Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Relaxed process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

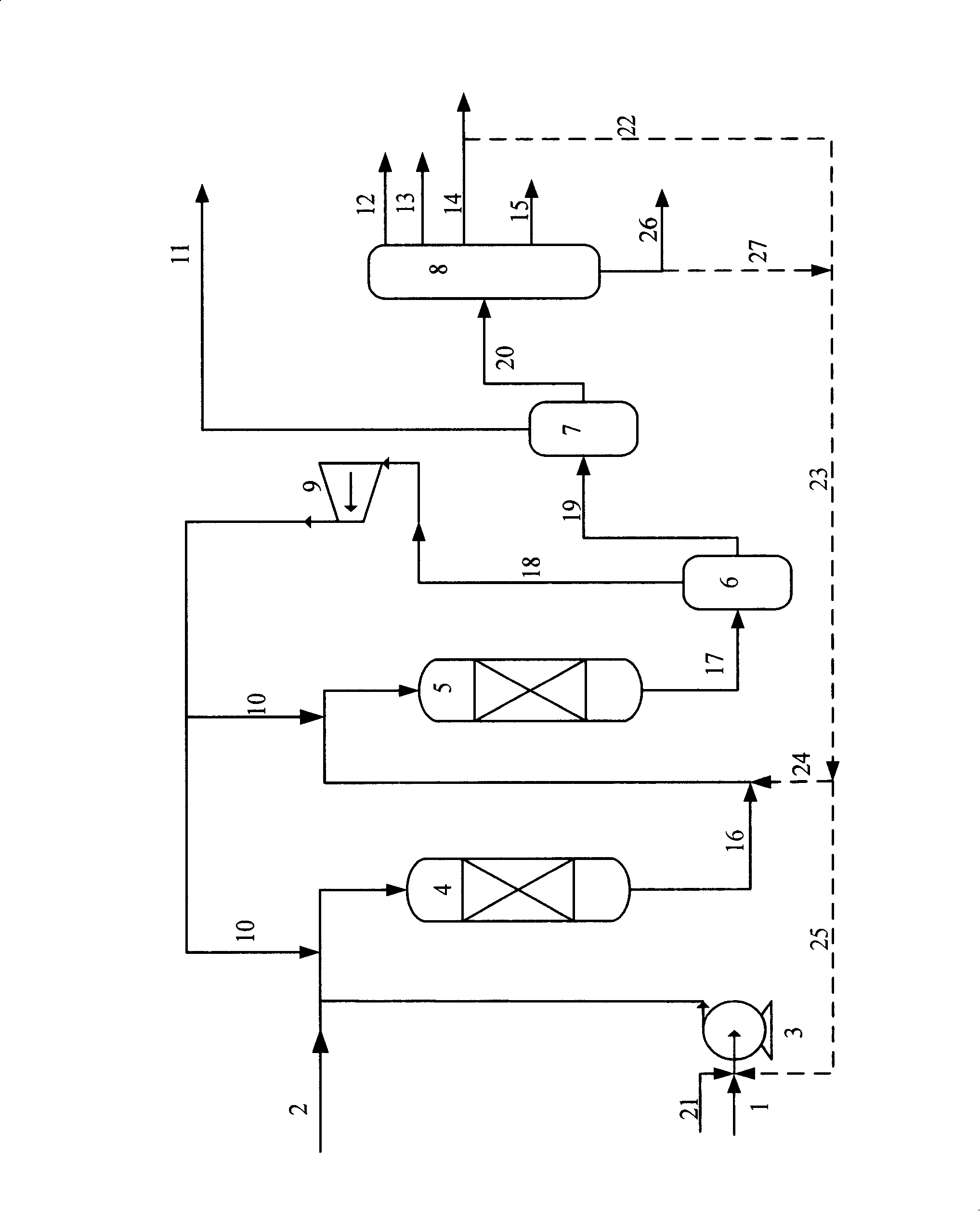

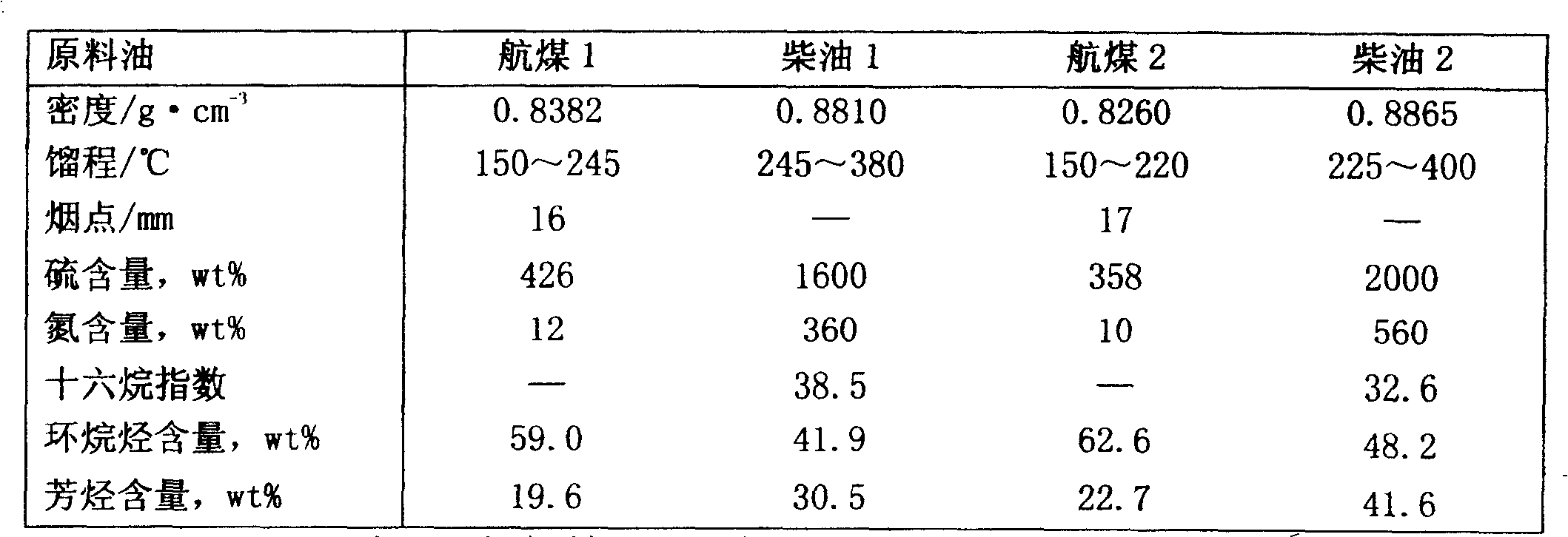

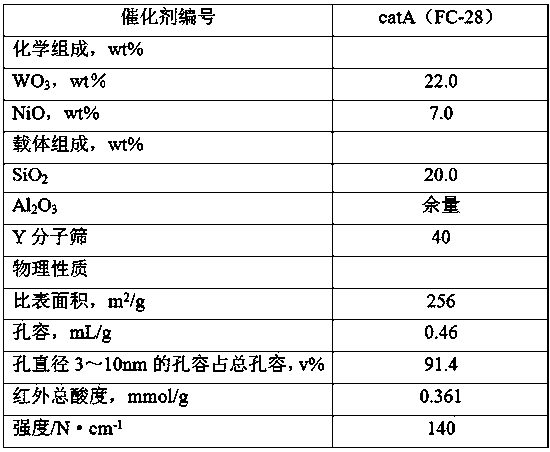

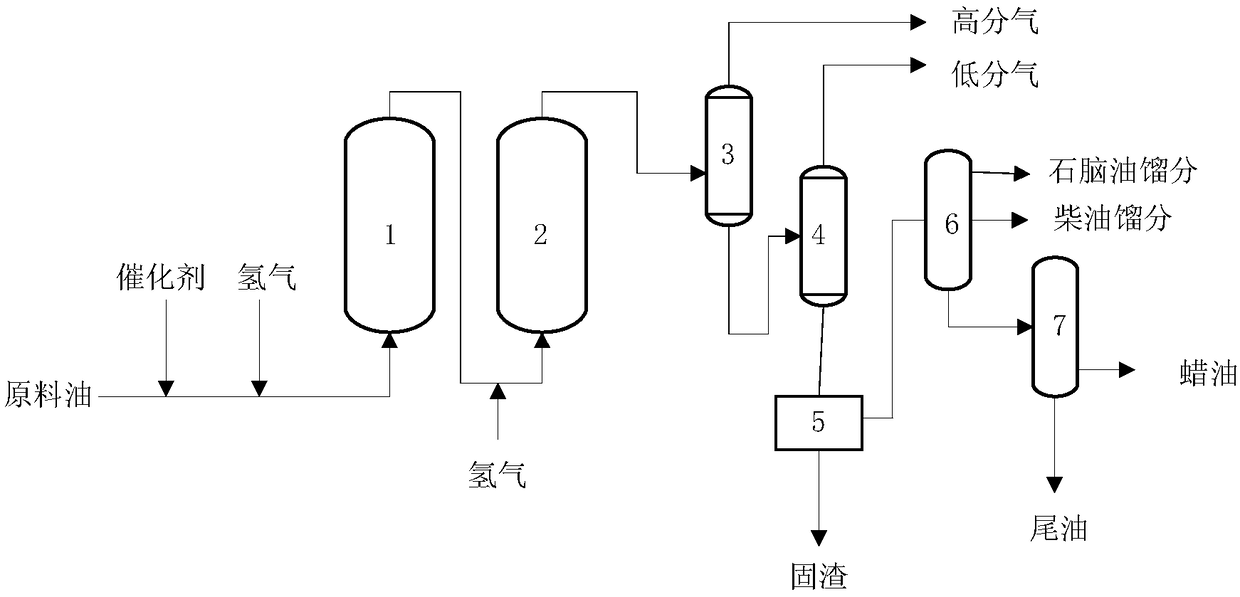

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

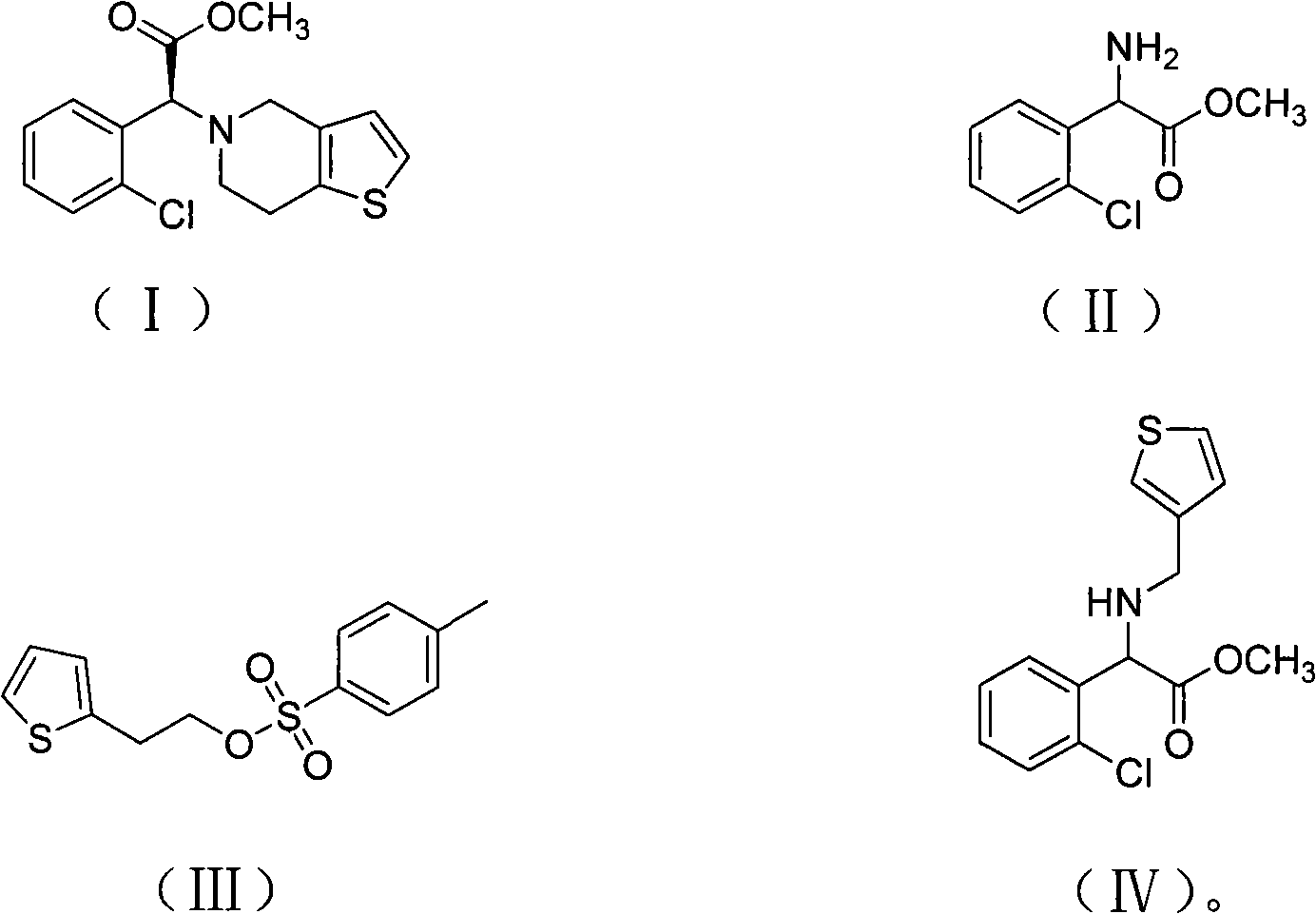

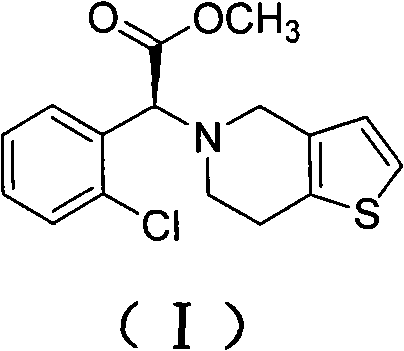

Method for preparing clopidogrel and salts thereof

The invention provides a preparation method for clopidogrel and the salts of clopidogrel, belonging to the field of medical and chemical technology. The invention solves the problems of more reaction steps, long technical route, high cost and low purity of the existing preparation method for clopidogrel. The preparation method for clopidogrel comprises the following steps: a. synchronous resolution and racemization; b. preparation of (plus) alpha-(2 - thiophene triethylamine yl) -2 - (2 - chlorophenyl) methyl acetate; c. preparation of target product clopidogrel through cyclization reaction. The clopidogrel can generate medicinal salt with acids in a solvent. The preparation method for clopidogrel and the salts of clopidogrel has simple technology, easy operation, lower costs and higher product purity.

Owner:江苏八巨药业有限公司

Preparation process for superfine powder of zirconium oxide

InactiveCN1559982AUniform particle size distributionNarrow particle size rangeZirconium oxidesGranularityMetallic materials

The invention relates to a ultrafine zirconium oxide (ZrO2) powder preparing method. ZrO2 is a high temperature-resistant, wearable, corrosion-resistant inorganic nonmetallic material, the proper-sized ultrafine ZrO2 powder is an important chemical raw material to prepare high-performance refined ceramics, like electronic ceramics, functional ceramics, structural ceramics, etc. and has increasingly wide applications in the technical fields of aviation, spaceflight, machinery, chemical engineering, electronics, automobiles, energy sources, etc. It adopts zirconium oxychloride and salvolatile as precursor raw material, uses uniform codeposition method to prepare wet ZrO2 gel, then drying at 100-150 deg.C at 0.3-1.0 MPa, and burning at 700-1000 deg.C to make ultrafine ZrO2 powder. It can obtain the ultrafine ZrO2 powder, particle size 0.1-0.5 mum, specific surface area 15-30 sq m / g and distribution range of particle size narrow. The ultrafine ZrO2 powder properly acts as the chemical raw material for refined ceramics.

