Multi-metal noumenon catalyzer for hydrodesulphurization of diesel oil, producing method and application of the same

A bulk catalyst and hydrodesulfurization technology, which is applied in the direction of refining to remove heteroatoms, etc., can solve the problems of high catalyst preparation cost, unfriendly raw materials, large catalyst particles, etc., and achieve simple and cheap raw materials, easy synthesis process, and high dispersion degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of NiMoW bulk catalyst among the present invention:

[0039] a. Weigh ammonium molybdate and ammonium metatungstate respectively, wherein Mo 6+ 0.01mol, W 6+ 0.01mol, they were dissolved in 350ml of water, ethylene glycol and cetyltrimethylammonium chloride mixed solvent to form a solution, and the solution was heated to the reaction temperature, stirring constantly; The basic nickel carbonate prepared by the disclosed method of Encyclopedia, containing Ni 2+ 0.03mol, it was dissolved in a small amount of polar solvent, made into a suspension, and heated to the reaction temperature; this reaction suspension was slowly added to the colorless transparent solution to form a light green reaction solution, at 150 Reflux reaction at the reaction temperature of ℃ for 20 hours; the yellow-green powder obtained by the reaction was filtered, washed, and dried at 120 ℃ to obtain a NiMoW catalyst precursor.

[0040] B, then the precursor of this catalyst is roast...

Embodiment 2

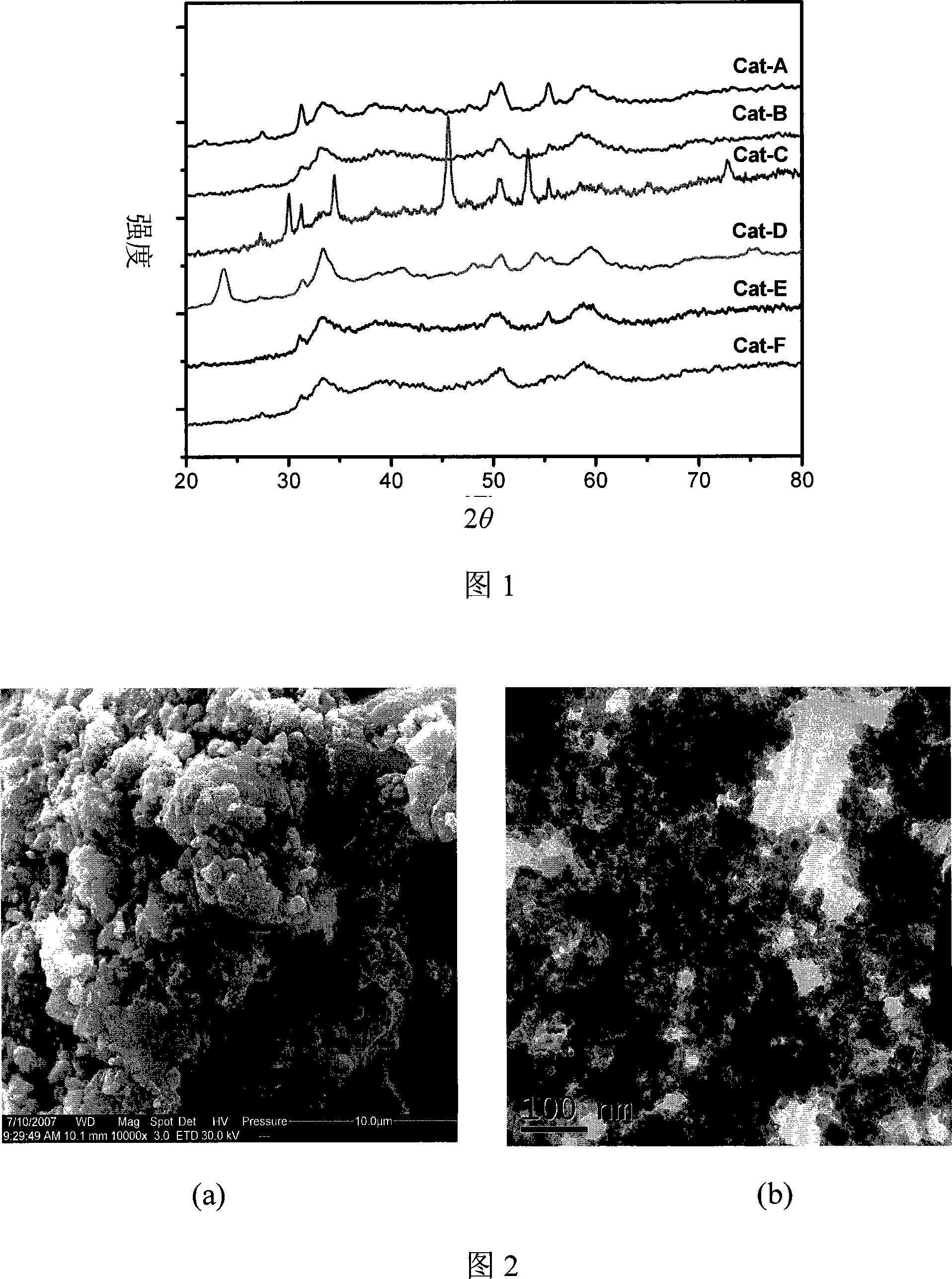

[0045] Same as Example 1, except that only polar solvent water and ethylene glycol are used in step a, and the synthesized catalyst product is represented by Cat-B. Its XRD characterization results are listed in Figure 1.

Embodiment 3

[0047] Same as Example 1, except that the polar solvent ethylene glycol is used in step a, and the synthesized catalyst product is represented by Cat-C. Its XRD characterization results are listed in Figure 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com