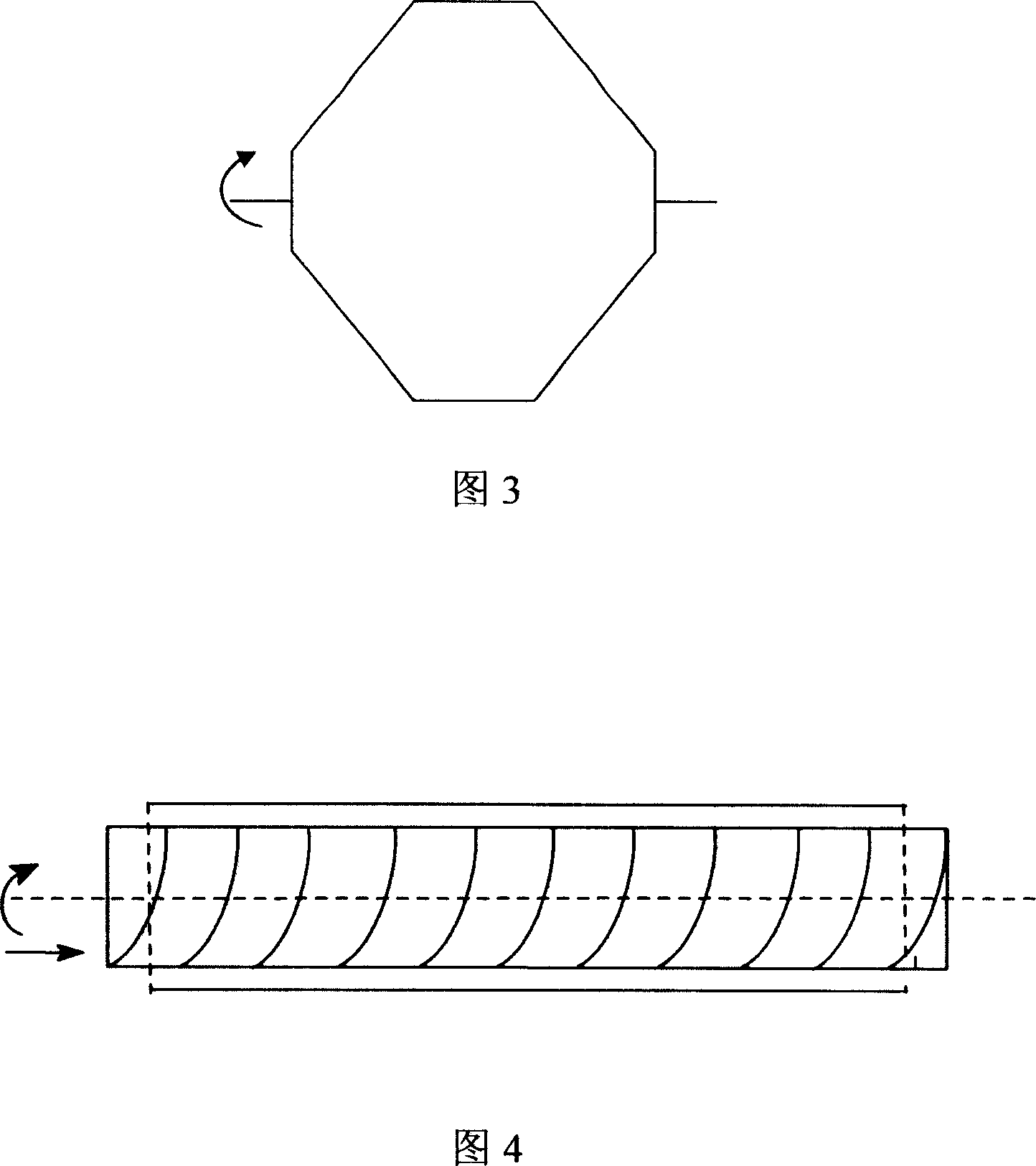

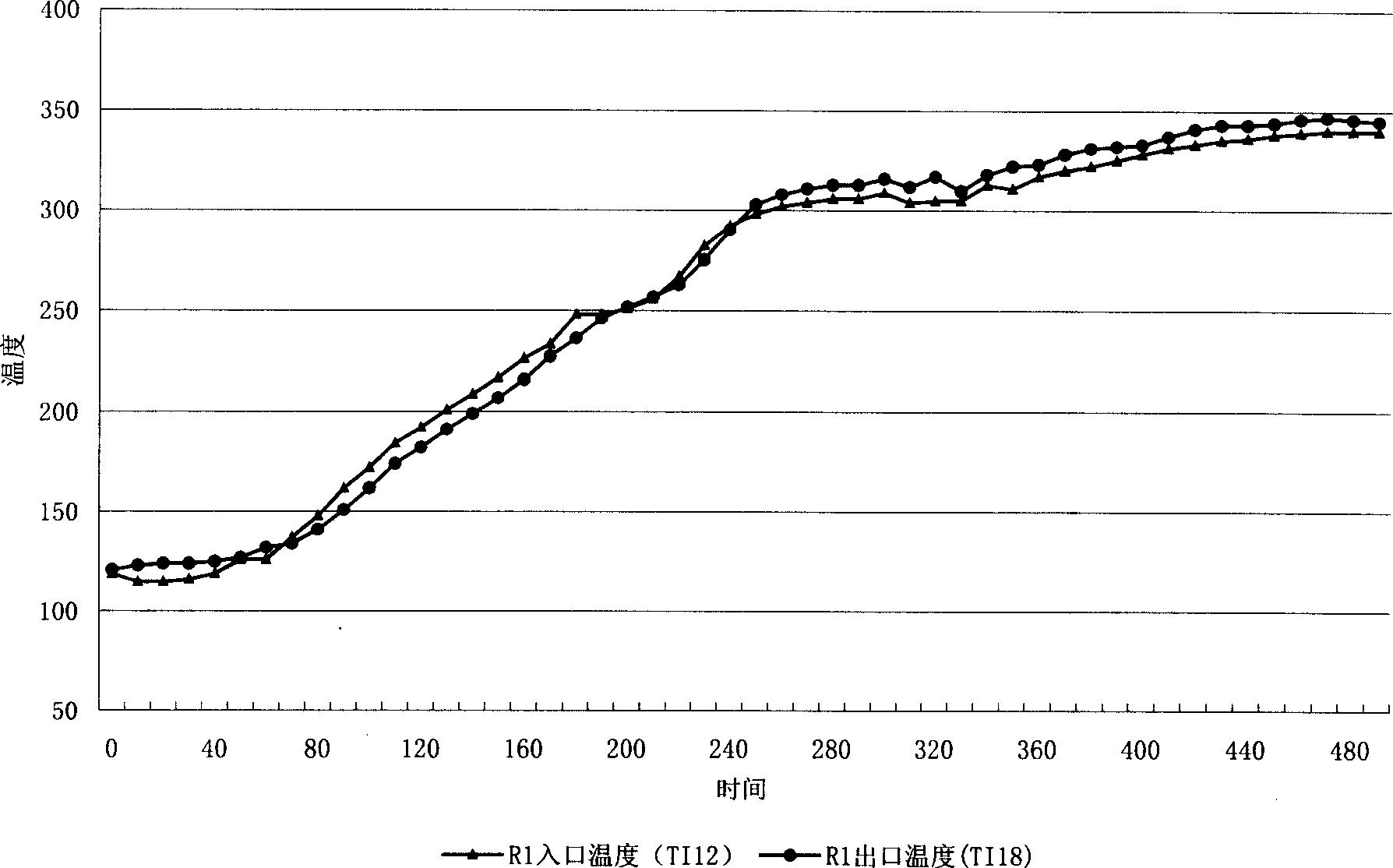

Hydrogenation catalyst processing method

ActiveCN101417245AImprove vulcanization effectImprove hydrogenation reaction performanceMolecular sieve catalystsCatalyst activation/preparationOrganic solventWater vapor

The invention relates to a processing method used for a hydrogenation catalyst, comprising the detailed process as follows: the catalyst carrier is dipped in catalyst active metal component and dried to certain water content; subsequently, organic solvent and elemental sulfur are introduced; and finally, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the water contained in the catalyst adjusts the interaction of the sulfur and the active composition of the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

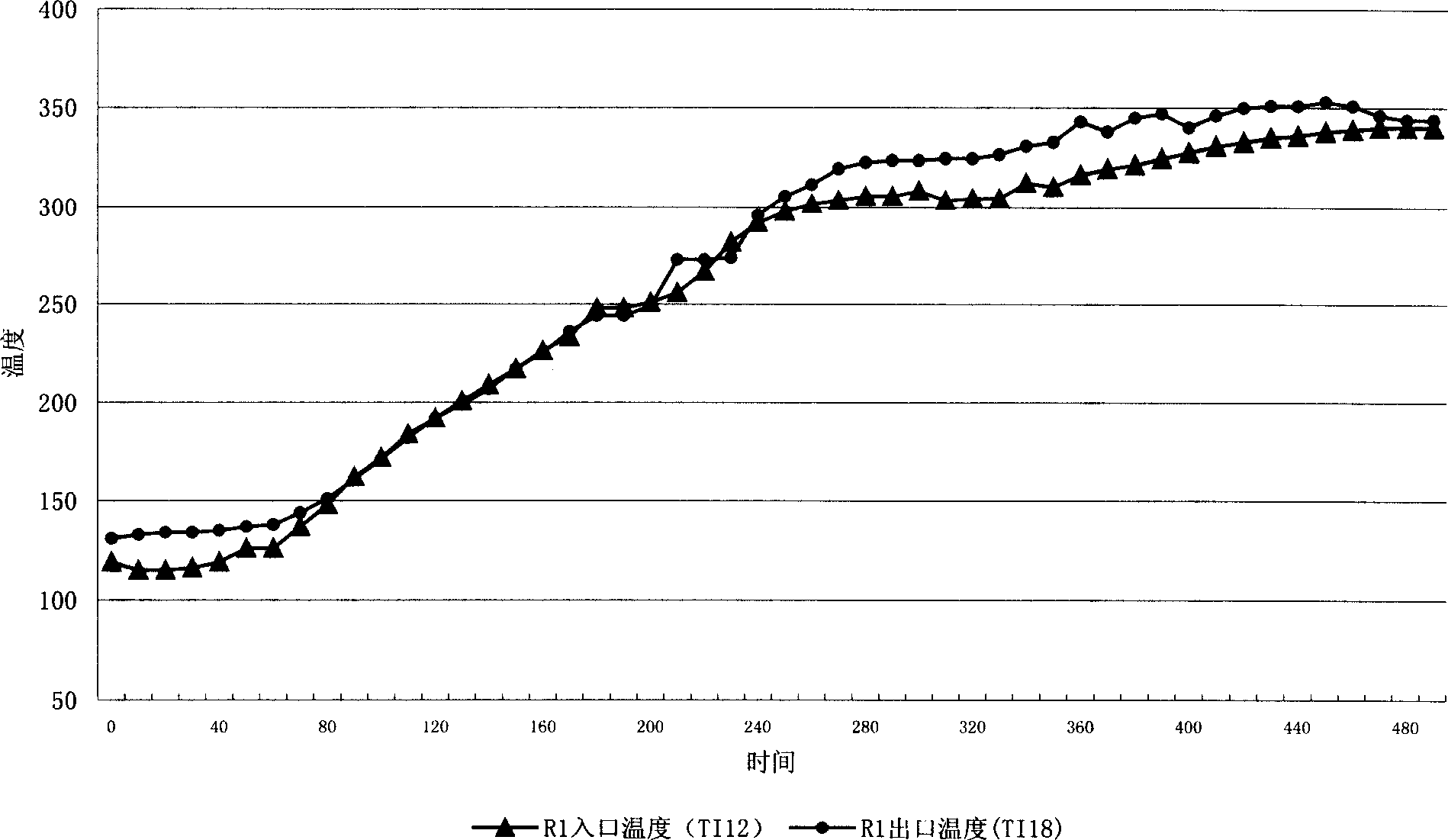

Processing method before using hydrogenation catalyst

ActiveCN101417246AEasy to useIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventWater vapor

The invention relates to a processing method before the application of hydrogenation catalyst, comprising the detailed process as follows: organic solvent, elemental sulfur and water are introduced in oxidated hydrogenation catalyst; subsequently, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the added water adjusts the interaction of the sulfur and the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalyst of sulfur containing transition metal atomic cluster compound for hydrodesulfurizing

InactiveCN1785517ARaw materials are easy to obtainLow priceCatalyst activation/preparationRefining to eliminate hetero atomsChemical reactionElectrolysis

A process for preparing the catalyst containing the S and the atom cluster compound of transition metal (Mo or W) and used for hydrodesulfurizing is disclosed. Said atom cluster compound of Mo or W is prepared from its oxide through electrolyzing in acid solution, sulfurizing, oxidizing, concentrating, separation and chemical reaction. Its advantage is high hydrodesulfurizing performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sulfuration method of secondary active center diesel oil hydrodesulfurization catalyst

ActiveCN103773434AImprove hydrodesulfurization activityCatalyst activation/preparationRefining to eliminate hetero atomsHydrodesulfurizationEngineering