Owner:HARBIN ENG UNIV

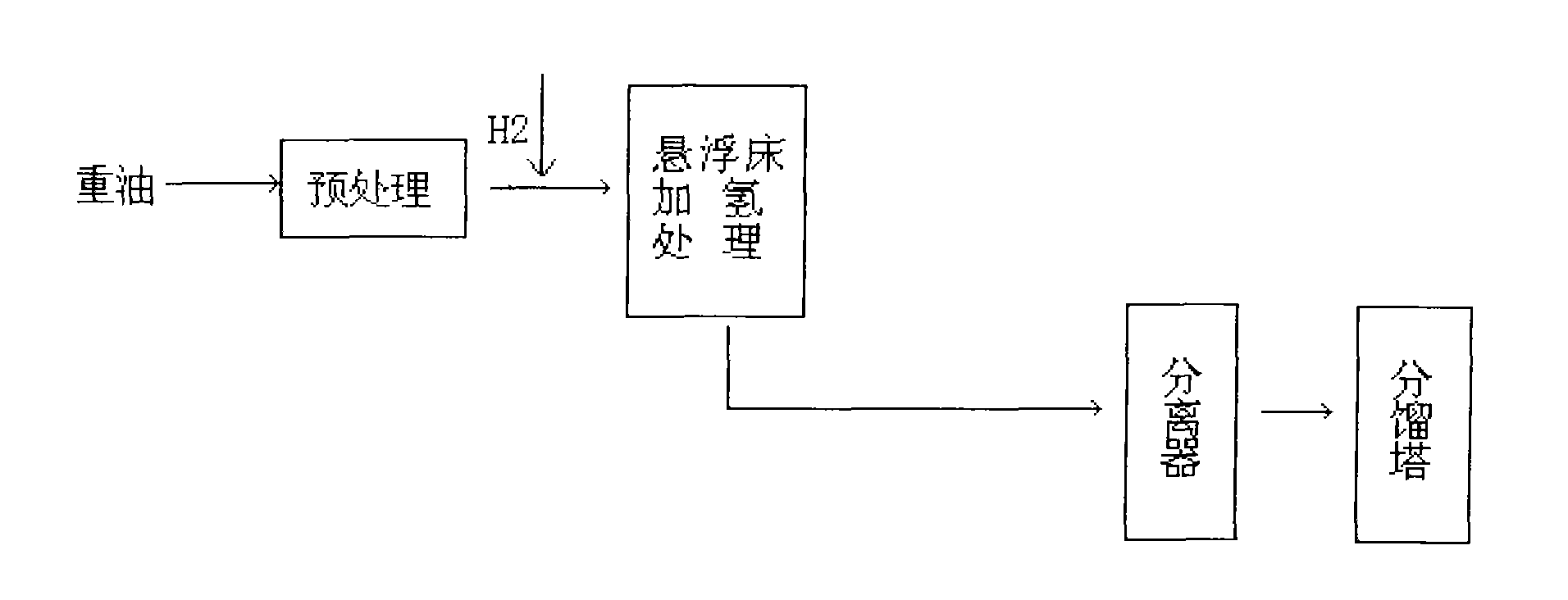

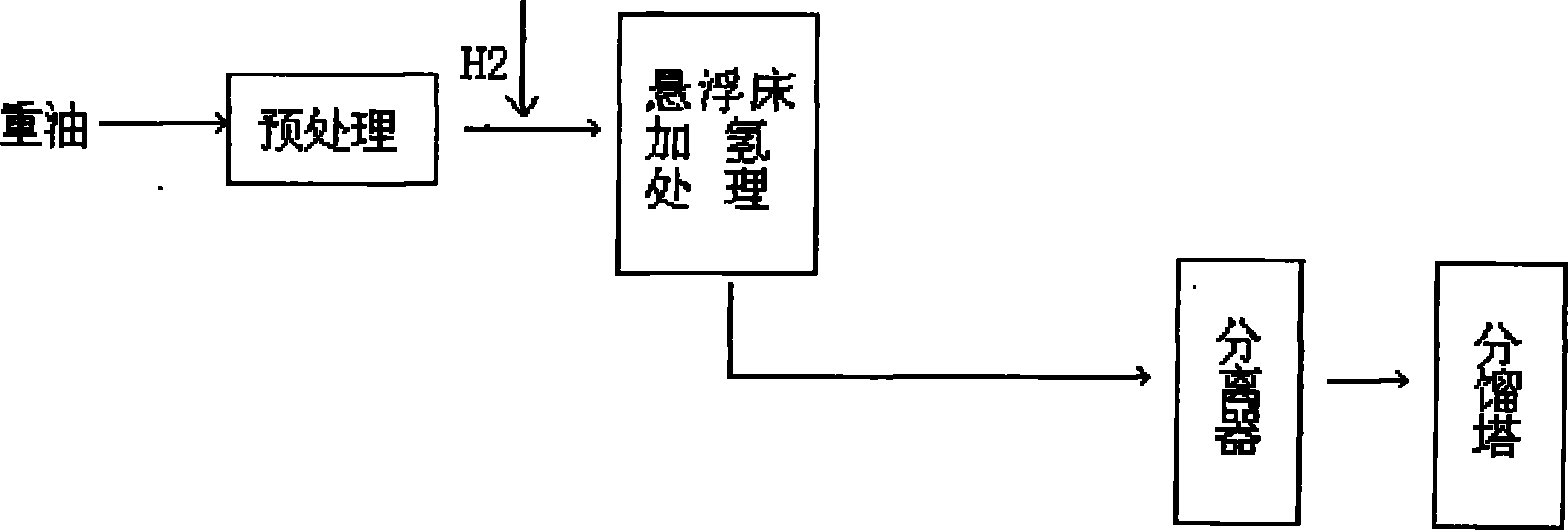

Heavy oil hydrogenation modifying method

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

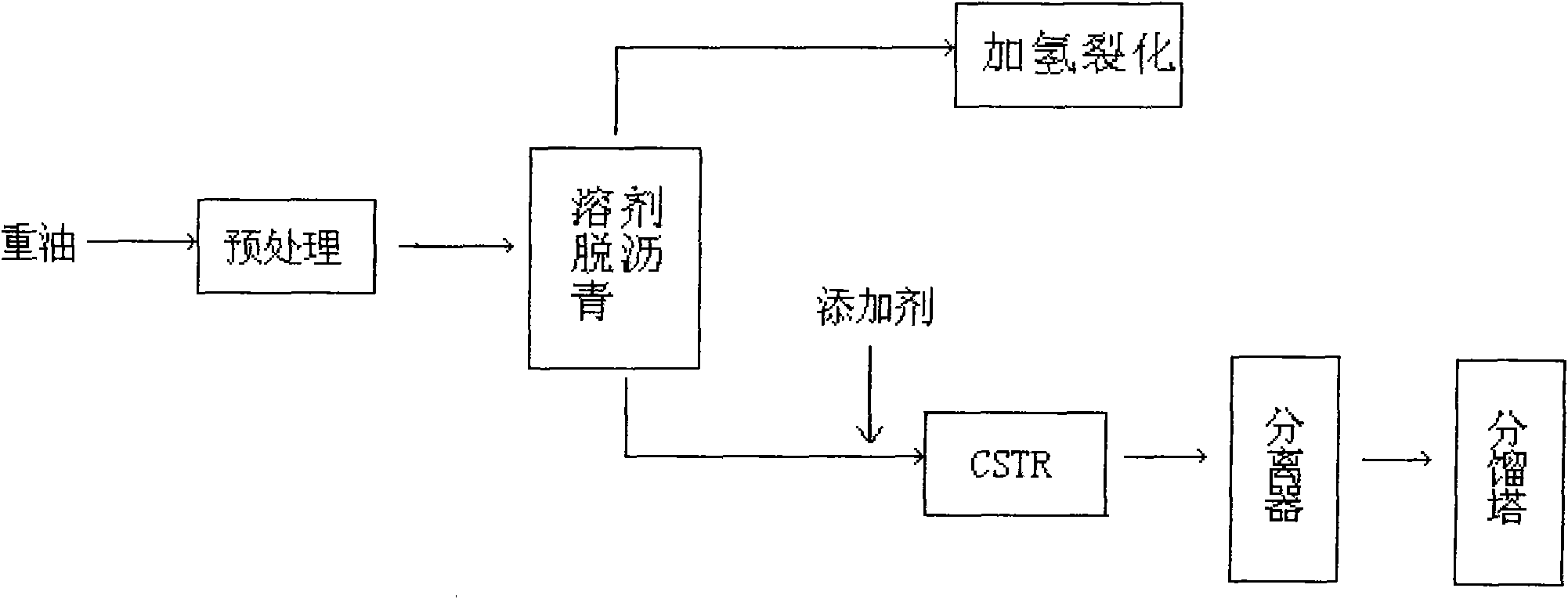

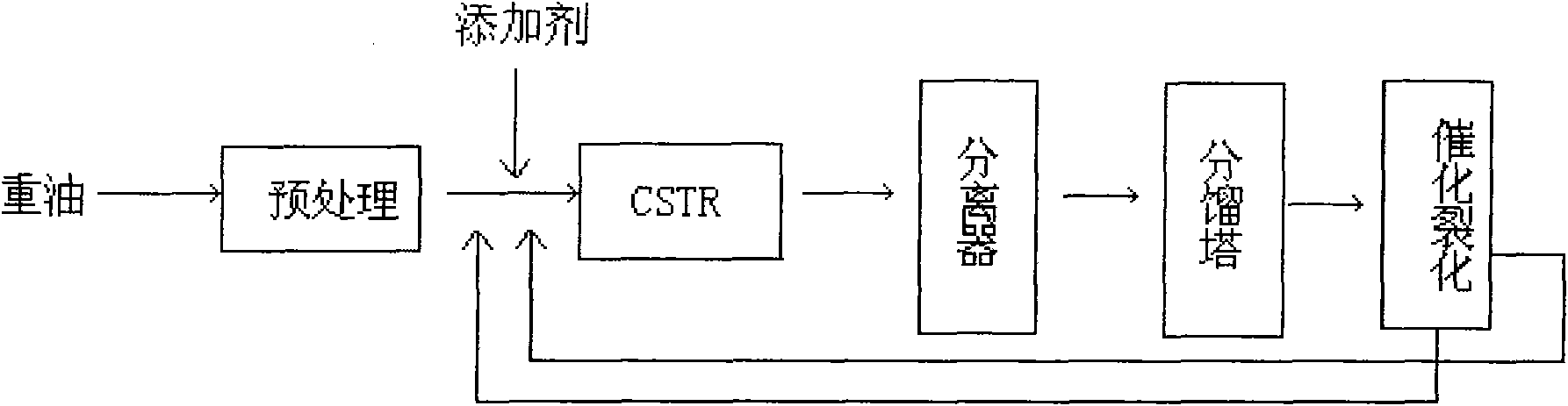

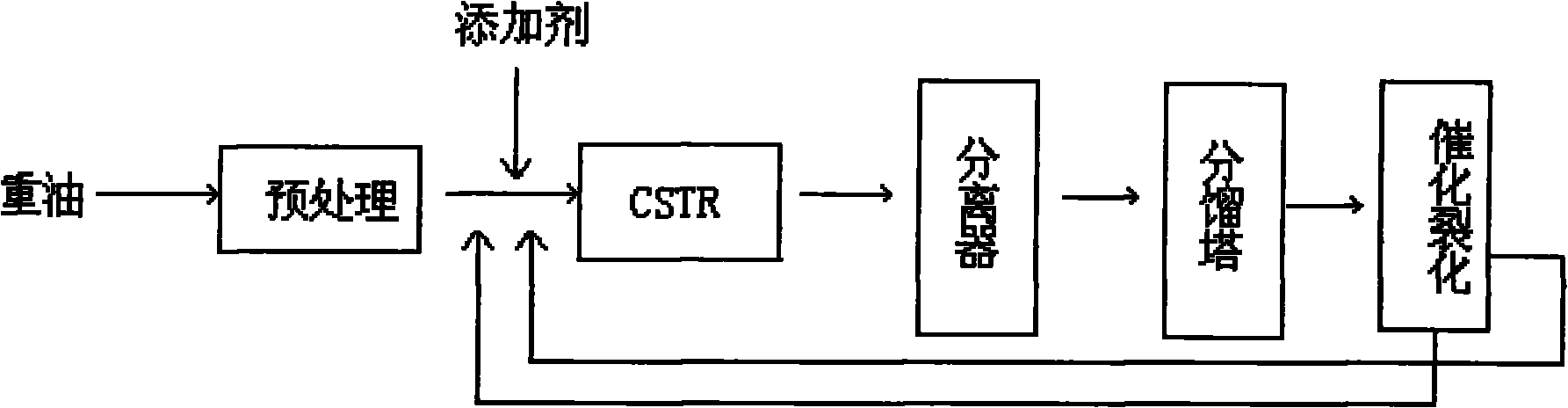

Combined process for heavy oil modification

ActiveCN101942337AImprove fusion effectImprove responseTreatment with hydrotreatment processesLight treatmentFuel oil

The invention discloses a combined process for heavy oil modification. A heavy oil raw material is first subjected to solvent de-asphalting treatment, the de-asphalted oil obtained by the solvent de-asphalting is subjected to catalytic cracking or hydro-cracking treatment, and the de-oiled asphalt obtained by the solvent de-asphalting is subjected to supercritical treatment, wherein the supercritical treatment method for the de-oiled asphalt comprises supercritical treatment of mixture of de-oiled asphalt and hydrogen supply solvent, the hydrogen supply solvent comprises tetrahydronaphthaleneor decahydronaphthalene, the mixing weight ratio of the heavy oil raw material to the hydrogen supply solvent is 1:0.5-1:10, and the supercritical treatment is performed for 0.2 to 5 hours under the pressure of 15 to 40MPa at the temperature of between 300 and 500 DEG C. The method can effectively improve the utilization rate of poor-quality heavy oil, has low coking rate and stable production process, and can be used for light treatment of various heavy and poor raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfur-tolerant shift process for preparing methyl methanol syngas

ActiveCN101412932AReduce energy consumptionGood energy saving effectCombustible gas chemical modificationOrganic compound preparationSyngasChemistry

The invention provides a CO sulfur tolerant shift method for preparing methanol synthesis gas. The method at least comprises the following two stages of shift: crude gas is pretreated and is heated up to 180 to 260 DEG C, the gas enters a first reactor for the shift reaction when a water to gas volume ratio is 0.1 to 0.55, the bed temperature is 330 to 420 DEG C, and the CO volume content is 36 to 48 percent after the first shift reaction; and the gas from the first reactor is cooled down to 200 to 280 DEG C through heat exchange and water spray, the gas enters a second reactor for the shift reaction when a water to gas volume ratio is 0.1 to 0.75, the bed temperature is 390 to 450 DEG C, and the dry basis CO volume content in the final outputted gas is 8 to 35 percent. A CO sulfur tolerant shift catalyst is used during the two stages of shift. The outputted gas at the second stage can be directly used or for preparing the methanol synthesis gas or be used for preparing the methanol synthesis gas after a third stage of deep shift gas distribution. The method has the advantages of low water to gas ratio, energy conservation, low equipment cost, wide raw material sources, and the like.

