Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Improve temper resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate with great heat and abrasion resistance and manufacturing method thereof

ActiveCN103205650AExcellent mechanical properties and wear resistanceImprove hardness and wear resistanceQuenchingSteel plates

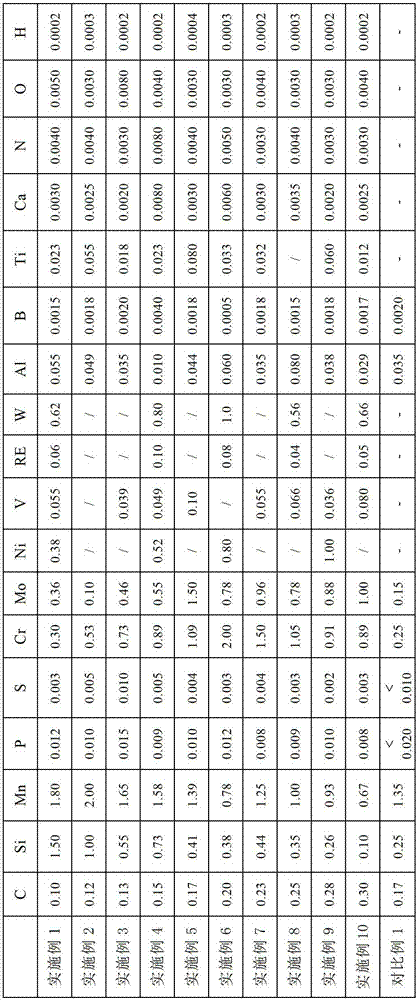

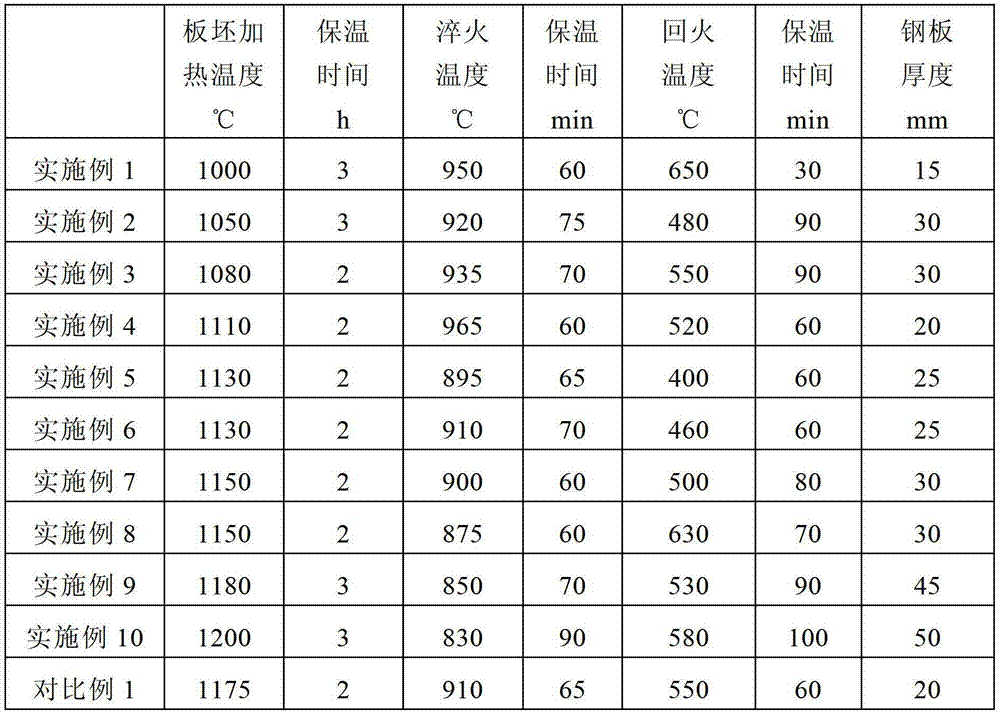

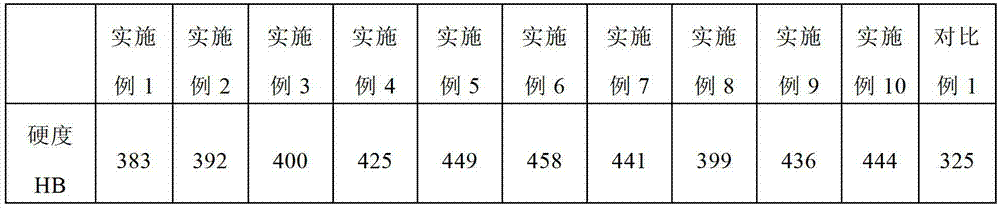

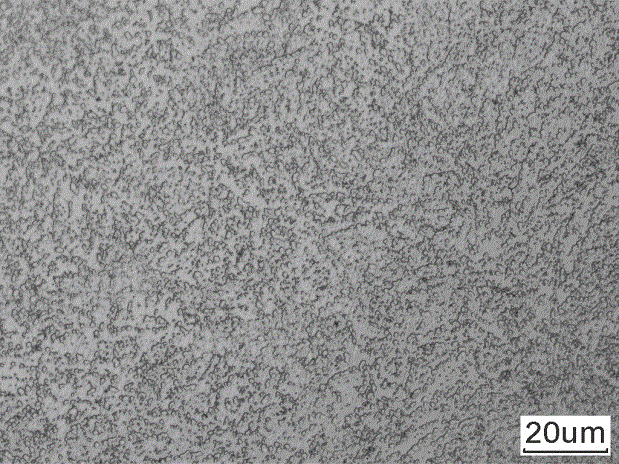

The present invention provides a steel plate with great heat and abrasion resistance and a manufacturing method thereof. The steel plate comprises the following chemical composites, in percentage by weight: 0.10-0.30% of C, 0.10-1.50% of Si, 0.50-2.00% of Mn, 0-0.015% of P, 0-0.010% of S, 0.2-2.00% of Cr, 0.10-1.50% of Mo, 0-1.00% of Ni, 0-0.10% of V, 0-0.10% of RE, 0-1.00% of W, 0.010-0.080% of Al, 0.0005 -0.0040% of B, 0-0.080% of Ti, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0004% of H and the balance being Fe and inevitable impurities. The mechanical properties of the steel plate are that the Brinell hardness is greater than 360HB, and the 500 DEG C tensile strength is more than 1000MPa. The steel plate obtained by the various components through processes such as quenching and tempering has excellent mechanical properties and abrasion resistance, and is particularly suitable for various mechanical parts which are easy to wear while working under high temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

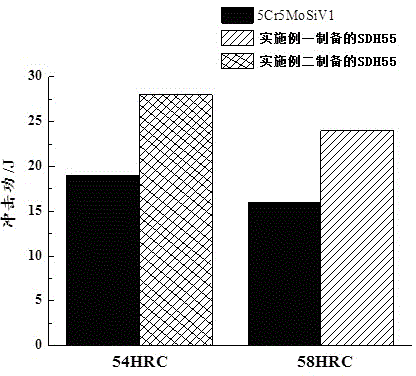

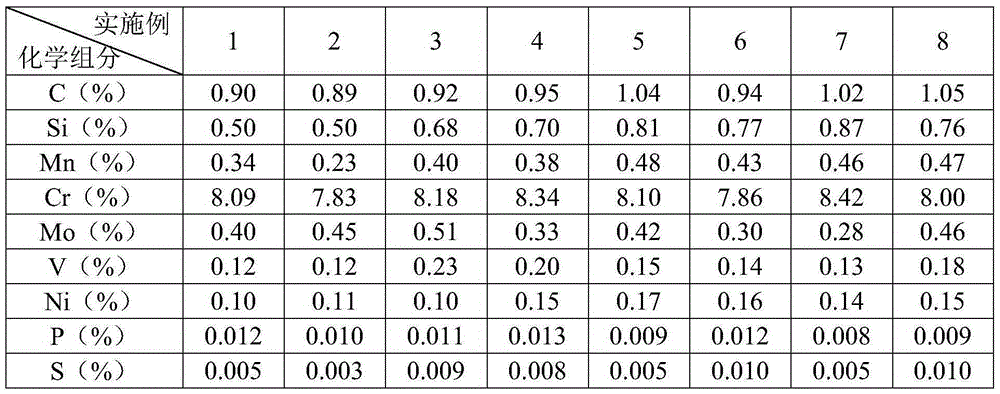

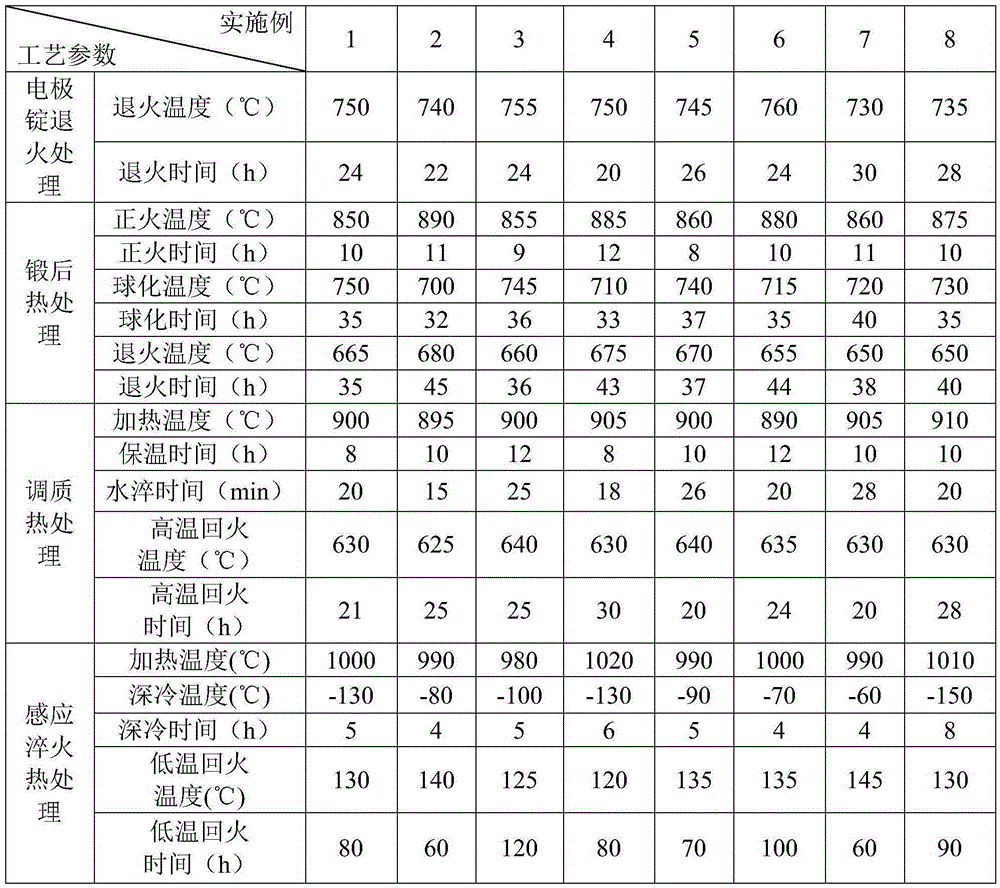

Alloy steel SDH55 for shield machine tools and production method thereof

The invention discloses alloy steel SDH55 for shield machine tools and a production method thereof. The alloy steel comprises, by weight, 0.4% to 0.55% of C, 0.10% to 0.40% of Si, 0.10% to 0.30% of Mn, 5.10% to 6.50% of Cr, 2.20% to 3.00% of Mo, 0.45% to 0.85% of V, the balance of Fe and unavoidable impurity elements, including not greater than 0.005% of S and not greater than 0.010% of P. The alloy steel high in wear resistance and high in toughness is made by means of matching, smelting, casting and electroslag remelting, by thermal feeding for high-temperature homogenous treatment after demolding, and by means of multidirectional forging, soft annealing and ultra-fining treatment; the problem that the current tools for shield machines are of short lives due to wear and failure and edges cracking caused by low toughness is solved; the alloy steel is of great significance to the development of the industry of special steels of shield machine tools.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

High-wear-resisting cold roll and manufacturing method thereof

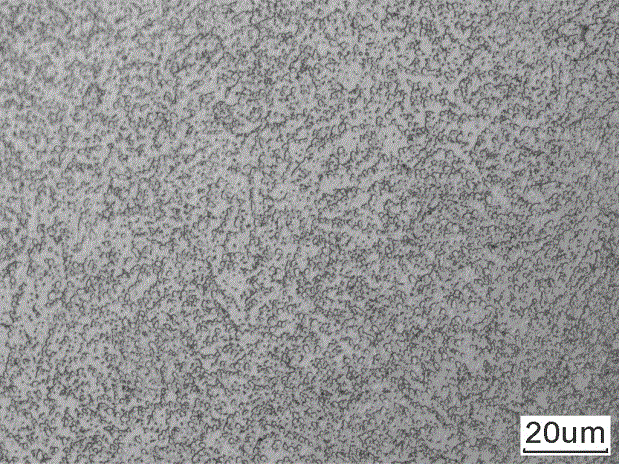

ActiveCN105385959AManufacturing Process Step ImprovementsImprove purityMetallurgyHigh wear resistance

The invention relates to a high-wear-resisting cold roll. Chemical components in the cold roll comprise, by weight percentage, 0.80%-1.20% of C, 0.4%-1.20% of Si, 0.20%-0.50% of Mn, 7.50%-9.00% of Cr, 0.20%-1.00% of Mo, 0.05%-0.50% of V, less than or equal to 0.40% of Ni, less than or equal to 0.015% of S, less than or equal to 0.015% of P and the balance Fe and inevitable impurities. The high-wear-resisting cold roll has the high wear resistance; and under the same using condition, the service life of the roll is prolonged by more than one time than a roll made of original common chrome steel system materials.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Carbides-free bainite wear resistant steel plate and production process thereof

ActiveCN101338399AImprove hardenabilityHigh strengthTemperature control deviceProduction lineWear resistant

The invention relates to a steel and a production technique thereof, in particular to a non-carbide bainite wear-resistant steel plate and a production technique thereof; the component weight percentages are: 0.15 to 0.25 percent of C, 1.50 to 2.00 percent of Mn, 0 to 0.015 percent of P, 0 to 0.006 percent of S, 1.30 to 2.00 percent of Si, 0.20 to 0.60 percent of Al, 0.60 to 1.00 percent of Cr, 0.25 to 0.50 percent of Mo, 0.010 to 0.035 percent of Nb and the rest is Fe. The production technique is carried out according to the following working procedures: (1) feeding a continuous casting plate to a heating furnace for heating; (2) feeding the continuous casting plate after being heated into a hot rolling production line to carry out the rolling of controlled rolling and controlled cooling; (3) carrying out middle-low temperature drawing temper on a rolling steel plate after the rolling is finished. The non-carbide bainite wear-resistant steel plate can be produced by the working procedures without carrying out online or offline hardening and tempering thermal processing which not only can simplify the working procedures of production, but also can improve the performance and the quality of a product as well as obtain the bainite wear-resistant steel with high intensity and high toughness.

