Solar cell with high conversion rate

A technology with high conversion rate of solar cells, applied in the field of solar energy, can solve the problems of low lighting efficiency and lower lighting rate of solar cells, and achieve the effects of ensuring permeability, reducing costs, and improving photoelectric conversion efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

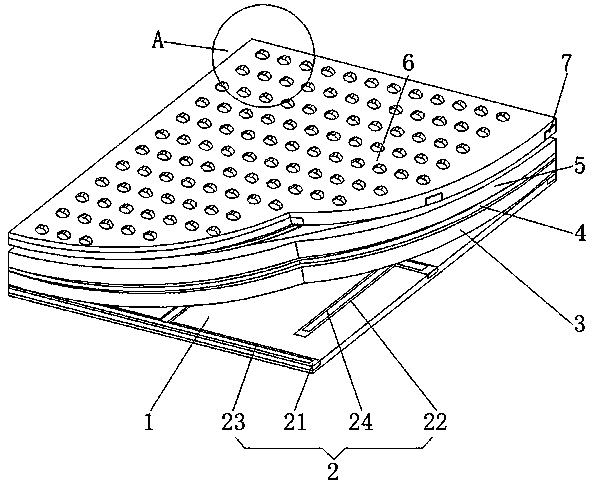

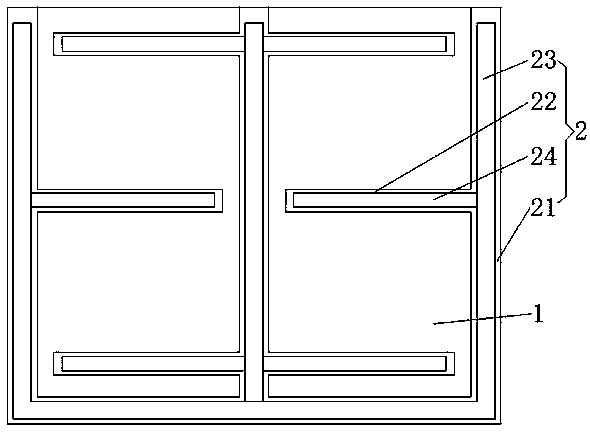

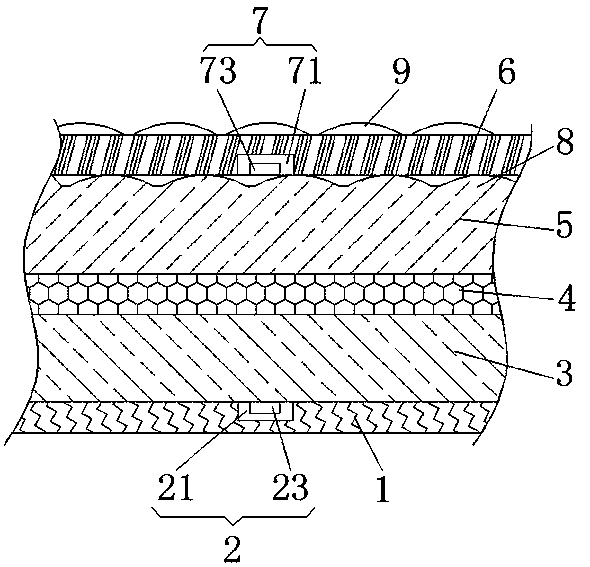

[0037] The following is attached Figure 1-6 The present invention is described in further detail.

[0038] A solar cell with a high conversion rate, such as Figure 1-4 As shown, a substrate 1 is included, a first conductive layer 2 is arranged on the substrate 1, and a P+ amorphous silicon layer 3 is arranged on one side of the substrate 1 located on the first conductive layer 2, and the P+ amorphous silicon The side of the layer 3 far away from the first conductive layer 2 is provided with an intrinsic amorphous silicon layer 4, and the side of the intrinsic amorphous silicon layer 4 far away from the P+ amorphous silicon layer 3 is provided with an N+ amorphous silicon layer. Layer 5, the side of the N+ amorphous silicon layer 5 far away from the intrinsic amorphous silicon layer 4 is provided with a protective layer 6, between the protective layer 6 and the opposite side of the N+ amorphous silicon layer 5 A second conductive layer 7 is provided.

[0039] The solar cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com