Owner:青岛联信催化材料有限公司

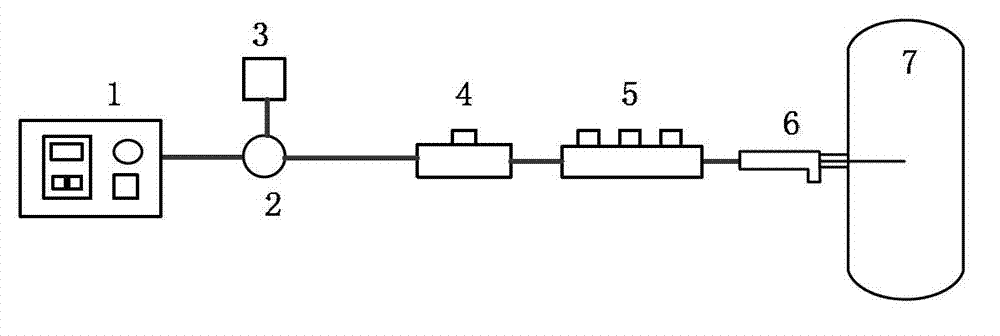

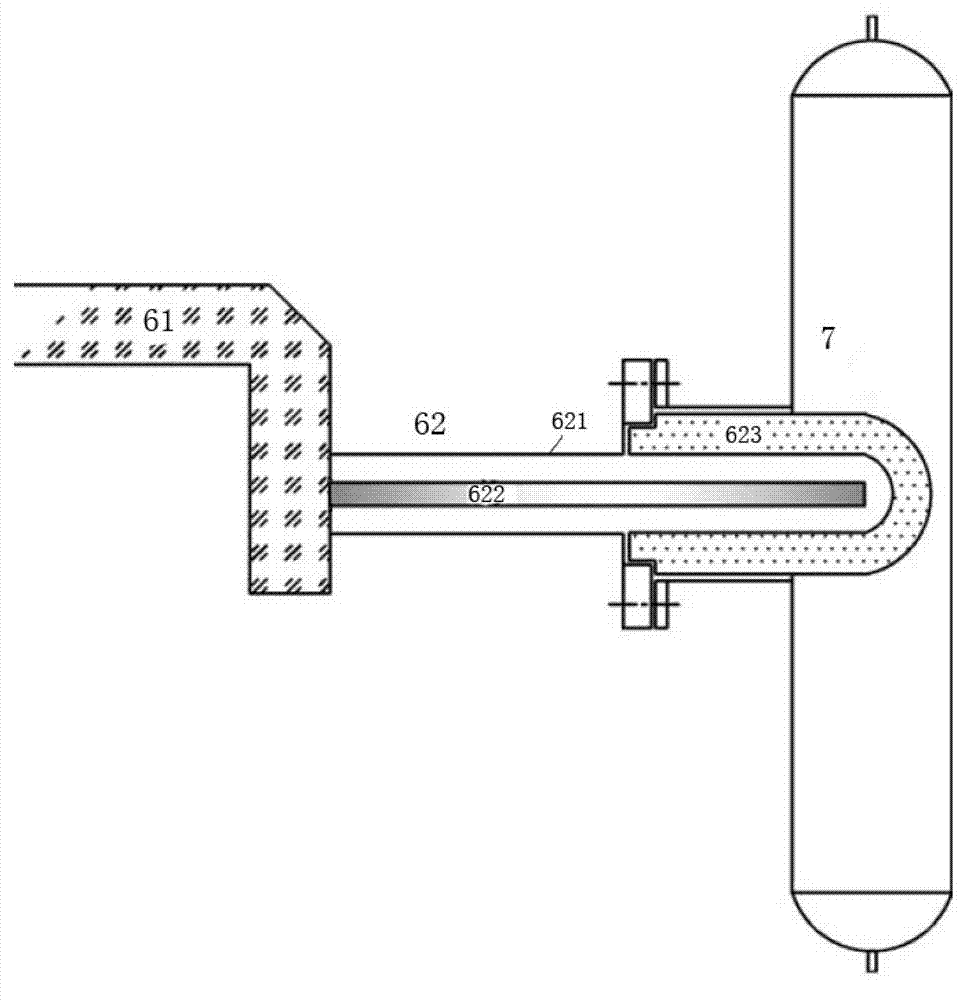

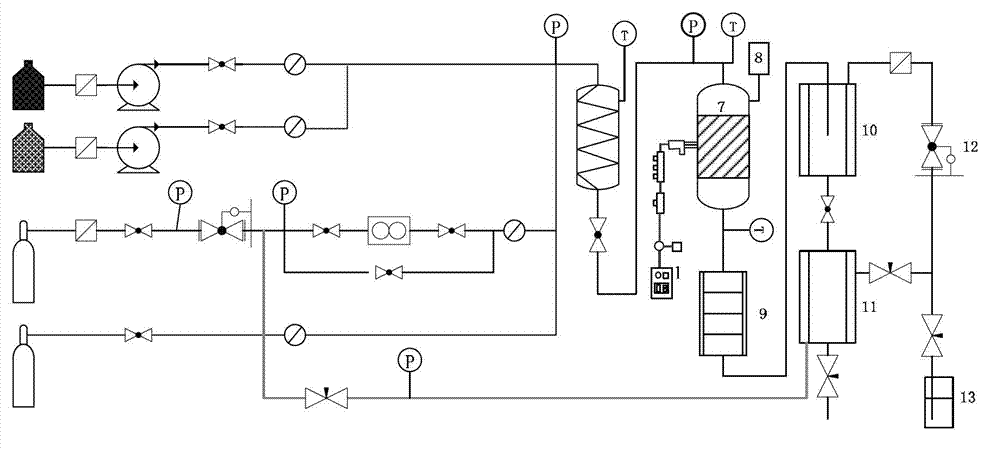

Microwave heating device and application thereof

InactiveCN102773055AImprove sealingUniform microwave distributionHeat treatmentsEnergy based chemical/physical/physico-chemical processesHydrodesulfurizationProcess engineering

The invention provides a microwave heating device and an application thereof, wherein the device comprises a microwave reactor and a microwave generation and transmission device, the microwave generation and transmission device comprises a microwave source, a circulator, a water load, a directional coupler, an automatic tri-dowel regulator and a waveguide according to a microwave transmission sequence, in the waveguide section, a mode of converting a rectangular wave guide into coaxial transmission is adopted, and a probe enters the center of the reactor from the side wall of the microwave reactor for guiding the microwave into the reactor. According to the device, microwaves in the reactor are uniformly distributed; and moreover, the device has good sealing performance, can be practically applied for any reaction which utilizes microwave to heat, such as an application of continuous oil product hydrodesulfurization, technological conditions can be alleviated, the oil product desulfurization degree is effectively improved, and the oil refining economical efficiency is improved.