The invention discloses a sulfuration method of a secondary active center diesel oil hydrodesulfurization catalyst. According to the sulfuration method, in sulfuration processes of the secondary active center diesel oil hydrodesulfurization catalyst, sulfuration is carried out under a relatively high pressure at a relatively low temperature firstly; and then sulfuration is carried out under a relatively low pressure at a relatively high temperature. The sulfuration method is capable of forming more CoMoS phases which are more dispersive, and more sulphur vacancies and desulfurization centers, so that hydrodesulfurization activity of the secondary active center diesel oil hydrodesulfurization catalyst is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

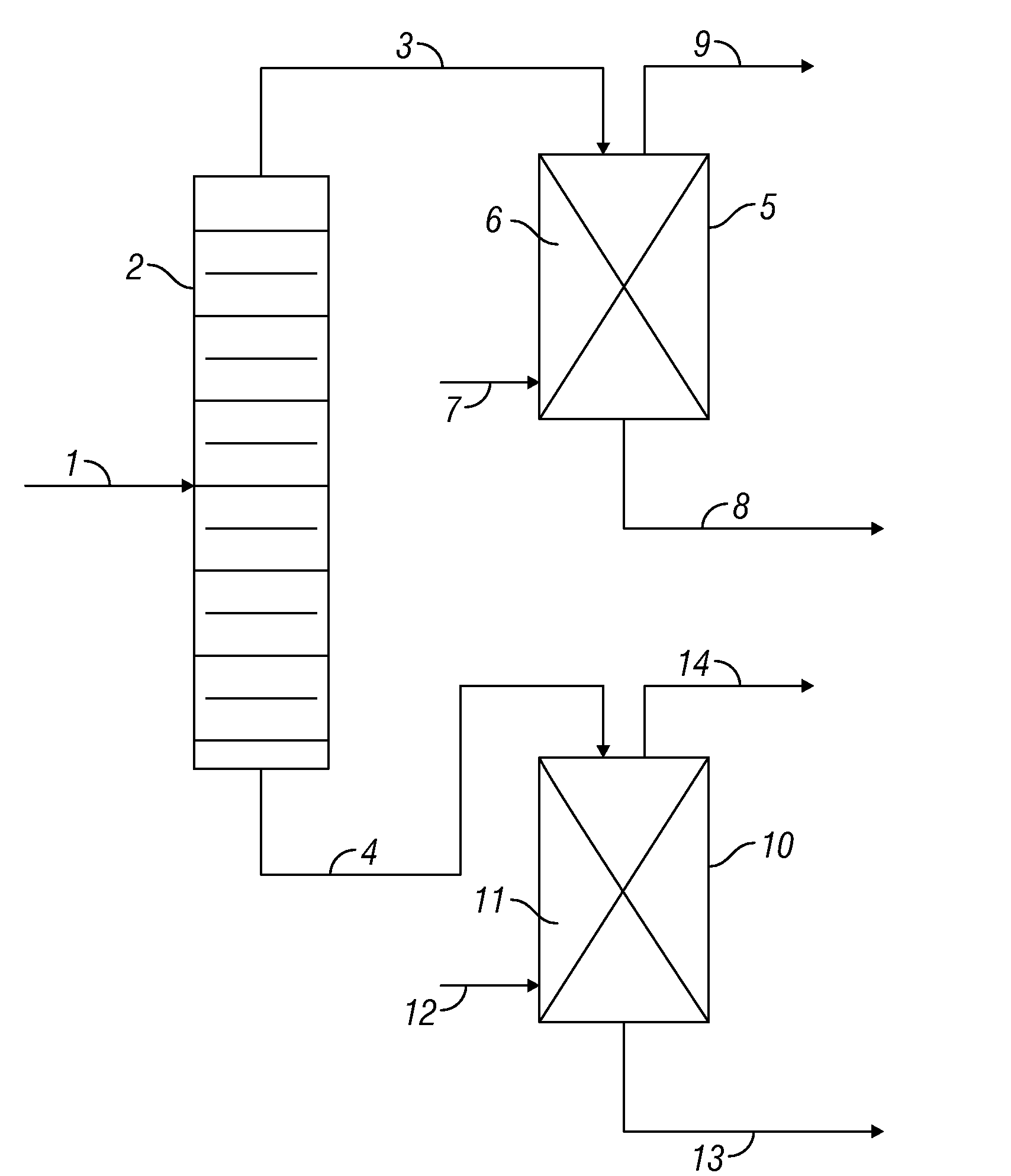

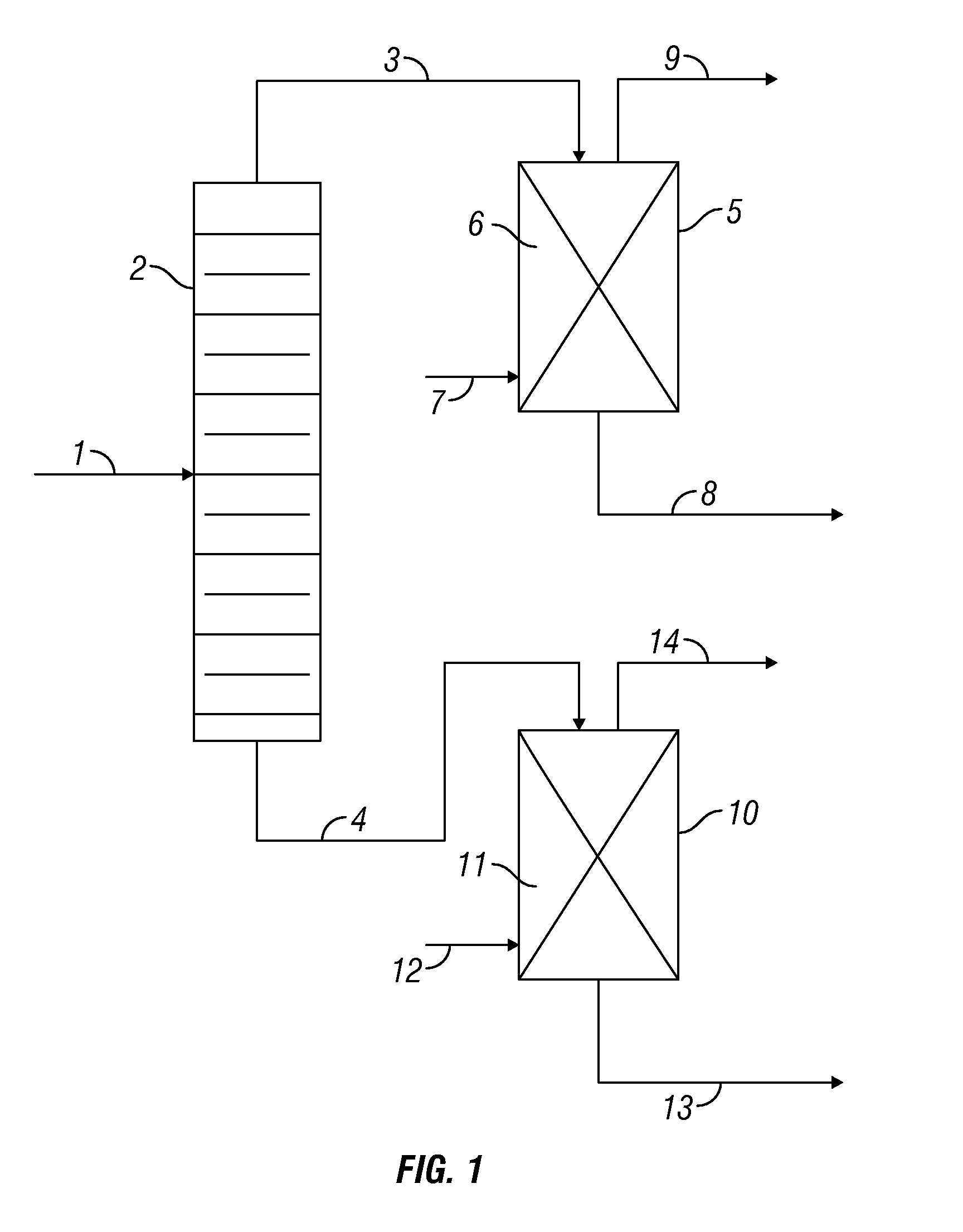

Heavy and inferior raw material hydrotreatment method

ActiveCN102465010ALarge apertureStrong metal capacityTreatment with hydrotreatment processesHydrogenation reactionFixed bed

The invention discloses a heavy and inferior raw material hydrotreatment method. A boiling bed reactor is combined with a fixed bed reactor. Raw oil and hydrogen enter from the bottom of the boiling bed reactor. The hydrogenation reaction is carried out under the fixed bed hydrogenation condition. A material is discharged from the bottom of the fixed bed reactor and enters into a separation system. A mixed catalyst of at least two catalysts with different properties is used in the boiling bed hydrotreatment reactor. In comparison with the prior art, the method provided by the invention can be used to effectively improve the operation performance of boiling bed residuum hydrotreatment and fixed bed hydrotreatment technologies and raise the hydrogenation activity level and flexibility of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

