Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Improve hardness and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with great heat and abrasion resistance and manufacturing method thereof

ActiveCN103205650AExcellent mechanical properties and wear resistanceImprove hardness and wear resistanceQuenchingSteel plates

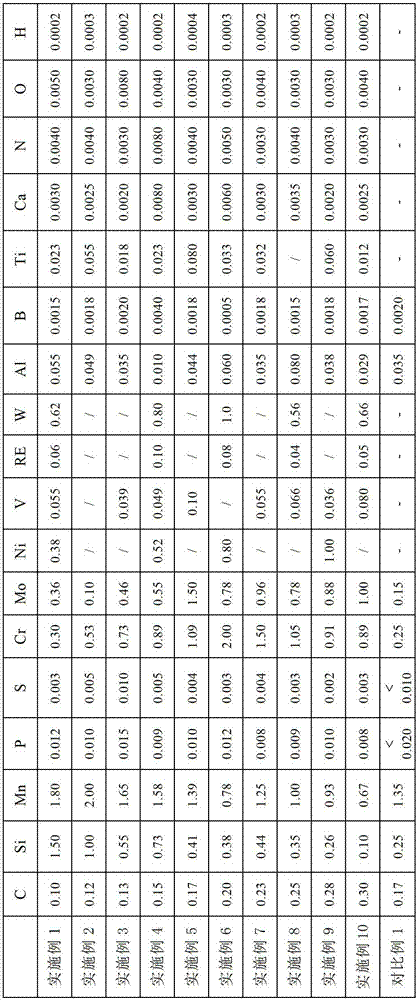

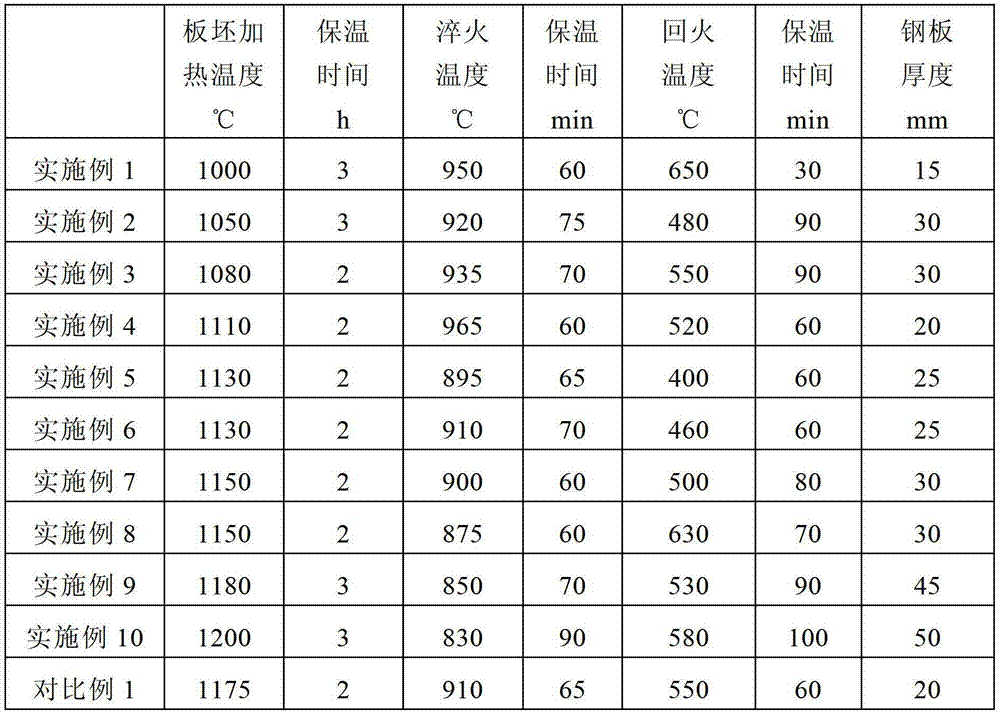

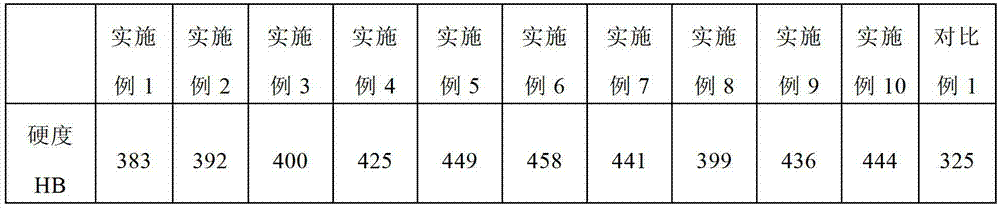

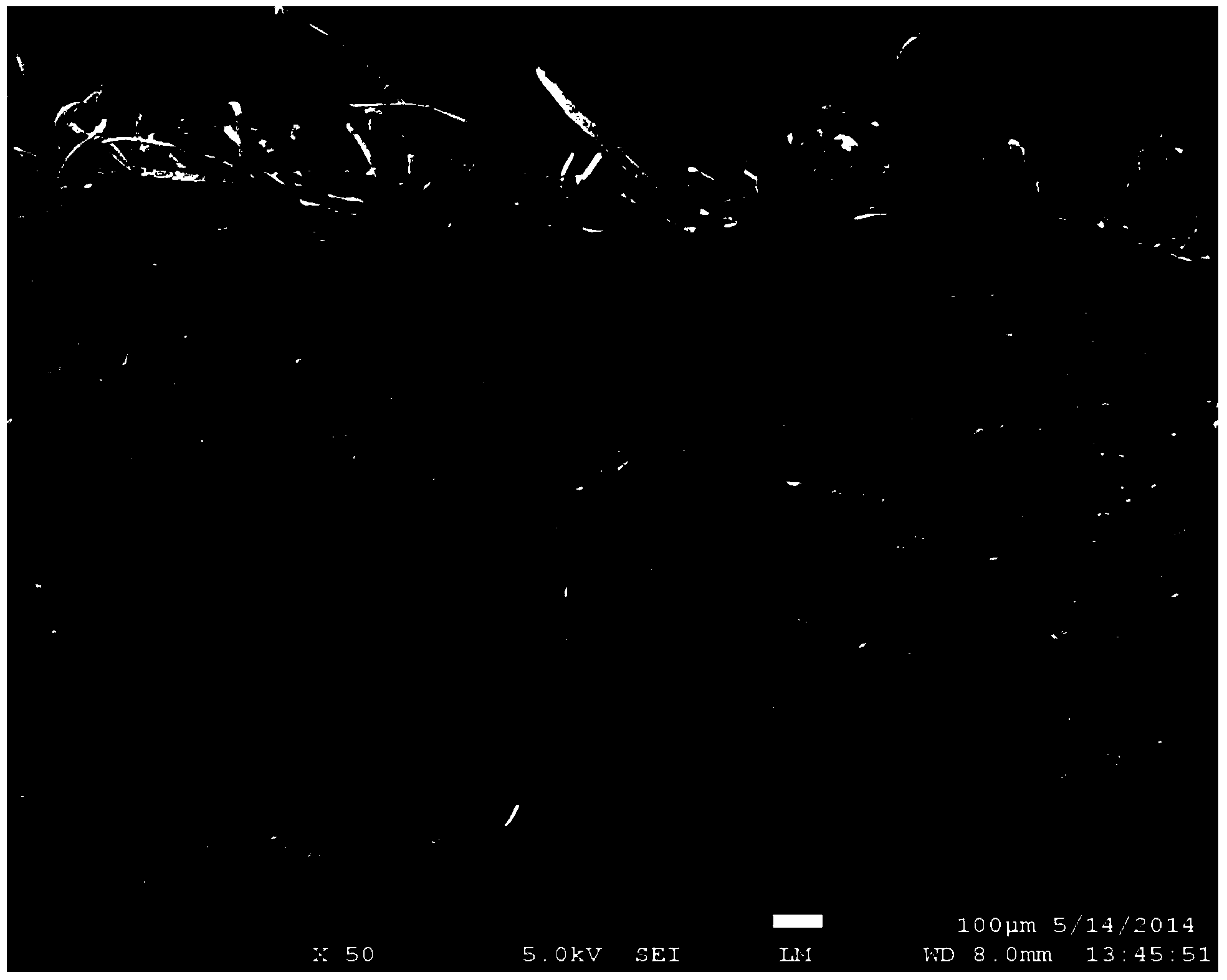

The present invention provides a steel plate with great heat and abrasion resistance and a manufacturing method thereof. The steel plate comprises the following chemical composites, in percentage by weight: 0.10-0.30% of C, 0.10-1.50% of Si, 0.50-2.00% of Mn, 0-0.015% of P, 0-0.010% of S, 0.2-2.00% of Cr, 0.10-1.50% of Mo, 0-1.00% of Ni, 0-0.10% of V, 0-0.10% of RE, 0-1.00% of W, 0.010-0.080% of Al, 0.0005 -0.0040% of B, 0-0.080% of Ti, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0004% of H and the balance being Fe and inevitable impurities. The mechanical properties of the steel plate are that the Brinell hardness is greater than 360HB, and the 500 DEG C tensile strength is more than 1000MPa. The steel plate obtained by the various components through processes such as quenching and tempering has excellent mechanical properties and abrasion resistance, and is particularly suitable for various mechanical parts which are easy to wear while working under high temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

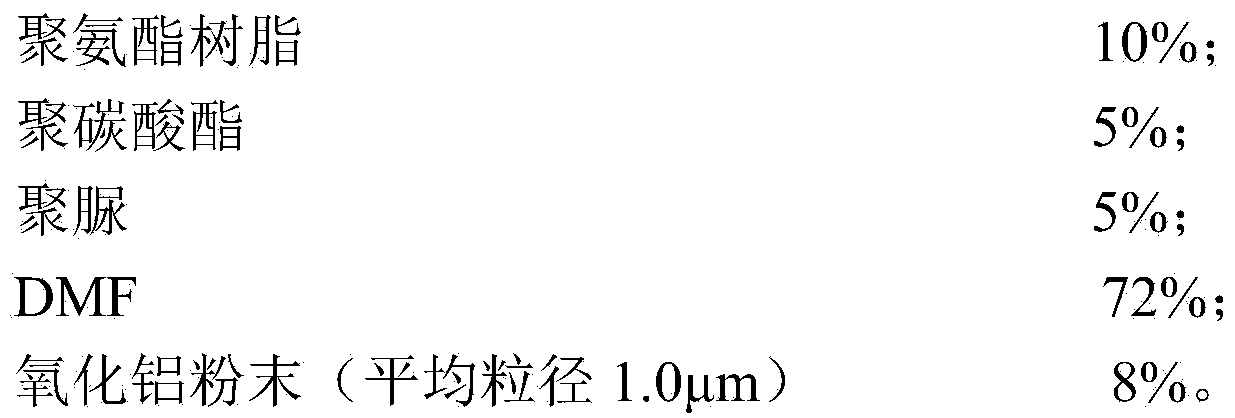

Manufacturing method of polyurethane polishing pad

ActiveCN104385120AGood water permeabilityImprove hardness and wear resistanceAbrasion apparatusLapping toolsEnvironmentally friendlyEnvironmental resistance

The invention relates to a manufacturing method of a polyurethane polishing pad with high water permeability, hardness and abrasion resistance, and the polyurethane polishing pad manufactured by using the method. The method comprises the following steps: soaking a non-woven fabric or a knitted fabric serving as a substrate material into socking liquid (polyurethane resin, an organic solvent and a polishing agent); picking the soaked non-woven fabric or knitted fabric out, soaking the non-woven fabric or knitted fabric into pre-coagulation soaking liquid in water, and drying to obtain the polyurethane polishing pad. By adopting the manufacturing method of the polyurethane polishing pad, the hardness and the water permeability of a product can be enhanced simultaneously. For example, the hardness of the product is 80 degrees, and the water permeability is 248ml / cm<2>.h by using the conventional manufacturing process. The hardness of the product is up to 90 degrees, and the water permeability is 3,522ml / cm<2>.h by using the manufacturing method disclosed by the invention. By adopting the manufacturing method of the polyurethane polishing pad, the use of the organic solvent can be reduced greatly, and the production cost is reduced greatly. A process is low in energy consumption, and is environmentally friendly.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method for graphene-like reinforced building ceramic glaze surface

PendingCN108164141AImprove hardness and wear resistanceGood application prospectSingle layer grapheneClaywaresIndustrial scaleCeramic glaze

The invention relates to a preparation method for a graphene-like reinforced building ceramic glaze surface. The preparation method comprises the following steps: respectively adding 1 to 3% of high-temperature quenched graphite and 3 to 8% of a sugar or starch substance in terms of the mass of a building ceramic glaze material, applying a ball-milled glaze pulp onto a ceramic green body, carryingout drying, and carrying out sintering in a roller kiln so as to obtain a building ceramic tile. According to the invention, by utilization of a method of combining high-temperature quenching and mechanical ball-milling, a graphene oxide material with a single-layer or multi-layer structure is obtained, and is reduced into graphene-like under the action of high temperature, so the hardness and wear resistance of the building ceramic glaze surface are greatly improved. The product glaze surface provided by the invention has a microhardness of 726 to 755 Hv and reaches a wear-resistant grade of5 grades or more. The method provided by the invention has the advantages of simple and rapid operation, low cost, applicability to industrial scale production and good application prospects.