Owner:北京众诚汇微能源科技有限公司 +1

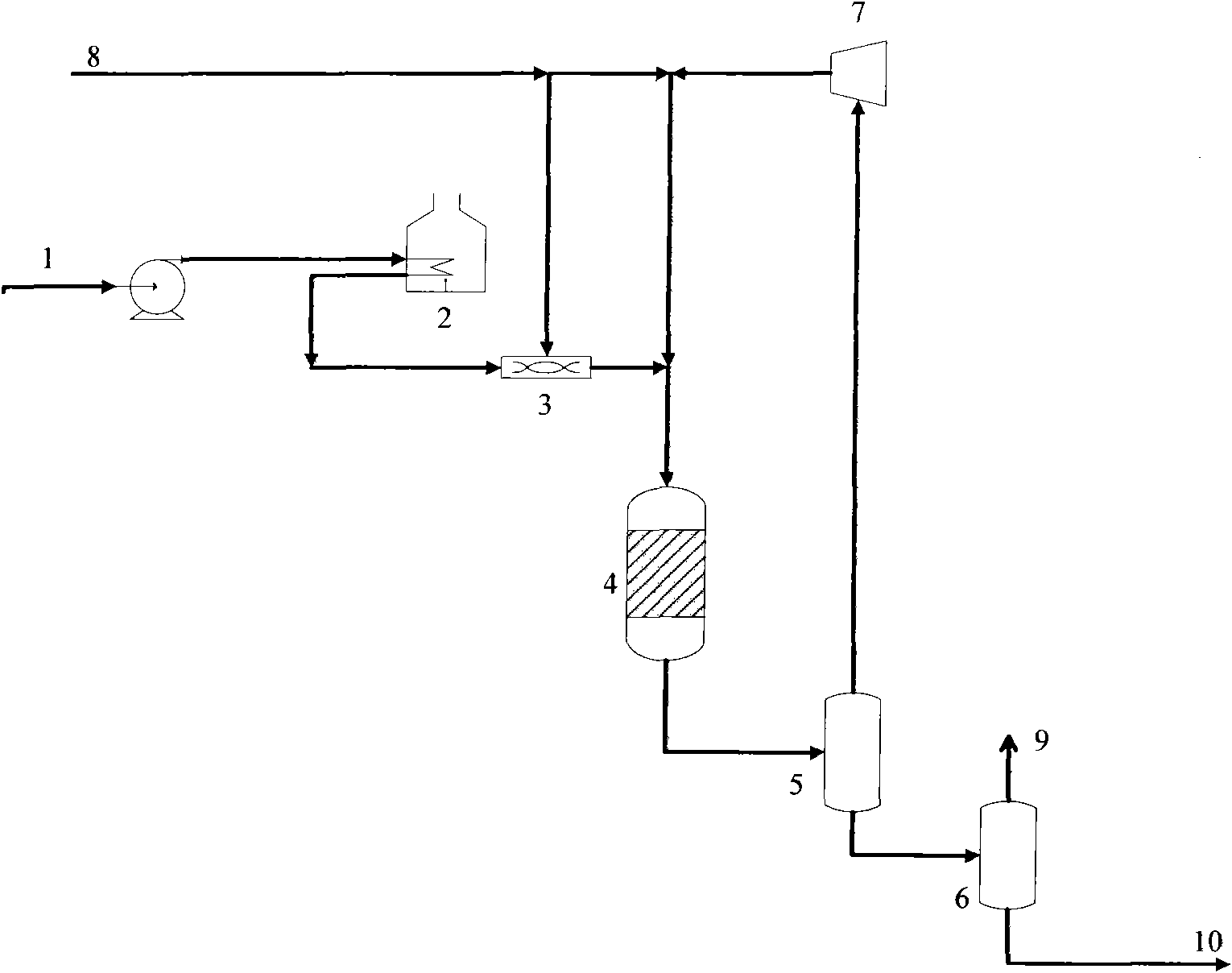

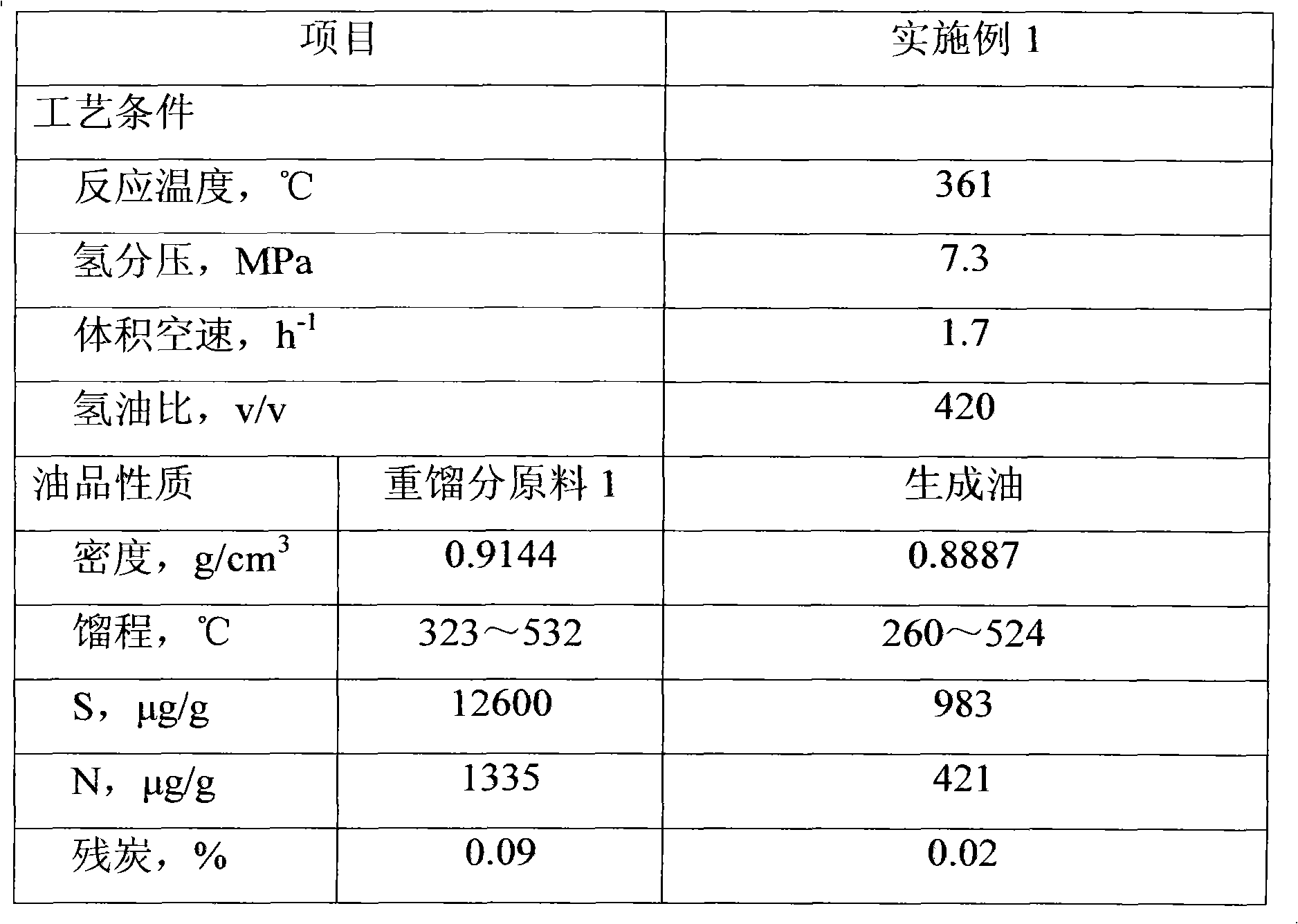

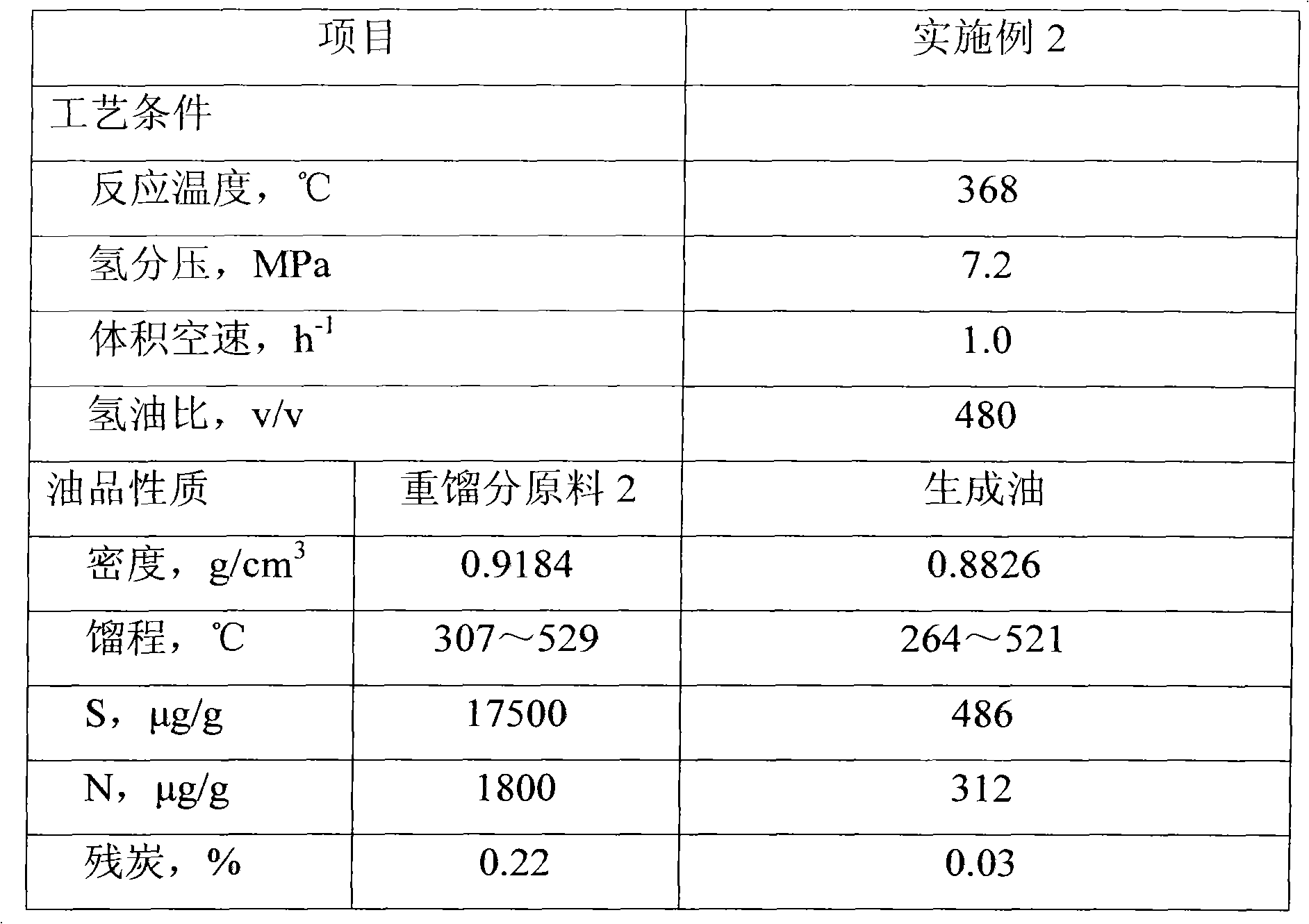

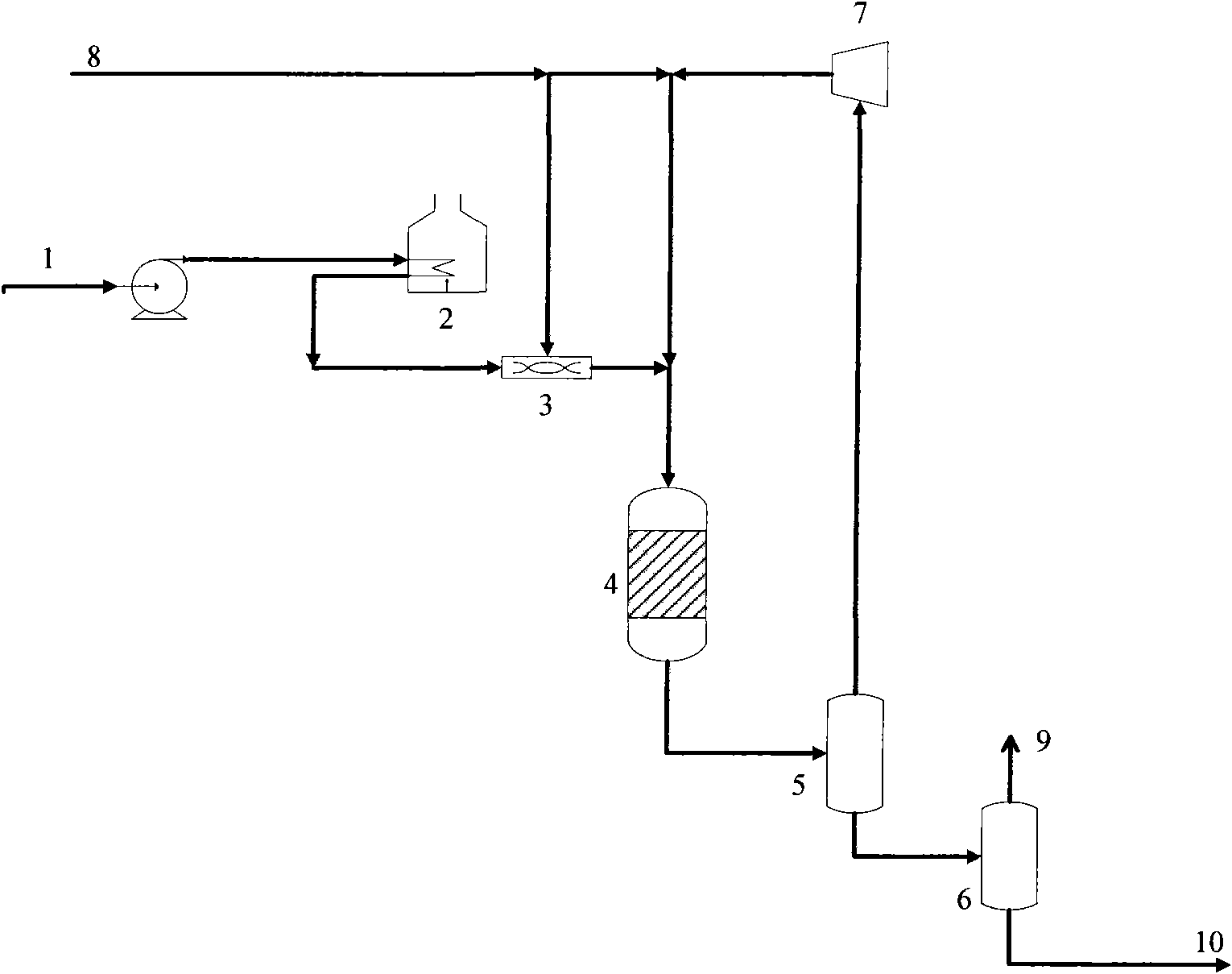

Method for hydrotreating heavy distillates

InactiveCN102041046AIncrease the amount of dissolutionQuick responseHydrocarbon oils refiningPetrochemicalChemistry

The invention relates to a method for hydrotreating heavy distillates, which comprises the following steps of: firstly, fully mixing raw oil with hydrogen gas through a heating furnace in a gas-liquid mixer; then, contacting with a hydrotreating catalyst at a low hydrogen-oil volume ratio under mild technological conditions, and carrying out a conventional hydrorefining reaction. Compared with the conventional hydrotreating method, the invention can obtain better refining effect under the same technological conditions. The method provided by the invention aims at heavy distillates of petrochemical enterprises, such as vacuum gas oil, coke gas oil, deasphalted oil or mixture oil thereof, and the heavy distillate products produced by using the technological method can be used as high-quality raw materials of catalytic cracking units or hydrocracking units. The method provided by the invention has simple technological flow, stable operation and good product characters; and a new hydrogenation unit can be built, and the old unit can also be used through reformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low-aromatics solvent oil by hydrogenation

The invention relates to a method for producing low-aromatics solvent oil by hydrogenation. The method comprises the following steps of: passing raw material oil through a heating furnace, then fully mixing the raw material oil and hydrogen gas in an oil-gas mixer, and contacting with a hydrogenation catalyst in a lower hydrogen-oil volume ratio and under milder process conditions to undergo the common hydrogenated purification reaction. Compared with the conventional hydrogenated purification process, the method can achieve the same effect as the conventional purification process under milder process conditions. By the method, the low-sulfur and low-aromatics solvent oil products can be produced. In addition, the method also has the advantages of simple process flow, stable operation, high product properties and low energy consumption, and the new establishment of a hydrogenation device and the modification of the original device are both ok.

Owner:CHINA PETROLEUM & CHEM CORP +1

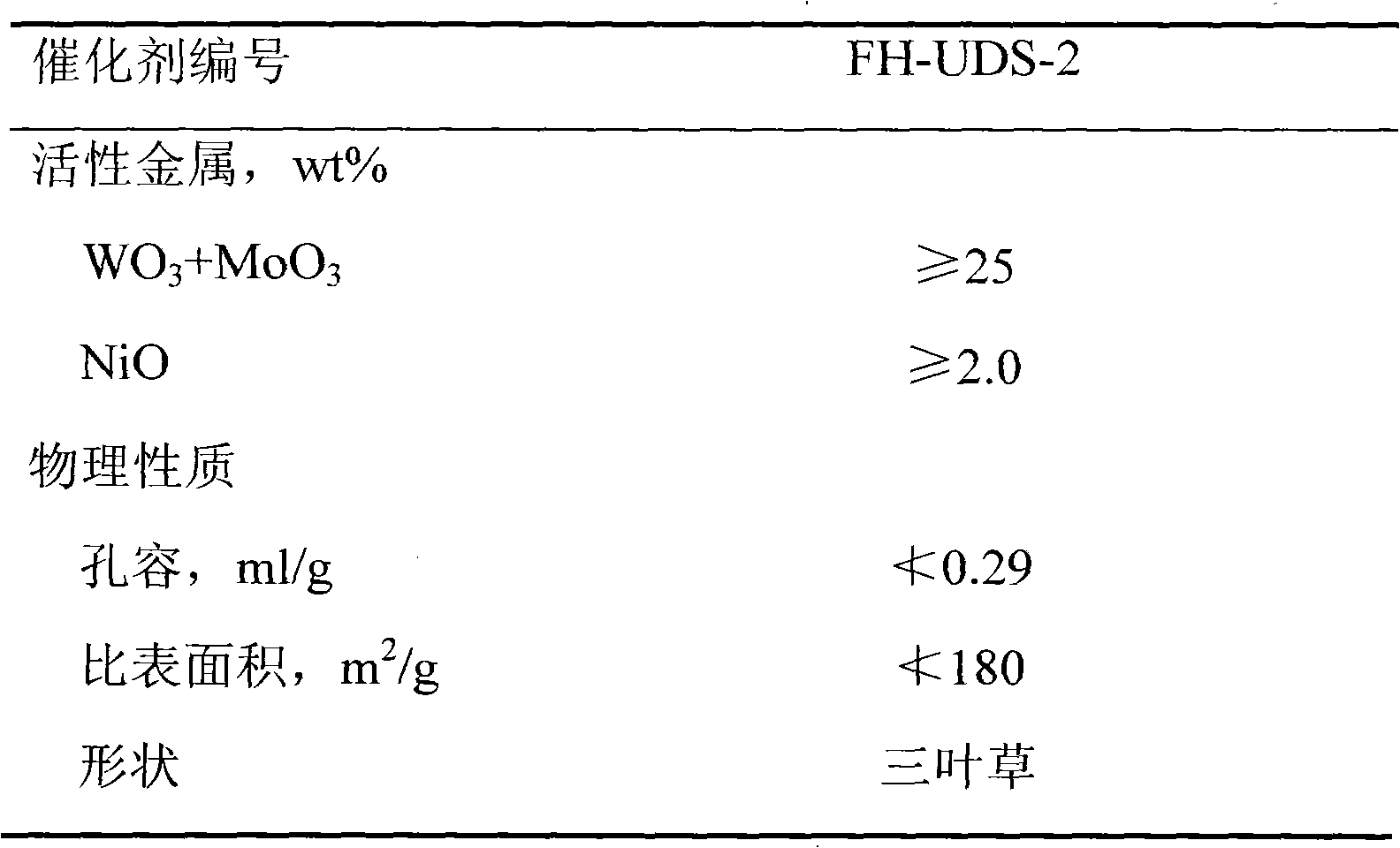

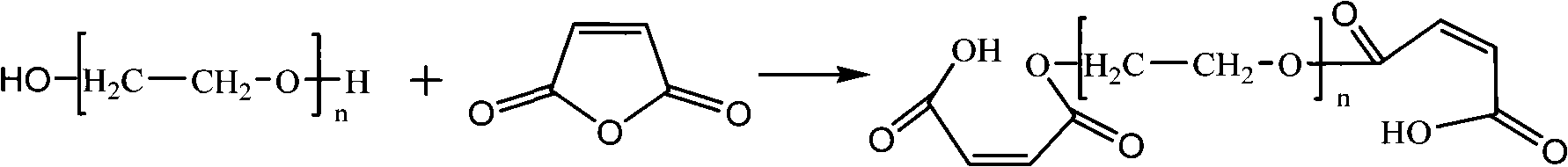

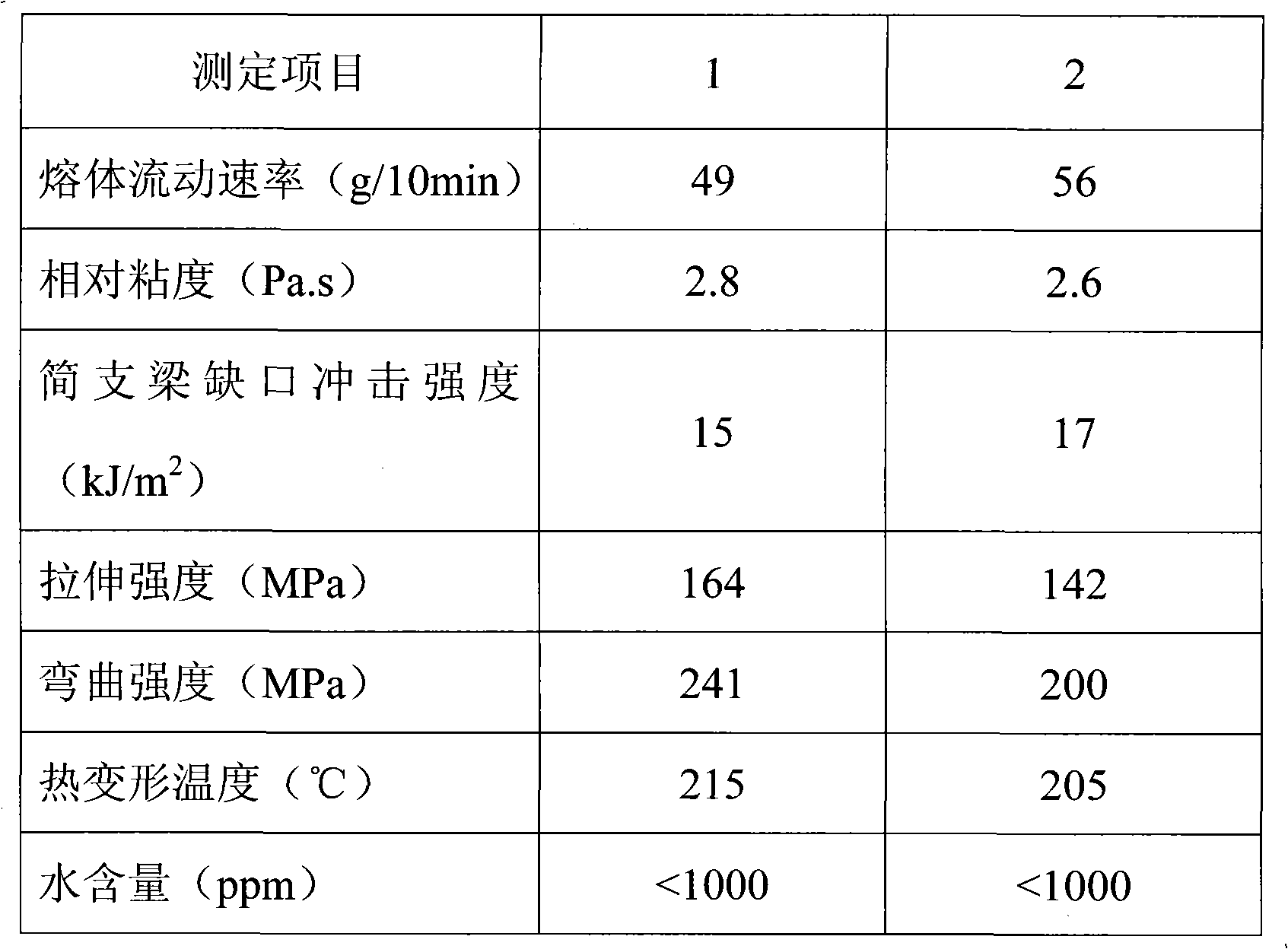

Special PA6 injection molding material used for direct injection molding and preparation method thereof

The invention provides a special PA6 injection molding material used for direct injection molding and a preparation method thereof. The special PA6 injection molding material mainly comprises, by weight, 40 to 80% of nylon 6 resin, 10 to 25% of a plasticizer, 5 to 25% of a reinforcing agent and 0.2 to 5% of an anti-oxidant, wherein, the plasticizer is maleic anhydride grafted polyethylene glycol, the reinforcing agent is silane coupling agent grafted nanometer SiO2, and the anti-oxidant comprises (3,5-di-tert-butyl-4-hydroxyphenyl)propionyl-hexylenediamine and phosphite triester mixed according to a ratio of 0-1:0-1. The preparation method for the special PA6 injection molding material is to subject pure PA6 and auxiliary agents to melt blending or to add auxiliary agents into caprolactam monomers for polymerization in a manner of blending. Addition of auxiliary agents in PA6 resin enables the resin to have improved mechanical properties, surface smoothness, fluidity and aesthetic appearance and to meet requirements for high strength precision products.