Owner:NANJING IRON & STEEL CO LTD

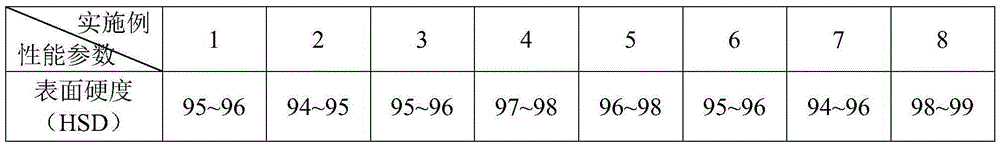

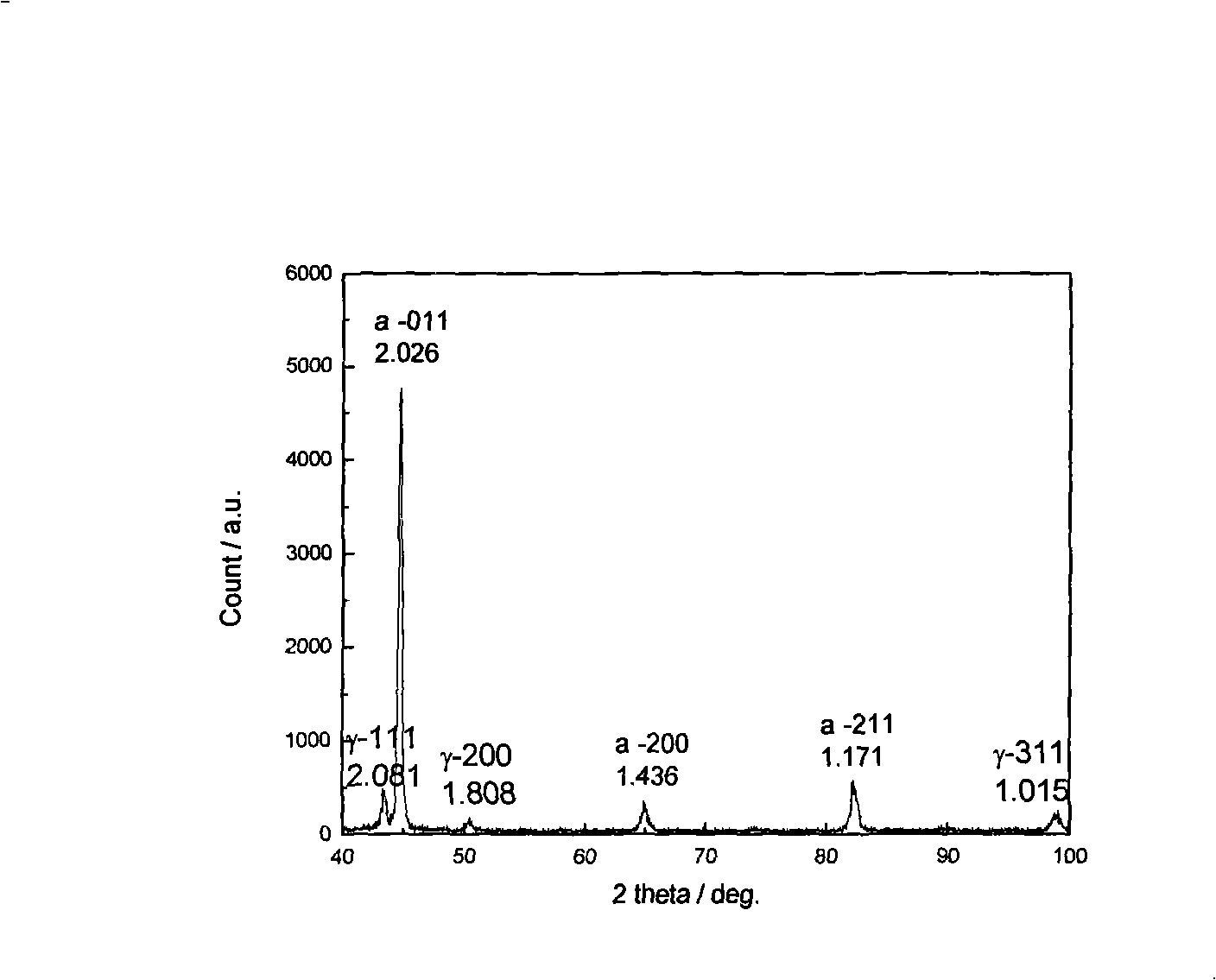

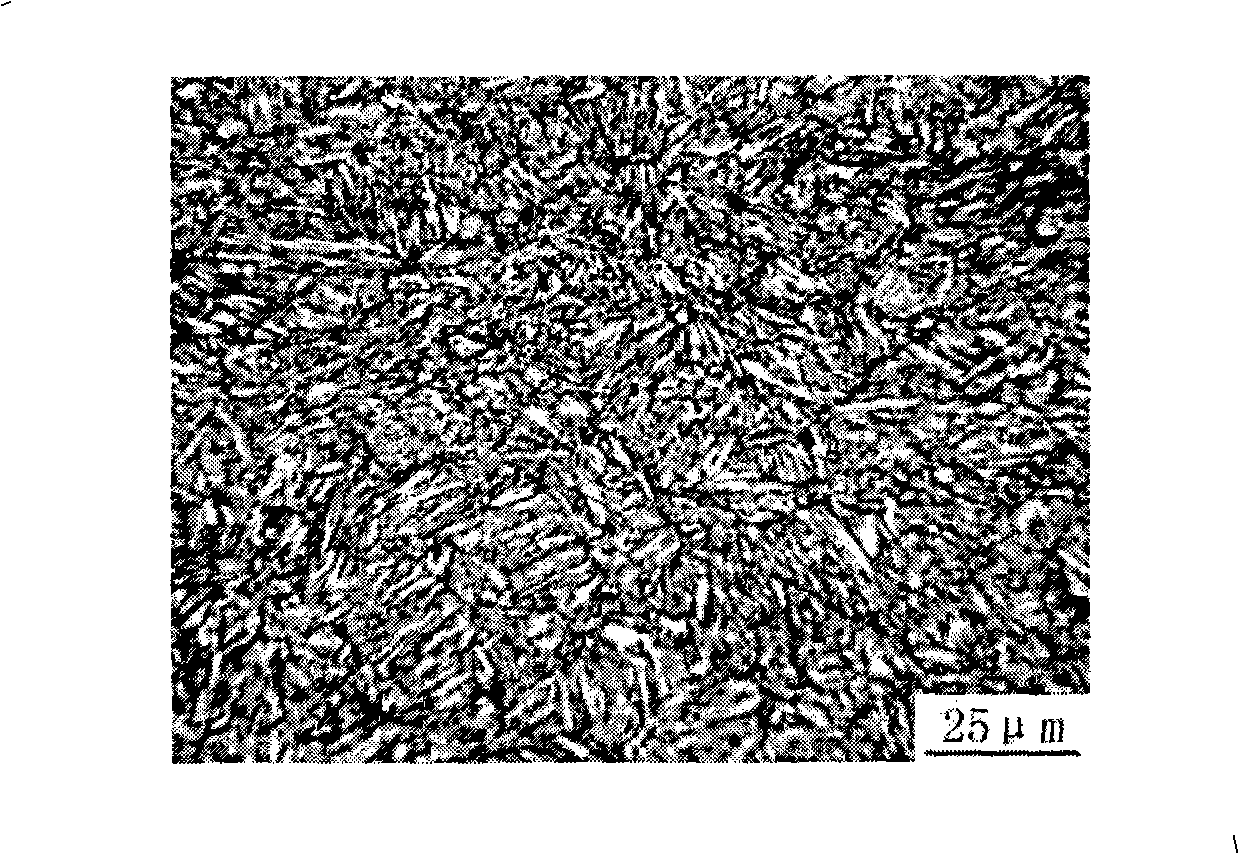

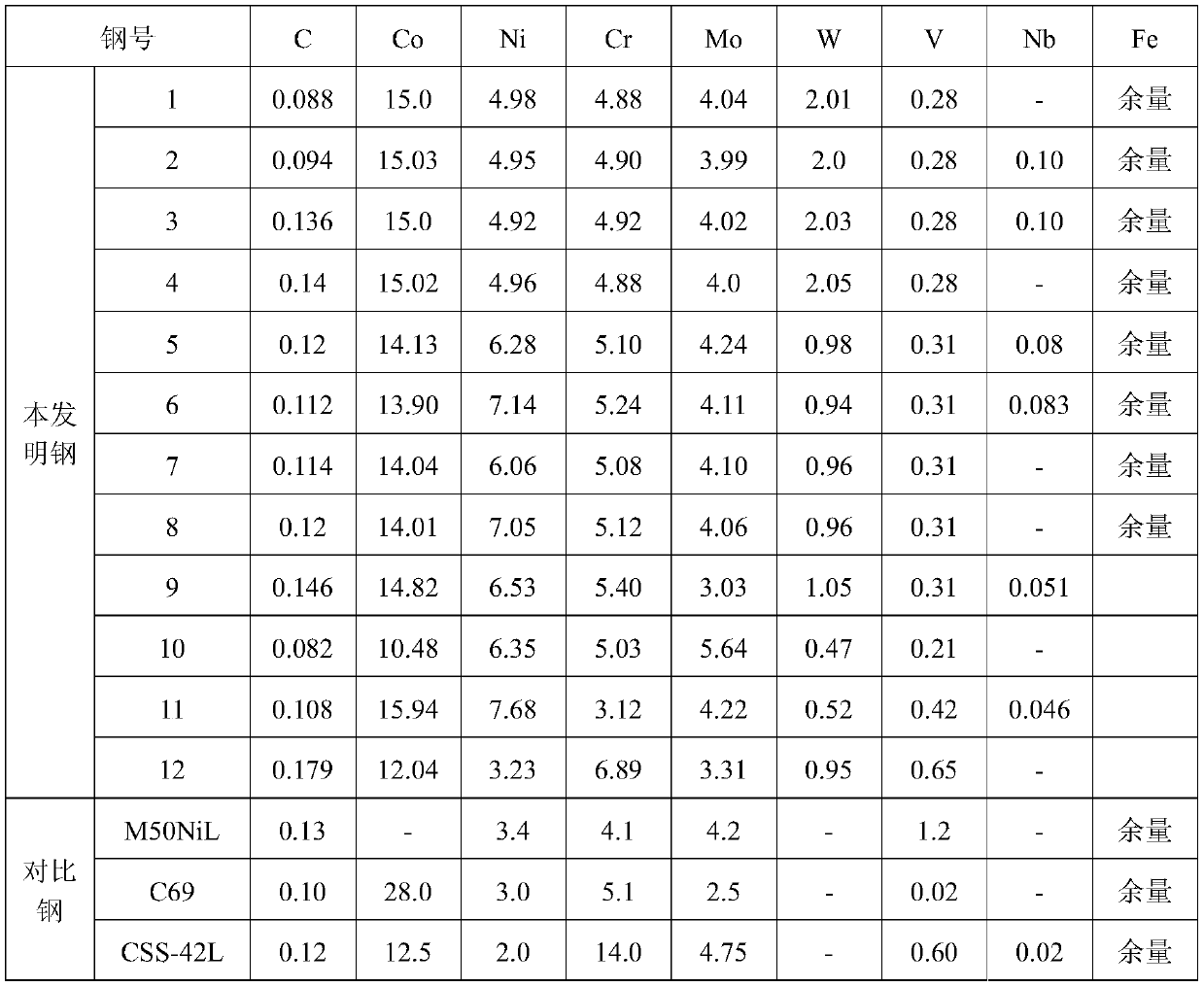

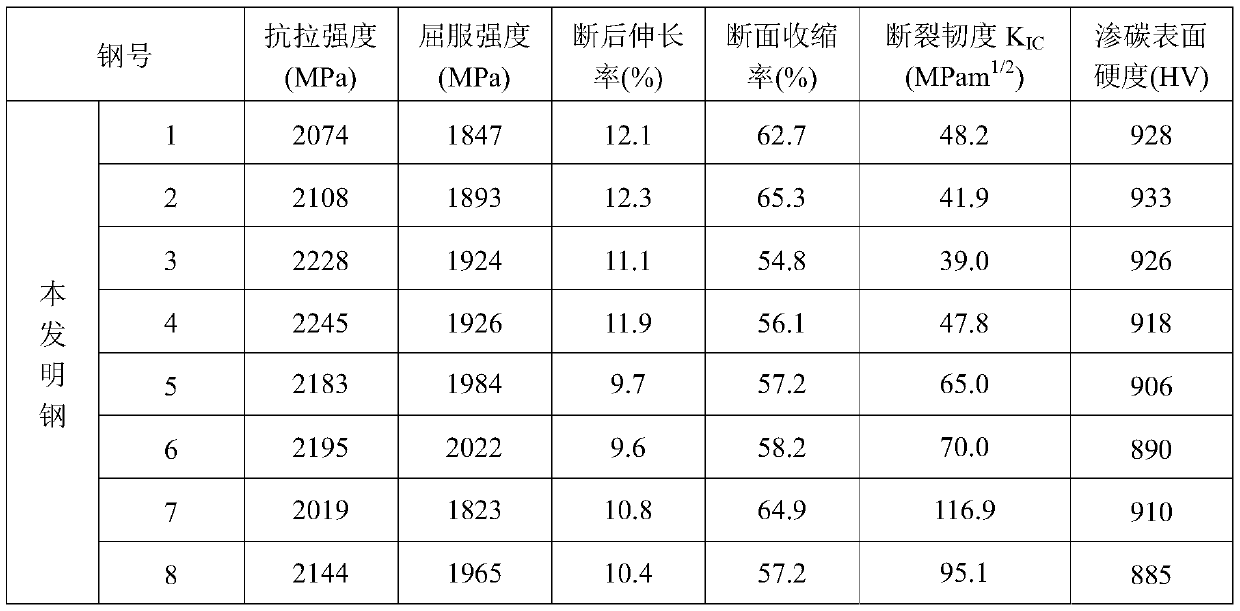

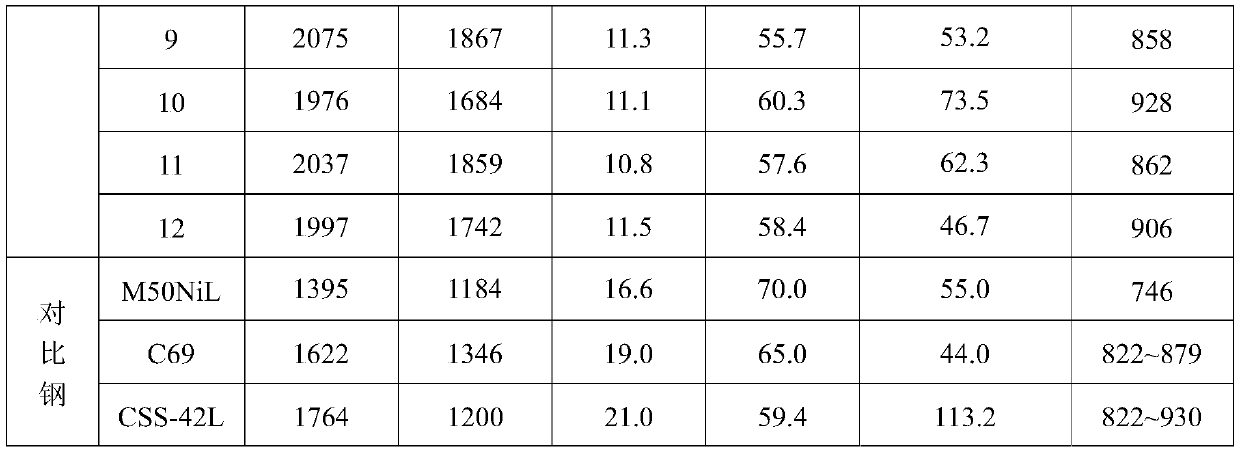

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Large alloy steel forge piece water cooling quenching tempering technology

