Combined hydrogenation method

A hydrocracking and hydrotreating technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of high chemical hydrogen consumption, cetane number cannot meet higher quality requirements, etc., and achieve improvement The effect of color and acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

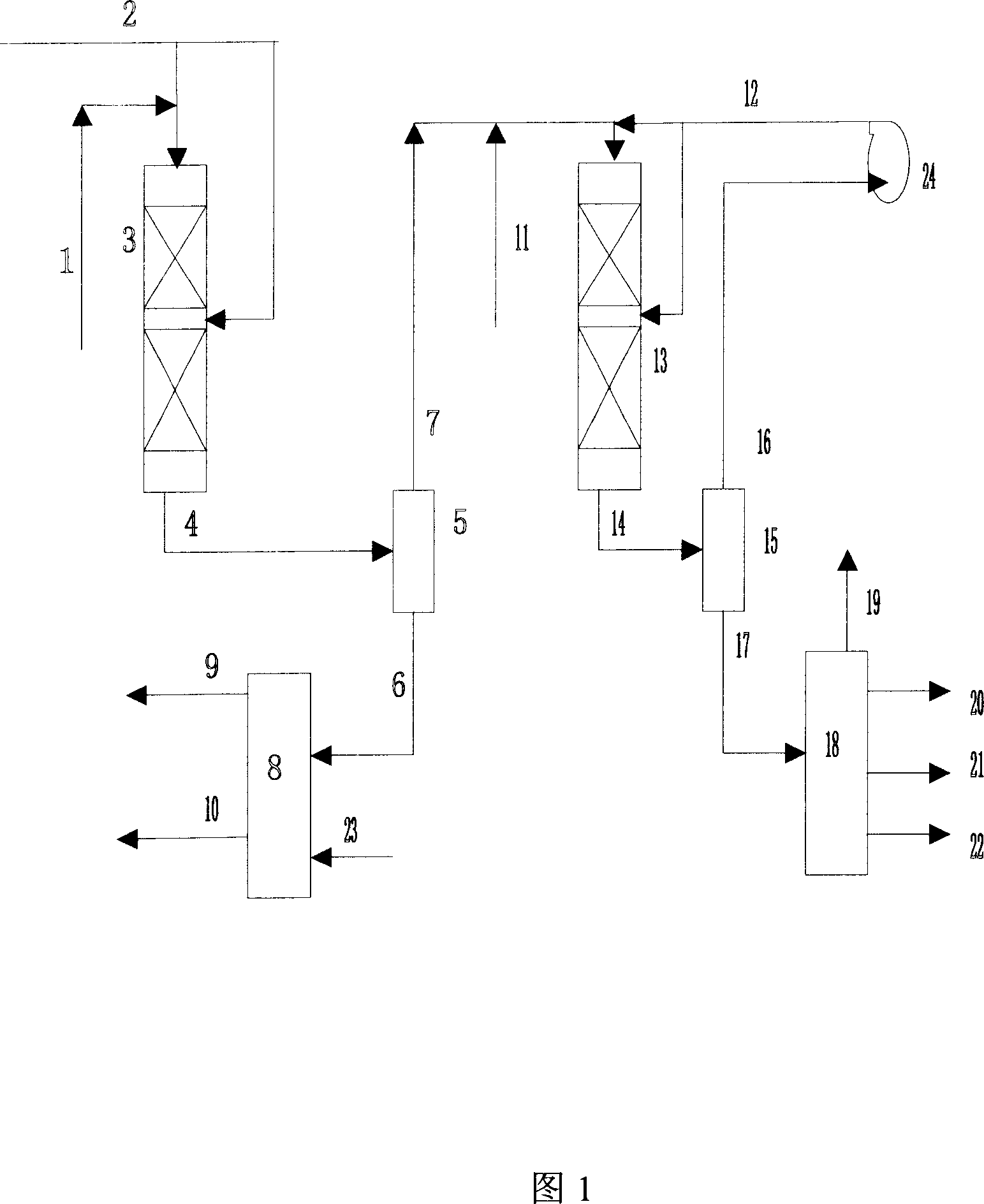

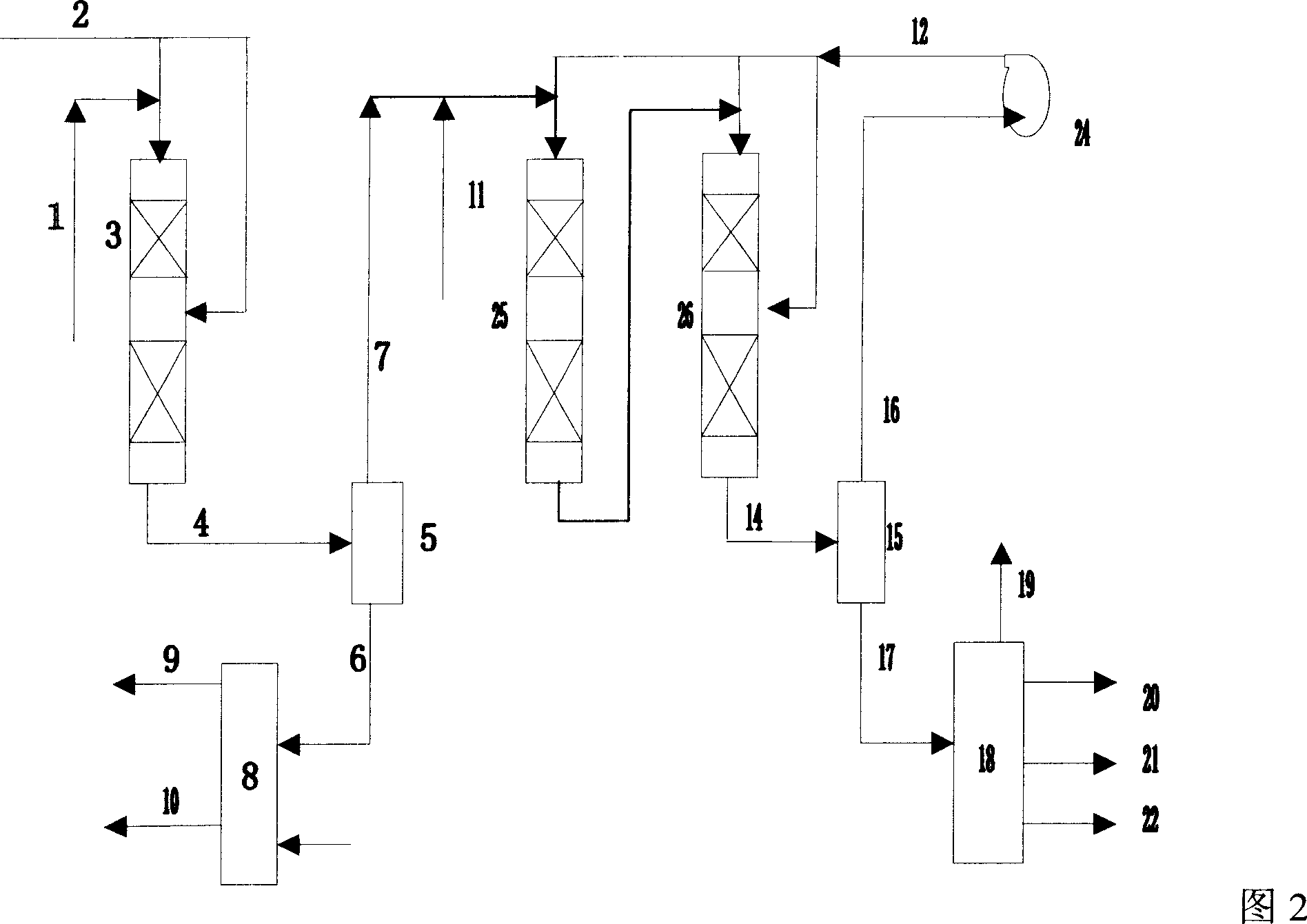

Image

Examples

Embodiment 1~6

[0034] The properties of jet fuel and diesel fractions distilled from two different AGOs (AG01 and AG02) are listed in Table 1. Experiments were carried out with different aviation kerosene and diesel oil as raw materials. The process conditions and product properties are listed in Table 2 and Table 3 respectively.

[0035] Table 1 Properties of raw oil

[0036] Raw oil

Jet fuel 1

Diesel 1

Jet fuel 2

Diesel 2

Density / g·cm -3

Distillation range / ℃

Smoke point / mm

Sulfur content, wt%

Nitrogen content, wt%

cetane index

Naphthene content, wt%

Aromatic content, wt%

0.8382

150~245

16

426

12

-

59.0

19.6

0.8810

245~380

-

1600

360

38.5

41.9

30.5

0.8260

150~220

17

358

10

-

62.6

22.7

0.8865

225~400

-

2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com