Owner:CHINA PETROLEUM & CHEM CORP +2

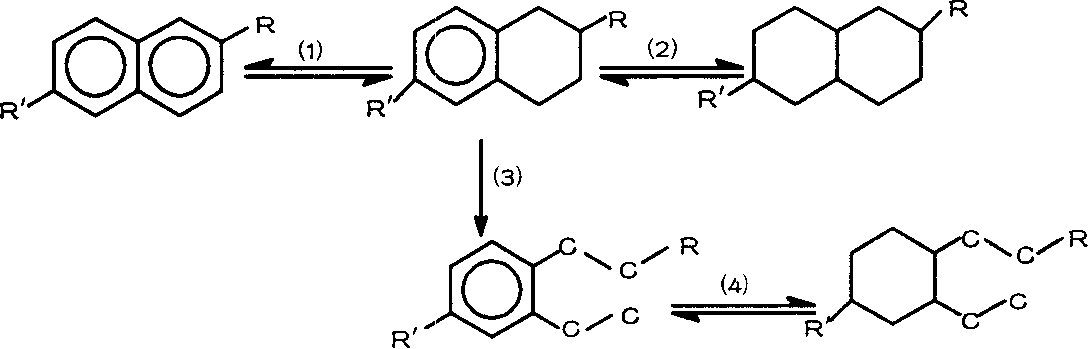

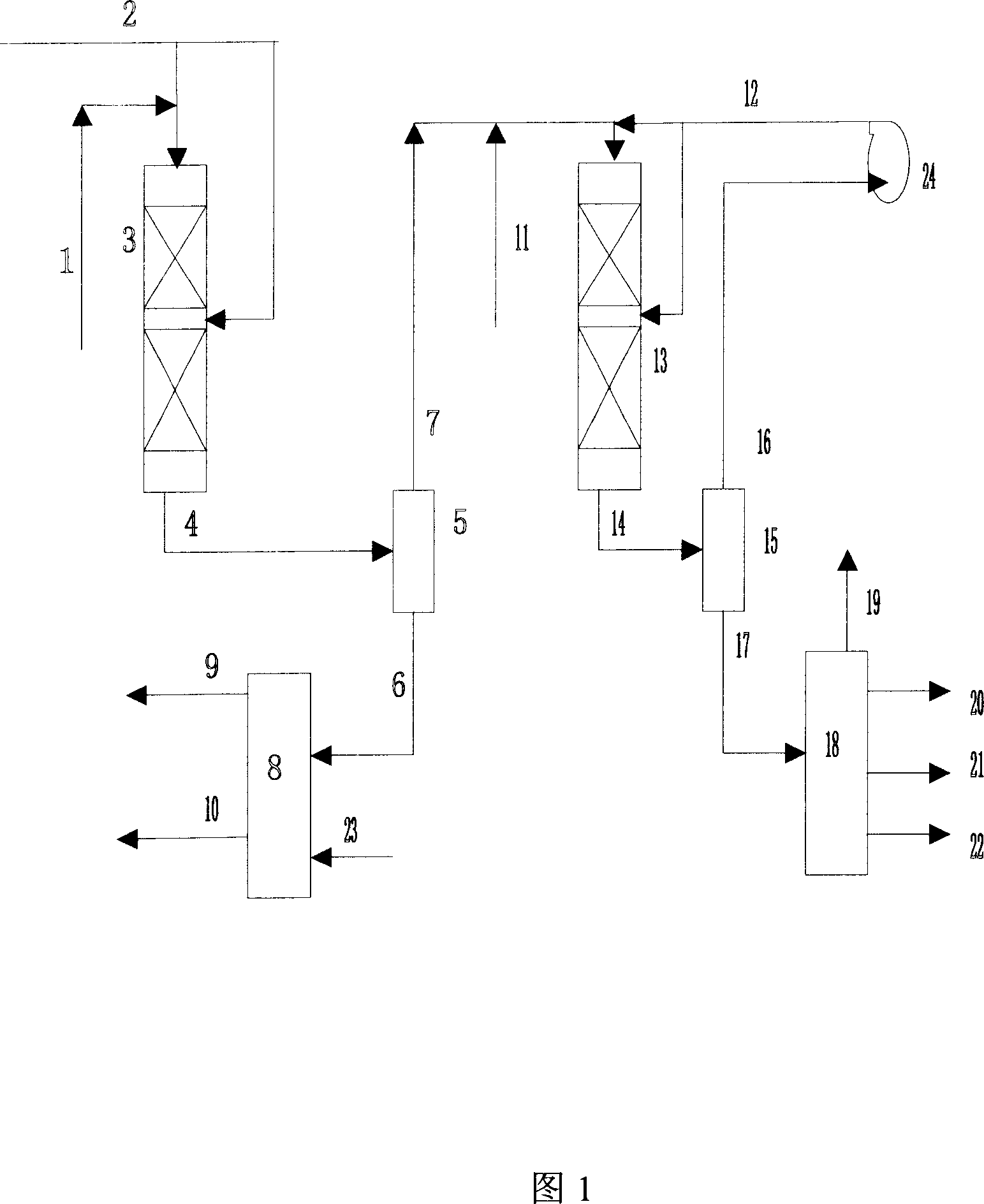

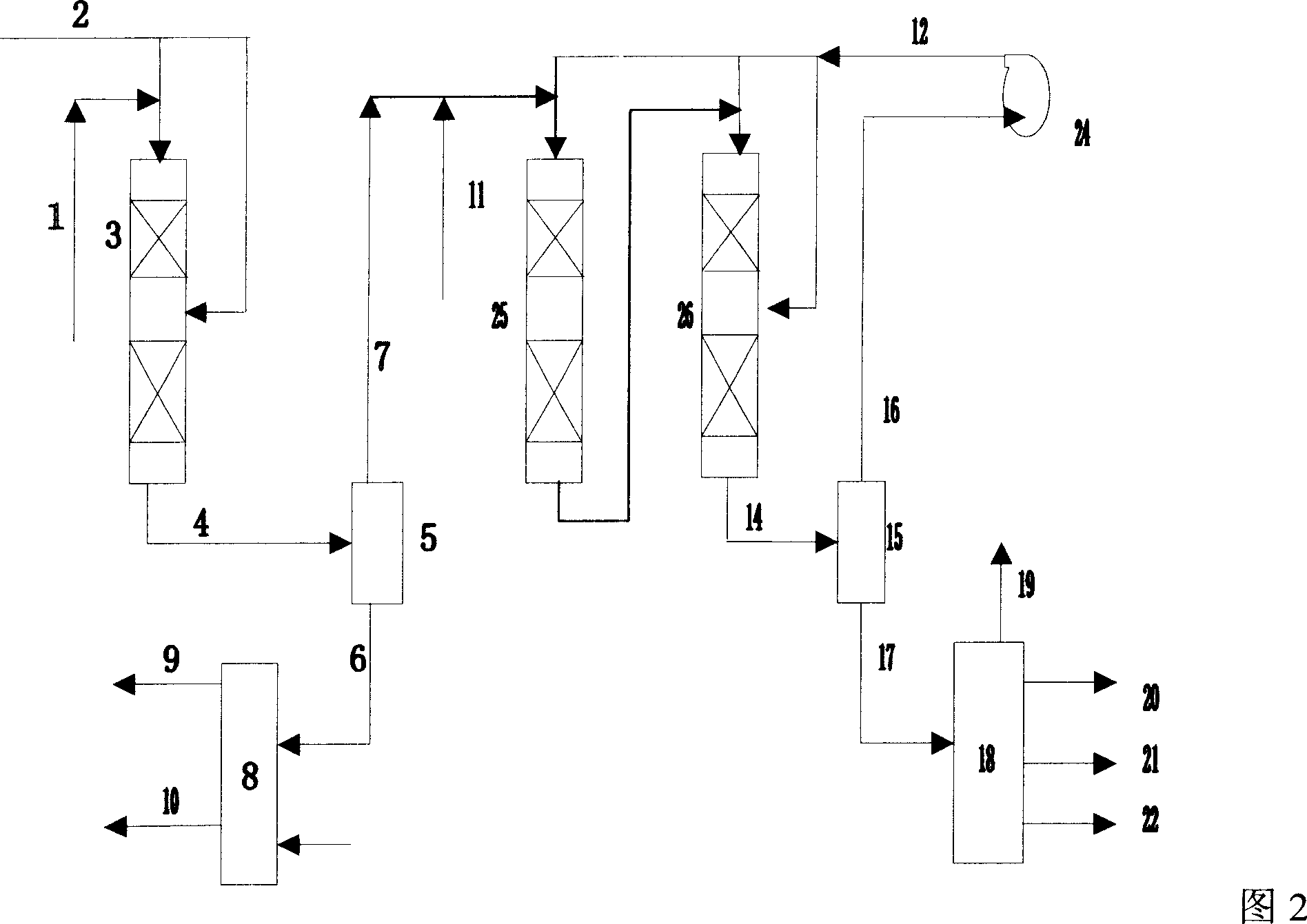

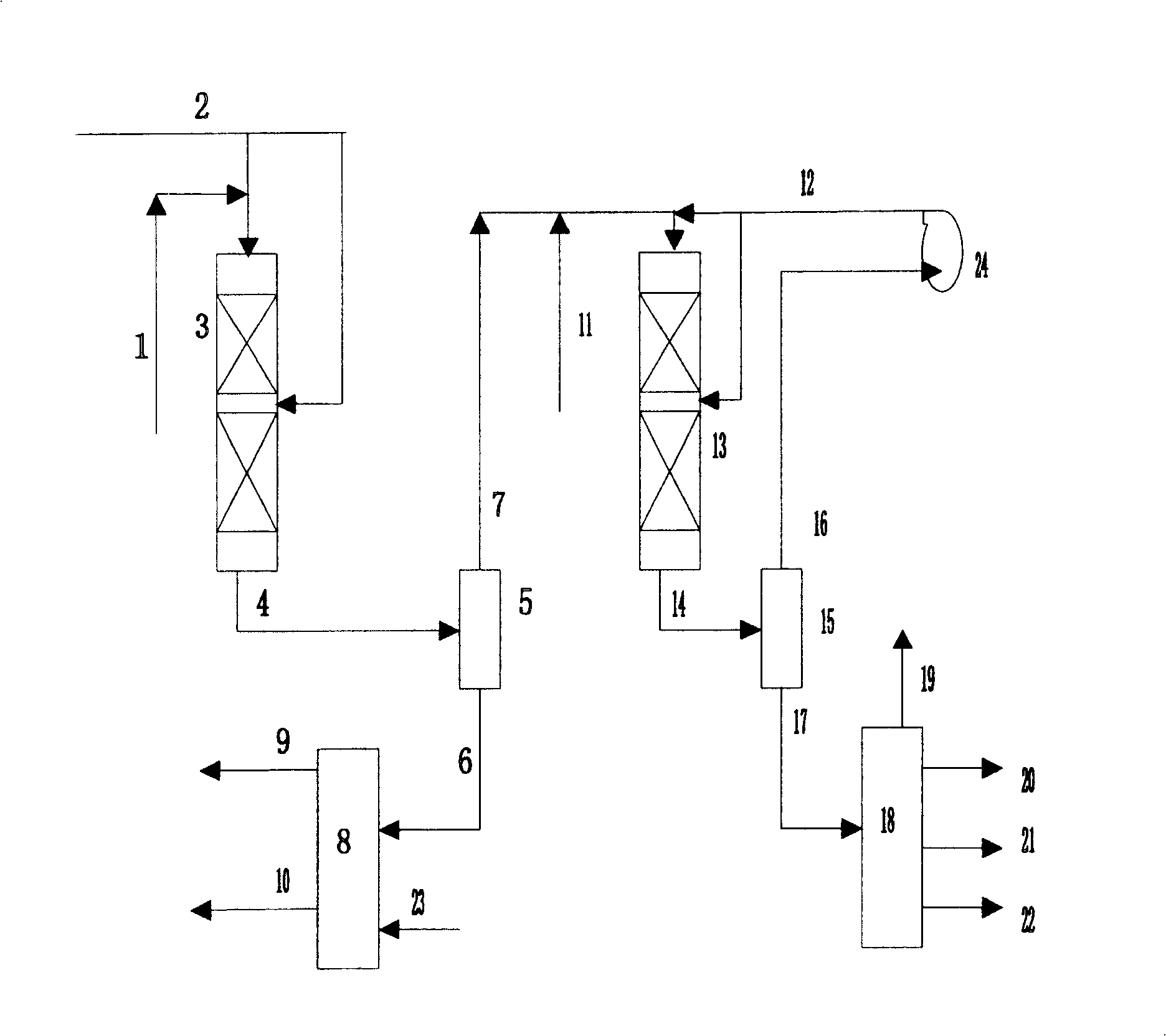

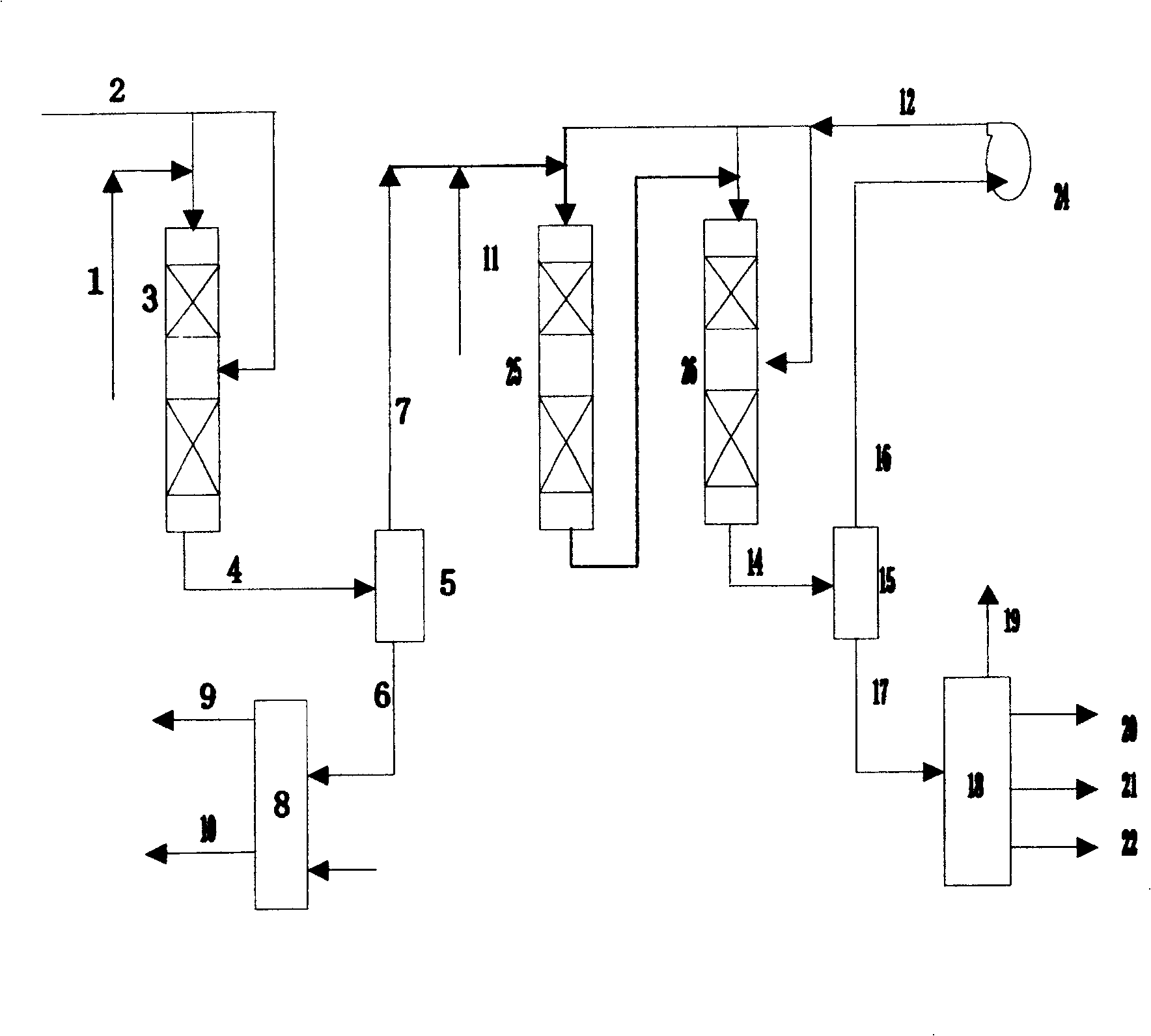

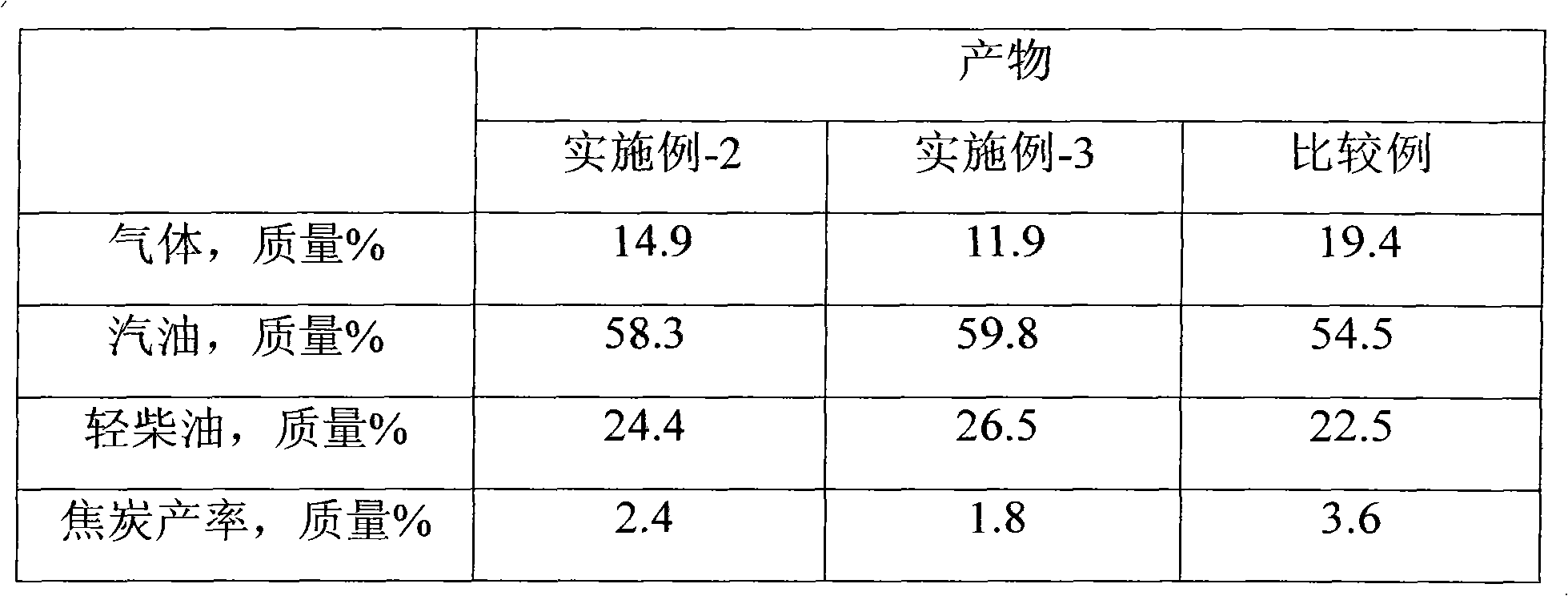

Combined hydrogenation method

ActiveCN1952069AGood for deep saturationReduce loadTreatment with hydrotreatment processesNaphthaProduct gas

