Heavy oil hydrocracking technology

A heavy oil hydrogenation and process technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of low desulfurization rate and denitrification rate, improve the desulfurization rate and denitrification rate, and is conducive to desulfurization The effect of denitrification and temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

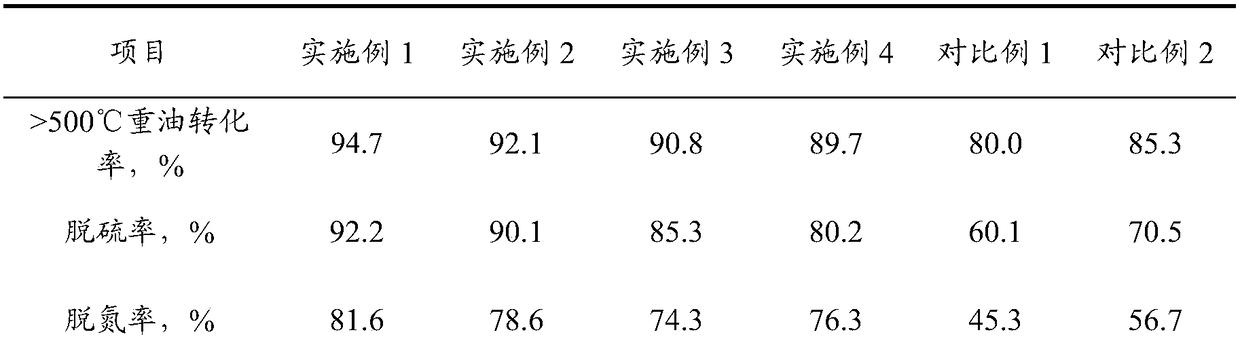

Embodiment 1

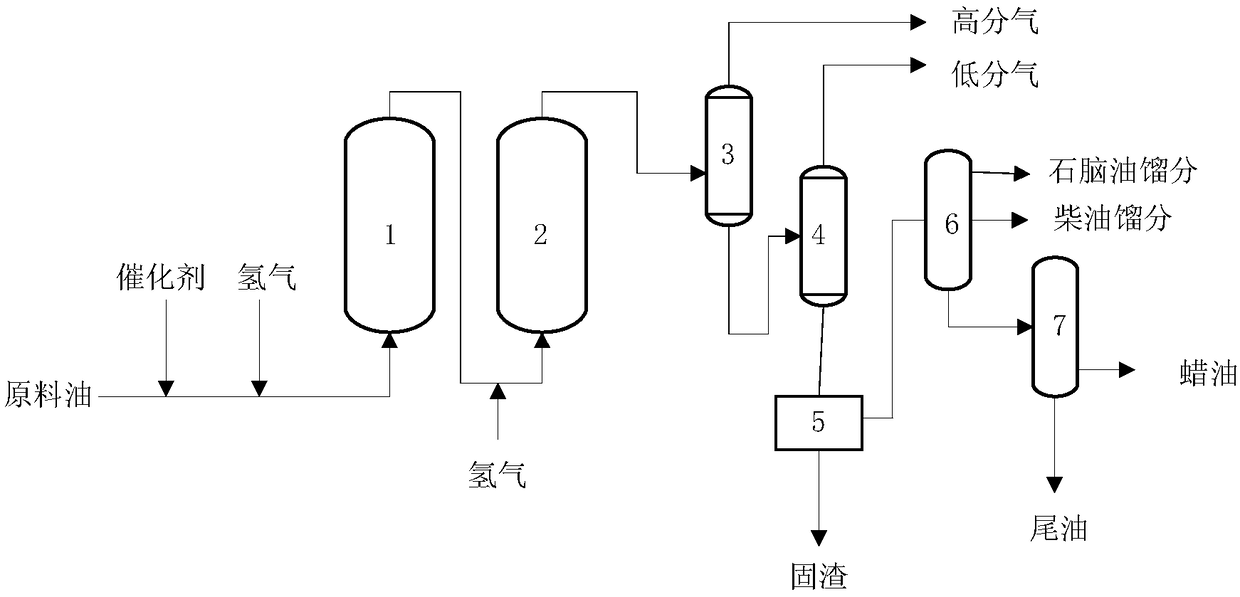

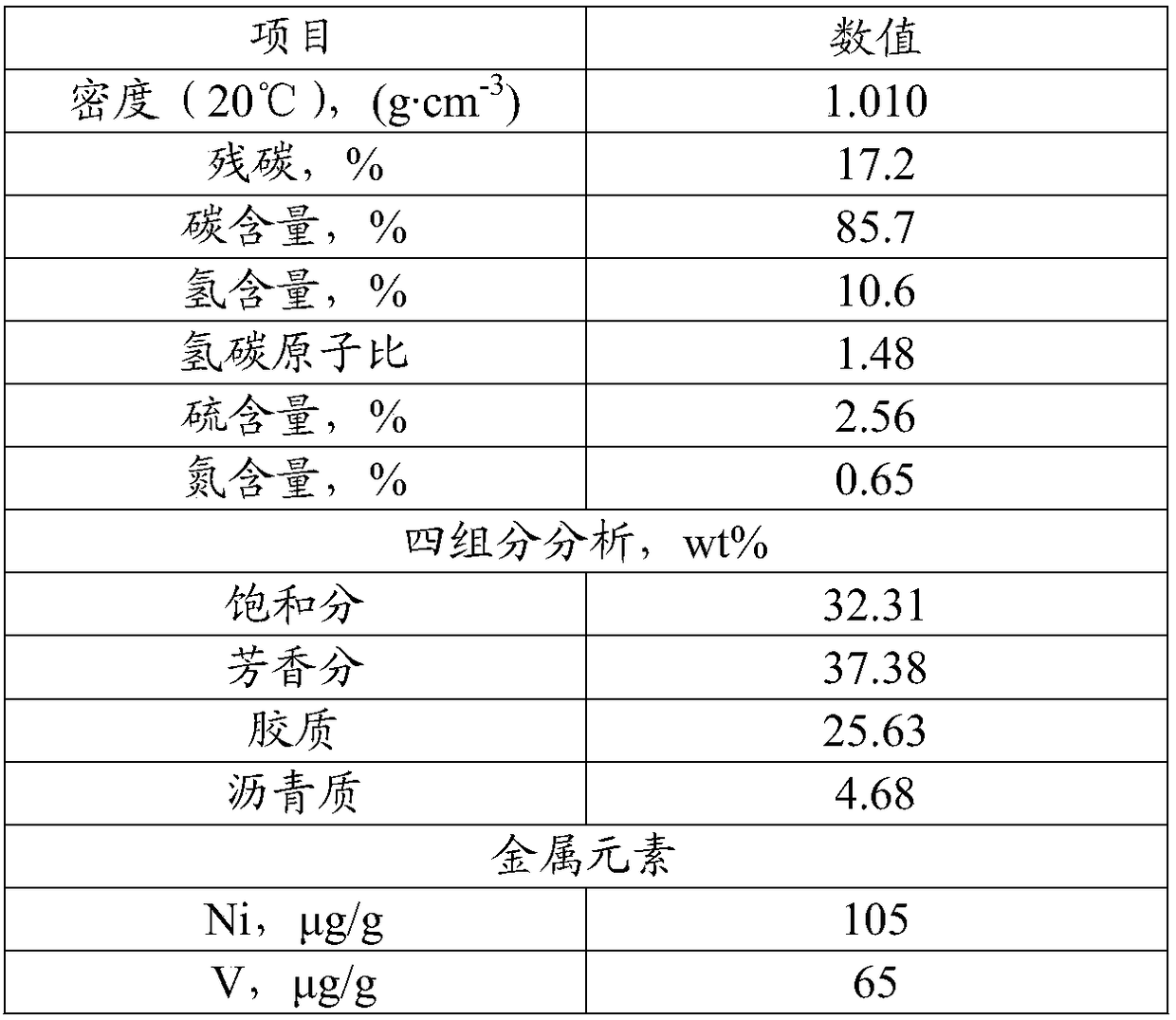

[0044] The hydrogenation reaction of the heavy oil hydrocracking process provided in this example is realized through two series-connected suspension beds, and a typical low-quality vacuum residue is selected as the heavy oil raw material. The residual carbon content, sulfur content, and nitrogen content of the vacuum residue are , colloid, asphaltenes and metals are all high, and the properties of this raw material are shown in Table 1.

[0045] Table 1 Evaluation of inferior vacuum residue used

[0046]

[0047] For the device used in this embodiment, see figure 1 , the specific process steps are as follows:

[0048] Using nickel phosphomolybdate aqueous solution as a hydrocracking catalyst, Co-Mo / Al 2 o 3 As a hydrorefining catalyst, it is mixed with heavy oil raw materials, and the amount of the catalyst used is controlled to be 1000 μg / g and 300 μg / g in terms of metal, and then the mixture is mixed with hydrogen to control the hydrogen-to-oil ratio to 1500. Put the...

Embodiment 2

[0053] The heavy oil hydrocracking process provided in this example uses the same inferior vacuum residue as in Example 1 as the heavy oil raw material.

[0054] The specific steps of the heavy oil hydrocracking process provided in this example are as follows:

[0055] Using nickel phosphomolybdate aqueous solution as a hydrocracking catalyst, Co-Mo / Al 2 o 3 As a hydrorefining catalyst, it is mixed with heavy oil raw materials, and the amount of the catalyst used is controlled to be 10 μg / g in terms of metal, and then the mixture is mixed with hydrogen to control the hydrogen-to-oil ratio to 1000. Put the raw material mixture mixed with hydrogen into the bottom of the primary suspension bed 1, control the reaction temperature to 460°C, the reaction pressure to 16MPa, and the space velocity to 1h -1 , to carry out the primary hydrocracking reaction.

[0056] The primary hydrocracking product output from the top of the primary suspension bed 1 is mixed with fresh hydrogen, an...

Embodiment 3

[0060] The heavy oil hydrocracking process provided in this example uses the same inferior vacuum residue as in Example 1 as the heavy oil raw material.

[0061] The specific steps of the heavy oil hydrocracking process provided in this example are as follows:

[0062] Nickel phosphomolybdate aqueous solution as hydrocracking catalyst Co-Mo / Al 2 o 3 As a hydrorefining catalyst, it is mixed with heavy oil raw materials, and the amount of the catalyst used is controlled to be 10 μg / g in terms of metal, and then the mixture is mixed with hydrogen to control the hydrogen-to-oil ratio to 1000. Put the raw material mixture mixed with hydrogen into the bottom of the primary suspension bed 1, control the reaction temperature to 460°C, the reaction pressure to 16MPa, and the space velocity to 1.3h -1 , to carry out the primary hydrocracking reaction.

[0063] The primary hydrocracking product output from the top of the primary suspension bed 1 is mixed with fresh hydrogen, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com