Owner:JINGDEZHEN CERAMIC INSTITUTE

High-performance powder metallurgy oil-containing bearing and manufacturing method thereof

ActiveCN103909270AImprove hardness and wear resistanceImprove sintering performancePowder metallurgyWear resistant

The invention discloses a high-performance powder metallurgy oil-containing bearing and a manufacturing method thereof. The high-performance powder metallurgy oil-containing bearing comprises a steel sleeve on the outer layer and a powder metallurgy copper powder layer on the inner layer, and the powder metallurgy copper powder layer is composed of, by weight, 6-14% of Al powder, 4-12% of Sn powder, 1-5% of alloy enhancing elements, 1-3% of a solid lubricant, 0.5-2% of paraffin and the rest copper powder. The manufacturing method includes the processing steps of powder stirring, blank pressing, pretreating, washing, press fitting, sintering, machining and vacuum oil immersion. The high-performance powder metallurgy oil-containing bearing has good wear-resistant and lubricating performance, hardness of the copper powder alloy layer can be more than or equal to 60HRB, and adhesion between the alloy layer and a steel back layer can be effectively guaranteed.

Owner:COB PRECISION PARTS

Abrasion-resistant lining plate for cone crusher

InactiveCN105316567AImprove toughnessImprove hardness and wear resistanceAlloy elementPrecious metal

The invention discloses an abrasion-resistant lining plate for a cone crusher and relates to the technical field of crusher lining plates. Alloy elements in the lining plate include 2.30-2.80% of C, 22.0-24.0% of Cr, 1.32-1.85% of Si, 0.15-0.23% of Mn, 0.17-0.32% of B, 0.25-0.40% of V, 0.15-0.28% of N, 0.15-0.26% of W, 0.54-0.82% of Cu, 0.02-0.06% of Ce, 0.15-0.22% of Al, 0.07-0.12% of Co, 0.22-0.35% of Ti and the balance Fe and unavoidable impurities. The ratio of the optimized elements is more reasonable and all the elements achieve the synergistic effect, so that the lining plate is high in hardness, good in tenacity and resistant to impact and abrasion; the service life of the lining plate is two to three times longer than that of a common steel abrasion-resistant material; the lining plate meets the work demands of medium and large cone crushers; besides, the raw material sources are rich, precious metal such as Mo and Ni are not contained, and the production cost is low.

Owner:ANHUI SANFANG NEW MATERIAL TECH CO LTD

Boehmite sol type wear-resisting concrete sealing hardening agent and preparation method of boehmite sol type wear-resisting concrete sealing hardening agent

The invention discloses a boehmite sol type wear-resisting concrete sealing hardening agent. The boehmite sol type wear-resisting concrete sealing hardening agent is prepared from the following components in percentage by weight: 30 percent to 60 percent of boehmite sol, 3 percent to 8 percent of nano particles, 5 percent to 10 percent of a silane coupling agent, 1 percent to 5 percent of wax powder, 0.1 percent to 0.5 percent of a surfactant, 5 percent to 11 percent of ethanol and the balance of de-ionized water, wherein the silane coupling agent is selected from tetraethoxysilane, 3-aminopropyltriethoxy silane, gamma-glycidyloxypropyltrimethoxysilane, gamma-(methacryloxy)propyltrimethoxysilane, bi-(trimethoxysilicylpropyl)amine, bi-(triethoxysilylpropyl)amine, 1,2-bi(trimethoxysilyl)ethane and the like. The invention further discloses a preparation method of the boehmite sol type wear-resisting concrete sealing hardening agent.

Owner:集纳(温州)新材料科技有限公司

Wear-resistant coating for laser manufacturing of high-speed elevator traction wheel

InactiveCN106756255AImprove corrosion resistanceImprove hardness and wear resistanceMetallic material coating processesWear resistantCast iron

The invention discloses a wear-resistant coating for laser manufacturing of a high-speed elevator traction wheel. The wear-resistant coating is characterized in that a priming coating between a base material and a functional layer is not needed; a semiconductor laser unit is directly used for cladding a cobalt-base alloy wear-resistant coating on a nodular cast iron base material of the elevator traction wheel; and the wear-resistant coating comprises, by weight, 1.1-1.3% of C, 22-24% of Cr, 1.0-1.3% of Si, 1.3-1.5% of Ni, 0.1-0.15% of Mn, 2.5-2.8% of Mo, 4.5-4.7% of W, 2.8-2.9% of Fe, 1.6-1.8% of B, and the balance Co. According to the wear-resistant coating, by regulating the composition proportion of all the elements, an obtained cladding layer is free of inclusions, pores, cracks and other defects and is good in wear resistance and corrosion resistance and suitable for laser cladding of the high-speed elevator traction wheel.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Aldehyde-removing negative ion odor-free wooden door paint

InactiveCN103788854AGood flexibility and feelImprove hardness and wear resistancePolyurea/polyurethane coatingsIonChemistry

The invention discloses an aldehyde-removing negative ion odor-free wooden door paint which comprises a wooden door paint main agent and a curing agent, wherein the mass ratio of the wooden door paint main agent to the curing agent is 1: (0.1-0.15); the wooden door paint main agent comprises 40-45% of hydroxyl polyurethane resin, 20-25% of hydroxyl acrylic resin, 8-10% of titanium dioxide, 3-6% of nanosilicon dioxide, 5-8% of nano negative ion powder, 1.5-2% of film formation auxiliary agent, 0.1-0.2% of surface active agent, 0.1-0.5% of defoaming agent, 0.05-0.3% of multifunctional additive, 0.1-0.2% of preservative, 0.2-0.7% of mould inhibitor and the balance of water; the curing agent is formed by compounding sulfonate modified polyisocyanate and propylene glycol methyl ether acetate according to the mass ratio of 1: 1.3. The aldehyde-removing negative ion odor-free wooden door paint has the functions of effectively preventing damp and mould, is bubble-tight, free from miliaria and good in gloss, and has good adhesive force and wear resistance; furthermore, what is more, the aldehyde-removing negative ion odor-free wooden door paint is capable of effectively and continuously generating the negative ions, so that the indoor formaldehyde is effectively removed, and the content of the formaldehyde is greatly reduced.

Owner:广东黑马新材料科技有限公司

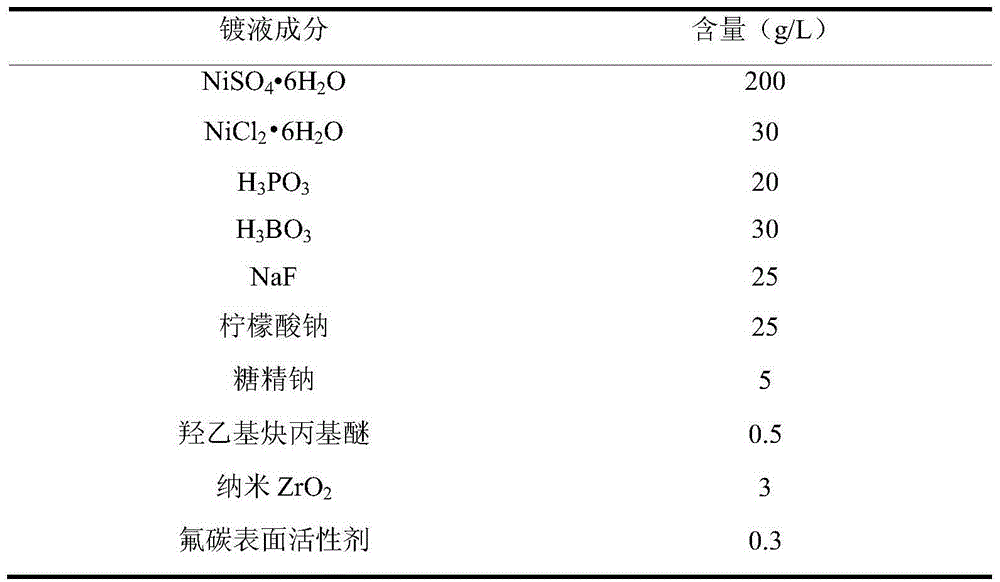

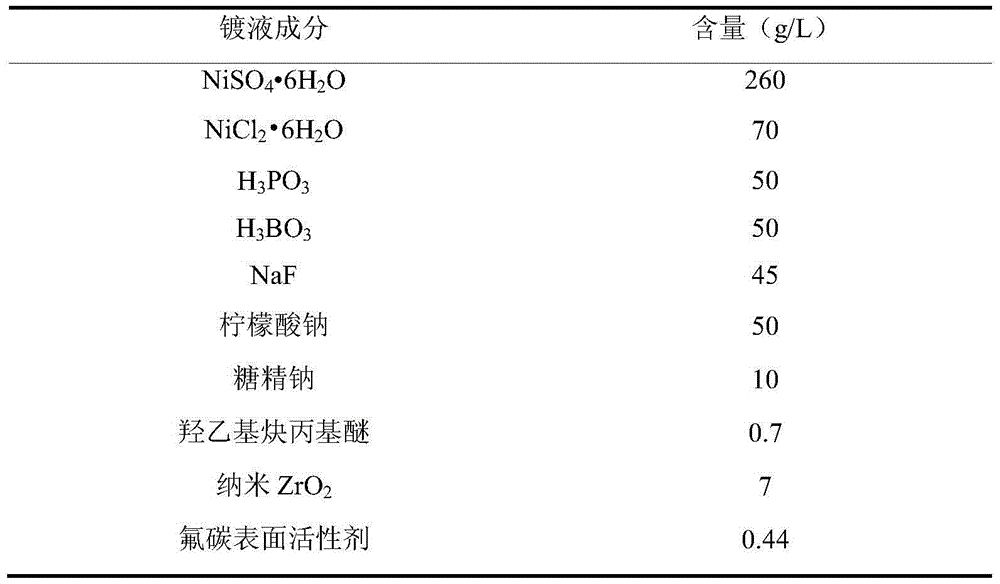

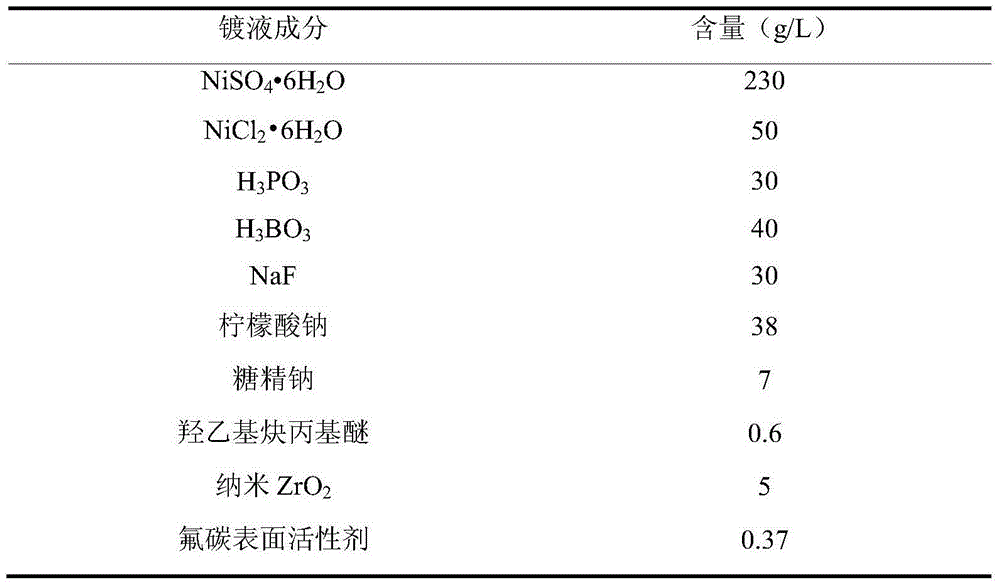

Electroplating solution for nano-ZrO2 composite plating of Ni-P alloy and electroplating method