The invention disclosed an associated hydrogenating technology. The invention is about deep hydrogenationg refinement of poor quality ship-coal by neo-hydrogen (such as cyclane radical or cyclane intermediate radical). The gas which is rich in hydrogen is used as the supplementary gas in hydrocracking process of diesel oil; the invention adopts hydrocracking method to treat poor quality diesel oil; the gas which is rich in hydrogen can be recycled. In the invention, the poor quality ship-coal contacts the neo-hydrogen first so as to get the high-quality ship-coal products; by hydrocracking the diesel oil, the producer can produce high quality diesel oil directly, as well as some high quality ship-coal and high arene naphtha. The invention can save the investment of devices and equipments; it also has the advantage of less hydrogen consumption, less energy expenditure, and small circulated hydrogen compressor volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting FCC oil slurry aromatic hydrocarbons

The present invention relates to a method for extracting FCC oil slurry aromatic hydrocarbons. The method comprises that: 90% by mass of furfural and 10% by mass of dimethyl sulfoxide are adopted as a continuous phase in a pulse filler extraction tower, a FCC oil slurry is adopted as a disperse phase, and extraction separation is performed at a temperature of 60 DEG C according to a catalyst / oil mass ratio of 2:1-3:1, wherein the extracted phase is obtained from the bottom of the tower, and the raffinate phase is obtained from the top of the tower; and the extracted phase and the raffinate phase respectively enter a pressure reduced rectification tower, solvent recovery is performed under a pressure of 26.66 KPa at a tower bottom temperature of 121.8 DEG C according to a reflux body mass ratio of 1:1, and the recovered two solvents return to the inlet of the extraction tower so as to be recycled. According to the present invention, the aromatic hydrocarbon content in the extracted oil (gum and asphaltene are removed) obtained after extraction is more than 90%, the saturated hydrocarbon content of the raffinate oil is less than 10%, and the characteristic indexes of the oil product of the present invention are superior to the characteristic indexes of the oil product extracted with pure furfural; and the method has characteristics of simple process, simple equipment, simple operation, mild process conditions, low power consumption, wide application rang and easy large-scale industrial production.

Owner:PETROCHINA CO LTD +2

Method for producing cleaning diesel oil from coal directly liquidized oil

ActiveCN101144026AHigh yieldImprove blending effectLiquid hydrocarbon mixture productionEmission standardCoal liquefaction

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Preparation of zirconia superfine powder by hydrolysis method

The invention discloses a superfine zirconium oxide powder production in a water decomposing method. The tech is by low temperature low pressure drying and burning the zirconium oxide wet gelatin composed in water decomposing method, obtaining superfine zirconium oxide powder. By adopting the method the sphere particle zirconium oxide superfine powder with small particle diameter and narrow particle size distribution can be obtained and applied on fine ceramic composing, catalyzer and other fields.

Owner:HARBIN ENG UNIV

Combined hydrogenation method

ActiveCN100448956CGood for deep saturationRaise quality standardsTreatment with hydrotreatment processesNaphthaProduct gas

The invention disclosed an associated hydrogenating technology. The invention is about deep hydrogenationg refinement of poor quality ship-coal by neo-hydrogen (such as cyclane radical or cyclane intermediate radical). The gas which is rich in hydrogen is used as the supplementary gas in hydrocracking process of diesel oil; the invention adopts hydrocracking method to treat poor quality diesel oil; the gas which is rich in hydrogen can be recycled. In the invention, the poor quality ship-coal contacts the neo-hydrogen first so as to get the high-quality ship-coal products; by hydrocracking the diesel oil, the producer can produce high quality diesel oil directly, as well as some high quality ship-coal and high arene naphtha. The invention can save the investment of devices and equipments; it also has the advantage of less hydrogen consumption, less energy expenditure, and small circulated hydrogen compressor volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sodium acetate

InactiveCN103833543ABest ratioRelaxed process conditionsOrganic compound preparationCarboxylic acid salt preparationSodium acetateGranularity

The invention discloses a preparation method of sodium acetate. According to the preparation method, optimal reactant ratio is determined based on researches on sodium acetate synthesis and crystallization technology, strong alkaline liquid filtration is not needed, condensation or proportion adjustment is not needed, conventional sample equipment is adopted, heating is not needed by technical processes, technical conditions are mild and stable, and requirements on equipment are low. Quality of obtained products is capable of meeting with requirements of Chinese pharmacopoeia 2010 and reagent grade standards; crystal size is uniform; yield is high; the preparation method is suitable for GMP industrial production of pharmaceutic adjuvants, and food-grade and reagent-grade industrial production.

Owner:TIANJIN KERMEL CHEM REAGENT

Combined process method for heavy oil modification

ActiveCN101942338AImprove fusion effectImprove responseTreatment with hydrotreatment processesFuel oilSlurry

The invention discloses a combined process method for heavy oil modification, which comprises the following steps of: mixing heavy oil raw materials and a hydrogen supply solvent for supercritical treatment, and making the heavy oil subjected to the supercritical treatment enter a catalytic cracking unit for treatment; and performing a cracking reaction in the presence of a cracking catalyst, and separating reaction products to obtain dry gas, liquefied gas, gasoline, diesel oil, heavy cycle oil and slurry oil, wherein the heavy cycle oil partially or totally cycles for the supercritical treatment, and the slurry oil partially or totally cycles for the supercritical treatment. The supercritical treatment method for the heavy oil raw materials comprises the step of mixing the heavy oil raw materials and the hydrogen supply solvent for the supercritical treatment, wherein the hydrogen supply solvent comprises tetrahydronaphthalene or decahydronaphthalene. The method has the advantages of capacity of effectively improving the utilization rate of poor-quality heavy oil, low coking rate, stable production process, and suitability for light treatment of various heavy and poor-quality raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

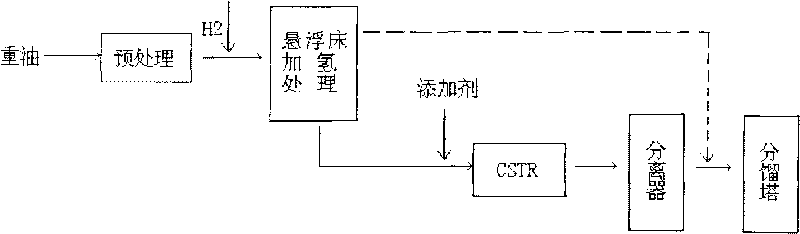

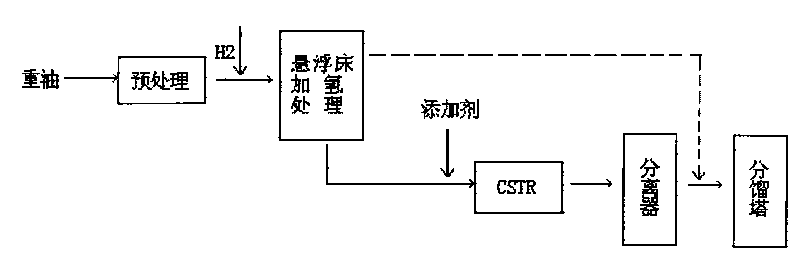

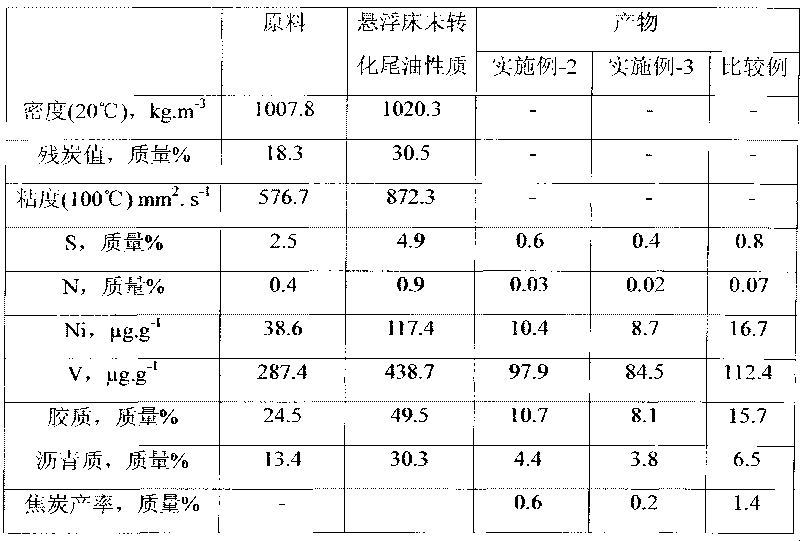

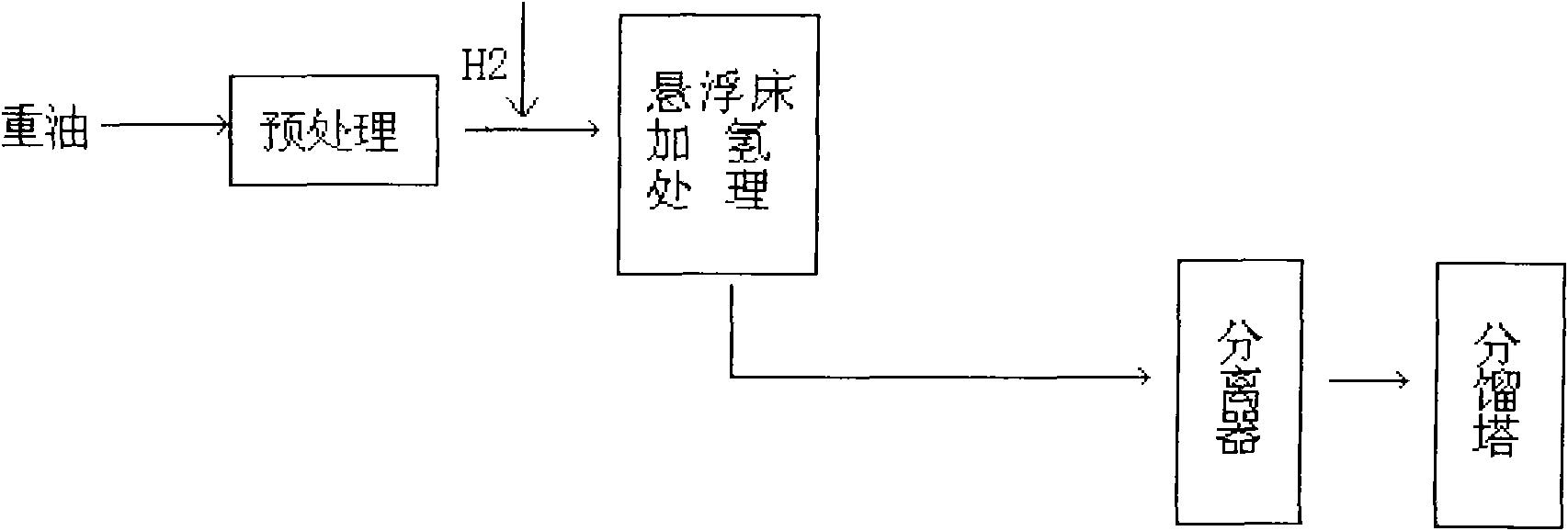

Combined technological method for heavy oil modification

The invention discloses a combined technological method for heavy oil modification, which comprises the following steps: carrying out suspension bed hydrogen cracking on heavy oil raw material under a suspension bed hydrogen cracking condition; separating reactor effluent of the suspension bed hydrogen cracking step; mixing the unconverted tail oil of the suspension bed hydrogen cracking step with a hydrogen-donor solvent and carrying out supercritical treatment, wherein the hydrogen-donor solvent comprises tetrahydronaphthalene or decahydronaphthalene, and the supercritical treatment conditions are as follows: the pressure is 15-40MPa, the temperature is 300-500 DEG C, and the treating time is 0.2-5 hours; and carrying out fractionation treatment after solid impurities are separated fromthe treated product. The combined process for heavy oil modification of the invention organically combines the suspension bed hydrogen cracking and the supercritical treatment, gives full play to theadvantages of the two technologies, achieves the synergic coordination effect, reduces coking tendency, simultaneously enhances the reaction effect, improves the impurity removal capacity, improves the operational stability of the suspension bed hydrogen cracking, and can treat more inferior raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