InactiveCN110904312AGrain refinementImprove organizationQuenching devicesTemperingPollutant emissions

The invention belongs to the technical field of forge piece machining, and particularly relates to a large alloy steel forge piece water cooling quenching tempering technology. The provided large alloy steel forge piece water cooling quenching tempering technology comprises the following steps including discharging, forging, heat treatment after forging, rough turning, ultrasonic detection, watercooling quenching tempering, sampling detection, finish turning and final checking. A specific control scheme is provided for water cooling quenching of medium-low-carbon alloy steel, medium-high-carbon alloy steel and tool and mould steel forge pieces, the water cooling quenching crack risk is greatly reduced, and pollutant emission in the quenching process is reduced. Meanwhile, the mechanical performance of a forge piece body completely meets the technical requirement. Particularly, for the same product with the through quenching layer depth requirement, high-cooling-rate water is adopted for quenching cooling, a deeper through quenching layer can be obtained compared with adoption of organic quenching liquid and quenching oil for cooling, and accordingly tempering resistance and comprehensive mechanical performance of the forge piece are improved.

Owner:SHANDONG IRAETA HEAVY IND

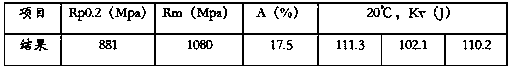

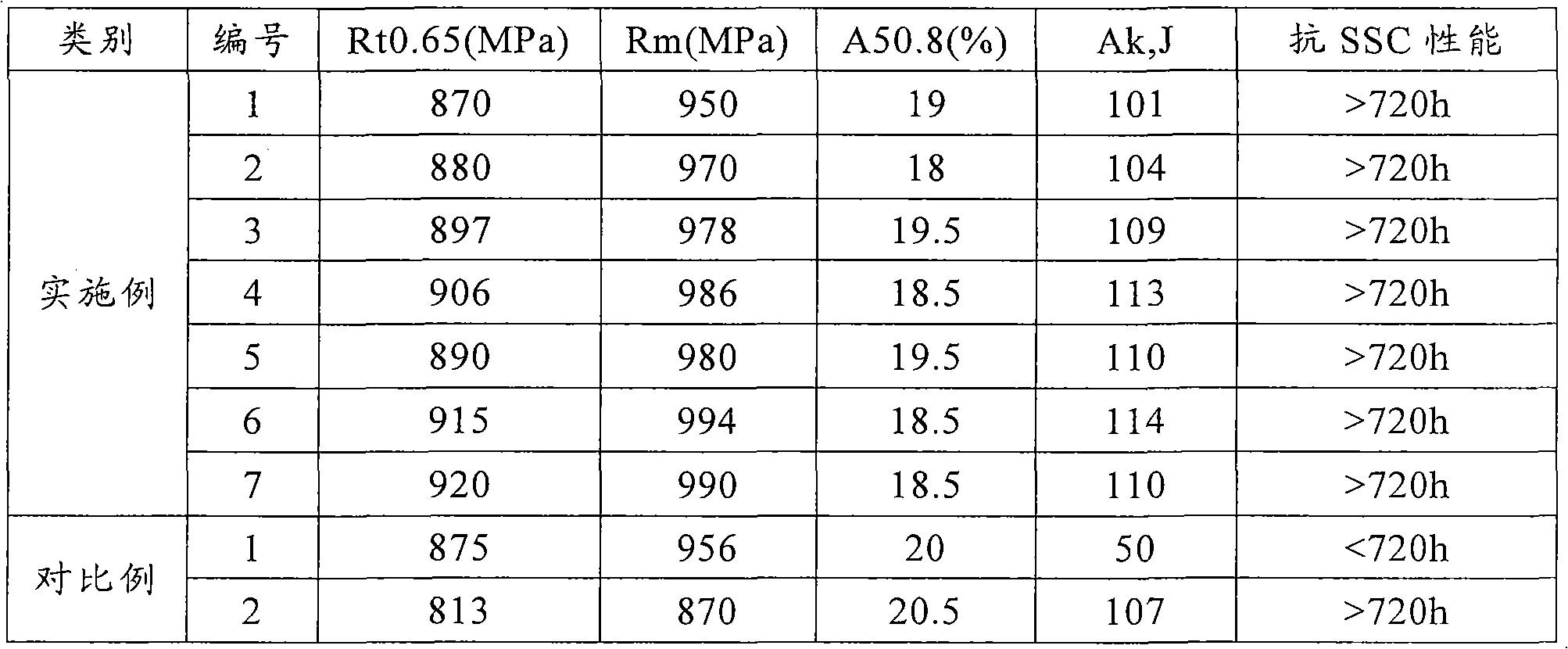

High-strength hydrogen-sulfide environmental corrosion-resistant seamless petroleum casing pipe and manufacturing method thereof

InactiveCN101929313AImprove hardenabilityImprove temper resistanceDrilling rodsDrilling casingsWell drillingHigh intensity

The invention discloses a high-strength hydrogen-sulfide environmental corrosion-resistant seamless petroleum casing pipe which conforms to a 125ksi steel grade and comprises the following components in mass percentage: 0.25-0.35 percent of C, 0.1-0.5 percent of Si, 0.4-1.0 percent of Mn, 0.1-2.0 percent of Cr, 0.2-2.0 percent of Mo, 0.03-0.3 percent of V, 0.01-0.3 percent of Nb, less than 0.015 percent of P, less than 0.010 percent of S and the balance of Fe and inevitable impurities. The seamless petroleum casing pipe can be widely applied to sulfur-contained deep-well and ultradeep-well drilling and mining operations and has quite broad application prospect. The invention also discloses a manufacturing method of the seamless petroleum casing pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

Heat treatment process for surface hardening and carbonitriding of hydraulic parts

ActiveCN102534465AReasonable heating distributionReasonable heating distribution makes hydraulic parts heated reasonablySolid state diffusion coatingCarbon potentialNitrogen

The invention provides a heat treatment process for surface hardening and carbonitriding of hydraulic parts, which includes the following steps: a washing the hydraulic parts preparing for heat treatment to remove greasy dirt; b warming a carburizing multi-purpose furnace, and performing pre-carburizing treatment; c putting the hydraulic parts washed cleanly through the step a in the carburizing multi-purpose furnace, and performing strong carburizing; d adjusting carbon potential after the strong carburizing to perform diffusion; e putting the hydraulic parts after carbonitriding in the stepd in a quenching chamber of the carburizing multi-purpose furnace to be quenched, filtering oil and discharging from the furnace; and f washing the hydraulic parts of the step e, and putting the hydraulic parts in a tempering furnace to be tempered to obtain products.

Owner:SHANDONG CHANGLIN MACHINERY GRP

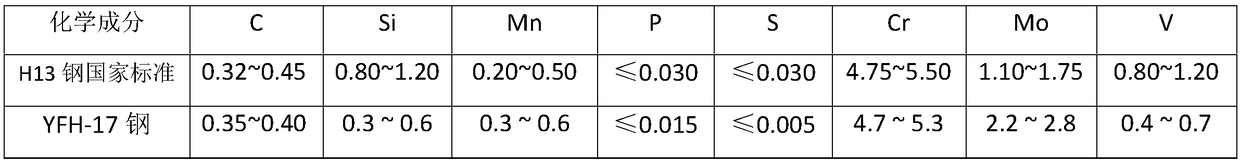

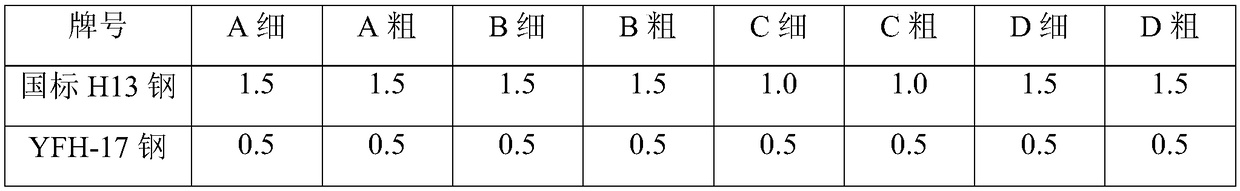

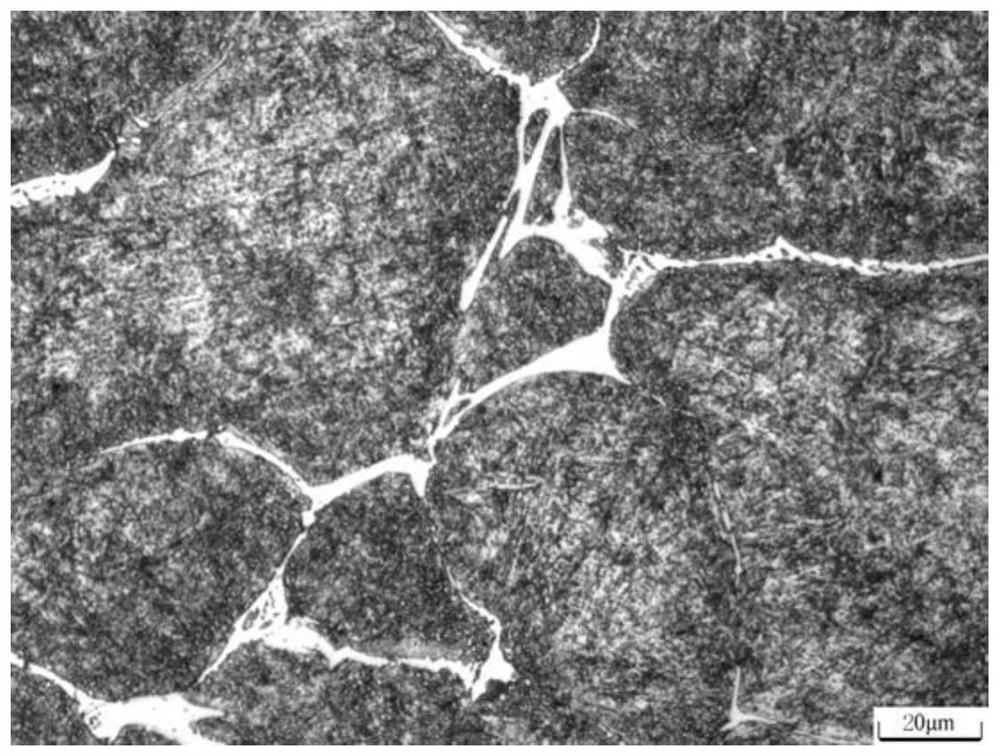

Optimization method and processing step of high-end hot work die steel

InactiveCN108265232AImprove thermal fatigue resistanceGood thermal strength and toughnessHot workCorrosion

The invention provides an optimization method and a processing step of high-end hot work die steel. On the basis of national standard die steel H13, an optimized raw material formula, an optimized melting process and an optimized heat treatment process are adopted, and the high stability of the H13 is combined, so that heat fatigue resistance and tempering resistance are further improved, better hot strength and toughness are realized, and the service life of a die is remarkably improved. The optimization method and the processing step of the high-end hot work die steel have the following characteristics and advantages of (1) high purity and prolonged fatigue life of the die; (2) high isotropy and excellent shock cracking resistance; (3) excellent toughness and excellent wear resistance; (4) excellent hardenability and dimension stability during high-temperature heat treatment; and (5) excellent hot flush corrosion resistance and excellent hot fracturing resistance.