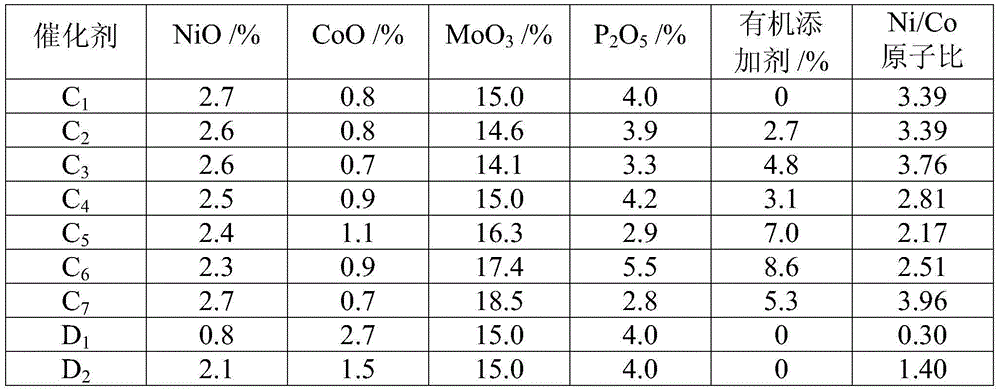

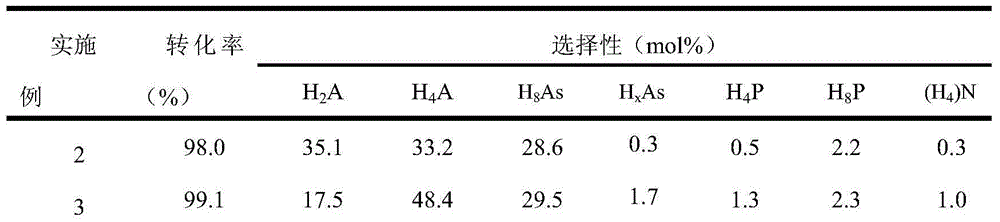

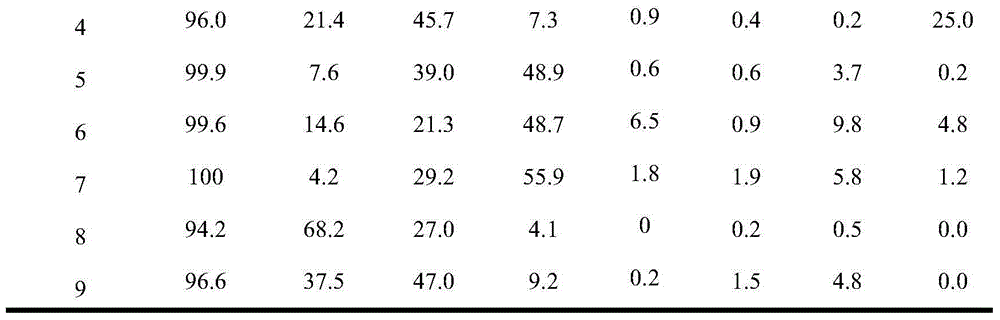

Hydrotreatment catalyst and application thereof

ActiveCN105478129AImprove performanceImprove hydrodesulfurization activityOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsComponent LoadCobalt

The invention relates to a hydrotreatment catalyst and an application thereof. The catalyst comprises a carrier and hydrogenation active metal components loaded on the carrier. The catalyst is characterized in that the hydrogenation active metal components are nickel, cobalt and molybdenum. In terms of oxides based on the weight of the catalyst, the sum of the contents of nickel and cobalt is 2-10wt% and the content of molybdenum is 10-30wt%, wherein the atomic ratio of nickel to cobalt is 1.4-10. The catalyst is suitable to be used in hydrocarbon oil hydrotreatment for preparing clean oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for hydrogenation catalyst for polycyclic aromatic hydrocarbons, catalyst and application thereof

ActiveCN105772034ASulfur resistanceImprove hydrodesulfurization activityPhysical/chemical process catalystsMolybdenum sulfidesPolycyclic aromatic hydrocarbonSulfur

The invention provides a hydrogenation catalyst for polycyclic aromatic hydrocarbons. The hydrogenation catalyst is a molybdenum disulfide (MoS2) catalyst prepared in a microemulsion system. The molybdenum disulfide catalyst provided by the invention has the advantages of sulfur tolerance, high hydrodesulfurizing activity, high polycyclic-aromatic-hydrocarbon hydrogenation activity, simplicity in process operation, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