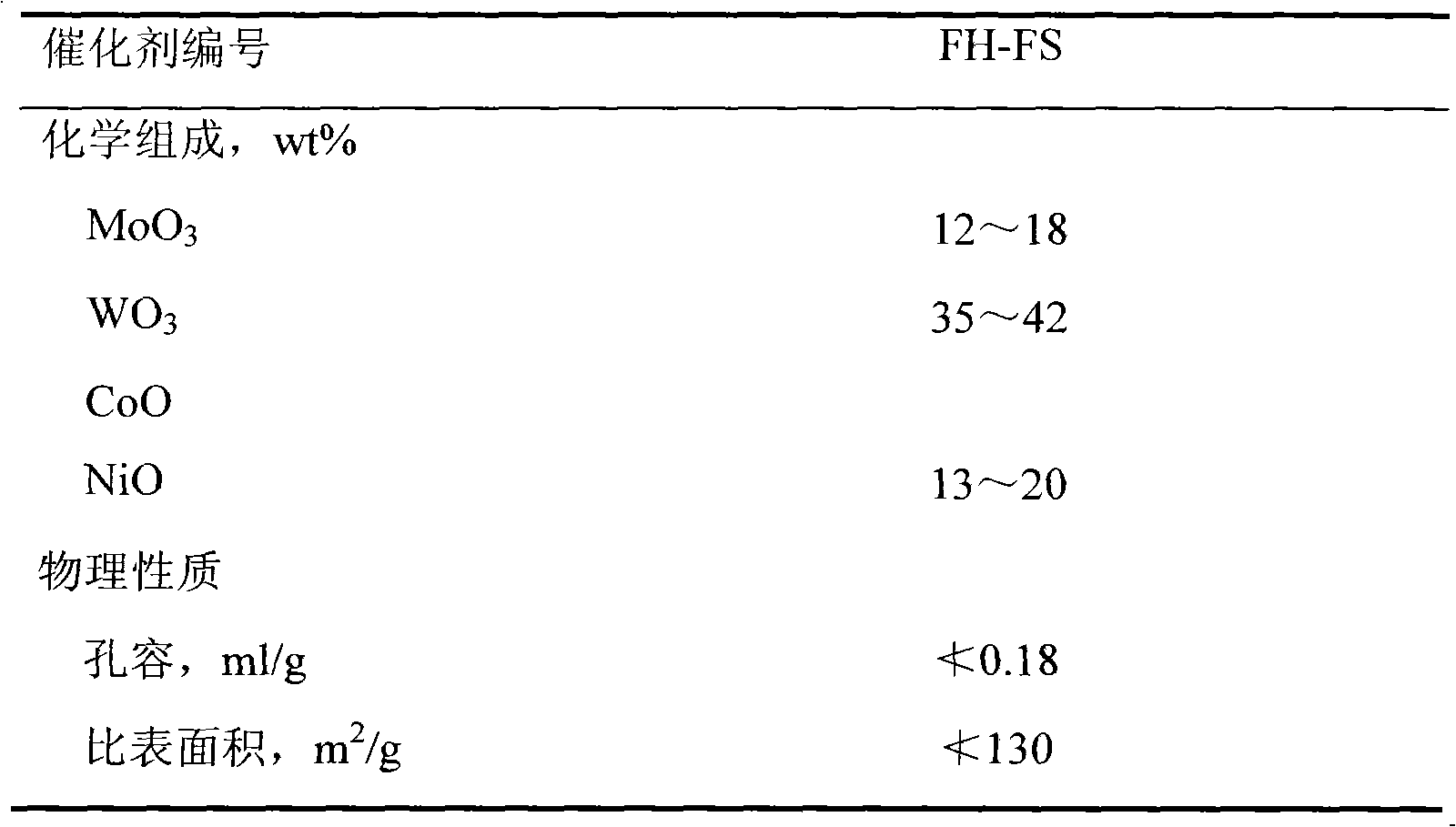

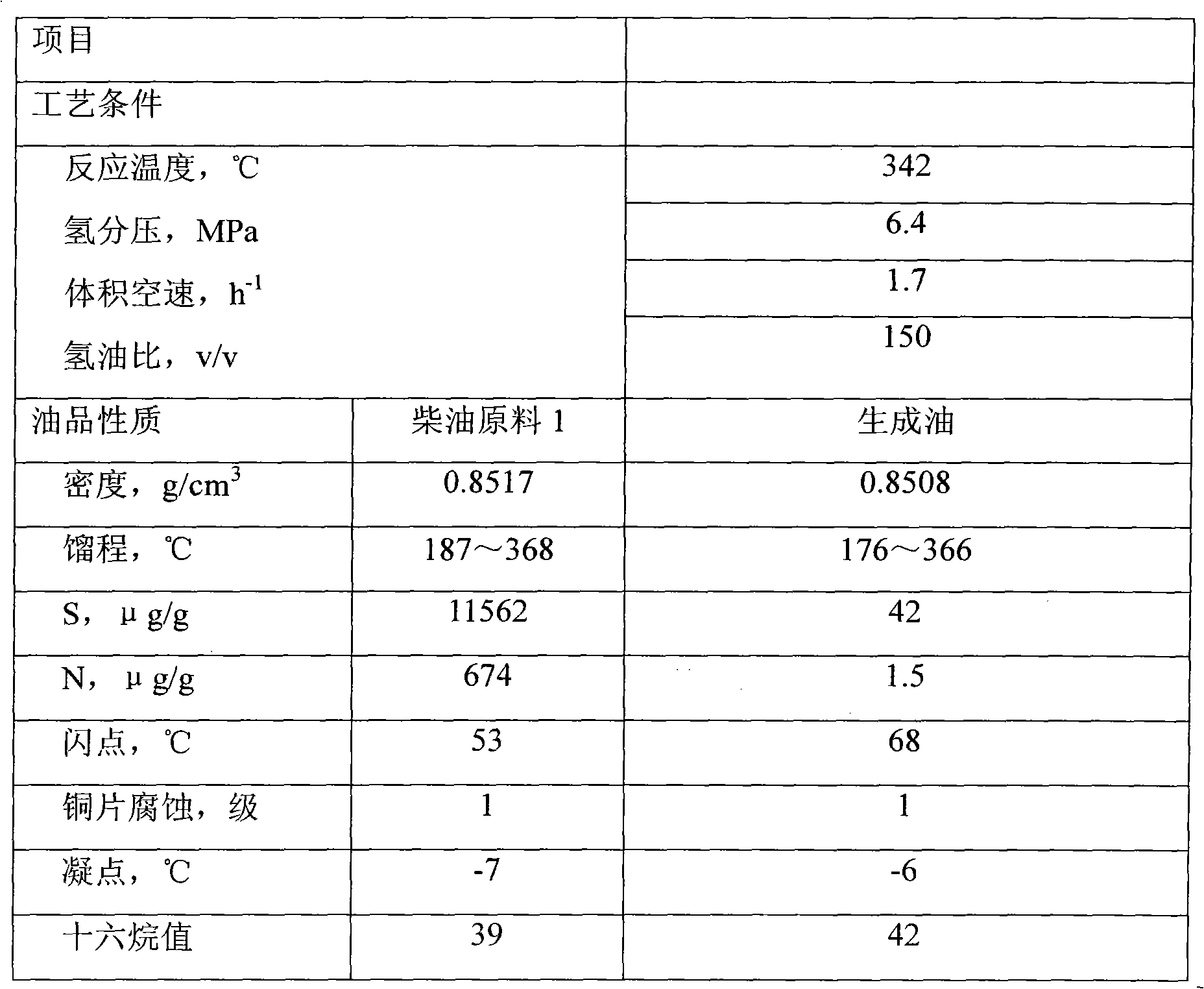

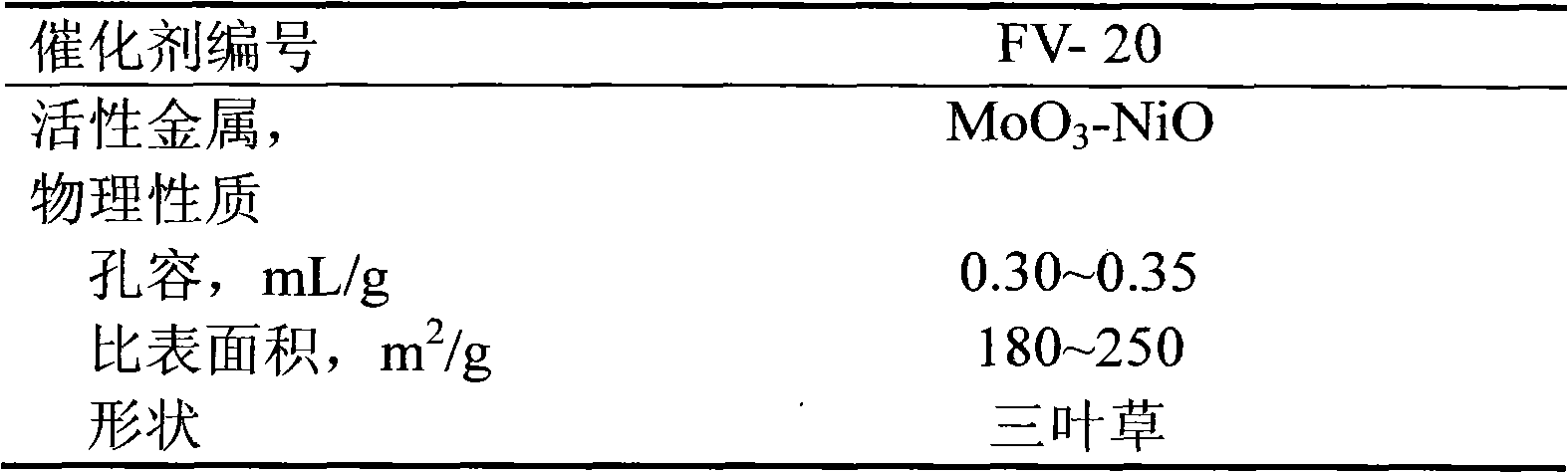

Method for hydrotreating poor diesel

InactiveCN101942319AIncrease the amount of dissolutionShorten the timeHydrocarbon oils refiningHydrogenPetrochemical

The invention relates to a method for hydrotreating poor diesel. The method comprises the following steps: thoroughly mixing raw oil with hydrogen in an oil-gas mixer through a heating furnace, and carrying out conventional hydrofining reaction by contacting with hydrogenation catalyst at low hydrogen / oil volume ratio under moderate technological conditions. Compared with the conventional hydrofining technique, the invention can acquire better refining effect under the same technological conditions. The method is used for poor diesel fractions in petrochemical corporations, such as coking diesel, catalytic diesel, visbreaking diesel or mixture thereof with straight-run diesel. The method can be used for producing ultralow-sulfur clean diesel of which the sulfur content is lower than 50 mu g / g, has the advantages of simple technical process, stable operation and favorable product quality, and can use newly built hydrogenation units or reform old units.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Waste white clay recovery and utilization method

ActiveCN109908881ARelaxed process conditionsReduce manufacturing costCombustible gas purificationFilter regenerationSolid phasesChemistry

The invention discloses a waste white clay recovery and utilization method, which comprises: carrying out mixing treatment on waste white clay and water, and separating the obtained material through standing to obtain three layers of a solid phase, a water phase and an oil phase; carrying out mixing treatment on the obtained solid phase and a treating agent, standing, removing the uppermost layermaterial, and further carrying out solid-liquid separation to obtain filtrate and waste white clay; and washing the waste white clay, and drying to obtain regenerated white clay. According to the present invention, with the method, oil, colloid and asphaltene can be separated from the waste white clay while the structure of the white clay is not damaged so as to conveniently achieve the subsequentregeneration and reuse of the white clay, other pollutions are not generated during the treatment, and the activity of regenerated white clay is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenated modification method for petroleum wax substance

InactiveCN101942341AImprove solubilityQuick responsePetroleum wax refiningParaffin waxHydrogenation reaction

The invention relates to a hydrogenated modification method for a petroleum wax substance, which comprises the following steps of: fully mixing the petroleum wax substance serving as a raw material and hydrogen in a gas-liquid mixer through a heating furnace, then making the mixture contact a hydrogenation catalyst in a low hydrogen-wax volume ratio under mild process condition, and performing the conventional hydrogenation reaction. Compared with the conventional hydrogenation process, the method can achieve the same effect as the conventional refining under the mild process condition. The method can produce high-quality paraffin products of various brands, and has the advantages of simple process flow, stable operation, good product property and capabilities of reducing the energy consumption of a device, improving the product yield and newly building a hydrogenation device or reforming an old device.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Heavy oil hydrogenation modifying method

ActiveCN102041047BReduce and ease harshnessEasy to operateHydrocarbon oil crackingFuel oilHydrogen supply

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

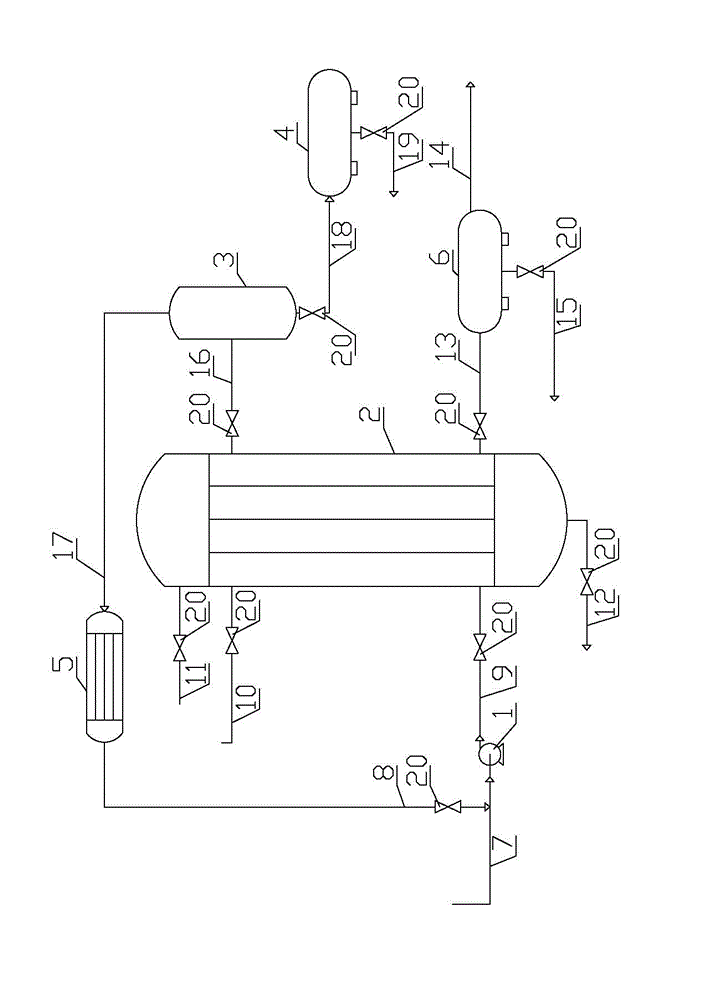

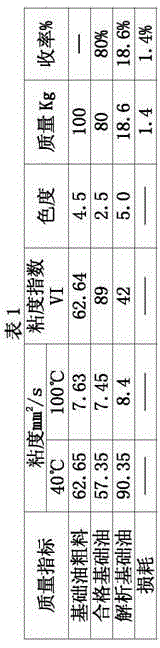

Adsorption separation device and method for improving base oil viscosity index

InactiveCN102827634BThe purpose of increasing viscosity and separatingHigh viscosityTreatment with plural serial refining stagesSorbentBuffer tank

The invention relates to the technical field of mixture refining with hydrocarbon as a main and relates to an adsorption separation device and an adsorption separation device method for improving a base oil viscosity index. An adsorption separation device comprises a pump, an adsorption tower, a fractionation tank, a buffer tank, a condenser and a recovery tank, the adsorption tower, the fractionation tank, the buffer tank, the condenser and the recovery tank are respectively and fixedly installed on a support, a first pipeline is fixedly connected with an inlet end of the pump, an outlet of the condenser is fixedly connected with the first pipeline through a second pipeline, and an outlet of the pump is fixedly connected with a lower shell side inlet of the adsorption tower through a third pipeline. According to the adsorption separation device and the adsorption separation method, the use is convenient, purposes of improving base oil viscosity and separating through matched use of the adsorption tower, the fractionation tank, the recovery tank and the condenser are achieved, and the adsorption device has the advantages of being simple in process operation, soft in technological condition, small in investment, recycled in adsorbing materials and free of pollution on environment, and improving the base oil viscosity index and oxidation stability.

Owner:XINJIANG MODERN PETROCHEM IND

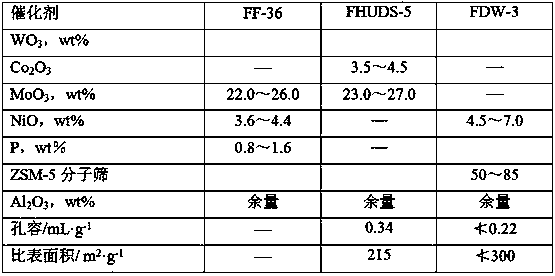

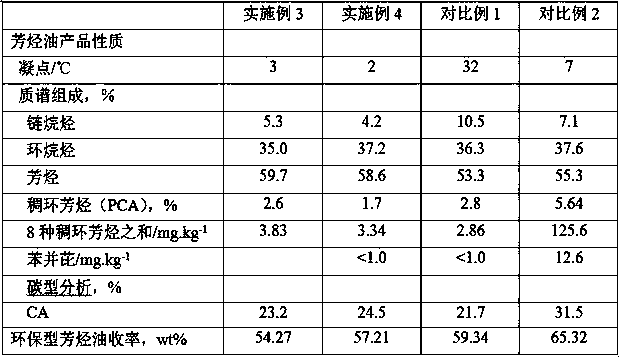

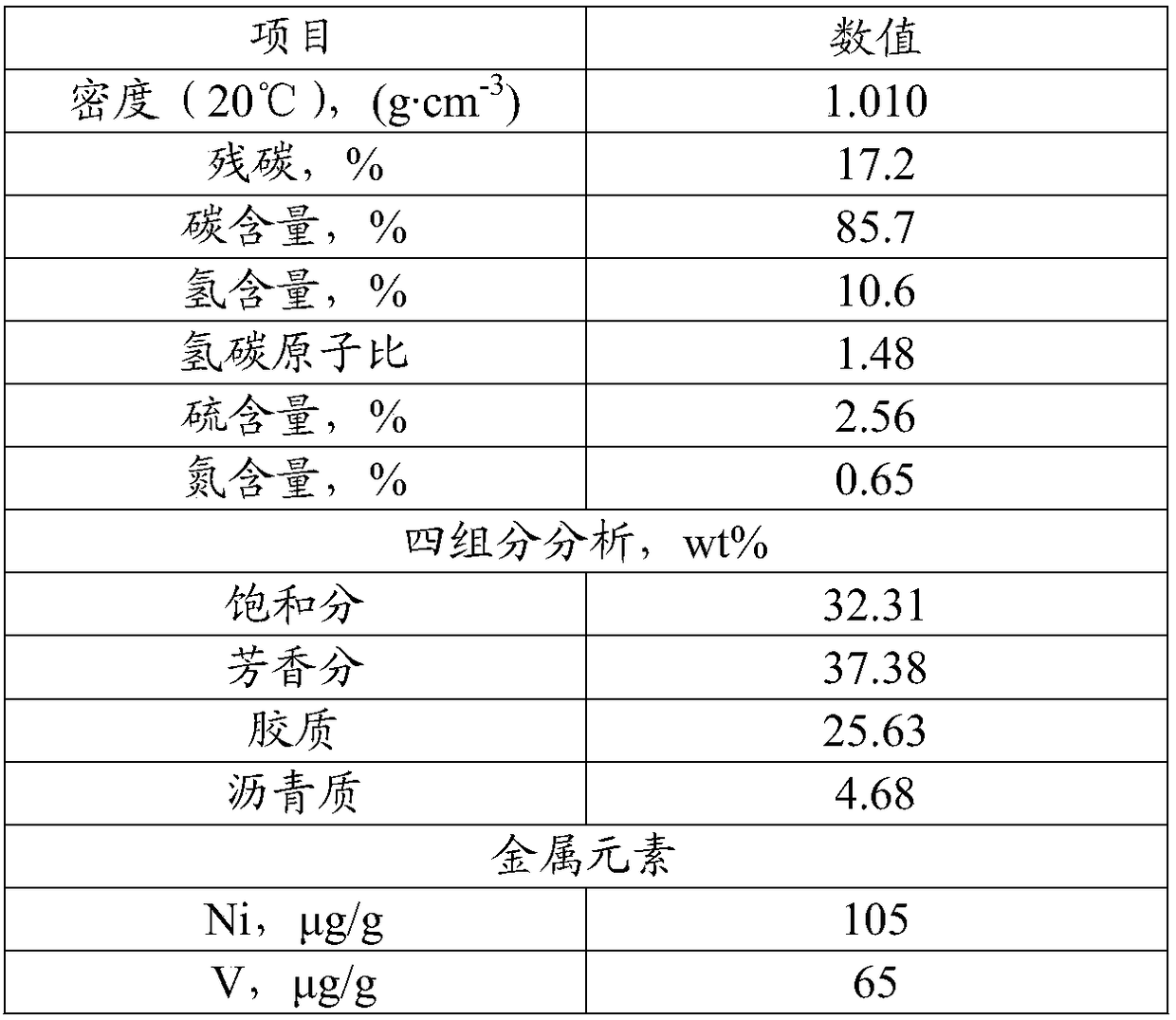

Production method of environment-friendly aromatic hydrocarbon oil for tires

ActiveCN111378498AAdaptableReduce lossesTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