Owner:浙江嵊州元丰模具有限公司

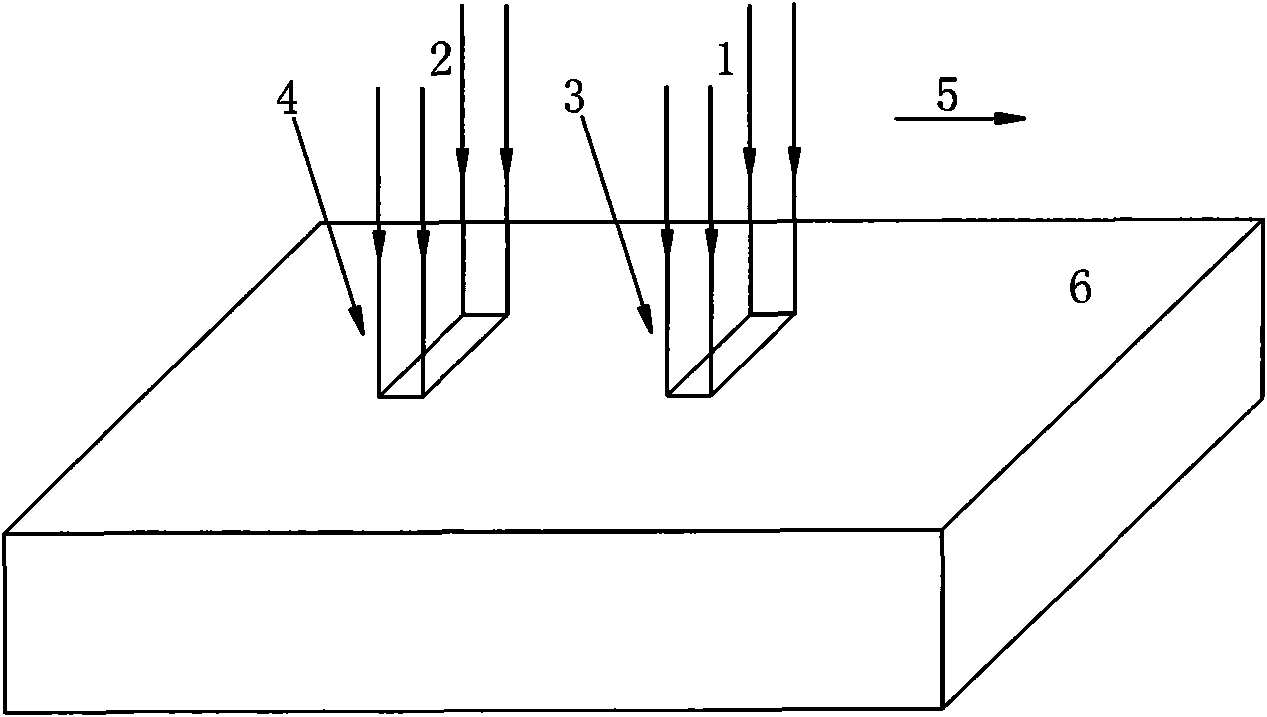

Surface composite strengthening technology for precipitation hardening stainless steel and precipitation hardening stainless steel material

The invention discloses a surface composite strengthening technology for precipitation hardening stainless steel and a precipitation hardening stainless steel material processed by the technology. In the technology, two laser beams are utilized to carry out controllable selection deep-layer solid solution and alloying composite strengthening treatment on a substrate synchronously, thus solving the problem existing when two techniques of solid solution and alloying are synchronously composited, and the invention also provides a laser treatment method which not only has high local fatigue resistance and high solid solution strengthening depth but also obtains higher surface hardness, wear resistance and anti-cavitation performance, so that the overall strengthening layer depth, performance and hardening gradient of the material at a processing area are controlled, and the application range of the precipitation stainless steel is enlarged.

Owner:姚建华

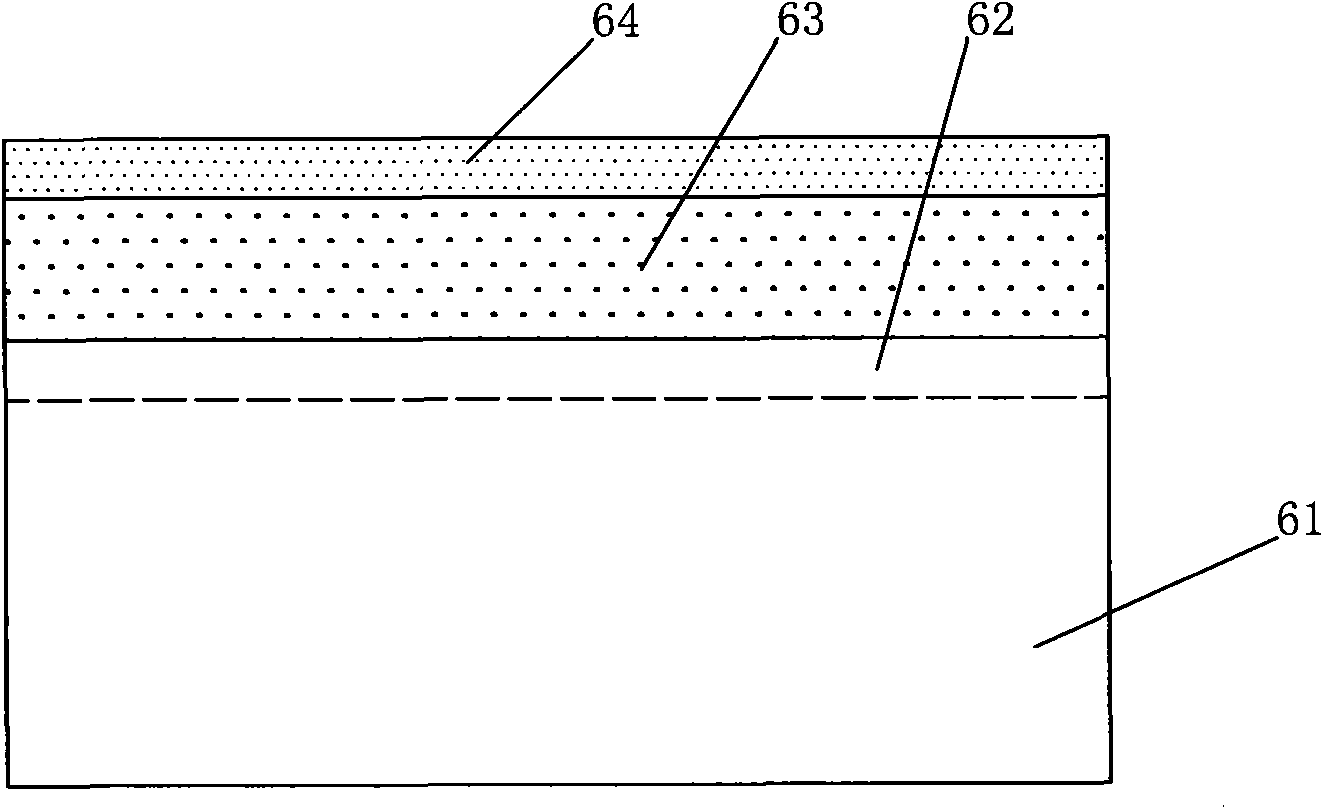

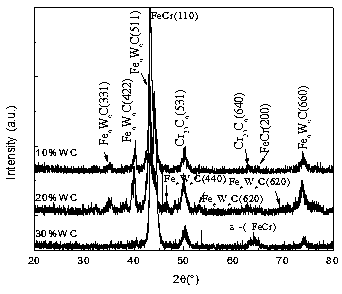

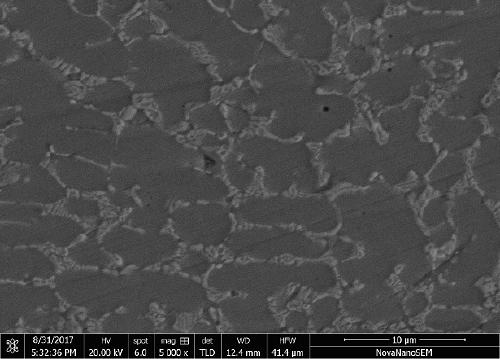

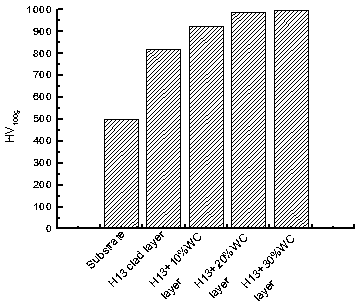

Micro-nano particle reinforced wear-resistant corrosion-resistant laser cladding layer and preparation method thereof

InactiveCN110438487AImprove appearance qualityQuality improvementMetallic material coating processesMicro nanoWear resistant

The invention discloses a micro-nano particle reinforced wear-resistant corrosion-resistant laser cladding layer and a preparation method thereof. The micro-nano particle reinforced wear-resistant corrosion-resistant laser cladding layer is prepared from Fe-based metal powder and WC particles added into the Fe-based metal powder, wherein the particle size of the iron-based metal powder and the particle size of the Fe-based metal powder are consistent, the mass percent of the WC particles added into the Fe-based metal powder is 10-30%, and the Fe-based metal powder is prepared from C, Fe, Cr, Si, Mn, Mo and V. The prepared micro-nano particle reinforced wear-resistant corrosion-resistant laser cladding layer has the advantages of being high in hardness, excellent in sliding friction wear resistance, impact abrasive wear resistance and salt fog corrosion resistance and capable of effectively prolonging the service life of components in electric power, petrochemical engineering and machinery industries, and in addition, the preparation method is simple.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Aluminum-containing hot extrusion mold steel and production method thereof

InactiveCN108531821ALow costImprove wear resistanceSolid state diffusion coatingIncreasing energy efficiencyWear resistantAlloy

The invention relates to aluminum-containing hot extrusion mold steel and a production method thereof. According to the hot extrusion mold steel, the content of C is increased on the basis of H13 steel, the contents of Si, Cr and Mo are decreased, the total content of the alloy is about 2.5-3.5% less than that of H13, and the hot extrusion mold steel comprises the following main alloying elementsin percentage by mass: 0.45-0.60% of C, less than or equal to 0.30% of Si, less than or equal to 0.30% of Mn, 3.00-4.50% of Cr, 0.30-0.80% of Mo, 0.30-0.60% of V, 0.50-0.90% of Al, less than 0.015% ofP, less than 0.015% of S and the balance of Fe. High tempering resistance is obtained by balancing the Cr and Mo, and Al is added into the matrix so as to form an AlN highly wear-resistant strengthening phase by virtue of surface nitriding treatment. The preparation method of the steel in the invention comprises the following steps: compounding, smelting, casting, performing electro-slag remelting and annealing; performing high-temperature homogenized heat treatment, multi-directional forging and annealing; performing superfine heat treatment and isothermal annealing treatment; finally performing quenching and tempering treatment. The hot extrusion mold steel disclosed by the invention has the advantages of high wear resistance, excellent tempering resistance and the like under the conditions that the steel cost is low and toughness is equivalent to that of the H13 steel.