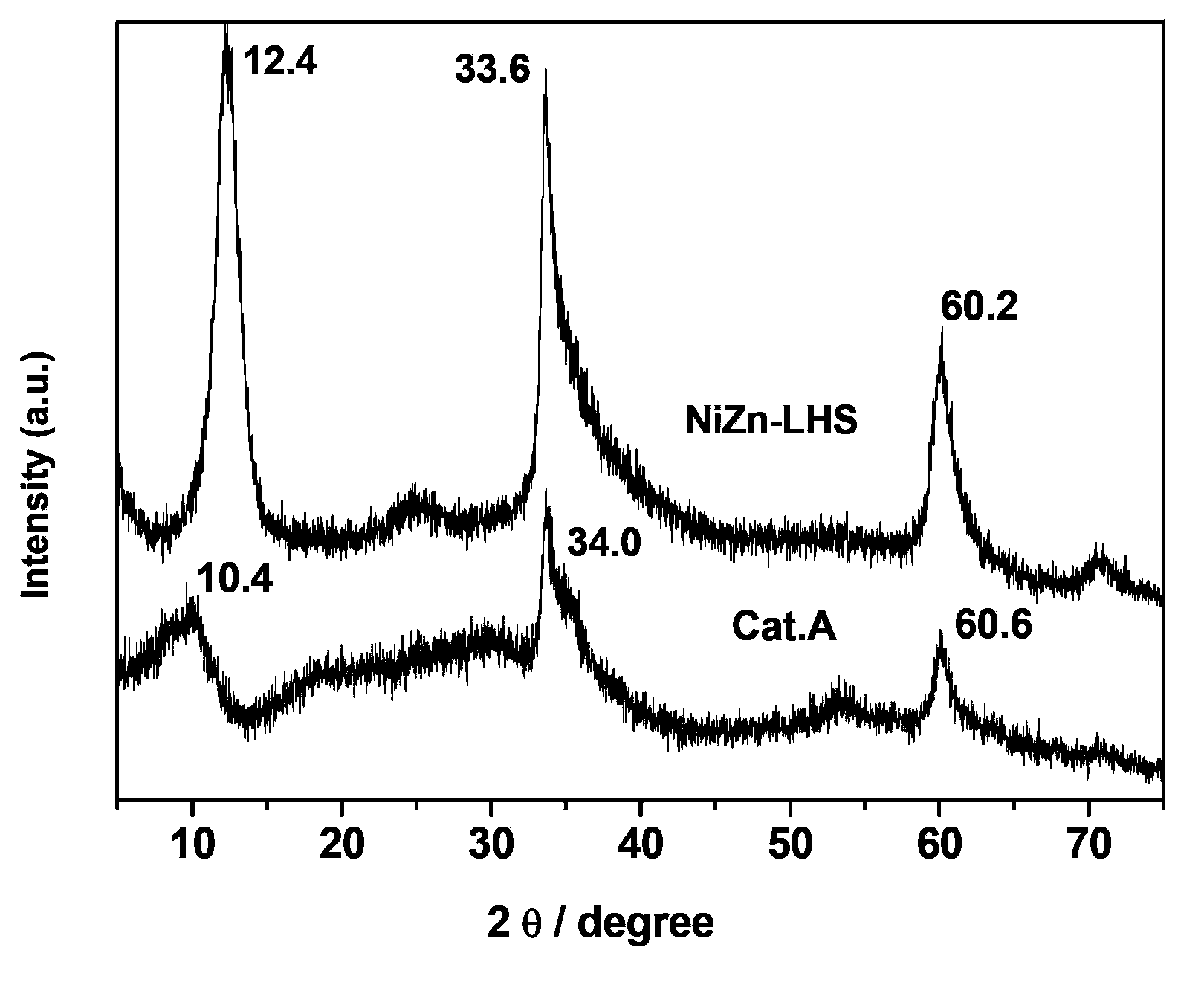

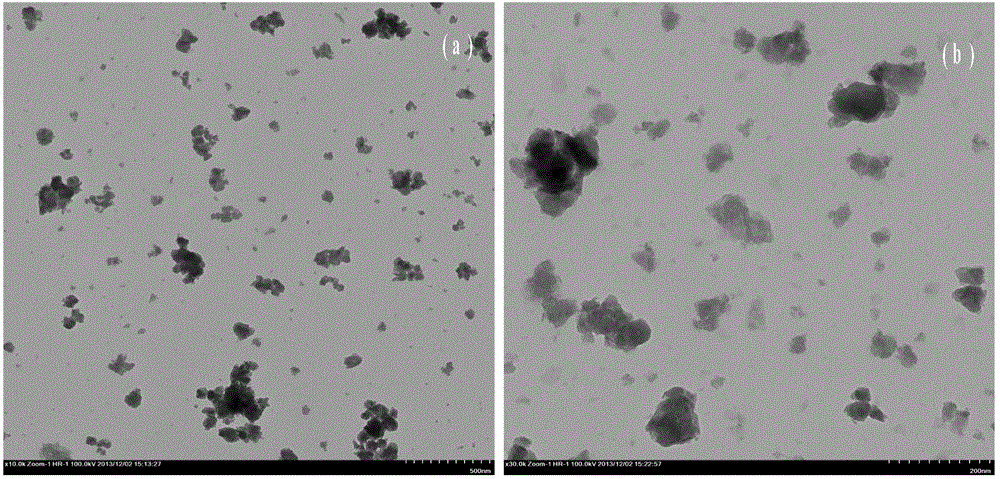

Multi-metal body catalyst with layered structure, preparation and applications thereof

InactiveCN105312060AEasy to operateGood dispersionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsDivalent metalHydrodesulfurization

The invention relates to a multi-metal body catalyst with a layer structure. The catalyst is applied to ultra-deep hydro-desulfurization and is composed of at least one metal from the VIII group, one divalent metal, one trivalent metal, and at least two metals from the VIB group. The catalyst is characterized by being composed of the following components (calculated in the form of oxides) in percentage by weight: 1 to 50 wt% of VIII metal, 1 to 50% of VIB metal, 1 to 50 wt% of divalent metal, and 1 to 50 wt% of trivalent metal. The invention also discloses a preparation method of the catalyst and applications thereof. The provided catalyst can be applied to hydro-desulfurization of diesel fraction containing 4,6-dimethyldibenzothiophene, and has an extremely-high hydro-desulfurization activity, the ultra-deep desulfurization is achieved, and the catalyst cost is reduced by introducing cheap divalent metal and trivalent metal.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

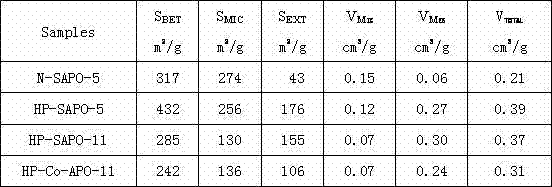

Preparation method for low-quality diesel hydrofining catalyst

ActiveCN102872908ALow sulfurLow nitrogenMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveActive component