The invention discloses a production method of environment-friendly aromatic hydrocarbon oil for tires. The environment-friendly tire aromatic hydrocarbon oil meeting the European Union standard can be produced by taking positive-sequence furfural extract oil with a relatively high condensation point as a raw material and adopting a hydrotreatment-hydrodewaxing-solvent extraction combined process.The method comprises the following steps: performing hydrotreatment on raw materials under mild conditions to saturate polycyclic aromatic hydrocarbon, performing hydrodewaxing to reduce the condensation point to 0-10 DEG C, and finally performing shallow extraction to obtain the environment-friendly aromatic hydrocarbon oil for tires. The method expands sources of raw materials for producing theenvironment-friendly aromatic hydrocarbon oil, and has the characteristics of strong raw material adaptability and mild process conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing oil content of spent bleaching clay

ActiveCN111375391AAchieve the purpose of recyclingNo structural damageOther chemical processesCombustible gas purificationPulp and paper industryAsphaltene

The invention discloses a method for reducing the oil content of spent bleaching clay. The method comprises the following steps: mixing spent bleaching clay, a pretreatment agent and water, and performing standing treatment on the mixture to separate the material into a solid phase, a water phase and an oil phase; mixing the obtained solid phase with the treatment agent, performing standing treatment, removing the material at the upper layer, further carrying out solid-liquid separation to obtain a filtrate and spent bleaching clay, washing the spent bleaching clay, and drying the spent bleaching clay to obtain regenerated bleaching clay. According to the method for reducing the oil content of the spent bleaching clay, grease, colloid and asphaltene in the spent bleaching clay can be separated out and the structure of the spent bleaching clay is not damaged, so that subsequent regeneration and repeated utilization of the spent bleaching clay are facilitated, no other pollution is generated in the treatment process, and the activity of the regenerated bleaching clay is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

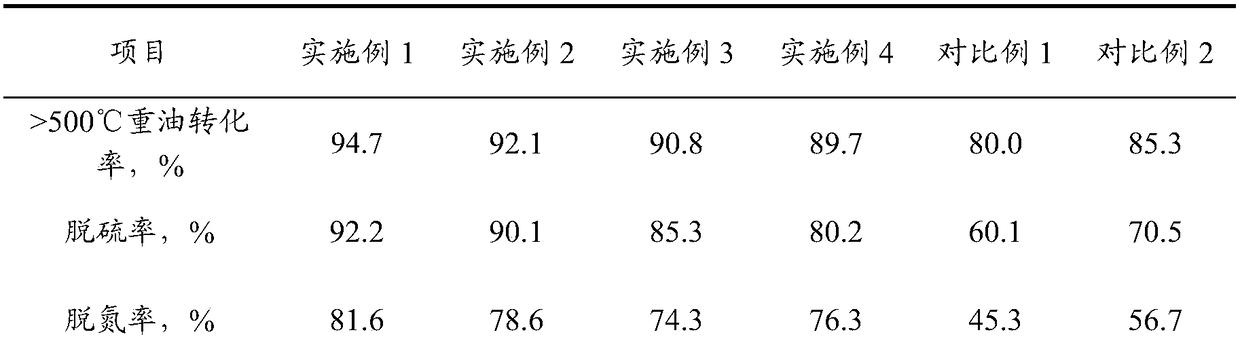

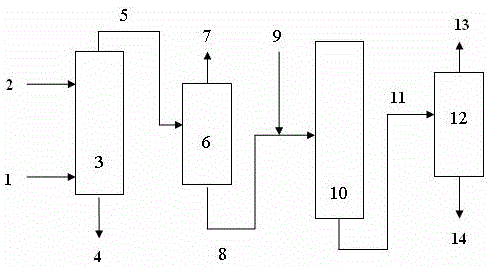

Heavy oil hydrocracking technology

ActiveCN108085057AImprove light conversion rateImprove qualityTreatment with hydrotreatment processesHydrogenHeteroatom

The invention belongs to the technical field of petrochemical industry, and relates to a hydrocracking technology. By a heavy oil hydrocracking technology provided by the invention, through addition of a hydrocracking catalyst and a hydrofinishing catalyst simultaneously in a hydrocracking reaction, in cooperation with supplementation of fresh hydrogen, the partial pressures of H2S and NH3 in a secondary hydrocracking reaction are reduced, and a hydrodesulfurization reaction and a hydrodenitrification reaction can be promoted to be reversely performed. The lightweight conversion rate of heavyoil is improved, and the desulfurization rate and the denitrification rate are greatly increased, so that an oil product with relatively high quality is directly and efficiently obtained. In allusionto the characteristics of components contained in the heavy oil, the time of inflating the secondary hydrogen and heating is further controlled, so that the reaction time is saved on the basis that amore easily cracked heavy oil component is hydrocracked as much as possible; through timely heating and supplementation of fresh hydrogen, hydrocracking and refinement of a heavy oil component which is more difficultly cracked for removing heteroatoms is promoted.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of production method of environment-friendly aromatic hydrocarbon oil

ActiveCN103773493BAdaptableSolution to short lifeTreatment with hydrotreatment processesColloidFurfural

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing solid impurities of catalytic slurry oil through low-temperature coalescence

ActiveCN112480959AEasy to removeNo risk of contaminationTreatment with plural serial refining stagesPtru catalystSlag

The invention discloses a method for removing solid impurities of catalytic slurry oil by low-temperature coalescence, which comprises the steps of heating, dehydrating, adding a liquid assistant, mixing, heating a solid assistant, mixing, and carrying out solid-liquid separation, thereby obtaining the purified catalytic slurry oil with low ash content in which solid impurities are removed. According to the invention, through the combined action of the liquid auxiliary agent and the solid auxiliary agent, tiny catalyst solid particles are aggregated into large particles, so that impurities areeasy to remove; the solid impurities in the catalytic slurry oil are separated out in a solid form, the process technology is novel, the operation is easy, and continuous separation can be achieved;the separated solid slag is in a loose solid state in appearance, is convenient to mix and burn with fire coal, and is environment-friendly; no concentrated solution or other liquid hazardous waste isgenerated, and no environmental pollution risk is caused; and the method has the advantages of mild process conditions, simple equipment, easy operation, continuous production, thorough solid-liquidseparation and high finished product yield, and the yield of the purified catalytic slurry oil obtained after separation reaches 99% or above.

Owner:MAOMING YINGPENG ELECTROMECHANICAL EQUIP

Preparation method of micro member for MEMS

InactiveCN1663906AImprove manufacturing yieldEasy to peelDecorative surface effectsChemical vapor deposition coatingProcess conditionsMaterials science

The invention discloses the micro-component preparation method for micro-electronic mechanic system use. The method is: clean the substrate of the component, then put it in the chemical casting liquor to cast nickel, at last remove the negative photo resist on the casting catalyzing base to get the micro-component. The invention has wide adaptation range. The substrate is only required smooth. The invention uses chemical casting replacing the electric casting, so as to the technique is simple and the cost is low. The invention has little requirements for the technique conditions and the finished products ratio is high.

Owner:SOUTHEAST UNIV

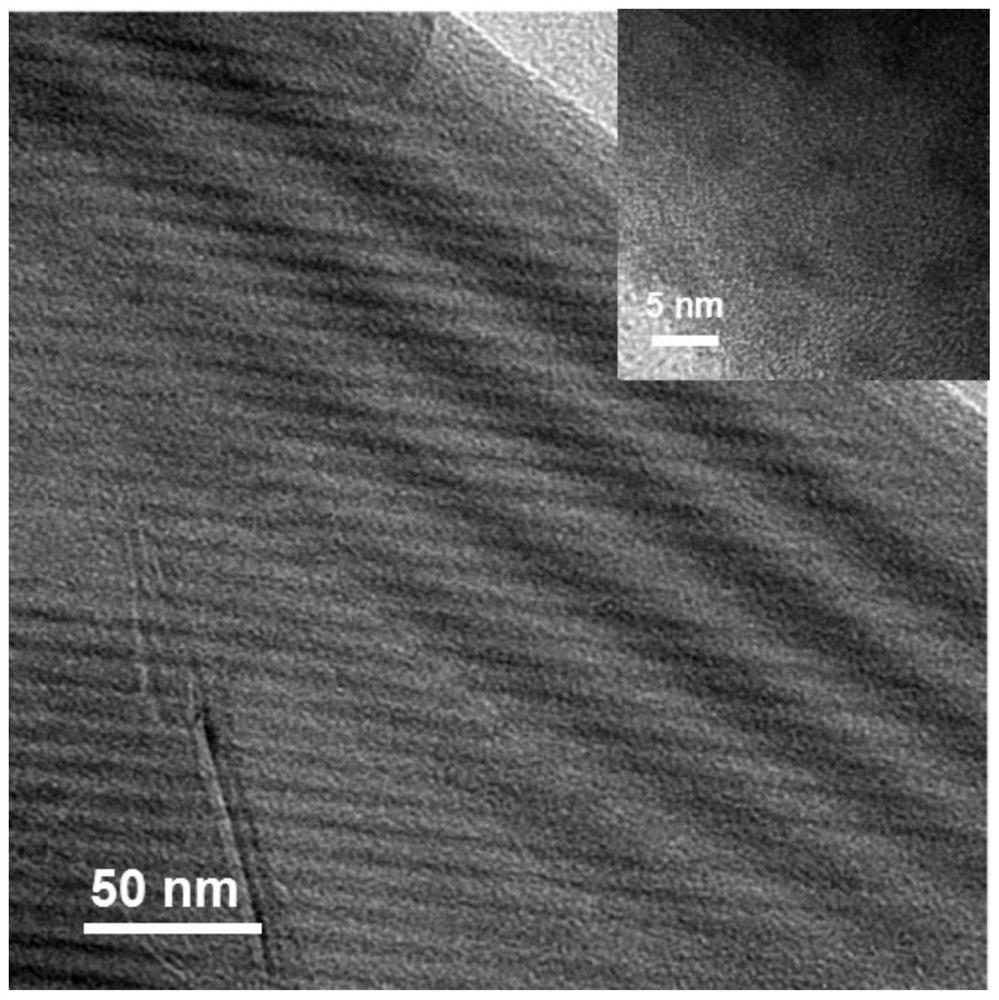

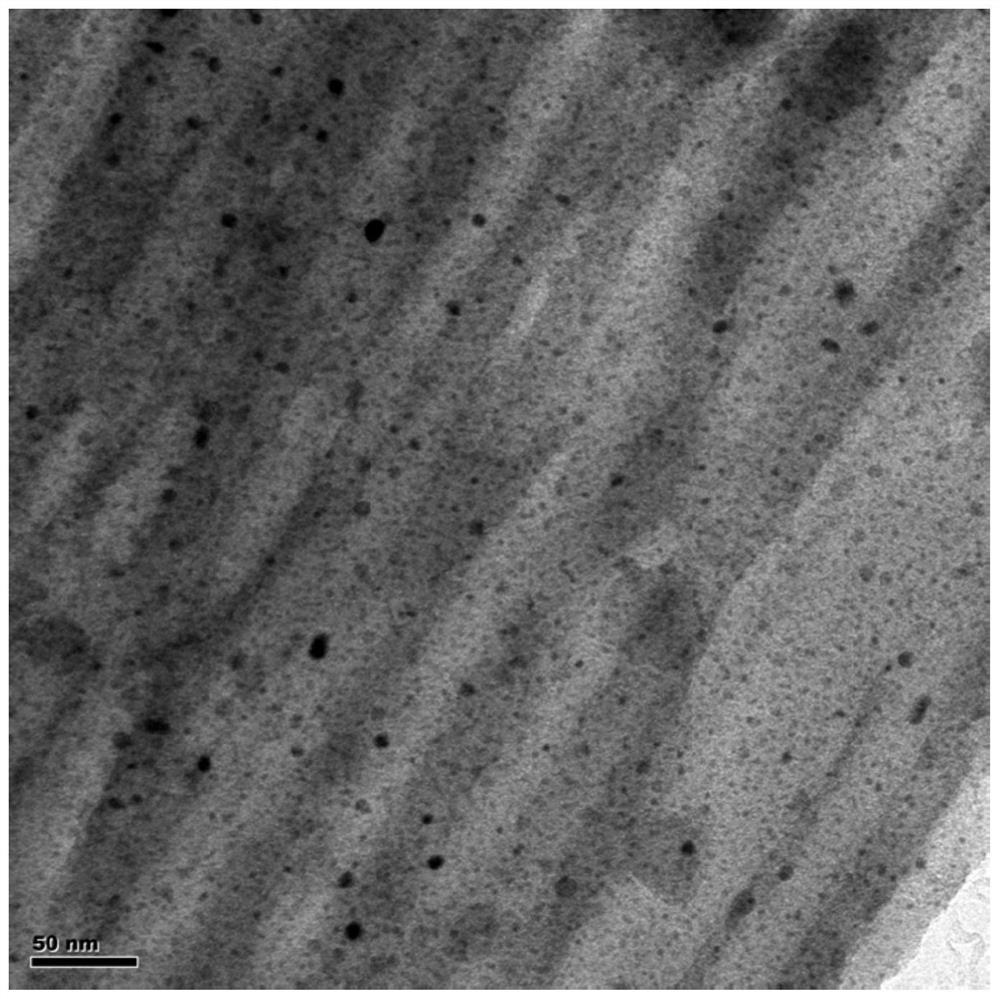

Nickel-based pure silicon type molecular sieve catalyst as well as preparation method and application thereof

InactiveCN113351239ALarge specific surface areaEvenly dispersedHydrocarbon from carbon oxidesMolecular sieve catalystsPtru catalystSilicic acid

The invention discloses a nickel-based pure silicon type molecular sieve catalyst. The specific surface area of the molecular sieve catalyst is 200-500m < 2 > / g, the size of the molecular sieve catalyst is 2-5nm, and the metal loading capacity of the molecular sieve catalyst is 5-10wt%. The preparation method of the nickel-based pure silicon type molecular sieve catalyst comprises the following steps of: mixing tetraethoxysilane, ethanol, diluted hydrochloric acid and a template agent; carrying out reflux condensation; making an obtained mixture stand still; adding a polymer spinning auxiliary solution and a metal salt solution, performing uniform stirring to obtain a spinning precursor solution; and carrying out electrostatic spinning, drying and roasting to finally obtain the pure silicon type molecular sieve catalyst. According to the nickel-based pure silicon type molecular sieve catalyst prepared by the electrostatic spinning method, the specific surface area of the catalyst is large; the active metal is uniformly dispersed on the carrier, the utilization rate of the active metal is high, the dispersity of the metal is high, the particle size is small, and the active metal is not easy to sinter in a strong exothermic reaction of synthesis gas methanation.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com