The invention discloses an electroplating solution for nano-ZrO2 composite plating of Ni-P alloy and an electroplating method. The electroplating solution includes 200-260g / L NiSO4.6H2O, 30-70g / L NiCl2.6H2O, 20-50g / L H3PO3, 30-50g / L H3BO3, 25-45g / L a fluoride, 25-50g / L citrate, 3-7g / L nano-ZrO2, 0.30-0.44g / L a fluorocarbon surfactant, 5-10g / L saccharin salt and 0.5-0.7g / L hydroxyethyl propargyl ether. The electroplating solution provided by the invention contains nano-ZrO2, and due to the rigidity of nano-ZrO2 itself, the hardness and wear resistance of the coating are improved. On the one hand, the nano-ZrO2 can fill the pores of the coating and wind and cover the surfaces of alloy metal grains to prevent infiltration of a corrosive liquid, and on the other hand the nano-ZrO2 and alloy metal micro-crystals compose a miniature primary battery to promote passivation of Ni-P alloy, thereby improving corrosion resistance.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

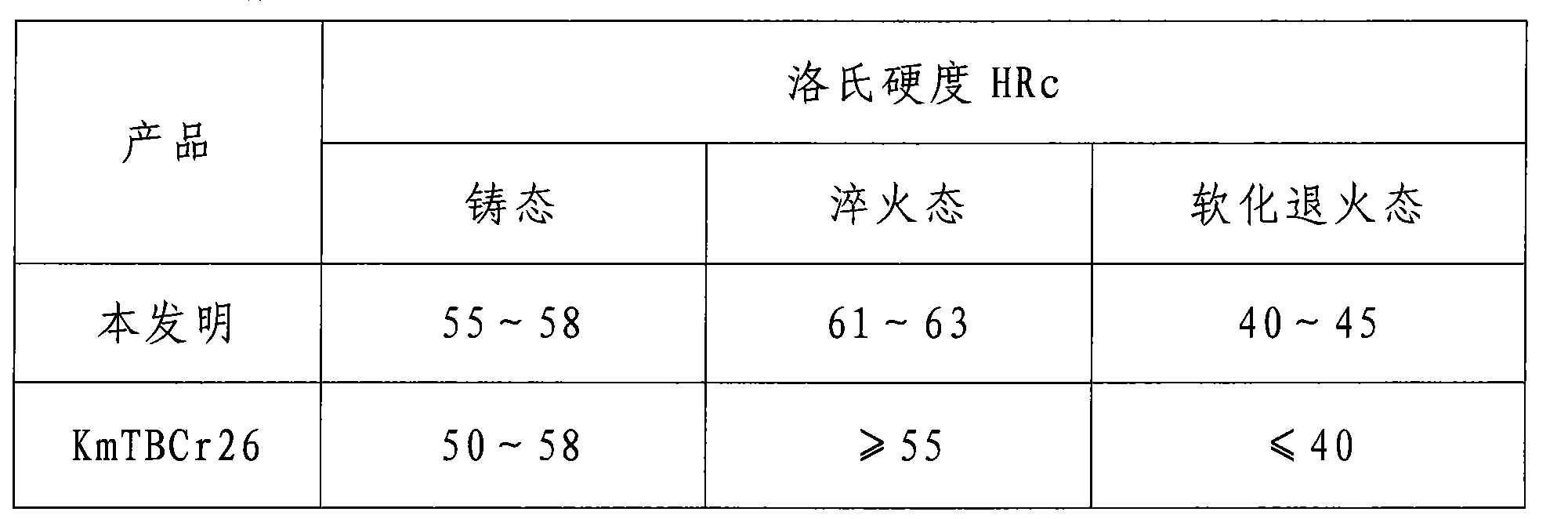

Wear resistant cast iron

InactiveCN101440454AImprove hardness and wear resistanceImprove metallographic structureWear resistantCast iron

The invention discloses a cast iron material with higher hardness, corrosion resistance, high-temperature oxidation resistance and abrasion endurance of an abrasive material with larger impact load. The cast iron material consists of the following compositions by weight percentage: 2.8 percent of C, 0.2 to 1.0 percent of Si, 0.5 to 1.0 percent of Mn, less than or equal to 0.06 percent of S, less than or equal to 0.1 percent of P, 21 to 23 percent of Cr, 0 to 1.5 percent of Ni, 1.0 to 1.5 percent of Mo, and the balance being Fe and unavoidable impurities. The cast iron material has the advantages of improving hardness and other comprehensive performances of the material, and being helpful for prolonging the service life of a finished product manufactured by the cast iron material.

Owner:蔡柏林

Technique for manufacturing steel grit

InactiveCN1519070AImprove hardenability and hardenabilityImprove hardness and wear resistanceOther chemical processesRecycling and recovery technologiesQuenchingScrap

Owner:FUJIAN DUOLENG STEEL GROUP

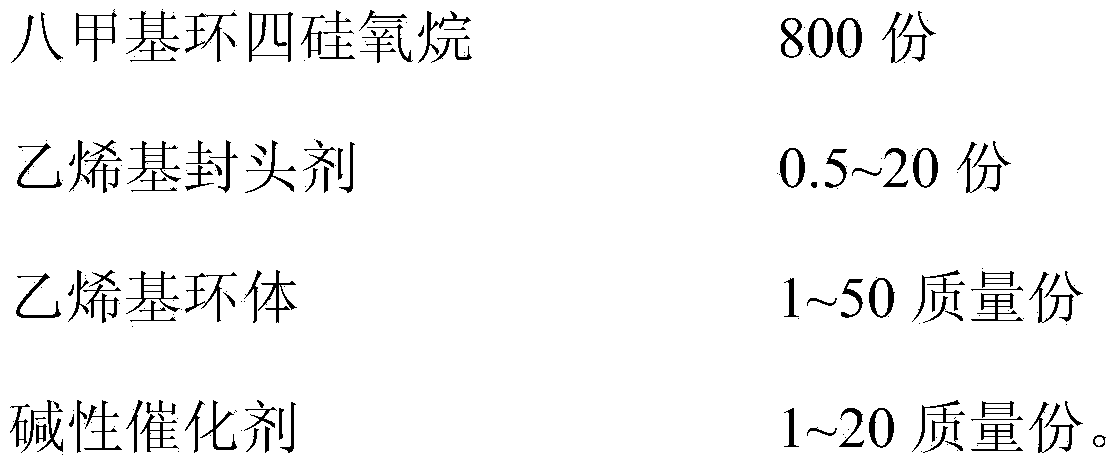

Preparation method of vinyl silicone oil

The invention relates to a preparation method of vinyl silicone oil, which comprises the following steps: adding 800 parts of octamethylcyclotetrasiloxane into a reaction kettle, stirring, adding 1-20 parts of alkaline catalyst into the reaction kettle, stirring, heating to 60-70 DEG C, keeping the temperature constant in a vacuum for 0.5-1 hour, adding 0.5-20 parts of vinyl terminating agent into the reaction kettle, stirring at the constant temperature of 60-70 DEG C for 5-10 minutes, adding 1-50 parts of vinyl cycle into the reaction kettle, stirring, heating to 90-100 DEG C, keeping the temperature constant for 4-6 hours, heating to 150-160 DEG C, keeping the temperature constant for 0.5-1 hour, and heating to remove low-boiling-point substances in vacuum until no micromolecules flow out, thereby obtaining the vinyl silicone oil. The vinyl silicone oil prepared by the method is used for a potting adhesive, and can enhance the wear resistance and hardness of the potting adhesive.

Owner:兆舜科技(广东)有限公司

Heat-resisting scratch-resisting car paint with modified waterborne polyurethane dispersoid

ActiveCN105255345AImprove heat resistanceImprove hardness and wear resistanceRubber derivative coatingsWax coatingsSolventIron oxide

The invention discloses heat-resisting scratch-resisting car paint with modified waterborne polyurethane dispersoid. The heat-resisting scratch-resisting car paint is prepared from, by weight, 100 parts of modified waterborne polyurethane dispersoid, 45 parts of acrylate, 20 parts of alkyd resin, 10 parts of dipropylene glycol butyl ether, 5 parts of organosilicone resin, 4.5 parts of chlorinated rubber, 6.5 parts of chlorcosane, 3 parts of iron oxide red, 3 parts of nitrocotton, 4 parts of high-strength carbon fibers, 6.5 parts of modified wollastonite, 7.5 parts of flaky aluminum sheets, 5 parts of mica powder, 3 parts of graphite powder, 4 parts of zinc oxide, 5 parts of cholamine, 6 parts of diacetone alcohol, 4.5 parts of phthalic anhydride, 4 parts of thickener, 2.5 parts of high-elasticity rubber, 3 parts of bactericide, 4 parts of curing agent, 6 parts of drier, 7 parts of silicone oil and 5 parts of petroleum solvent. The heat-resisting scratch-resisting car paint with modified waterborne polyurethane dispersoid is excellent in heat resisting and scratch preventing performance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Composite roll ring of high-speed steel

InactiveCN1212204CImprove hardness and wear resistanceExtended service lifeRollsMetal rolling arrangementsCast ironCompound (substance)

The invention is a kind of high-speed steel composite collars. The outer layer of the collars is high speed steel, the core of the collars is alloy nodular cast iron, the character lies in: the chemical elements o outer layer are: C 1.2-1.5%, Si 0.3-1.5%, Mn 0.4-1.0%, Cr 3.0-6.0 %, Mo 1.0-4.0%, V 1.0-4.0%, W 0.5-3.0%, Nb 0.5-2.0%, Ti 0.01-0.5%, RE 0.01-0.5%, P<0.05%, S<0.05%, the residue is Fe; the chemical elements of the core are: C 3.0-3.8%, Si 2.2-3.2%, Mn 0.3-0.8%, Ni 0.2-2.0%, Cr<0.3%, Mo<0.3%, Mg0.03-0.1%, RE>=0.03%, P<0.1%, S<0.03%, the residue is Fe. compared with current technology, the invention has a low cost, high rigidity, good wearability, long operation life and high efficiency.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +2