The invention discloses a preparation method for a low-quality diesel hydrofining catalyst, which is characterized in that the low-quality diesel hydrofining catalyst comprises an active component, a carrier and an additive; the active component is composed of one or more than one metal of both VIB group and VIII group; the carrier is composed of a multi-orifice AFI, an AEL molecular sieve and a Gamma-Al2O3; the additive is one or more than one of SiO2, TiO2, F and P; and the weight contents of the components are respectively as follows: 5-30 wt percent of the multi-orifice AFI and the AEL molecular sieve, 12-25 wt percent of metals of the VIB group, 3-15 wt percent of metals of the VIII group, 0-15 wt percent of additive, and the balance Gamma-Al2o3. According to the method, the specific surface area is 200-300 m<2> / g, the pore size is 0.30-0.80 cm<3> / g, the average pore diameter is 6-15 nm, and the mechanical strength is not lower than 15 N / mm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing sulfuration-type gasoline selective hydro-desulfurization catalyst

ActiveCN105521791AGood dispersionImprove catalytic activity of hydrodesulfurizationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationSulfur

The invention provides a method for preparing sulfuration-type gasoline selective hydro-desulfurization catalyst. A main content of the method is characterized in that hydrogenation active metal elements of the gasoline selective hydro-desulfurization catalyst are combination of Co and Mo, the hydrogenation active metal element Co is introduced and is calcinated, the hydrogenation active metal element Mo is introduced by employing an impregnation method and then is dried, the dried catalyst is directly and rapidly procured in short time without calcination, preferably, surface sulfur polymer reduction operation can be carried out. The catalyst has obvious usage performance by the method, and the method has the advantages of simple precuring step, short on-stream time of the catalyst, low heat energy consumption, less amount of a toxic vulcanizing agent which has easy corrosion performance, and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline hydrorefining catalyst, and preparation method thereof

ActiveCN108452846ALarge specific surface areaReduce interactionMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveComposite oxide

The invention discloses a gasoline hydrorefining catalyst. The gasoline hydrorefining catalyst comprises a carrier and an active component; the active component is loaded onto the carrier, a heteropoly acid is taken as the active component, and an Al2O3-TS-1-graphene composite oxide is taken as the carrier; the specific surface area of the gasoline hydrorefining catalyst ranges from 250 to 500m2 / g, the pore volume ranges from 0.5 to 0.8mL / g. The invention also relates to a preparation method of the gasoline hydrorefining catalyst. According to the preparation method, a molecular sieve is uniformly mixed with alumina and graphene, a nitric acid solution and an appropriate amount of water are added, and mixing kneading, strip extrusion, drying, and roasting are carried out so as to obtain the carrier of the gasoline hydrorefining catalyst; the carrier is subjected to dipping with a solution containing the heteropoly acid, and then drying and roasting are carried out so as to obtain the gasoline hydrorefining catalyst. The gasoline hydrorefining catalyst possesses a specific pore diameter, is large in pore volume, is high in hydrodesulfurization activity, and can be taken as a gasoline hydrorefining catalyst.

Owner:PETROCHINA CO LTD

Carrier of hydrogen desulfurization catalyst and preparation method and catalyst prepared by preparation method

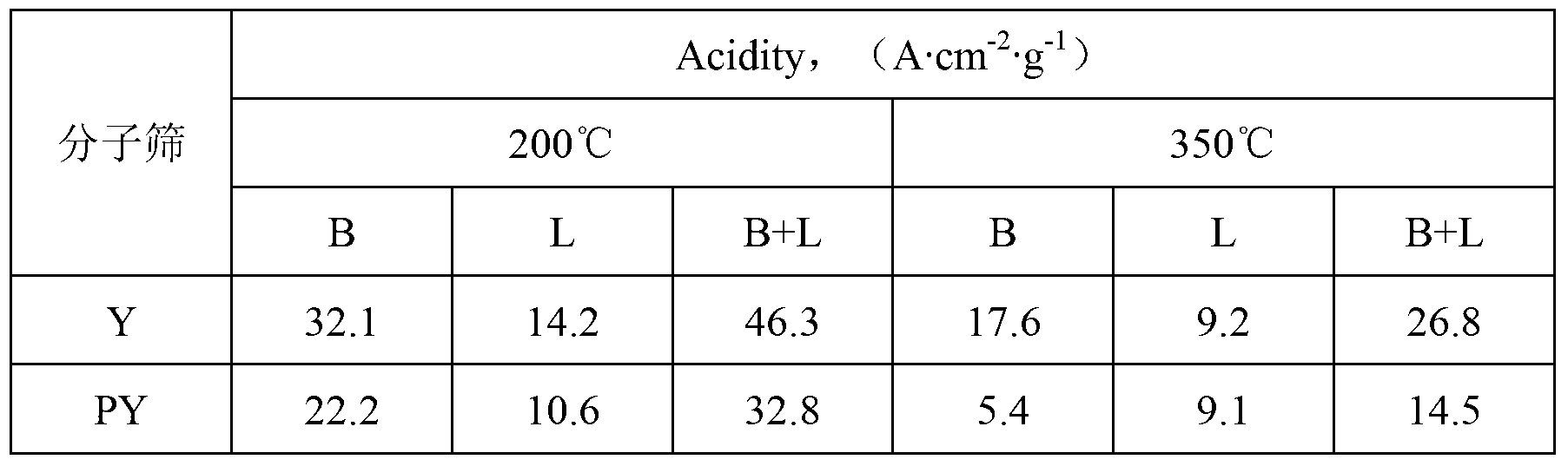

ActiveCN105772109AImprove hydrodesulfurization activityEnhanced overall recoveryCatalyst carriersMolecular sieve catalystsAdhesiveHydrodesulfurization

The invention provides a carrier of hydrogen desulfurization catalyst and a preparation method and catalyst prepared by the preparation method. The preparation method of the carrier includes performing contact exchange of high-aluminum and -silica ratio ammonium nitrate by a Y molecular sieve of small particles; performing zirconium modification of the exchanged Y molecular sieve to obtain Zr-modified Y sieve; mixing the Zr-modified Y molecular sieve with pseudo-boehmite, extrusion aid and adhesives, extruding, drying and roasting to obtain the carrier of the hydrogen desulfurization catalyst. The carrier of the hydrogen desulfurization catalyst has the Zr-modified Y sieve. The hydrogen desulfurization catalyst of the carrier is high in activity and good in desulfurization effect. The hydrogen desulfurization catalyst of the carrier is used for hydrogen desulfurization, and yield of diesel oil is up to 100%.