Owner:NINGBO HELI TECH CO LTD +1

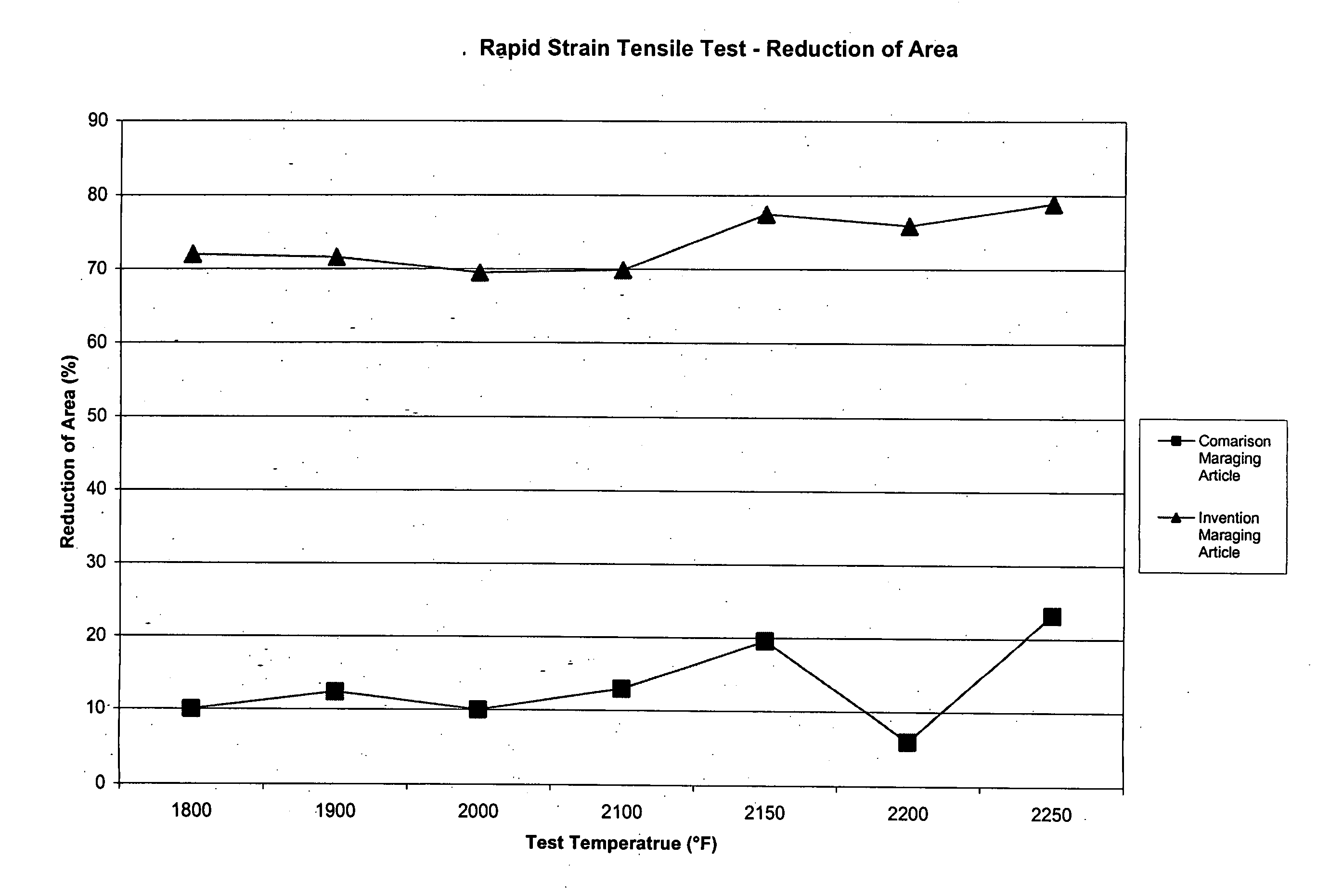

Maraging steel article and method of manufacture

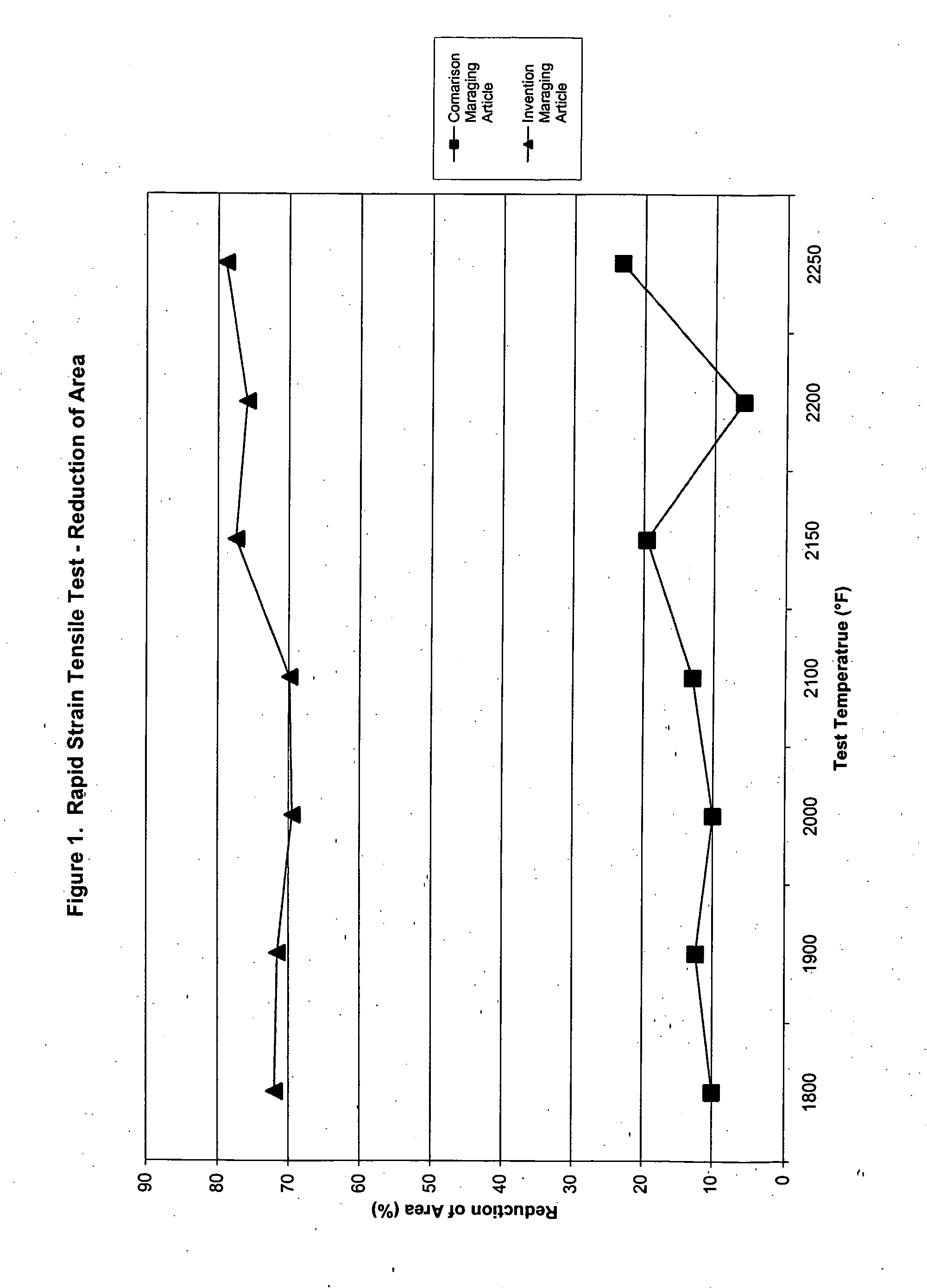

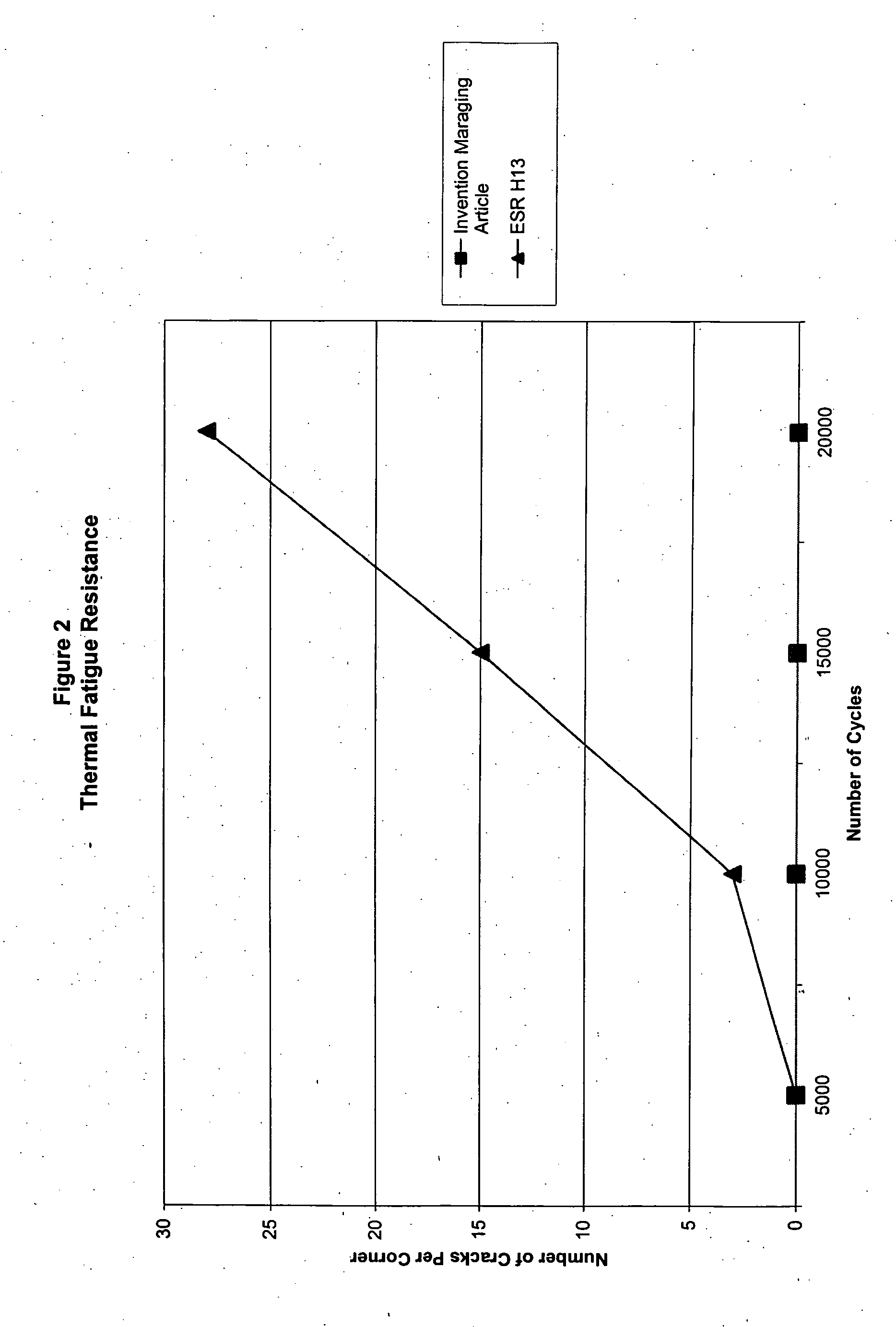

InactiveUS20070053784A1Lower solubilityImprove temper resistanceFoundry mouldsFoundry coresPowder metallurgyMaraging steel

A fully dense, powder-metallurgy produced maraging steel alloy article of prealloyed powder for use as a tool for high temperature applications. The article in the as-produced condition having a hardness less than 40 HRC to provide machinability and thereafter the article upon maraging heat treatment having a hardness greater than 45 HRC. A method for producing this article comprises compacting prealloyed powder to produce a fully dense article having a hardness less than 40 HRC and thereafter maraging heat treating to a hardness greater than 45 HRC.

Owner:ATI POWDER METALS +1

Preparation method of rolling bearing

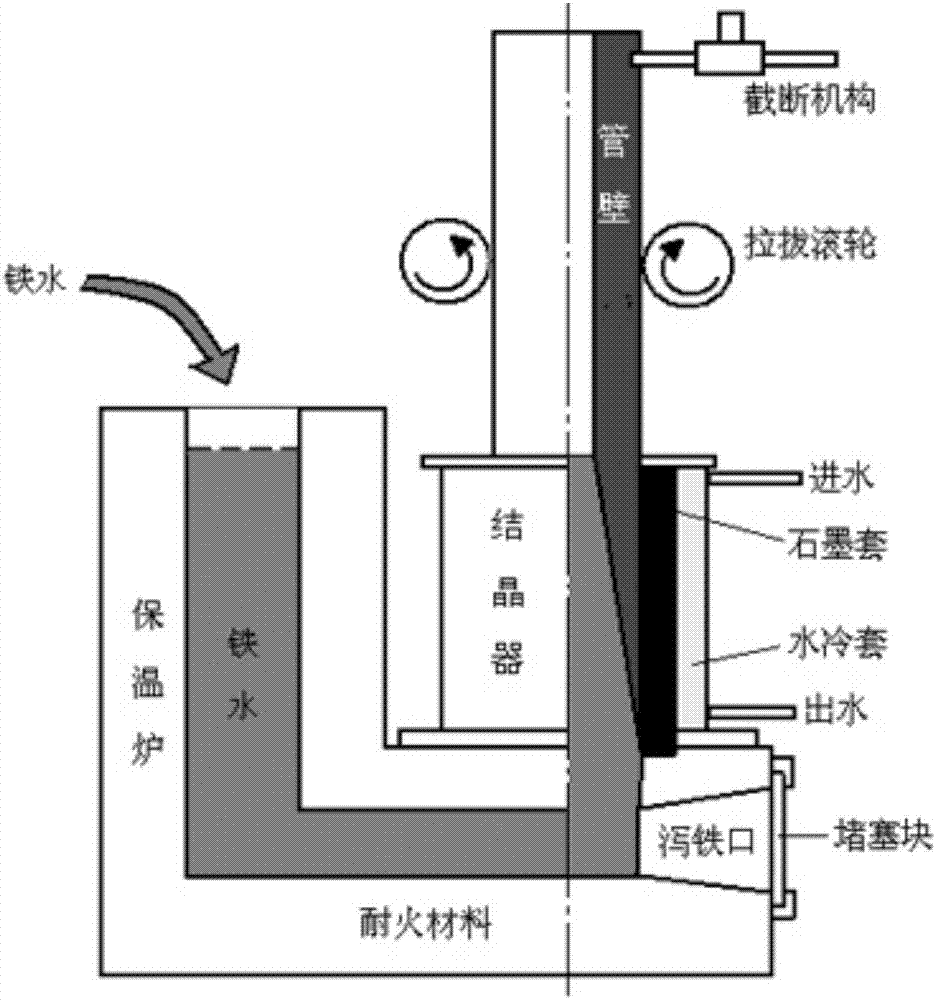

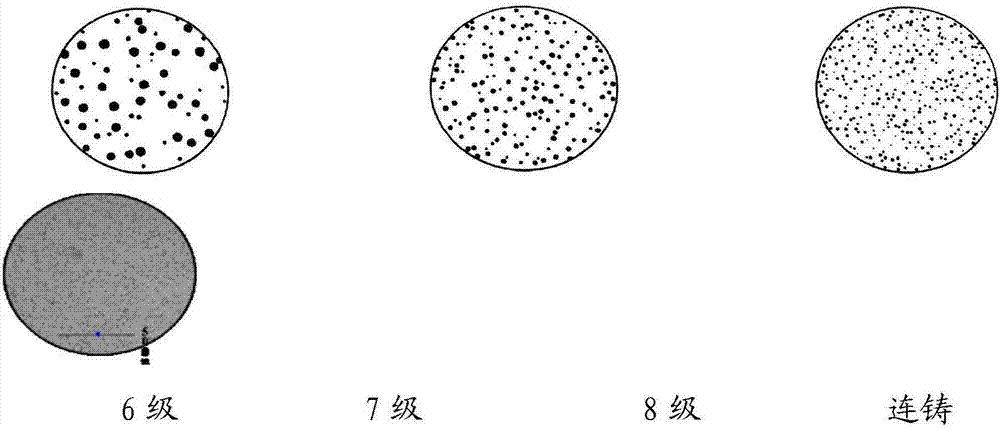

InactiveCN107504072AAvoid point contact fatigue damageImprove roundnessShaftsBearing componentsCast iron pipeWorking temperature

The invention provides a preparation method of a rolling bearing. Inner and outer rings and a retainer of the rolling bearing are made of a nodular cast iron material instead of bearing steel. A new casting method is provided for preparing nodular cast iron pipe blanks for the rolling bearing. Great change is made for material selection, the hot processing technology and hardness of the inner and outer rings and the retainer of the rolling bearing so as to combine the advantages of the rolling bearing and a self-lubricating sliding bearing. The self-lubricating sliding bearing which can operate under the working conditions of low rotational speed, high working temperature, not frequent injection of lubricating grease and frequent impact is provided for the metallurgical machinery and other equipment manufacturing fields.

Owner:张天贵

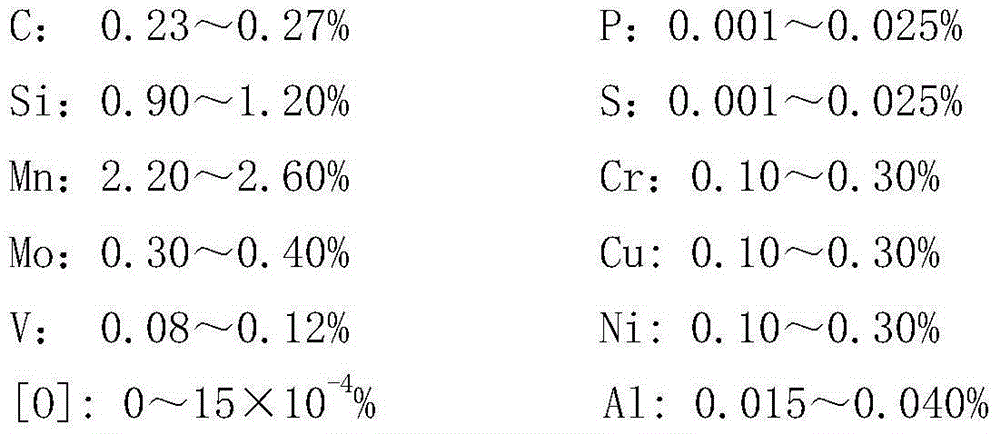

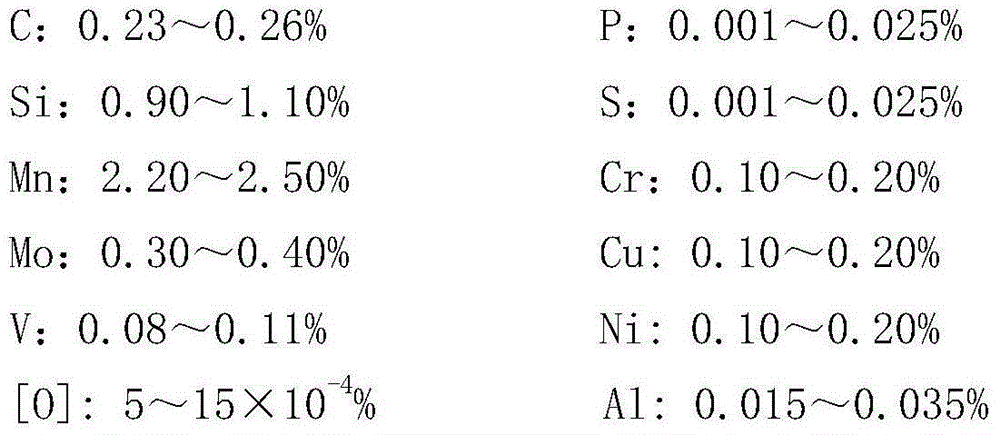

High-strength high-toughness wear-resisting steel for excavator bucket teeth and manufacturing method thereof