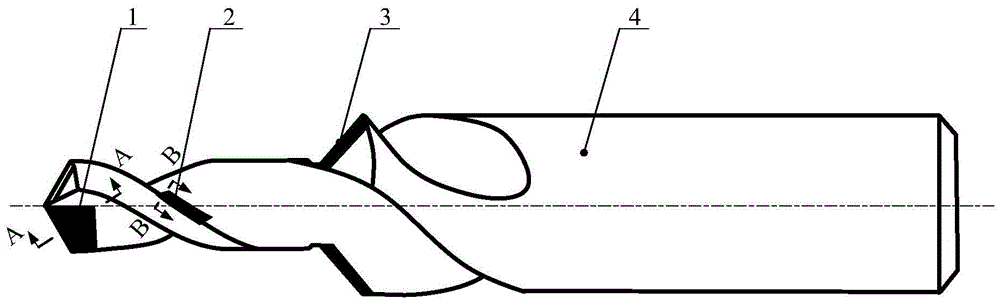

Drilling-reaming-dimpling integrated cutting tool

ActiveCN105642972AImprove hardness and wear resistanceExtended service lifeTransportation and packagingWorkpiecesTitaniumAluminium alloy

The invention claims a drilling-reaming-dimpling integrated cutting tool. A drilling part, a reaming part, a dimpling part and a handle part are sequentially arranged on a cutter body, and the distance between the reaming part and the dimpling part is 6-8mm; the drilling part is composed of a chisel edge, two main cutting edges and two secondary cutting edges; the main cutting edge is a straight line cutting edge, the rake angles and the relief angles of the points on the edge are the same, and a front tool face is provided with a chip breaker; the reaming part is composed of two spiral cutting edges; the dimpling part is composed of two spiral cutting edges; each part of the base material is hard alloy, and the working part of each cutting edge adopts PCD. Through the configuration of the cutting tool structure angel and the material, the drilling force of drilling aluminum alloy, titanium alloy and aluminum-titanium laminate is effectively reduced, the cutting tool abrasion is retarded, the burr production is inhibited, the hole shape precision and surface roughness of a processing hole can be improved, the processing quality is guaranteed, the processing efficiency is improved, and the service life of the cutting tool is prolonged.

Owner:SHANDONG UNIV

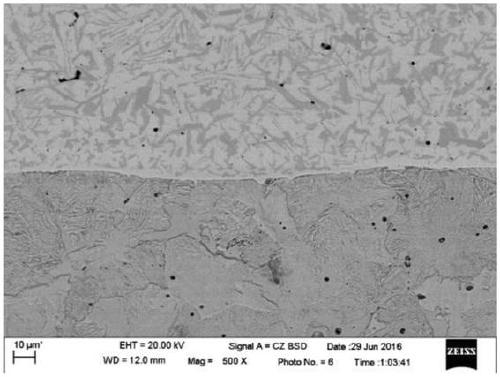

Piercing plug laser strengthening process dispensing with preheating before laser cladding

ActiveCN103572280ARelieve surfacing stressImprove hardness and wear resistanceMetallic material coating processesHigh intensityHardness

The invention relates to a laser strengthening process of a piercing plug. The laser strengthening process is characterized by firstly carrying out laser cladding on a transition alloy layer on the surface of a piercing plug matrix and then carrying out laser cladding on the high-strength alloy layer on the transition alloy layer, wherein the alloy powder adopted by the transition alloy layer is the nickel base alloy; the alloy powder adopted by the high-strength alloy layer is the cobalt base alloy. The laser strengthening process has the advantages that the transition alloy layer in the process has lower hardness than the high-strength alloy layer, plays a role in transition for the high-strength alloy layer with high hardness and high wear resistance and can well relieve the surfacing stress, so that even if the plug is not preheated or annealed, the residual surfacing stress can not have great impacts on the tissues of a laser cladding layer, thus effectively avoiding impacting the properties of the cladding layer by annealing, substantially improving the surface hardness and wear resistance of the piercing plug, simultaneously omitting the processes of preheating and annealing and also improving the production efficiency.

Owner:JIANGSU ZHONGOU FERTILIZER

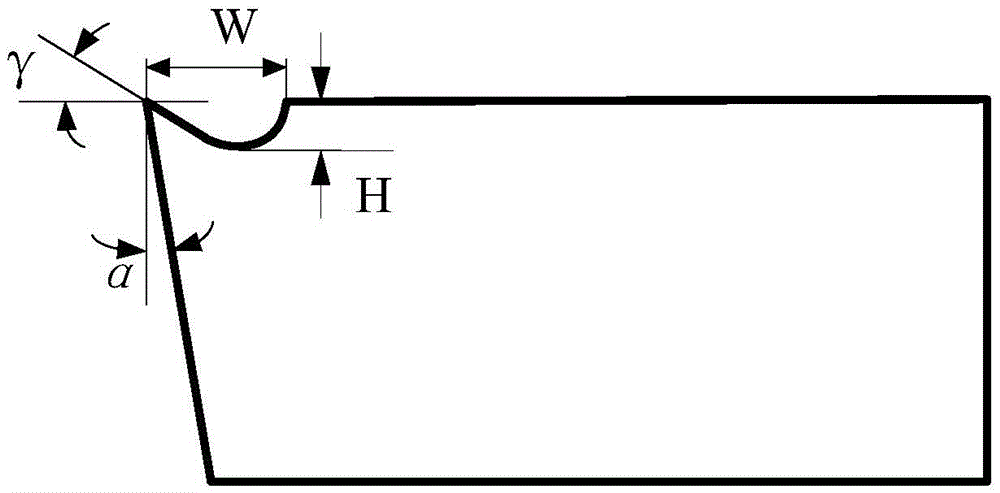

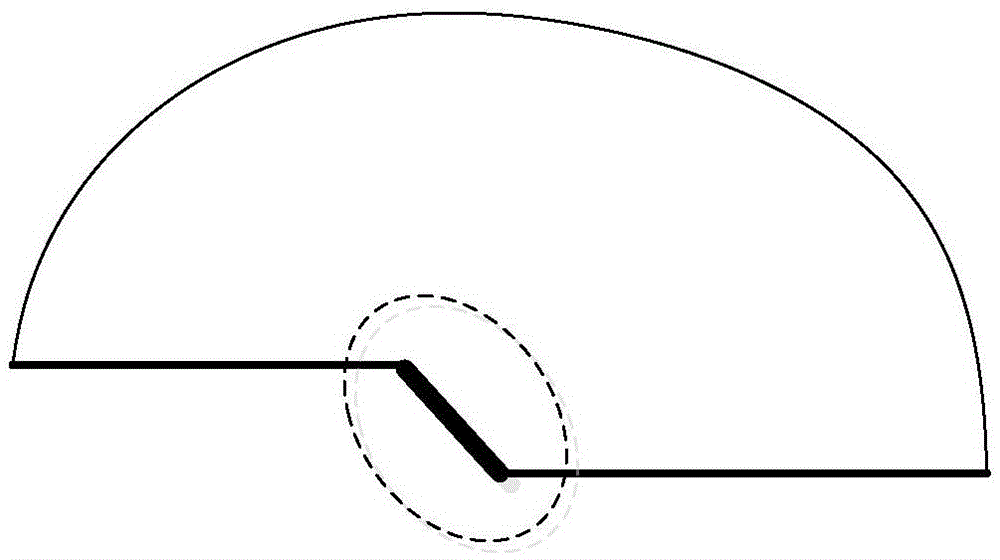

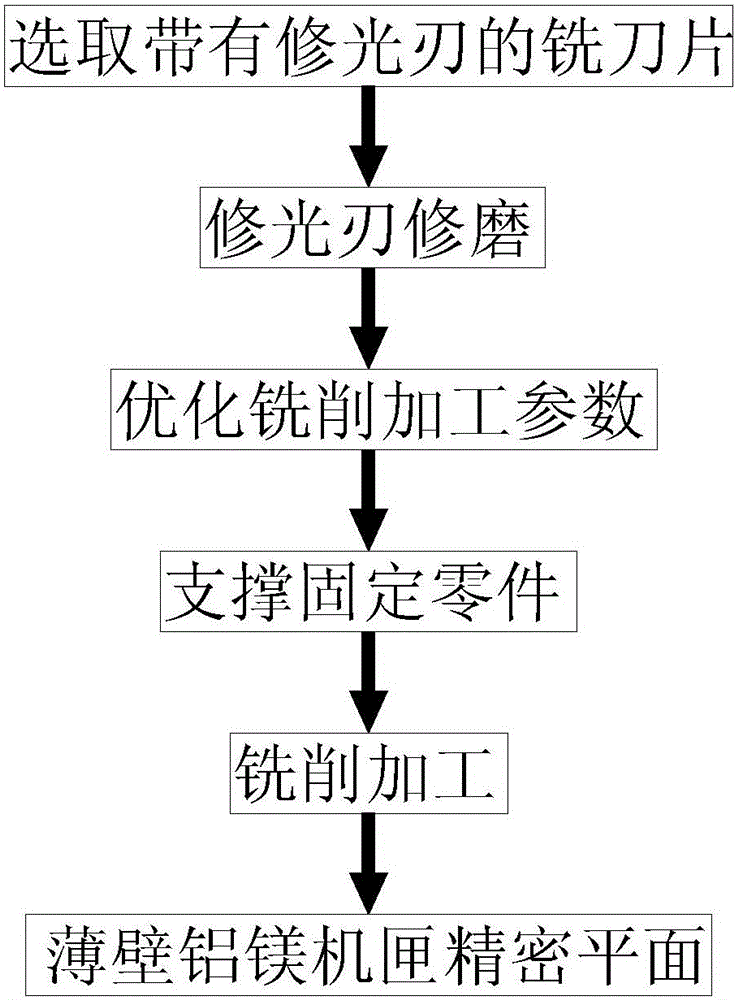

Method for milling precise cavity plane of thin-wall aluminum-magnesium cartridge receiver of aircraft engine

ActiveCN105665800AImprove hardness and wear resistanceHigh thermal conductivityMilling equipment detailsMilling cutting insertsThin walledMagnesium

The invention discloses a method for milling a precise cavity plane of a thin-wall aluminum-magnesium cartridge receiver of an aircraft engine. The method comprises the following steps: (a) selecting a diamond material and a milling blade with a smoothening edge, so that the plane cutting speed is increased, and the cutting efficiency is improved; (b) polishing the smoothening edge of the milling blade to form an angle alpha with a machined surface on the machined thin-wall aluminum-magnesium cartridge receiver; (c) optimizing milling machining parameters according to the milling blade and the smoothening edge of the milling blade; (d) fixing the machined thin-wall aluminum-magnesium cartridge receiver in a point supporting manner; and (e) carrying out surface milling machining on the precise cavity plane of the fixed machined thin-wall aluminum-magnesium cartridge receiver by virtue of the optimized milling machining parameters, so as to obtain the formed precise cavity plane of the thin-wall aluminum-magnesium cartridge receiver. According to the method, the plane cutting speed can be increased, the cutting efficiency can be improved, meanwhile, the cutting force can be decreased, and the friction between a cutter and machined parts is reduced, so that the vibration, cutter relieving and deformation of the plane in the machining cutting can be reduced, and finally the precision requirement of a big plane is guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

