Hydrogenation catalyst processing method

A technology of hydrogenation catalyst and treatment method, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation and other directions, can solve the problem of self-heating of sulfided catalysts, reduce the self-heating of catalysts, etc. effect, reducing the amount of sulfur loss and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

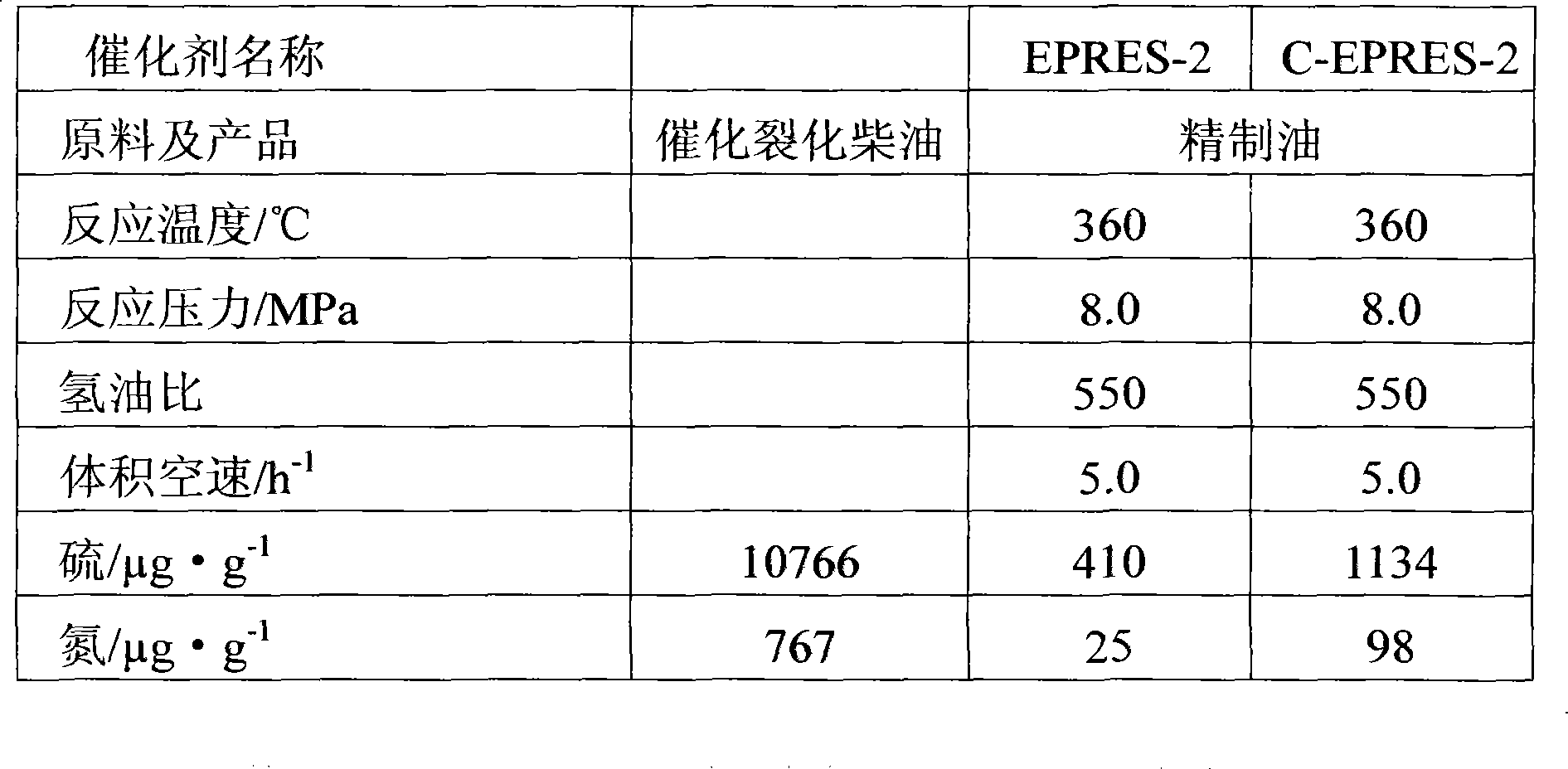

Examples

Embodiment 1

[0025] The catalyst was prepared according to the composition of the commercial hydrodesulfurization catalyst FH-5A (developed by Fushun Petrochemical Research Institute, produced by Wenzhou Huahua Group Co., Ltd.). The main composition and properties of the catalyst are shown in Table 1.

[0026] The specific pre-sulfurization process is as follows:

[0027] 1. After the catalyst carrier is impregnated with the active metal solution, it is dried at 80° C. for 2 hours, and the dried product contains 25% water based on the dry weight of the catalyst.

[0028] 2. The elemental sulfur powder is mixed with the catalyst obtained in step 1, and the amount of elemental sulfur introduced is 105% of the theoretical sulfur requirement of the catalyst. It is then mixed with coker diesel fraction, the amount of coker diesel fraction is 45% by weight of the catalyst.

[0029] 3. The catalyst obtained in step 2 was treated at normal pressure and 150° C. for 5 hours to obtain the hydrorefin...

Embodiment 2

[0031] The catalyst in the oxidation state is the same as in Example 1, which is FH-5A.

[0032] The specific pre-sulfurization process is as follows:

[0033] 1. After the catalyst carrier is impregnated with the active metal solution, it is dried at 50° C. for 8 hours, and the dry product contains 10% water based on the dry weight of the catalyst.

[0034] 2. Uniformly impregnating triethylamine on the catalyst obtained in step 1, the addition of triethylamine being 5% of the catalyst weight, to obtain a triethylamine-loaded aqueous catalyst.

[0035] 3. Mix elemental sulfur powder and organic solvent (the organic solvent is a mixture of catalytic cracking gasoline and rapeseed oil with a volume ratio of 8:1), the amount of organic solvent is 15% of the weight of the catalyst, and the amount of elemental sulfur is the theoretical metal content of the catalyst. 105% of the amount of sulfur, the above mixture is mixed with the catalyst loaded with triethylamine obtained in st...

Embodiment 3

[0040] The catalyst in the oxidation state is the same as in Example 1, which is FH-5A.

[0041] The specific pre-sulfurization process is as follows:

[0042] 1. After the catalyst carrier is impregnated with the active metal solution, it is dried at 110° C. for 3 hours, and the dried product contains 0.2% water based on the dry weight of the catalyst.

[0043] 2. Spray triethylamine and gluconic acid in the catalyst obtained in step 1 at a weight ratio of 4:1 to obtain a catalyst containing mixed organic additives.

[0044] 3. The volume ratio of vacuum distillate oil and peanut oil is a mixed solvent of 1:2. The amount of solvent is 0.5% of the catalyst weight. The mixed solvent is first introduced into the catalyst obtained in step 2, and then mixed with elemental sulfur solid powder. The amount of elemental sulfur is The catalyst contains 90% of the theoretical sulfur requirement of the metal.

[0045] 4. The material obtained in step 3 was treated at normal pressure at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com