A kind of qled display device, preparation method and application

A display device, display technology, applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of reducing the current density of the hole transport layer, uneven QLED light emission, poor flatness of the hole transport layer, etc. Effect of electron transport capability, enhancement of QLED display brightness, and hole transport capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

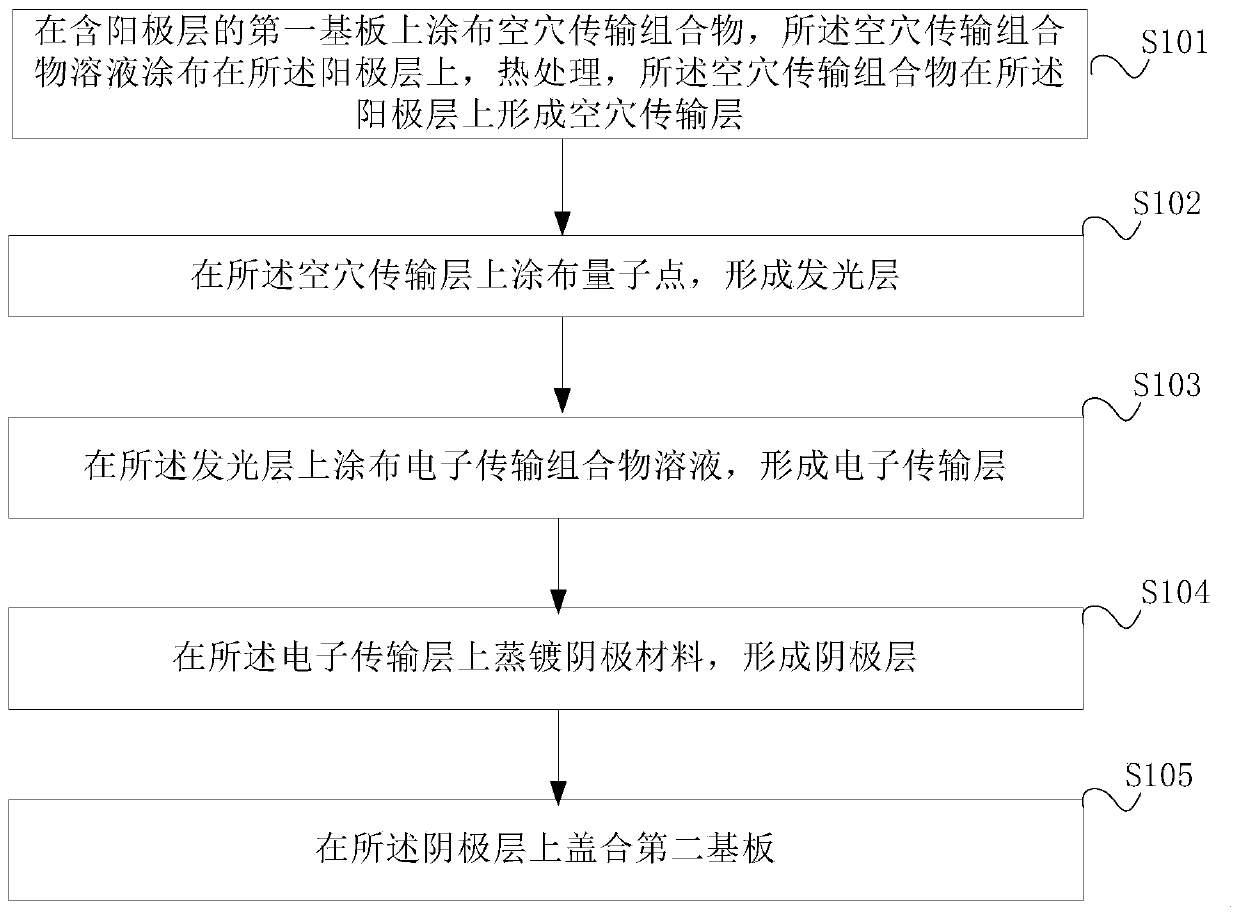

[0039] Please refer to the attached figure 2 , shows the flow chart of the method for preparing the QLED display device provided in the embodiment of the present application. attached by figure 2 As shown, the method includes the following steps:

[0040] S101: Coating a hole transport composition on the first substrate containing an anode layer, the solution of the hole transport composition is coated on the anode layer, heat treatment, the hole transport composition is on the anode layer A hole transport layer is formed on it.

[0041] In this embodiment, the first substrate contains an anode layer, and the existing first substrate that has been coated with an anode layer can be selected, and the anode material can be coated or vacuum-plated on the first substrate after the first substrate is selected. on the substrate. The first substrate may be a rigid substrate or a flexible substrate. Specifically, the rigid substrate may be a glass substrate, and the flexible subs...

Embodiment 2

[0062] A method for preparing a QLED display device. On a glass substrate containing 110nm thick ITO, spin-coat an ethanol solution of a hole-transporting composition, and form a hole-transporting layer after heat treatment. The thickness of the hole-transporting layer is 50nm. Delivery compositions include WO 3 and NiO, WO 3 The average particle size of NiO is 2nm, the average particle size of NiO is 7nm, NiO and WO 3 The ratio of parts by weight is 0.8:1, the heat treatment temperature is 400°C, and the treatment time is 30 minutes; the quantum dot orthogonal liquid is spin-coated on the hole transport layer to form a 40nm light-emitting layer, and the quantum dots are CdS / ZnS; on the light-emitting layer Spin-coat the ethanol solution of electron transport composition, form electron transport layer after heat treatment, the thickness of electron transport layer is 50nm, electron transport composition comprises ZnO and TiO 2 , the average particle size of ZnO is 3nm, TiO ...

Embodiment 3

[0065] A kind of preparation method of QLED display device, on the glass substrate that contains 50nm thick ITO, the ethanol solution of hole transport composition is spin-coated, forms hole transport layer after heat treatment, and the thickness of hole transport layer is 60nm, hole Delivery compositions include WO 3 and NiO, WO 3 The average particle size of NiO is 2nm, the average particle size of NiO is 10nm, NiO and WO 3 The ratio of parts by weight is 0.9:1, the heat treatment temperature is 450°C, and the treatment time is 40 minutes; spin-coat quantum dot orthogonal liquid on the hole transport layer to form a 50nm light-emitting layer, and the quantum dots are CdS / ZnS; on the light-emitting layer Spin-coat the ethanol solution of electron transport composition, form electron transport layer after heat treatment, the thickness of electron transport layer is 40nm, electron transport composition comprises ZnO and TiO 2 , the average particle size of ZnO is 2nm, TiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com