A three-layer integrated high-efficiency high-strength heat conduction sheet and its preparation method

A high-strength, thermally conductive sheet technology, which is applied in the direction of modification, processing and manufacturing, and solid material additive processing through conduction and heat transfer. performance and mechanical strength, to achieve the effect of simple and cheap raw materials, excellent mechanical strength, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

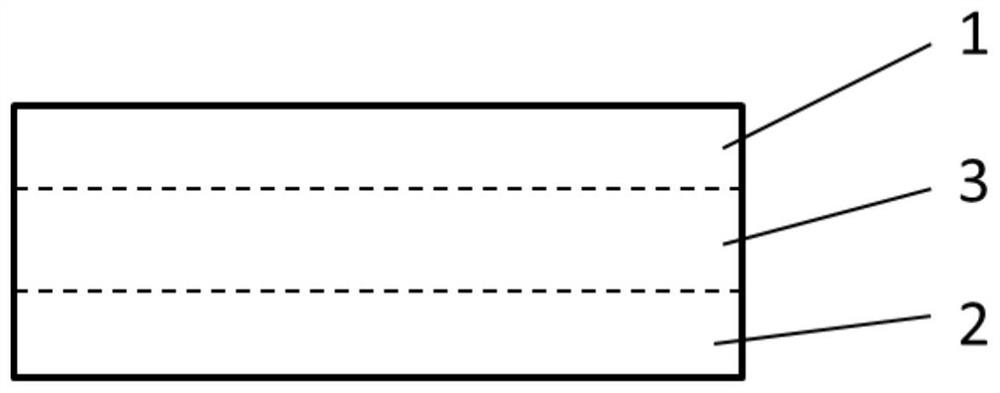

[0027] A three-layer integrated high-efficiency and high-strength heat conduction sheet, such as figure 1 , including a first protective layer 1, a second protective layer 2 and a heat conduction layer 3, the first protective layer 1 and the second protective layer 2 are respectively arranged on both sides of the heat conduction layer 3; the first protective layer The components of 1 include polymer powder, photoinitiator and crosslinking agent, the components of the second protective layer 2 include polymer powder, photoinitiator and crosslinking agent, and the components of the heat conducting layer 3 It includes polymer powder and thermally conductive filler, and the polymer powder used in the first protective layer 1, the second protective layer 2 and the thermally conductive layer 3 is the same polymer powder; through SLS The printing technology prints and forms the first protective layer 1 , the second protective layer 2 and the thermal conduction layer 3 in three layers...

Embodiment 2

[0039] A three-layer integrated high-efficiency and high-strength heat conduction sheet, such as figure 1 , including a first protective layer 1, a second protective layer 2 and a heat conduction layer 3, the first protective layer 1 and the second protective layer 2 are respectively arranged on both sides of the heat conduction layer 3; the first protective layer The components of 1 include polymer powder, photoinitiator and crosslinking agent, the components of the second protective layer 2 include polymer powder, photoinitiator and crosslinking agent, and the components of the heat conducting layer 3 It includes polymer powder and thermally conductive filler, and the polymer powder used in the first protective layer 1, the second protective layer 2 and the thermally conductive layer 3 is the same polymer powder; through SLS The printing technology prints and forms the first protective layer 1 , the second protective layer 2 and the thermal conduction layer 3 in three layers...

Embodiment 3

[0050] A three-layer integrated high-efficiency and high-strength heat conduction sheet, such as figure 1 , including a first protective layer 1, a second protective layer 2 and a heat conduction layer 3, the first protective layer 1 and the second protective layer 2 are respectively arranged on both sides of the heat conduction layer 3; the first protective layer The components of 1 include polymer powder, photoinitiator and crosslinking agent, the components of the second protective layer 2 include polymer powder, photoinitiator and crosslinking agent, and the components of the heat conducting layer 3 It includes polymer powder and thermally conductive filler, and the polymer powder used in the first protective layer 1, the second protective layer 2 and the thermally conductive layer 3 is the same polymer powder; through SLS The printing technology prints and forms the first protective layer 1 , the second protective layer 2 and the thermal conduction layer 3 in three layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com