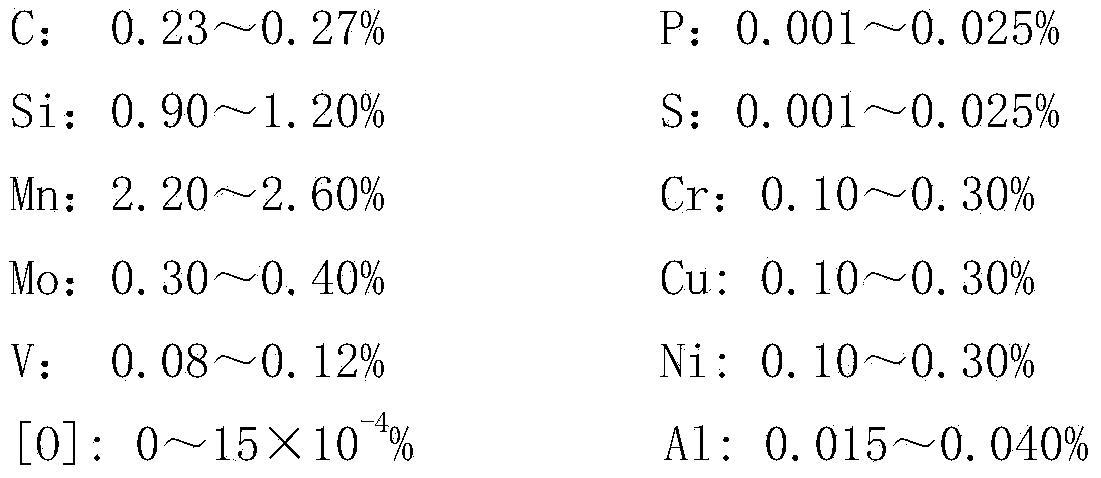

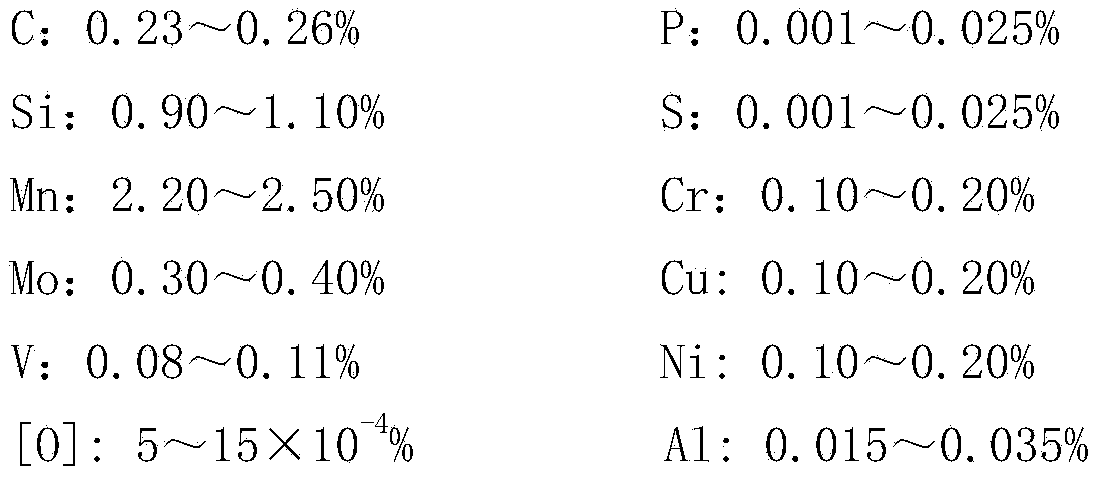

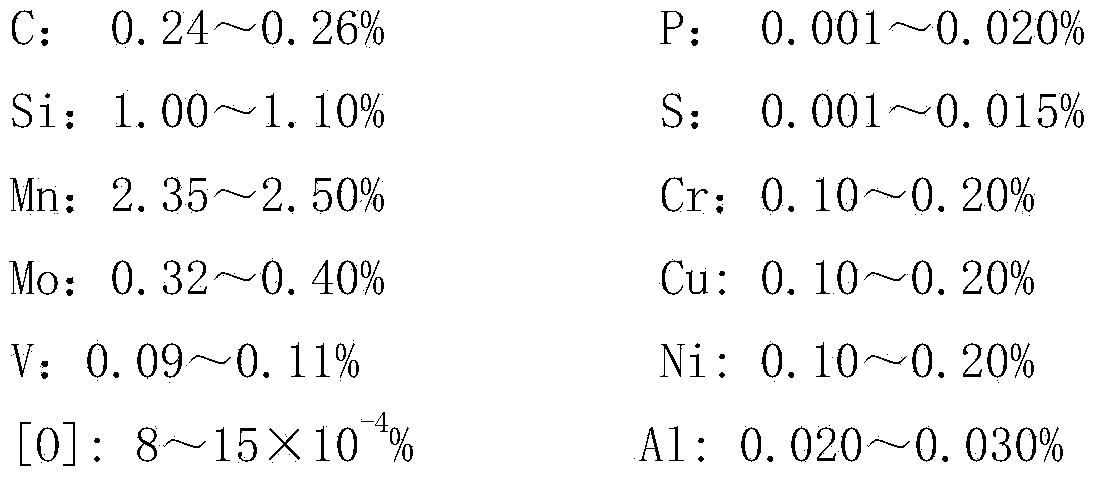

The invention relates to high-strength high-toughness wear-resisting steel for excavator bucket teeth and a manufacturing method thereof. The high-strength high-toughness wear-resisting steel comprises the following components in percentage by weight: 0.23-0.27% of C, 0.001-0.025% of P, 0.90-1.20% of Si, 0.001-0.025% of S, 2.20-2.60% of Mn, 0.10-0.30% of Cr, 0.30-0.40% of Mo, 0.10-0.30% of Cu, 0.08-0.12% of V, 0.10-0.30% of Ni, 0-15*10<-4>% of [O], 0.015-0.040% of Al and the balance of Fe and inevitable impurities. The invention also provides the manufacturing method of the steel for the excavator bucket teeth. The prepared low carbon silicon-magnesium-molybdenum-vanadium alloy has high strength, high toughness and high purity and is used for forging the excavator bucket teeth working in severe environments.

Owner:LAIWU IRON & STEEL GRP

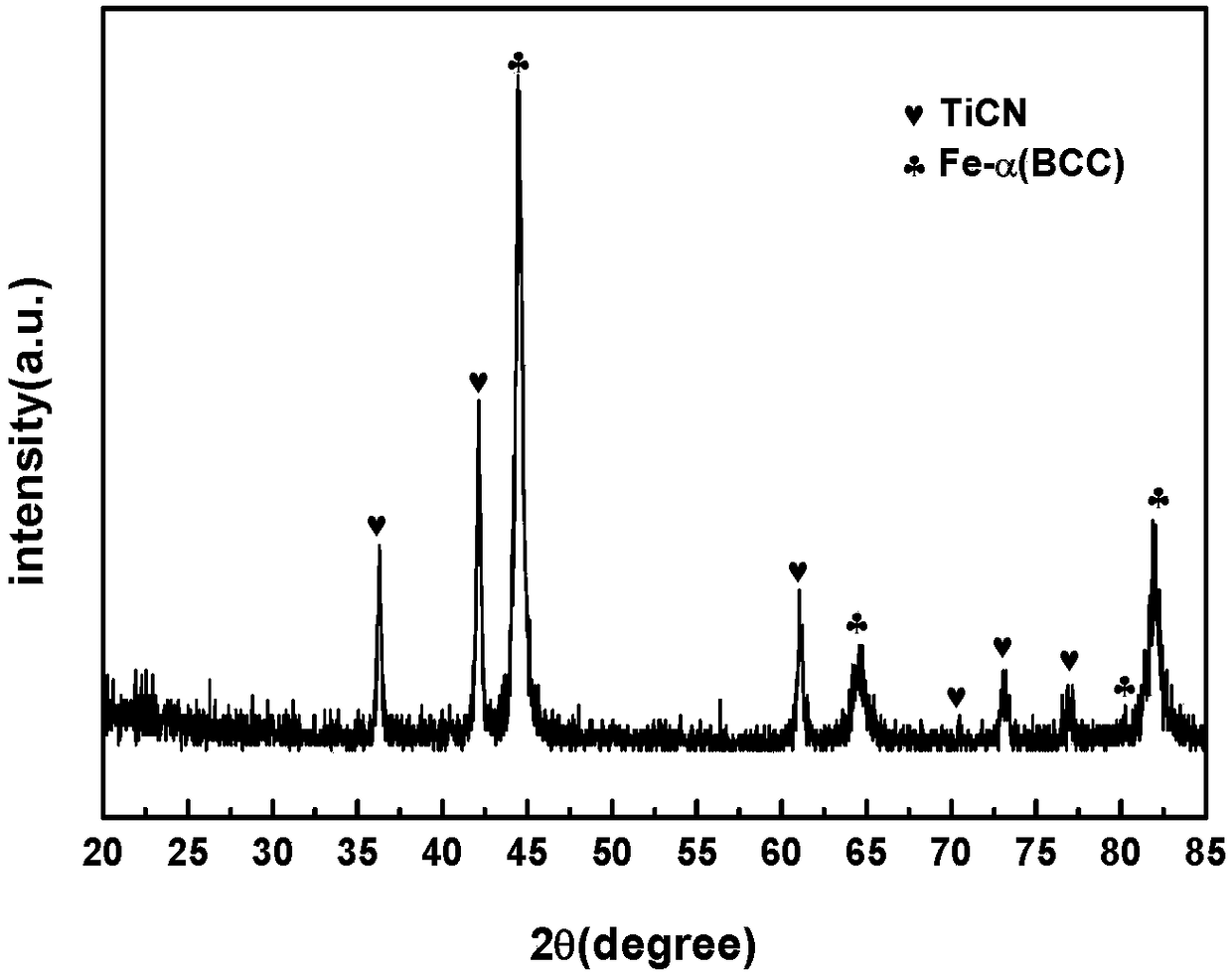

Ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool capable of coating and preparation method

The invention relates to an ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool capable of coating and a preparation method. The preparation method is characterized by comprising the following steps that the ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool takes Co-containing Fe-Mo-Cr alloy steel as a matrix, and TiCN with the mass fraction of 20-35% is added as a hard phase; the surface of powder is activated by adopting the method that quantitative preoxidation oxygen aeration is carried out after high-energy ball milling, the sintering activity of the matrix is improved, then the oxygen content (less than 800 ppm) is reduced substantially by a carbon and oxygen reduction reaction in the sintering process, and the sintering temperature is reduced; and the tempering resistance, the PVD coating property, the strength and the toughness of the ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool are improved by leading in a strengthening element of Co. The ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool has high strength (2800-4000 MPa) and high toughness (alpha k is equal to 7-15 J / cm2, KIC is equal to 20-28 MPa.m1 / 2), the limitation that a traditional steel-bonded hard alloy is only used for mid-and-low-end wear-resistant pieces can be broken through, and threading tools such as a PVD coating and squeezing screw tap and a cutting screw tap which are more wear-resistant than high-speed steel and are more edge-breaking-resistant than hard alloy are prepared.

