Production method of environment-friendly aromatic hydrocarbon oil for tires

A production method and aromatic oil technology, which is applied in the field of hydrogenation-solvent extraction combined process to produce environmentally friendly aromatic oil, which can solve the problems of no pour point depressing means and inability to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation process of the hydrogenation modification catalyst of the present invention comprises: after uniformly mixing the amorphous silica-alumina and the modified Y zeolite, adding a binder, kneading, rolling into agglomerates, extruding on an extruder to obtain a carrier, Reload the hydrogenation active metal.

[0036] The amorphous silicon-alumina used can be prepared by existing methods, such as a specific preparation method comprising the following steps:

[0037] a. Prepare sodium aluminate solution and sodium silicate solution;

[0038] b. Add the sodium aluminate solution and the sodium silicate solution into the gel forming tank concurrently, and ventilate and feed CO at the same time 2 gas, adjust sodium aluminate solution, sodium silicate solution and CO 2 Flow rate, control the pH value of the material in the gel tank to 9-11, control the neutralization reaction temperature to 20-50°C, and the neutralization reaction time to 0.5-1.5 hours;

[0039...

Embodiment 1

[0057] Prepare 700 solid sodium aluminate to a concentration of 200gAl 2 o 3 / L concentrated sodium aluminate solution, then diluted to a concentration of 35gAl 2 o 3 / L sodium aluminate working solution (a), take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 150gSiO 2 / L sodium silicate working solution 2L (b). Take a 30L steel plastic tank, open the container valves containing (a) and (b) respectively, and ventilate and feed CO with a concentration of 45v% at the same time 2 Gas, set the flow rate of (a) and (b) so that the reaction time is 1 hour, and quickly adjust the CO 2 flow rate, keep the pH of the system at about 10.0, and the reaction temperature is 30°C. After the reaction of (a) and (b) is completed, stop feeding CO 2 , and then the ventilation was stable for 40 minutes, and the slurry was filtered and washed with 85°C deionized water until neutral. Dry at 120°C for 8 hours, crush and sieve to obtain amorphous silica-alumina GL. ...

Embodiment 2

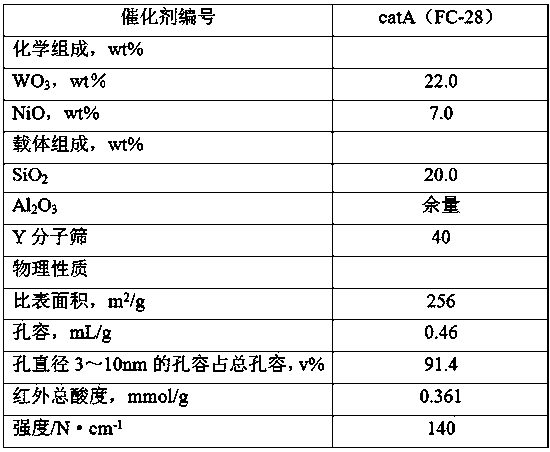

[0059] Get 100g silicon aluminum GL, 45g modified Y zeolite (SiO 2 / Al 2 o 3 40, unit cell constant 2.432nm, infrared acidity 0.19mmol / g, specific surface 866m 2 / g, pore volume 0.52mL / g) and 310g adhesive made by peptizing nitric acid and SB alumina, kneading, rolling, making extrudable paste, extruding into strips. Carrier A was obtained by drying at 110°C for 6 hours and calcining at 550°C for 4 hours. Then, 80 g of carrier A was impregnated with 200 mL of W-Ni co-impregnation solution in excess for 2 hours, dried at 110° C. for 6 hours, and calcined at 500° C. for 4 hours to obtain the hydrogenation modification catalyst catA. The physical properties of the hydrogenation upgrading catalyst are shown in Table 2.

[0060] Table 2 Hydro-upgrading catalysts.

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com