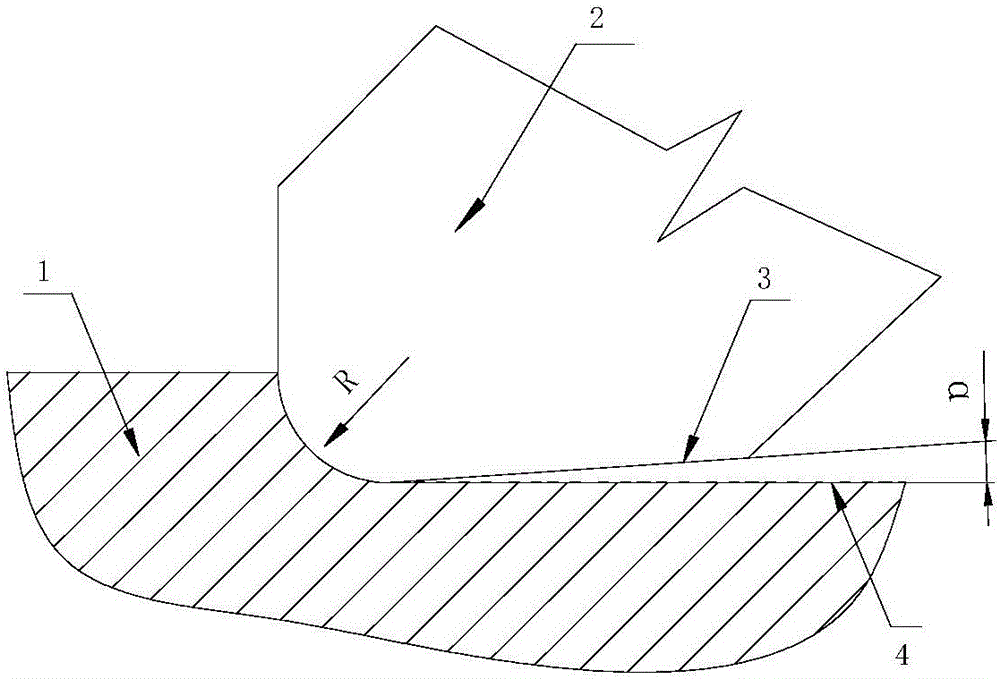

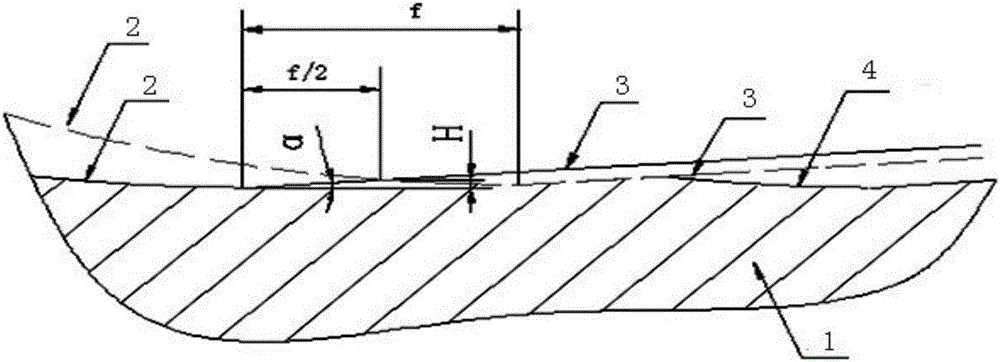

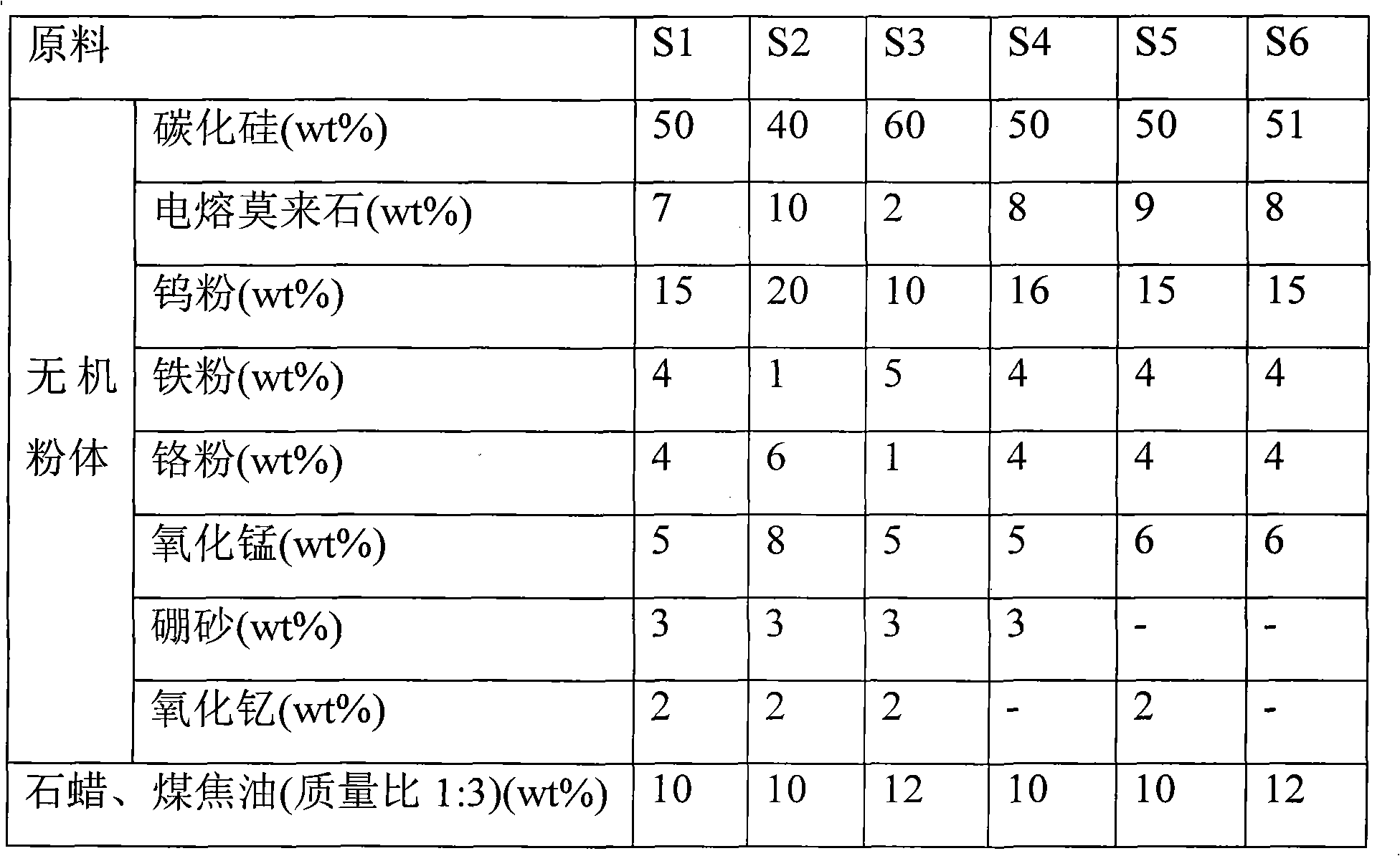

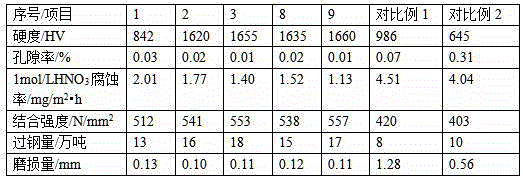

Composition composed of metal and ceramic and its preparation method, cermet and Raymond mill

InactiveCN102373357AImprove hardness and wear resistanceGood toughnessGrain treatmentsTungstenParaffin oils

The invention provides a composition composed of metal and ceramic, based on the total mass of the composition composed of metal and ceramic, the composition composed of metal and ceramic comprises the following ingredients: 40-60wt% of silicon carbide with 0.5-2 mum of particle size, 2-10%wt% of Corhart standard, 10-20wt% of tungsten powder, 1-5wt% of iron powder, 0.5-6wt% of chromium powder, 2-8wt% of manganese oxide, 8-15wt% of paraffin and coal tar. The cermet prepared by the composition composed of metal and ceramic has the advantages of high hardness and wear resistance of ceramic and toughness of alloy. In addition, the composition composed of metal and ceramic of the present invention has the characteristics of less molybdenum powder amount and low cost.

Owner:湖南永锐材料科技有限公司

Method for preparing nickel-boron alloy coating on continuous casting crystallizer copper plate surface

ActiveCN106011957AHot crack tendency and internal stress reductionImprove hardness and wear resistanceDodecylsulfonic acidCraquelure

The invention belongs to the technical field of surface treatment electroplating, and particularly relates to a method for preparing a nickel-boron alloy coating on a continuous casting crystallizer copper plate surface. The method comprises the following step: carrying out nickel-boron alloy electroplating on a pretreated copper plate substrate, wherein the electroplating solution is composed of 30-80 g / L nickel sulfamate, 30-50 g / L boric acid, 0.8-16 g / L sodium borohydride, 30-60 g / L ethylenediamine and 0.01-0.1 g / L sodium dodecylsulfate; and the electroplating conditions are as follows: the pH value of the electroplating solution is 3.5-4.5, the temperature is 45-65 DEG C, the copper plate substrate is the cathode, nickel pellets are the anode, and the current density is controlled at 1-3 A / dm<2>. The method can be used for obtaining the coating which has the advantages of high compactness and uniformly, excellent binding force, low thermal crack tendency, high hardness, excellent corrosion resistance and excellent wear resistance.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

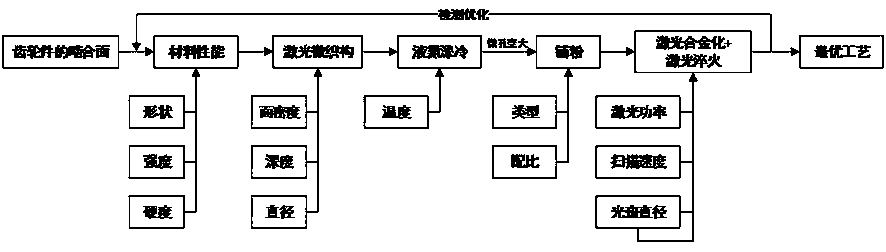

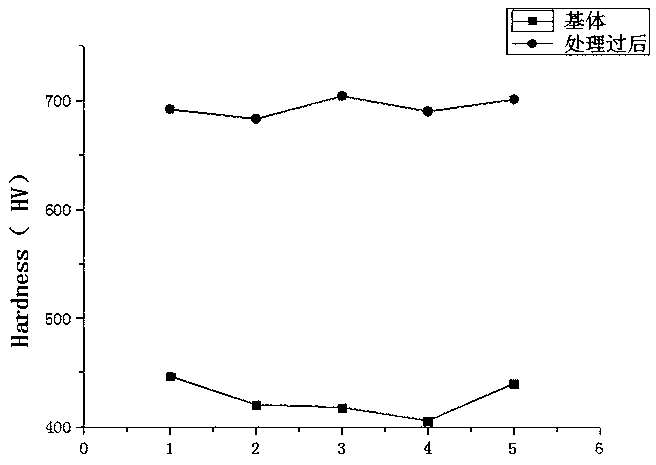

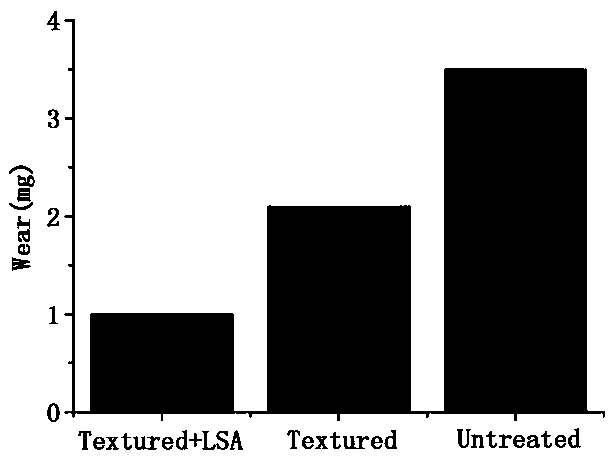

Laser surface alloying method for heavy-duty gears of marine platforms

ActiveCN109136518AEvenly distributedImprove hardness and wear resistanceFurnace typesMetallic material coating processesHeavy dutyHardness

The invention provides a laser surface alloying method for heavy-duty gears of marine platforms. The method includes: performing gear surface laser micro-texturing, preparing nickel-based abrasion-resistant alloy powder, performing liquid nitrogen cryogenic reaming, laying the nickel-based abrasion-resistant alloy powder in a reamed microtexture area, and subjecting the microtexture area to laseralloying, laser quenching, microtexture area hardness, abrasion resistance and friction coefficient detection and optimization. By a series of processes, laser alloying is performed after gear surfacemicro-texturing; due to adding of abrasion-resistant elements in uniform distribution in the laser alloying process, hardness and abrasion resistance of gear surfaces and gear portions in different depths are effectively enhanced; and service lives of the gears are prolonged.