Owner:PETROCHINA CO LTD +1

Hydrotreating catalyst and preparation method and application thereof

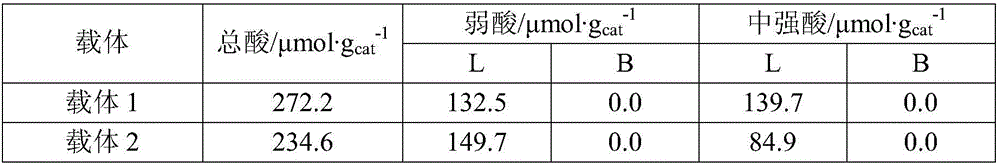

ActiveCN105833879AImprove the problem of high proportion of L acid on the surfaceReduce strong interactionsHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen treatment

The invention provides a hydrotreating catalyst and a preparation method and application thereof .The preparation method of the hydrotreating catalyst comprises the steps that firstly, an aluminum oxide carrier is prepared by adopting a complexing agent roasting-drying combined mode; secondly, complexing agent surface imprednation is conducted on the aluminum oxide carrier, and the aluminum oxide carrier is roasted and modified in inert gas to obtain a modified aluminum oxide carrier; lastly, metal active components are supported through isovolumetric stepped impregnation and directly dried without needing roasting, and then the hydrotreating catalyst is finally prepared .According to the preparation method of the hydrotreating catalyst, the problem that the ratio of L acid on the surface of the aluminum oxide carrier is high can be effectively solved, and meanwhile the strong interaction between active metal and the aluminum oxide carrier can be effectively weakened; the prepared hydrotreating catalyst is suitable for the hydrodesulfurization and hydrodenitrification process of coker gas oil with the high sulfur and nitrogen content and not only has the good hydrodenitrification activity but also has the good hydrodesulfurization activity.

Owner:PETROCHINA CO LTD +1

Beta zeolite-containing ultradeep hydrodesulfurization catalyst and preparation method thereof