Owner:XIANGTAN UNIV

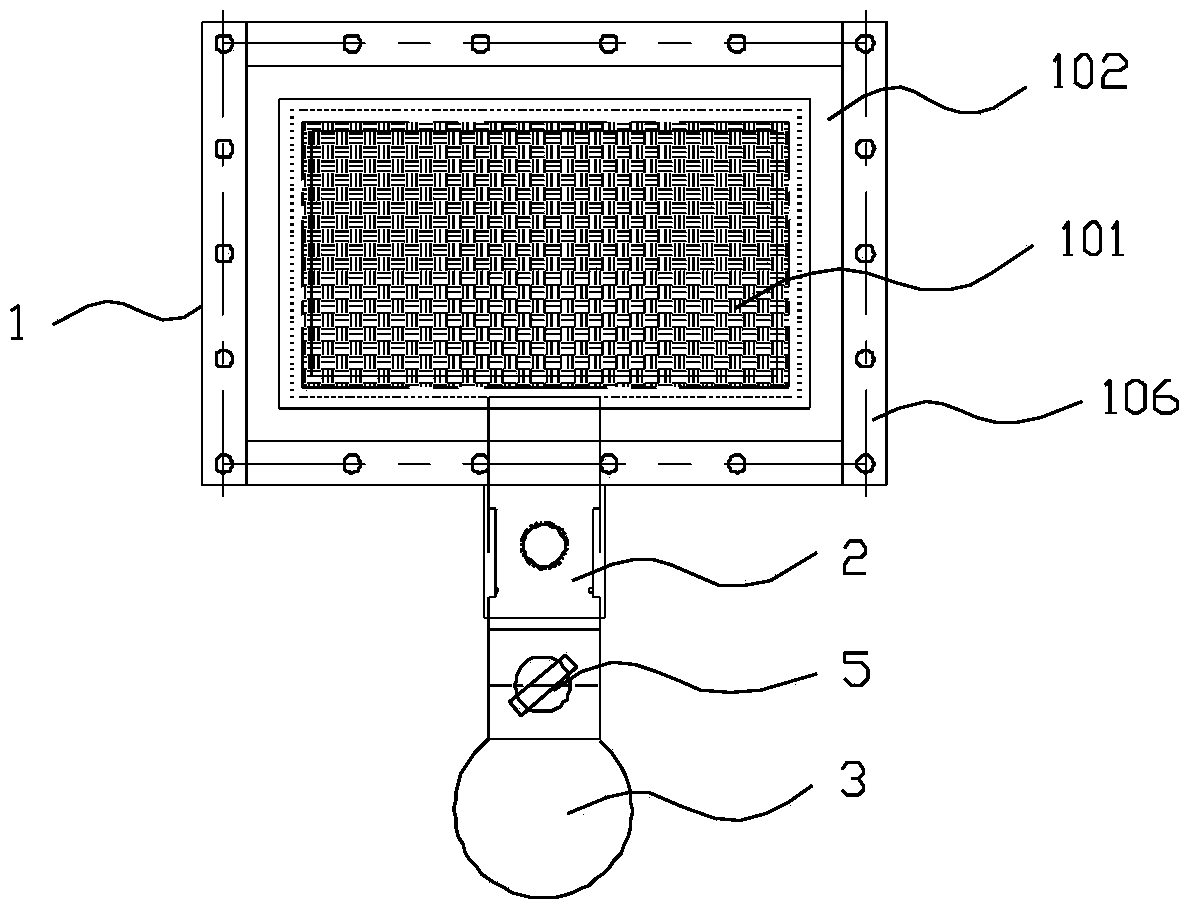

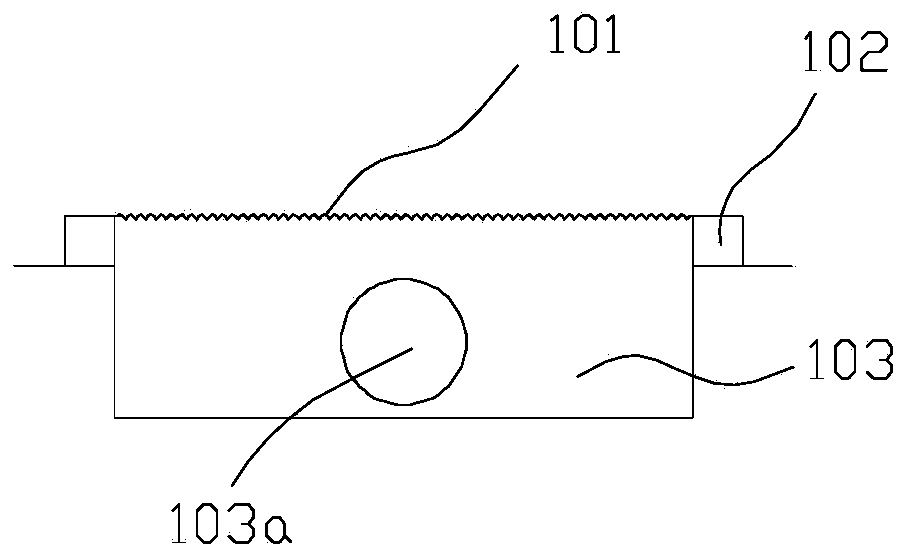

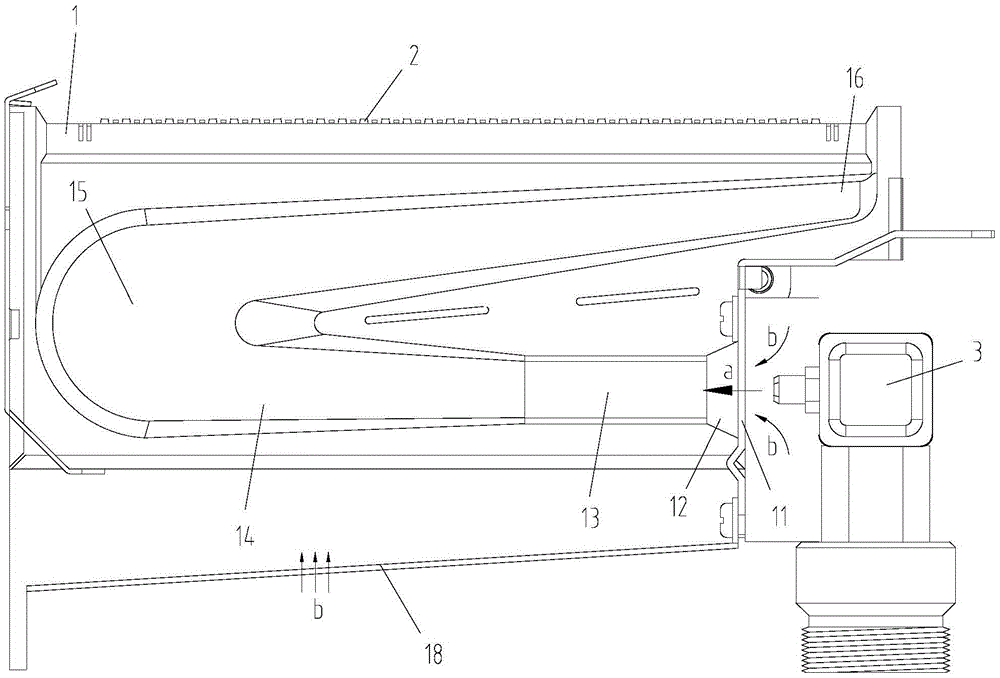

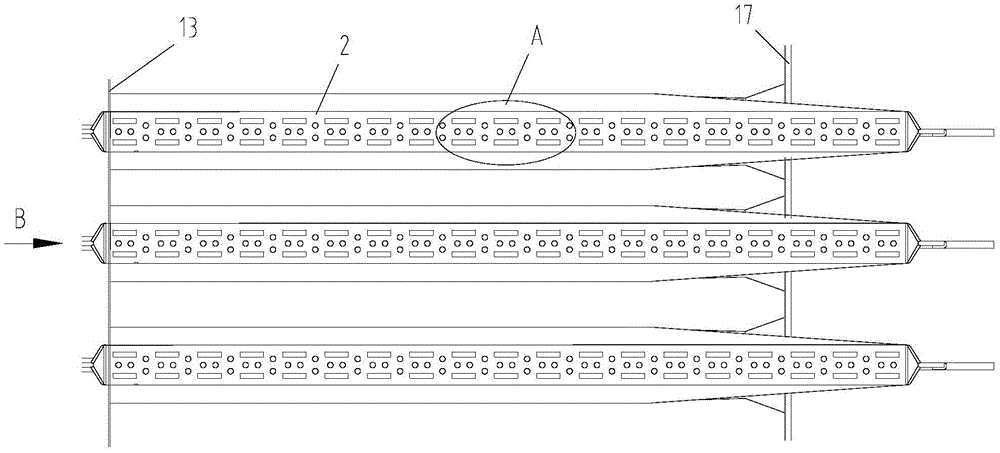

Energy-saving burner for premixed fuel gas to be burnt at positive pressure and steam generator

ActiveCN103953928ARealize automatic flameout protectionOvercome the disadvantages of easy ignition and deflagrationBoiler cleaning apparatusEnergy industryFiberDetonation

The invention discloses an energy-saving burner for premixed fuel gas to be burnt at a positive pressure and a steam generator. According to the burner, a burning surface of the burner is made from aludirome fabric; cooling devices are arranged in the circumferential direction along the edge of the burning surface; the fuel gas and air are completely mixed through a mixer and a premixing cavity, and are burnt at the positive pressure on the surface of the aludirome fabric. The problems that tempering is easily caused in positive-pressure burning, and ignition detonation is easily caused in premixed and enclosed burning are solved, and the burning process is safe and reliable. The burner is adopted in the steam generator; the mixed gas is rapidly burnt out in minimal sealed space formed between a burning part and an inner container of the steam generator, steam is generated fast, and waste heat produced during the steam generating process is effectively utilized; the sealed and premixed burning manner and the reasonable connection of all components enable the size of the steam generator is much less than that of the conventional steam generator; meanwhile, automatic drainage control effectively depresses and relieves the formation of water scale after the conventional steam generator is used for a long time.

Owner:珠海歌林能源科技有限公司

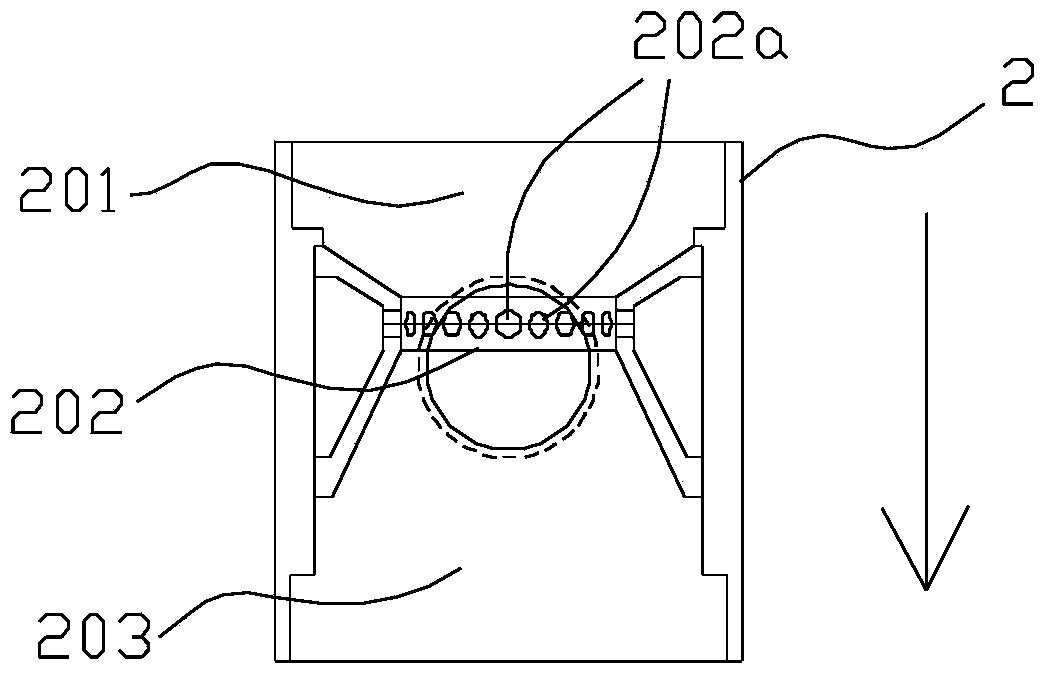

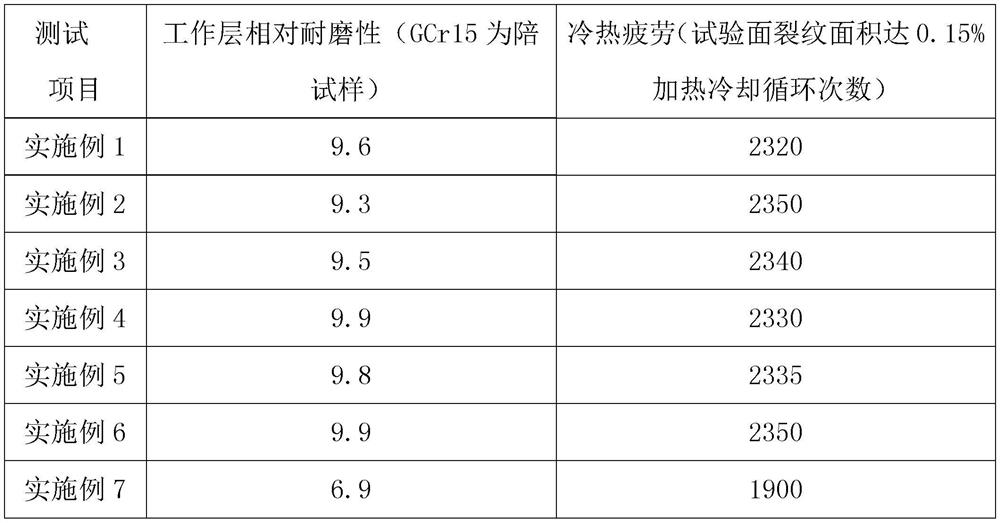

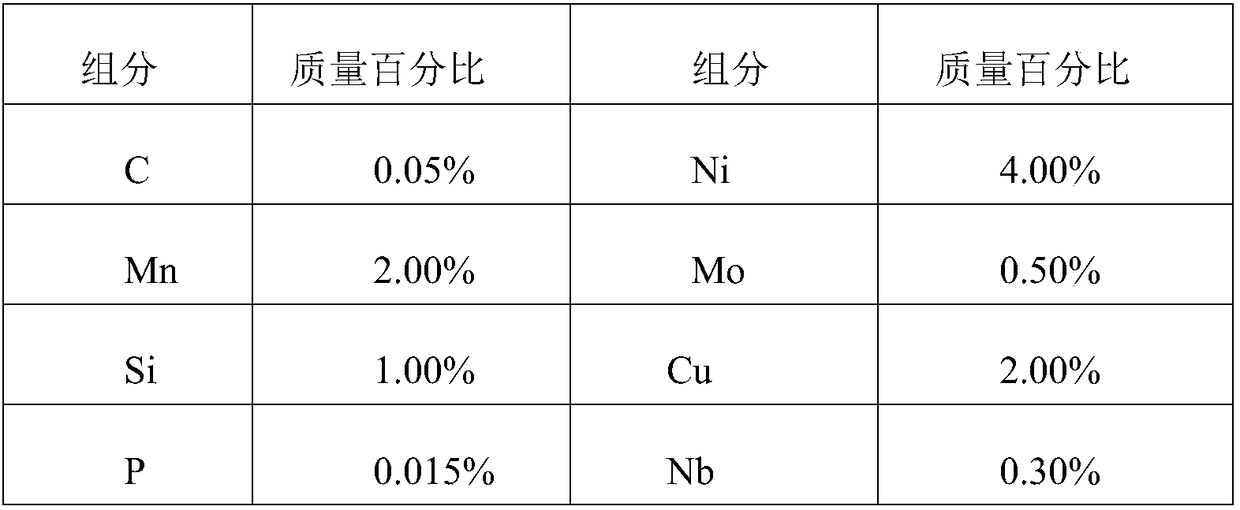

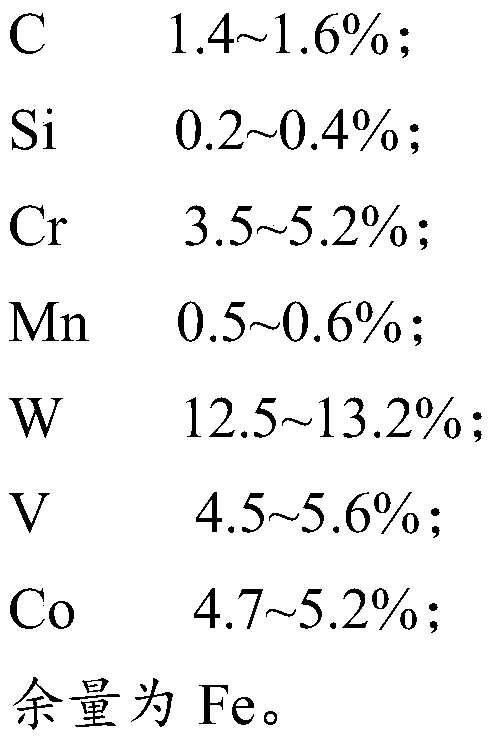

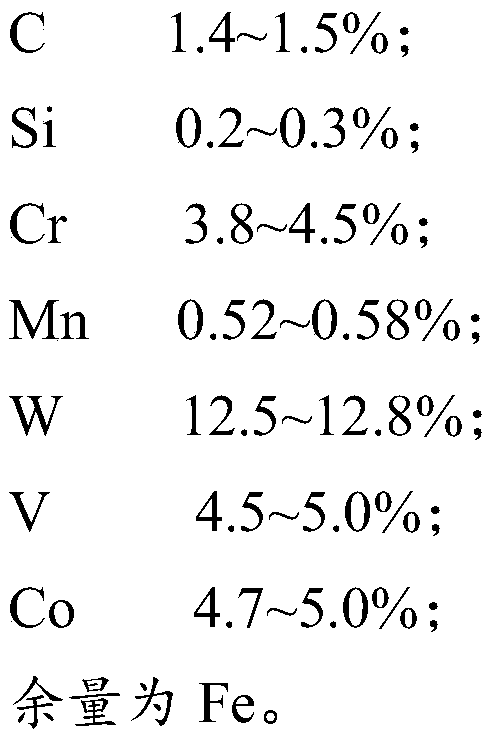

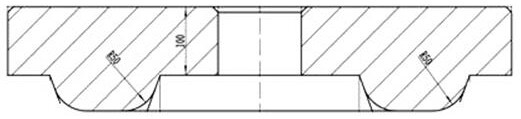

Preparation method of rough rolling high-speed steel working roll for full endless rolling of sheet billets