Owner:NANTONG UNIVERSITY

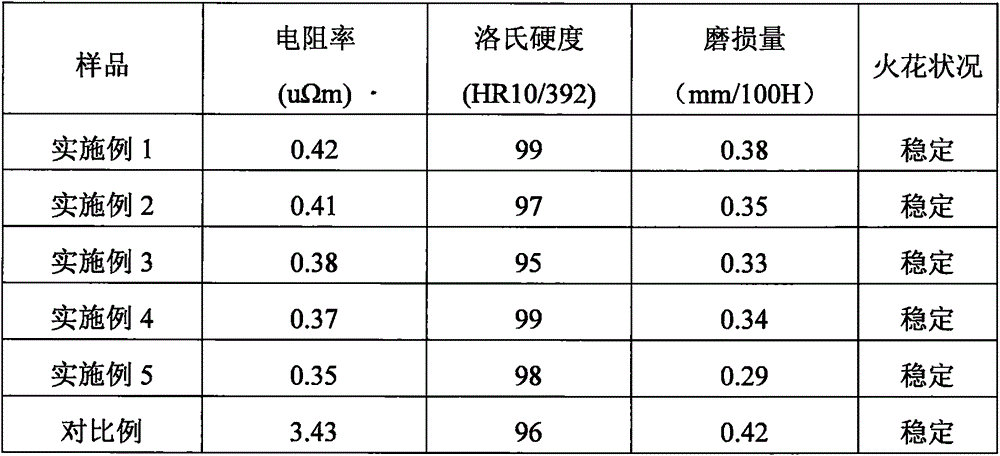

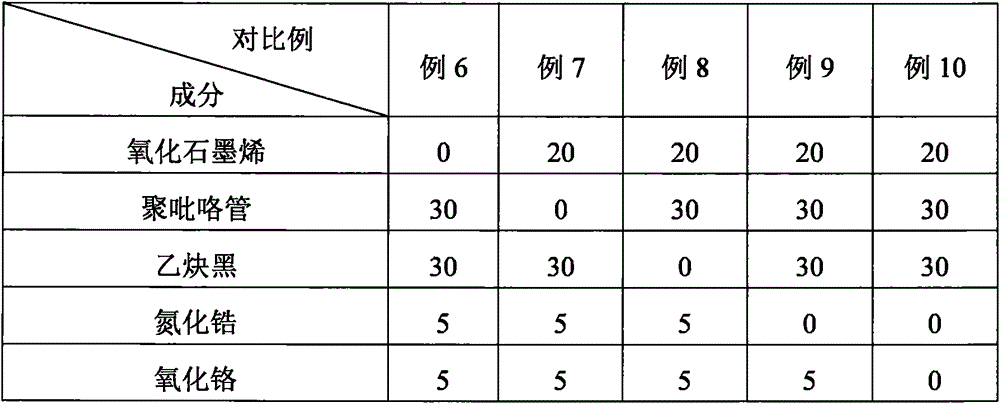

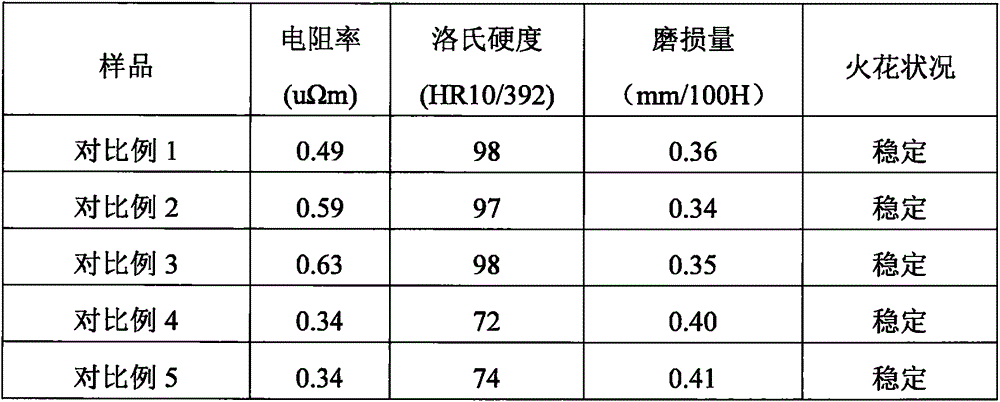

High-conductivity carbon brush materials and preparation method thereof

ActiveCN106410553AImprove hardness and wear resistanceImprove conductivityRotary current collectorBrushes manufactureHigh conductivityHardness

Owner:慈溪市华夏电器实业有限公司

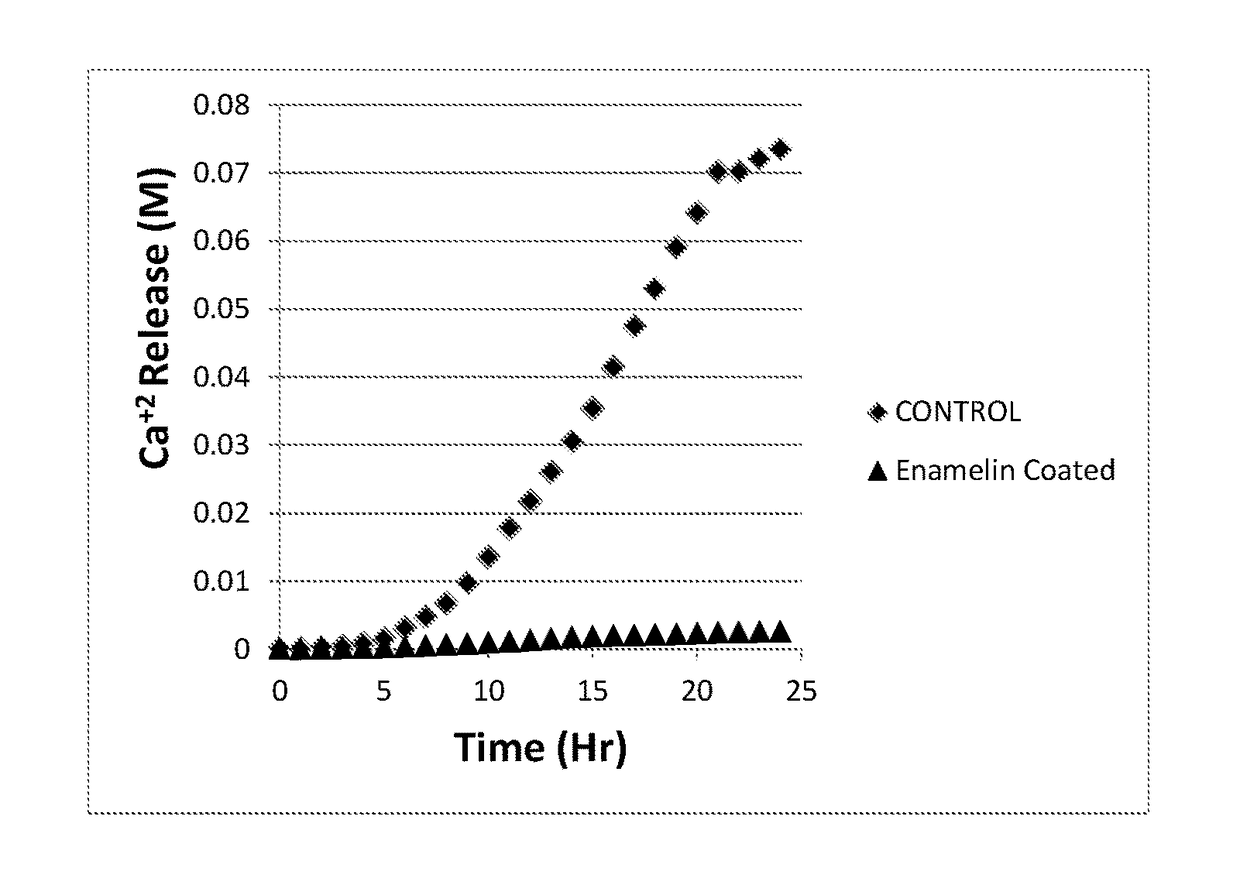

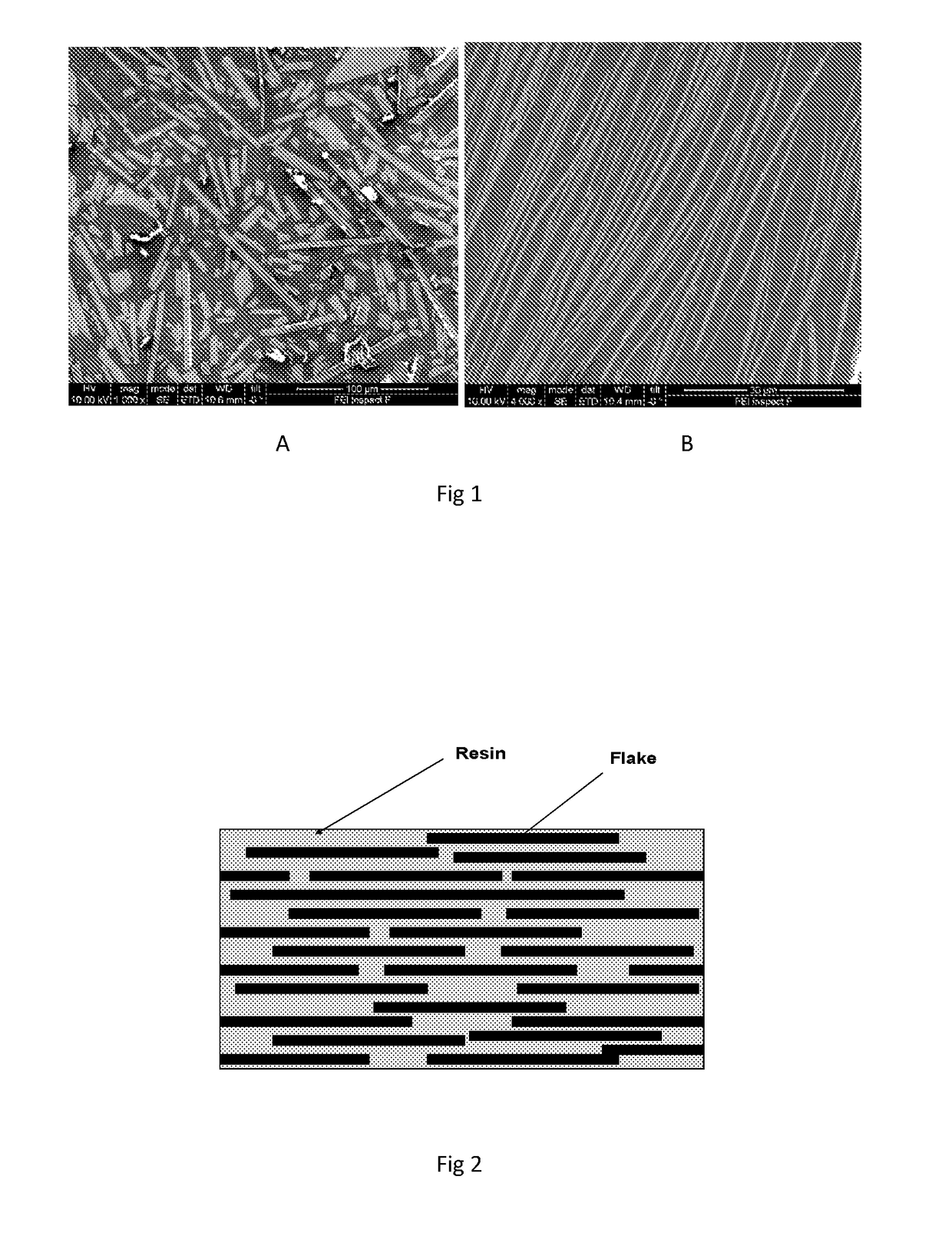

Dental Compositions

InactiveUS20180200153A1High functionalityImprove hardness and wear resistanceImpression capsDigestive systemCoatingOral cavity