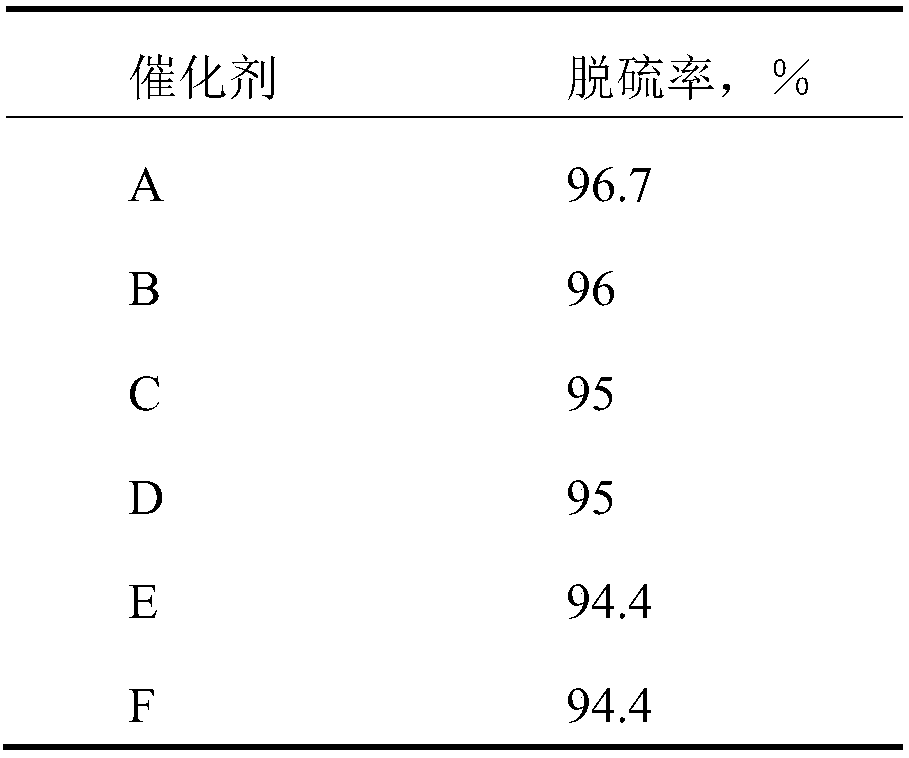

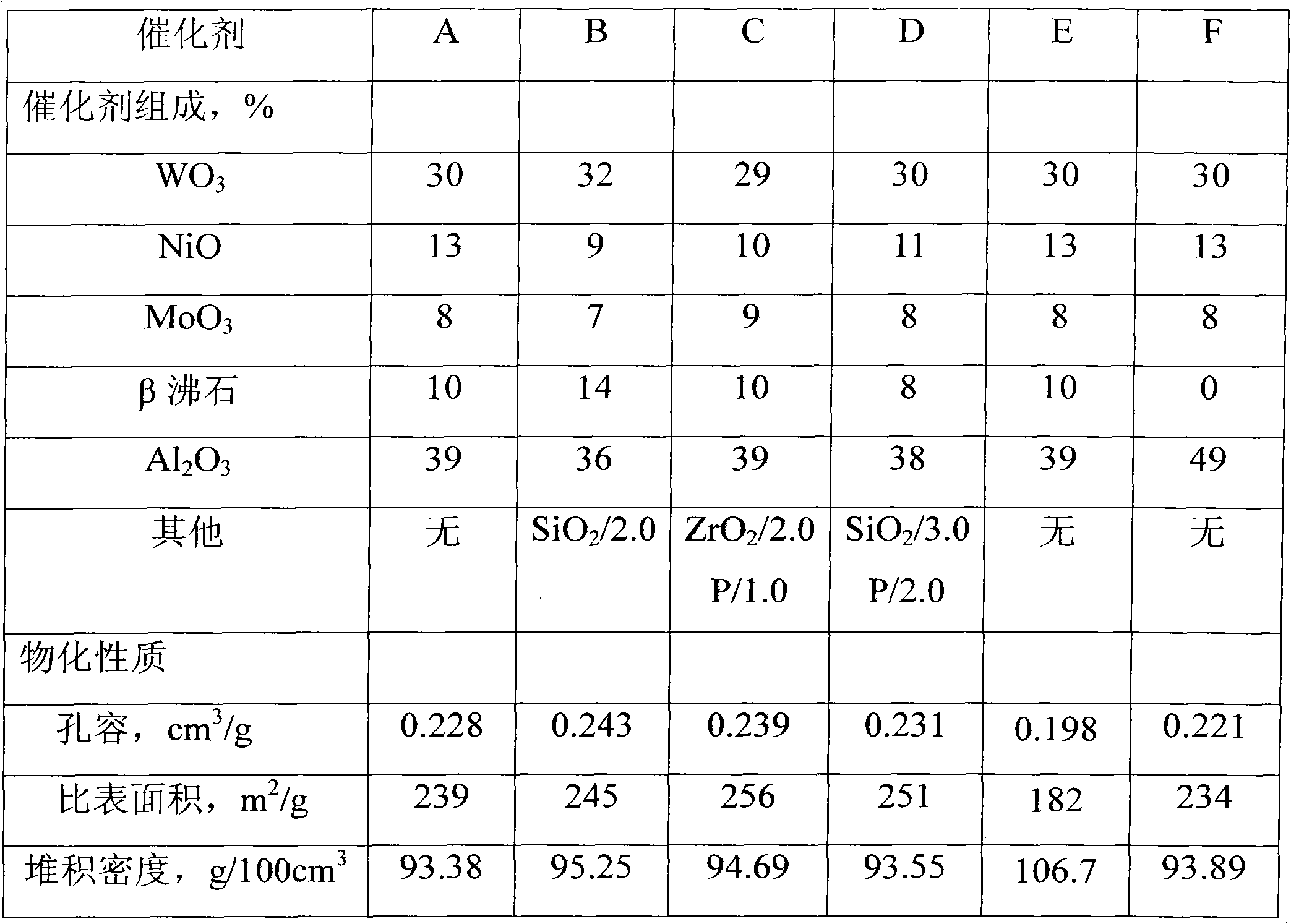

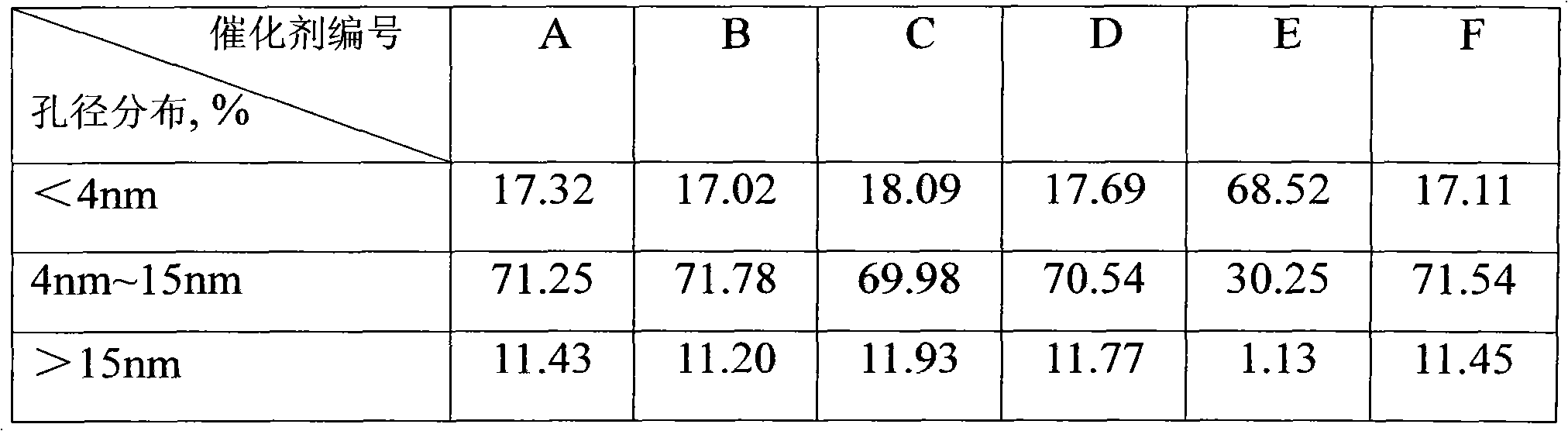

ActiveCN102049288AImprove hydrodesulfurization activityImprove pore structureMolecular sieve catalystsCatalyst activation/preparationComposite oxideWater soluble

The invention discloses a bulk phase deep hydrodesulfurization catalyst and a preparation method thereof. The components of the catalyst comprise a composite oxide (NixWyO2), MoO3, aluminum oxide and beta zeolite. The method comprises: adding a proper amount of water soluble nitrogen compound in a precipitation process of Ni, W and Al, gelatinizing, adding beta zeolite size, aging, pulping with MoO3, forming and activating. The method improves the porous structure of the catalyst, makes more metal active spots exposed from the surface of the catalyst, improves the utilization rate of active metals, and makes beta zeolite and metal having hydrogenation activity uniformly and fully contacted and better cooperated to realize ultradeep hydrodesulfurization of diesel. In addition, the increase in the aperture and pore volume of the catalyst allows a Ni-W active center to be fully utilized and molecules with complex large structures to contact the active center more easily, and the effect is more obvious particularly when distillate with high-macromolecule content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating catalyst and application thereof

ActiveCN107159302AImprove performanceImprove hydrodesulfurization activityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsWater vaporBiological activation

The invention relates to a hydrotreating catalyst and application thereof. The catalyst contains a carrier, and a metal component of family VIII and a metal component of family VIB which are loaded on the carrier. The catalyst is characterized in that the carrier contains heat-proof inorganic oxide, molecular sieves and charcoal, the carrier is prepared by a method in which the heat-proof inorganic oxide and / or the precursors of the heat-proof inorganic oxide, and the molecular sieves, carbon black powder and / or the precursors of charcoal are mixed, molded, dried and activated, wherein activation comprises the following steps: (1) under the existence of isolated air and / or inert gas, carrying out heating treatment to a molded material subjected to drying, keeping the heating treatment temperature at 400-800 DEG C, and maintaining the time for 0.5-8 hours; (2) under the ambience of water vapor and / or carbon dioxide, carrying out heating treatment to a product obtained in step (1), keeping the heating temperature at 600-950 DEG C, maintaining the time for 0.3-4 hours, and enabling the flow rate of the water vapor and / or carbon dioxide to be 50-500 normal liters / kilogram.hour. The catalyst is suitable for hydrotreatment of hydrocarbon oil so as to prepare a clean oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combination catalyst for diesel hydrodesulfurization and diesel hydrodesulfurization method

ActiveCN103316687ARealization of ultra-deep hydrodesulfurizationImprove hydrodesulfurization activityMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsTemperature controlActive component

The invention provides a combination catalyst for diesel hydrodesulfurization and a diesel deep hydrodesulfurization method. The combination catalyst comprises a first catalyst CAT-1 and a second catalyst CAT-2, wherein the first catalyst CAT-1 is prepared by drying and roasting after carrying an active component on a first support, and the first support is selected from a composite of two or three of TiO2, SiO2 and Al2O3; the second catalyst CAT-2 is prepared by carrying an active component on a second support, and the second support is selected from a composite of two or three of TiO2, SiO2 and Al2O3; and the active components of the two catalysts are selected from a combination of two or three of Co, Mo, Ni and W. The two catalysts are combined and filled according to a certain proportion; and the temperature gradient variation or step-by-step temperature control in the reaction process is utilized to fully display the characteristics of the two catalysts, so that the sulfur content in the diesel is reduced to 10 mu g / g below.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com