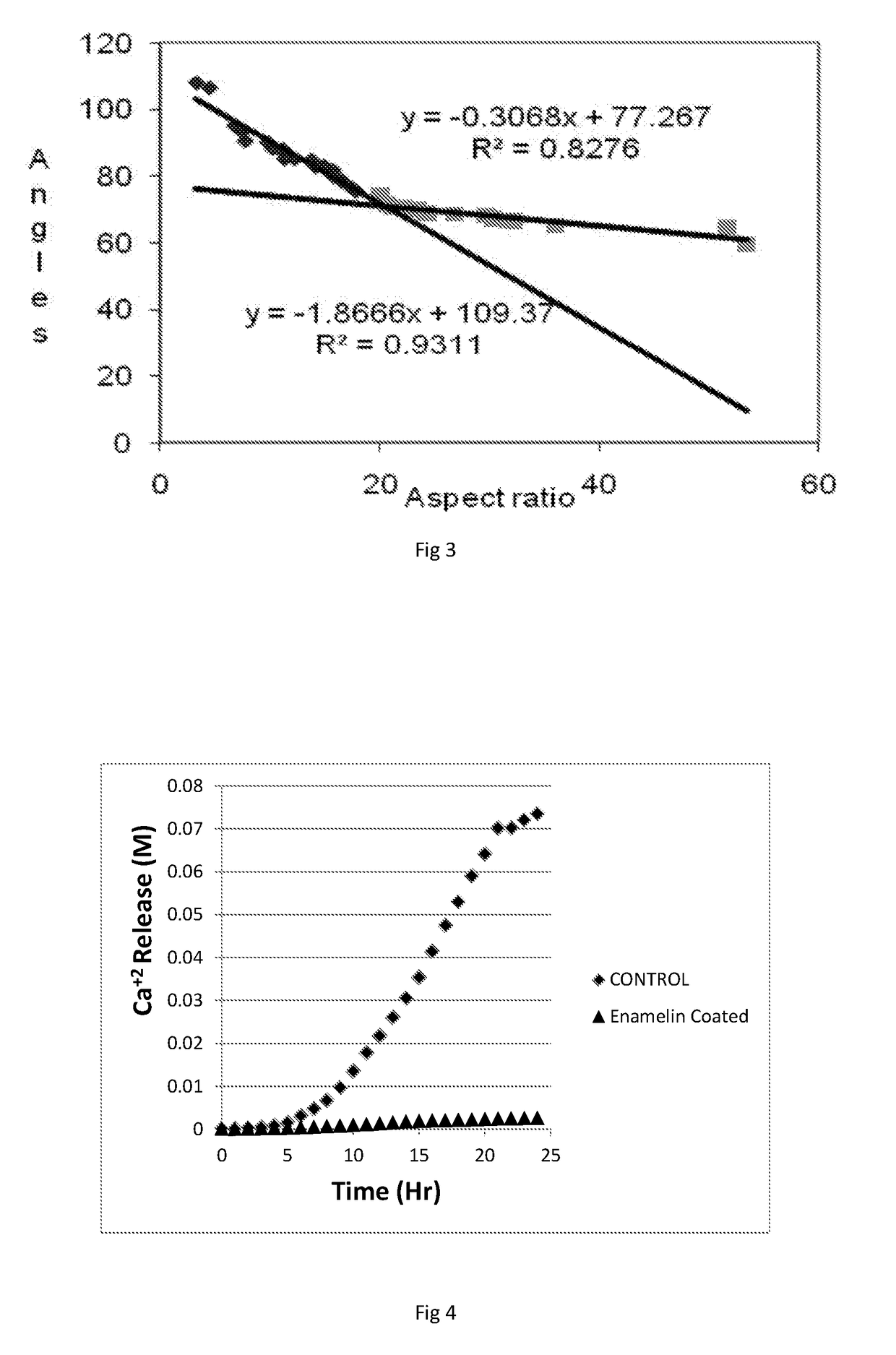

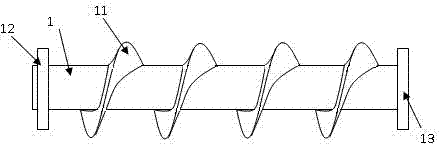

A dental composition is provided as a coating comprising glass flakes providing improved wear-5 resistance and aesthetic properties. The compositions may be used in the treatment of dentine hypersensitivity, dental caries, or in the protection of a tooth from the external environment of the mouth.

Owner:QUEEN MARY UNIV OF LONDON

High current pulsed electron beam surface treatment method for hard alloy coating tool

ActiveCN103789524AImprove organizationImprove hardness and wear resistanceFurnace typesHeat treatment furnacesPulse durationSurface finishing

The invention discloses a high current pulsed electron beam surface treatment method for a hard alloy coating tool. The method comprises the following process steps: cleaning the surface of the hard alloy coating tool to acetone to remove impurities such as oil dirt from the surface of the hard alloy coating tool; placing the treated hard alloy coating tool into a pulsed electron beam emission device to ensure that the tool surface to be treated is in the center of an electron beam irradiation spot, and vacuumizing a working chamber of the device to over 10<-3>Pa; performing irradiation bombardment on the coating tool through a pulsed electron beam with accelerating voltage of 10-15kV and pulse current of 100-200A, wherein the pulse duration is -10mu s, the pulse frequency is 0.1-10Hz, and the number of times of pulse is 1-50; after the treatment is finished, taking the tool out. By performing surface treatment on coatings such as single-layer TiN and TiAlN of a hard alloy matrix through the high current pulsed electron beam, the organization of the coating can be improved, and the hardness and wear resistance of the coating are improved.

Owner:凤城市合鑫机械制造有限公司

Superficial layer carburization process for automobile hub

ActiveCN105886999AReduced retained austenite and non-martensite contentImprove hardness and wear resistanceSolid state diffusion coatingFurnace typesQuenchingHardness

The invention relates to the technical field of hub production, in particular to a superficial layer carburization process for an automobile hub. The process comprises the following steps of impurity removal, ventilation, great permeation, diffusion, cooling, quenching and tempering. The thickness of the carburization layer of the hub obtained through the hub superficial layer carburization process is 2.5-3 mm, and the content of retained austenite and non-martensite of the outer superficial layer is effectively lowered; in addition, a great number of fine carbide particles which are distributed in a scattered mode are formed on the outer superficial permeation layer, and hardness and wear resistance of a hub steel piece are effectively improved.

Owner:HANSHAN ZHAOXIA CASTING

Preparation method for drug crushing shaft

ActiveCN107190133AImprove hardness and wear resistanceEvenly dispersedFurnace typesProcess efficiency improvementDrugQuenching

The invention relates to a preparation method for a drug crushing shaft. The preparation method comprises the following steps of smelting, annealing after die casting, deep cooling, partial quenching, tempering, finishing and the like. Through the reasonable arrangement for all steps, the hardness of the crushing shaft is improved, under the situation of no-adding cost, the hardness of the working surface of a crushing cutter is greatly improved, and meanwhile, by reasonably limiting the mode of the crushing cutter, the crushing cutter can be more durable and stronger.

Owner:徐州致诚会计服务有限公司

Heat-resisting and wear-resisting alloy steel material for drill bits and preparation method thereof

InactiveCN103820715AImprove red hardnessImprove hardness and wear resistanceProcess efficiency improvementTungstenCorrosion

The invention relates to a heat-resisting and wear-resisting alloy steel material for drill bits. The alloy steel material comprises the following chemical element constituents by mass percent: 2.0 to 2.3 percent of carbon, 9.6 to 9.9 percent of chromium, 1.4 to 1.6 percent of tungsten, 2.0 to 2.3 percent of molybdenum, 6.5 to 6.7 percent of cobalt, 1.2 to 1.3 percent of manganese, 0.4 to 0.6 percent of titanium, 1.1 to 1.3 percent of Be, 0.03 to 0.05 percent of La, 0.16 to 0.19 percent of Ho, and the balance of iron and other inevitable impurities. The cobalt, the tungsten and the molybdenum are added to alloy steel for the drill bits, provided by the invention, so that hardness and red hardness are increased; through adding the La, the Ho, the Be and the titanium, the hardness and the wear resistance of alloy are increased, at the same time, favorable toughness is kept, and the alloy steel material has favorable corrosion resistance. The alloy steel material is used for manufacturing deep hole drills, long drill bits and the like, the alloy steel material is not easy to break, the service life of the alloy steel material is long, and the cost of the alloy steel material is lower than that of high-speed steel.

Owner:MAANSHAN HENGYI MACHINERY MFG

Porcelain oxidation method of aluminium magnesium alloy

InactiveCN102312261AStrong combinationImprove hardness and wear resistanceAnodisationAmmonium sulfateOXALIC ACID DIHYDRATE

The invention relates to a porcelain oxidation method of aluminium magnesium alloy, which is characterized in that the method comprises the following steps: performing mechanical polishing, chemical oil removal, corrosion, cleaning, neutralization, cleaning, chemical oxidation, cleaning, hot water scalding (50 DEG C), blow-drying with compressed air, and oven drying of an aluminium material to form a porcelain film on the aluminium material surface; wherein the oxidation liquid adopted in the chemical oxidation steps comprises the following components: 1-10 g / L of sulfuric acid, 1-5 g. / L of oxalic acid, 0.1-1 g / L of boric acid, 1-5 g / L of nickel sulfate, 0.1-1 g / L of ammonium sulfate; the process parameters adopted in the chemical oxidation steps are that: current strength of 0.5-1 A / dm2 of, temperature of 40-55 DEG C, time of 40-50 min, and voltage of 20-40 V. The invention is applicable to aluminium magnesium alloy; the obtained film is silver gray; the film thickness is 5-15 microns; the film has good binding force, high hardness and wear resistance, and good thermal insulation, electrical insulation, and corrosion resistance.

Owner:WUJIANG SHI FINE WORKMANSHIP & ALUMINUM WORD MANUFACTORY

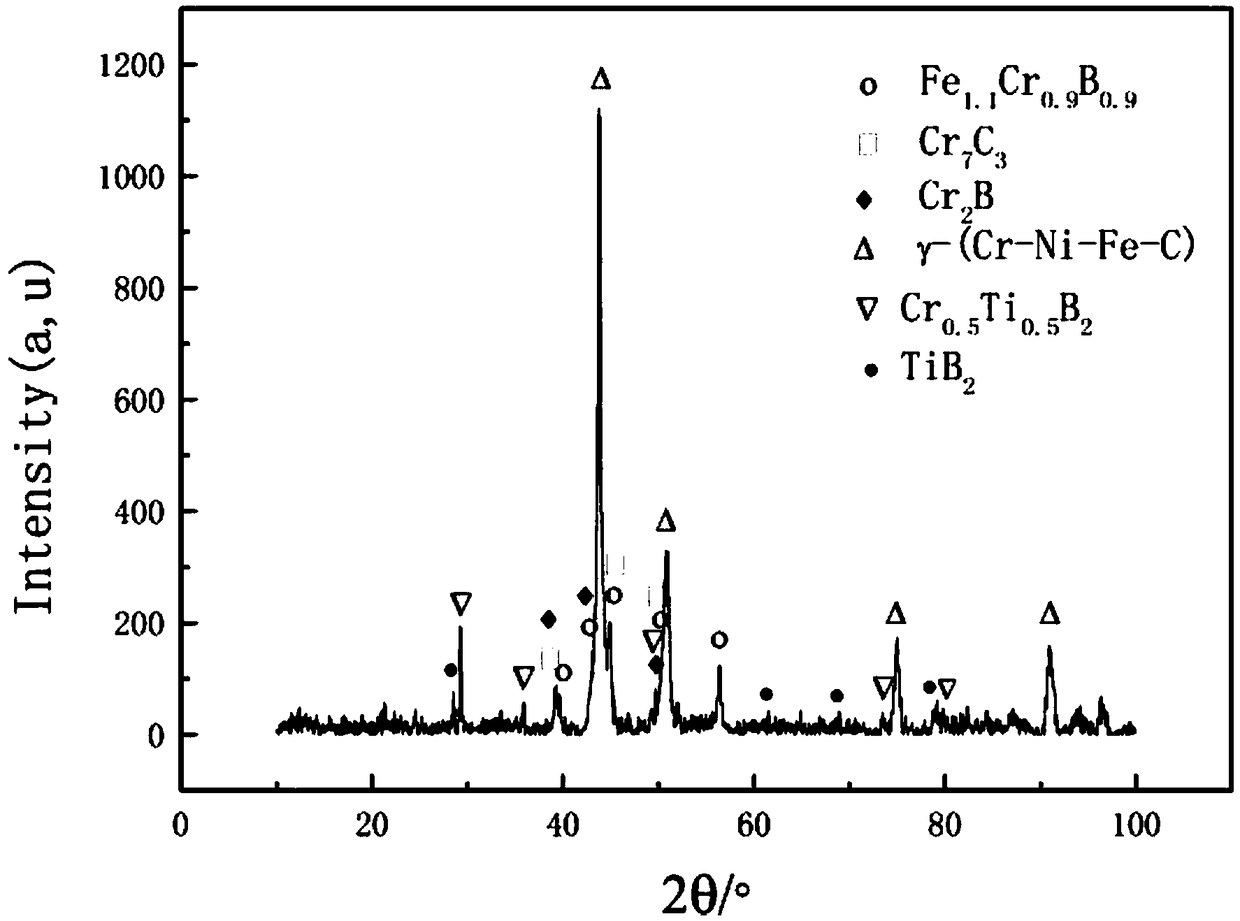

Ternary boride reinforced iron-based wear resistance coating and preparation method thereof

ActiveCN109023345AImprove hardness and wear resistanceThe preparation method is simple and easyMetallic material coating processesSurface finishingIron based alloy

The invention discloses a ternary boride reinforced iron-based wear resistance coating and a preparation method thereof, belongs to the field of metal material coating, and aims to provide the ternaryboride reinforced iron-based wear resistance coating with simple preparation, high coating wear resistance and low cost and the preparation method thereof. The ternary boride reinforced iron-based wear resistance coating is composed of raw materials of ternary boride powder and self-melting powder of iron-based alloy, or self-melting powder of nickel-based alloy, and a high wear resistant iron-based coating is prepared on the surface of a matrix material by an induction cladding process. The preparation method includes the following steps of preparation of the ternary boride powder, surface treatment of steel matrix Q235, preparation of induction cladding pre-coating, and heating by induction cladding equipment. The ternary boride reinforced iron-based wear resistance coating has high hardness and wear resistance, and can be applied to shovel teeth of excavators, lining boards of ball mills, scraper conveyors for coal mines, bearings and other places requiring wear resistance.

Owner:天津德天助非晶纳米科技有限公司

High-strength and high-toughness ceramic composite material and application thereof to manufacturing of cutter

The invention discloses a high-strength and high-toughness ceramic composite material and an application thereof to manufacturing of a cutter. The ceramic composite material is prepared from the following raw materials in parts by weight: 55 to 65 parts of zirconia, 20 to 30 parts of alumina, 6 to 8 parts of ceria, 4 to 6 parts of lanthana, 3 to 5 parts of borax, 1 to 3 parts of borazon, 2 to 4 parts of zinc dialkyl dithiophosphate, 0.6 to 0.8 part of sodium alginate, 0.4 to 0.6 part of sodium lignin sulfonate, 0.8 to 1.2 parts of sodium hexametaphosphate, 1 to 3 parts of polyethylene glycol and 7 to 9 parts of deionized water. The ceramic composite material provided by the invention has high hardness and wear resistance, is suitable for preparing the ceramic cutter and is difficult to age and break when being used for cutting high-hardness materials; the preparation process of the ceramic composite material is simple and feasible.

Owner:东莞市琦康电子有限公司

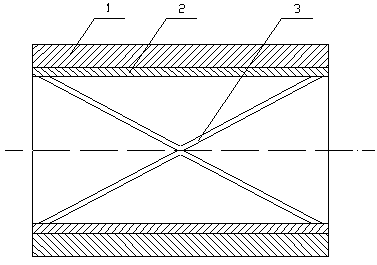

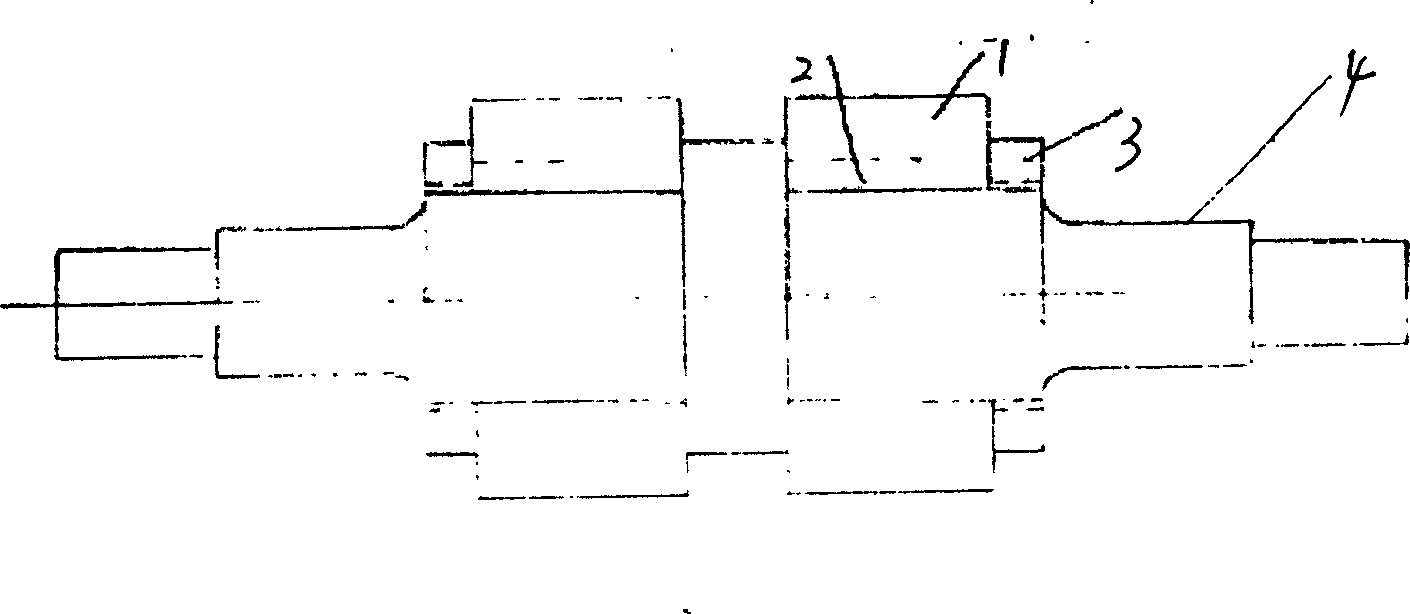

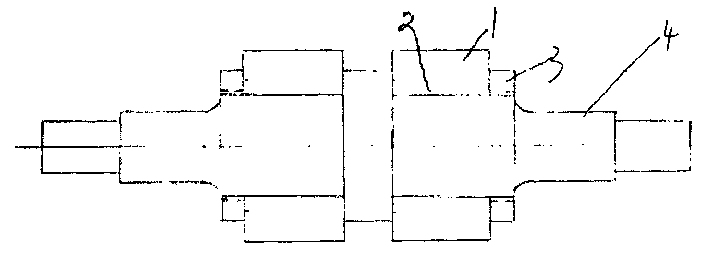

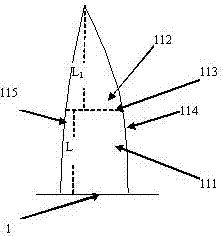

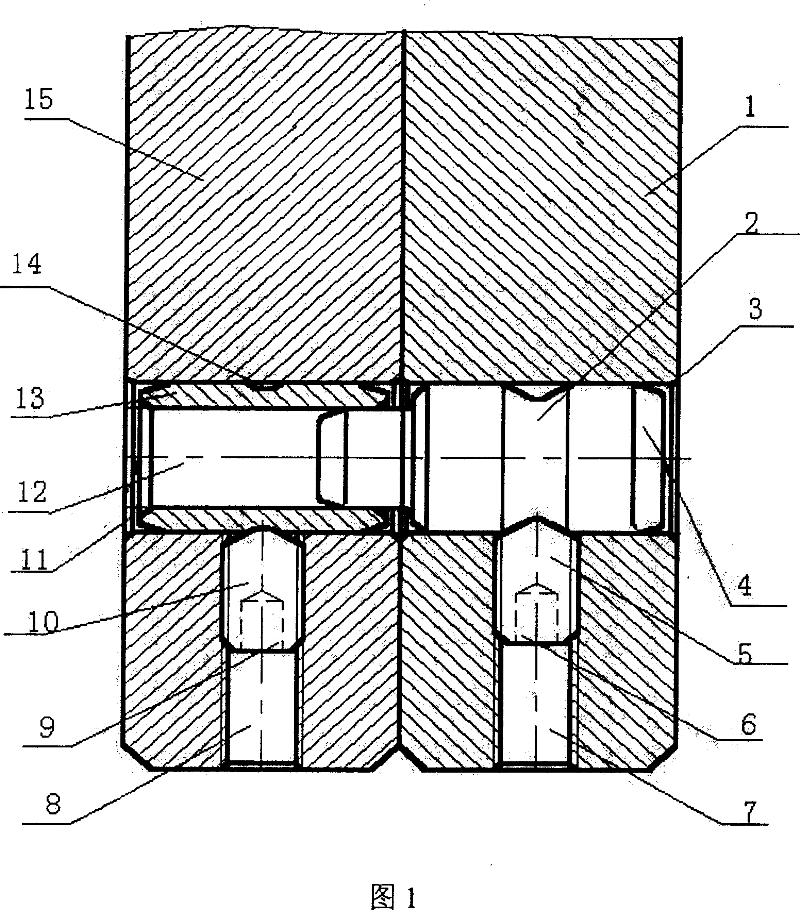

Method of locating the head of the plastic extruding forming mould and the mould head

InactiveCN101037018AImprove hardness and wear resistanceReduce positioning accuracy dropEngineeringMechanical engineering

The invention relates to a die head positioning method and die head on a plastic extrusion molding die. A locating pin (4) and locating pin sleeve (13) assorted with location holes (3,11) are respectively embeded into the location holes (3,11) correponding to adjacent two plates (1,15). The two plates (1,15) are located by one end of locating pin (4)embedding into locating pin sleeve(13). Multiple plates are located together to form die head. The plate location accuracy of the said die head is high, and the cost is low, and the reliability is high.

Owner:TONGLING TRINITY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com