PendingCN113547099AExtend the machine cycleImprove wear resistanceFurnace typesProcess efficiency improvementTemperingFerrochrome

The invention discloses a preparation method of a rough rolling high-speed steel working roll for full endless rolling of sheet billets. The preparation method comprises the following steps that A, scrap steel, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, ferrotungsten and electrode powder are taken as raw materials, a line frequency furnace is adopted for smelting outer-layer molten iron and core molten iron; B, the product manufacturing mode is centrifugal composite manufacturing, and after smelting components reach the standard, outer-layer molten iron and core molten iron are heated, discharged out of a furnace and poured; C, after pouring is completed, a box is opened in a cold mode, and rough machining is conducted after the box is opened in the cold mode; D, after machining is completed, a roll body is subjected to quenching heating and overall tempering treatment; and E, after quenching heating is finished, finish machining is conducted, and detection is conducted till a finished product is obtained. According to the method, the requirements of short-process endless rolling technologies such as ESP are met, and the roll quality is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Corrugated roller machining method

InactiveCN105624369AHigh surface hardnessImprove toughnessSolid state diffusion coatingHeat inorganic powder coatingEngineeringThermal treatment

The invention discloses a corrugated roller machining method. The corrugated roller machining method includes the following specific steps that raw materials are weighed by the weight part, a roller body of a corrugated roller is made of a 48 CrMo material in a hardening and tempering manner, shaft head welding and outer circle rough machining are conducted, the raw materials are machined into powder and then are put into a stirring machine to be evenly stirred, and a coating is obtained; the coating is evenly sprayed to the surface of the cleaned corrugated roller to be machined through a spray gun, and compound treatment and subzero treatment are conducted after the coating is dried; and the surface of the corrugated roller obtained after thermal treatment is completed is polished, and the tooth surface is plated with hard chrome or sprayed with a tungsten cobalt alloy. The surface of the corrugated roller machined through the corrugated roller machining method is high in surface hardness and reasonable in foundation hardness and has both the hardness and toughness, secondary mounting and grinding are not needed, the machining cycle is shortened, the service life is long, and the compound treatment and subzero treatment are adopted, so that the tempering resistance of the corrugated roller is improved greatly, grains obtained after subzero treatment is conducted are refined remarkably, the organization is more even, and the size is more stable.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

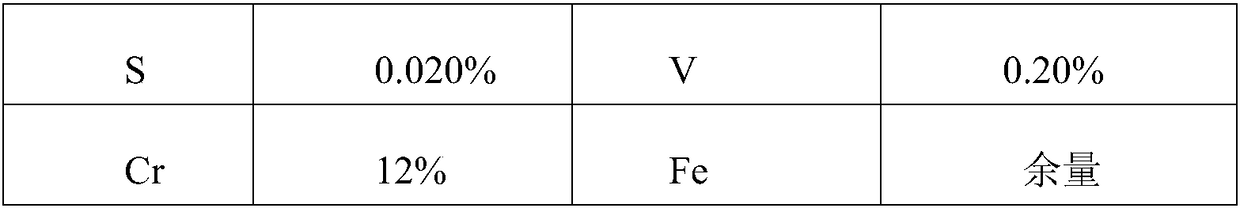

High-strength anticorrosion steel for gas valve and heat treatment process of high-strength anticorrosion steel

The invention discloses high-strength anticorrosion steel for a gas valve. The high-strength anticorrosion steel is composed of, by mass, 0.02-0.04% of C, 10.5-11.7% of Cr, 0.15-0.19% of Si, 0.62-0.73% of Mn, 0.45-0.52% of Ni, 0.15-0.17% of Re, 0.27-0.38% of Nb, 0.31-0.33% of Al, 0.11-0.13% of Y, 0.13-0.15% of Ti, 0.75-0.77% of Ca, 0.82-0.88% of B, 0.41-0.45% of Co, 0.23-0.31% of Mo, less than or equal to 0.03% S, less than or equal to 0.02% of P, 0.23-0.36% of rare earth metal and the balance Fe. The alloy elements of Co, Mo, Cr and Ti in the high-strength anticorrosion steel can improve the martensite tempering resistance and suppress dislocation substructure recovery; and Ni can improve the toughness of ferrite matrixes and refine crystal particles, the plasticity and toughness of the steel can be improved, the cleavage tendency is reduced, the nuclear driving force of Mo2C is improved through Co, and precipitation of fine and dispersed compounds containing Mo is facilitated.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Steel forge piece and machining method thereof

The invention discloses a steel forge piece and a machining method thereof. The problem that the overall performance of an austenitic stainless steel forge piece prepared through an existing machiningmethod is solved. According to the technical scheme, the steel forge piece comprises chemical components including, by mass, not larger than 0.08% of C, not larger than 2.20% of Mn, not larger than 1.50% of Si, not larger than 0.02% of P, not larger than 0.025% of S, 11%-13% of Cr, 2.00%-8.00% of Ni, 0.30%-0.60% of Mo, 1.50%-3.50% of Cu, not larger than 0.60% of Nb, not larger than 0.25% of V andthe balance Fe. The prepared forge piece has the beneficial effects of high strength, high tenacity, corrosion resistance, abrasion resistance, high weather fastness, high temperature resistance, lowtemperature resistance, high stability and the like.

Owner:TIANJIN RONGCHENG UNITED IRON & STEEL GRP CO LTD

Outdoor high-strength corrosion-prevention steel plate and processing technology thereof

InactiveCN108048758AHigh strengthImprove wear resistanceHot-dipping/immersion processesRare-earth elementUltimate tensile strength

The invention discloses an outdoor high-strength corrosion-prevention steel plate, and relates to the technical field of metal smelting. The outdoor high-strength corrosion-prevention steel plate comprises, by mass, 0.23%-0.38% of C, 1.24%-1.36% of Co, 0.91%-1.34% of Ni, 4.12%-5.36% of Cr, 0.86%-1.32% of Mo, 0.55%-0.57% of Al, 0.42%-0.78% of Ti, 0.13%-0.18% of Si, 0.09%-0.14% of Ge, 0.13%-0.16% ofW, 0.16%-0.21% of Re, 0.31%-0.34% of N, 5.21%-5.89% of rare earth elements, and the balance Fe and inevitable impurities. The invention further discloses a processing technology of the outdoor high-strength corrosion-prevention steel plate. The strength and toughness of the steel plate are effectively improved; and meanwhile the corrosion resistance of the steel plate is improved, and thus the service life of the steel plate is effectively prolonged.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

High-strength duplex stainless steel and heat-treatment technology thereof

The invention discloses a high-strength duplex stainless steel. The high-strength duplex stainless steel comprises the following chemical components in percentage by mass: C which is smaller than or equal to 0.03%, 16.0-16.5% of Cr, 2.1-3.3% of Ni, 0.31-0.35% of Mn, 1.2-2.2% of Mo, 0.24-0.31% of Co, 0.39-0.41% of Si, 0.14-0.16 of Nb, 0.17-0.19% of Ti, 0.12-0.15% of Ge, 0.52-0.54% of Cu, 0.25-0.31% of V, 0.05-0.07% of Ca, 0.15-0.19% of Re, 0.17-0.19% of Se, 0.015-0.025% of S, 0.021-0.023% of P, 5.5-6.6% of rare earth elements, and the balance of Fe and inevitable impurities. An corrosion-resistant plate made of the high-strength stainless steel disclosed by the invention not only is high in tensile strength and yield strength, but also high in corrosion resistance; and the rare earth elements are added, so that the interaction between a corrosive medium and the stainless steel is avoided, and besides, the extensibility of the stainless steel plate is improved, the functions of eliminating bubbles caused by hydrogen in steel ingots and reducing cracks in steel billets are added, and particles are refined.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

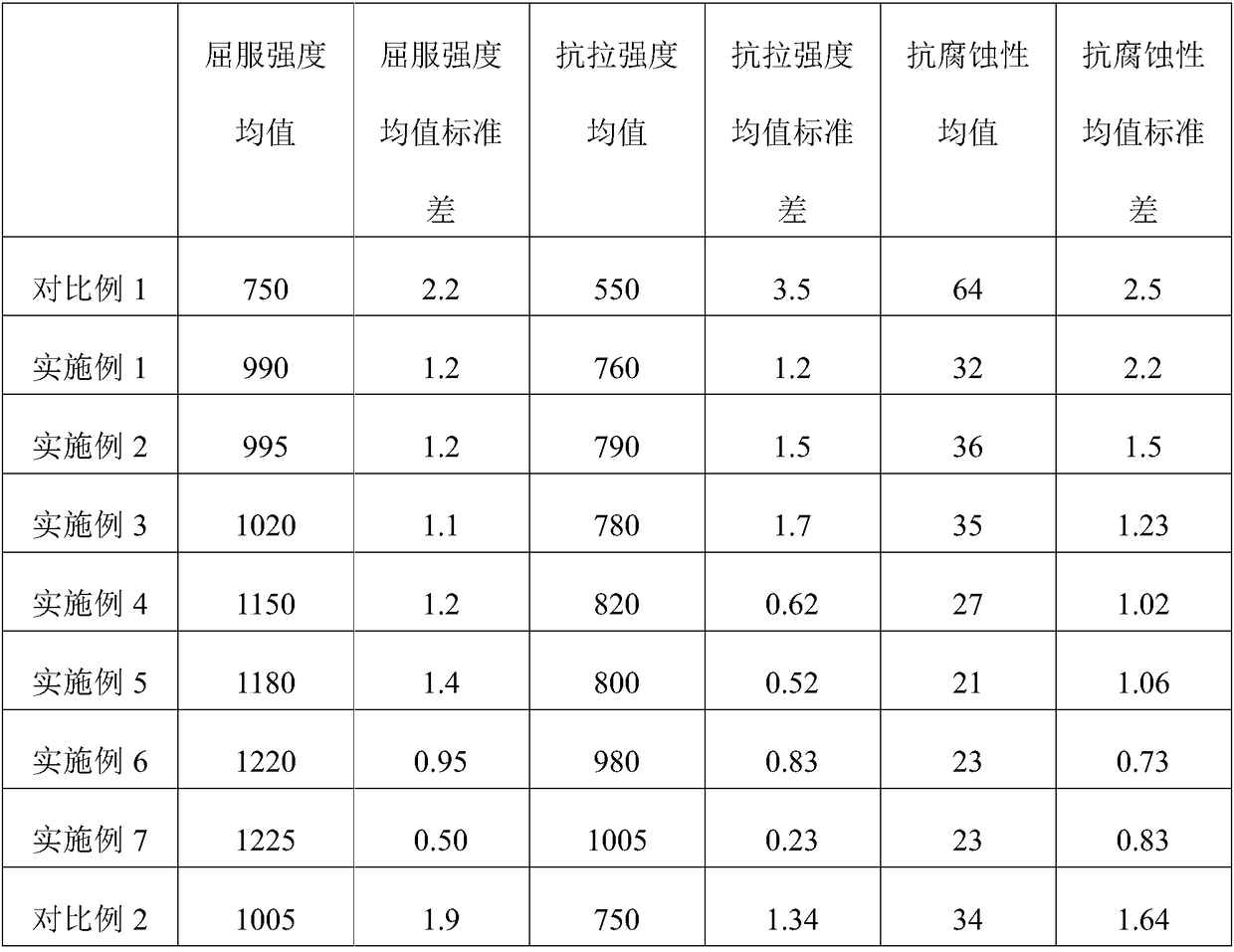

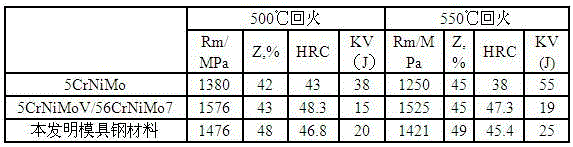

Special mold steel material for high-energy spiral pressure machine

The invention provides a special mold steel material for an SPKA22400 high-energy spiral pressure machine, for both solving the problem that the production efficiency is low when conventional 5CrNiMo mold steel is used and effectively lowering the material cost of a mold. The special mold steel material for the SPKA22400 high-energy spiral pressure machine is characterized by comprising the following materials in percentage by weight: 0.50-0.60% of C, 0.70-1.00% of Mn, less than or equal to 0.40% of Si, 0.70-1.00% of Cr, 1.40-1.80% of Ni, 0.25-0.40% of Mo, 0.10-0.15% of V and the balance of Fe and inevitable impurities.

Owner:WUXI TURBINE BLADE

High-strength, high-toughness, wear-resistant steel for excavator bucket teeth and manufacturing method thereof

The invention relates to high-strength high-toughness wear-resisting steel for excavator bucket teeth and a manufacturing method thereof. The high-strength high-toughness wear-resisting steel comprises the following components in percentage by weight: 0.23-0.27% of C, 0.001-0.025% of P, 0.90-1.20% of Si, 0.001-0.025% of S, 2.20-2.60% of Mn, 0.10-0.30% of Cr, 0.30-0.40% of Mo, 0.10-0.30% of Cu, 0.08-0.12% of V, 0.10-0.30% of Ni, 0-15*10<-4>% of [O], 0.015-0.040% of Al and the balance of Fe and inevitable impurities. The invention also provides the manufacturing method of the steel for the excavator bucket teeth. The prepared low carbon silicon-magnesium-molybdenum-vanadium alloy has high strength, high toughness and high purity and is used for forging the excavator bucket teeth working in severe environments.

Owner:LAIWU IRON & STEEL GRP

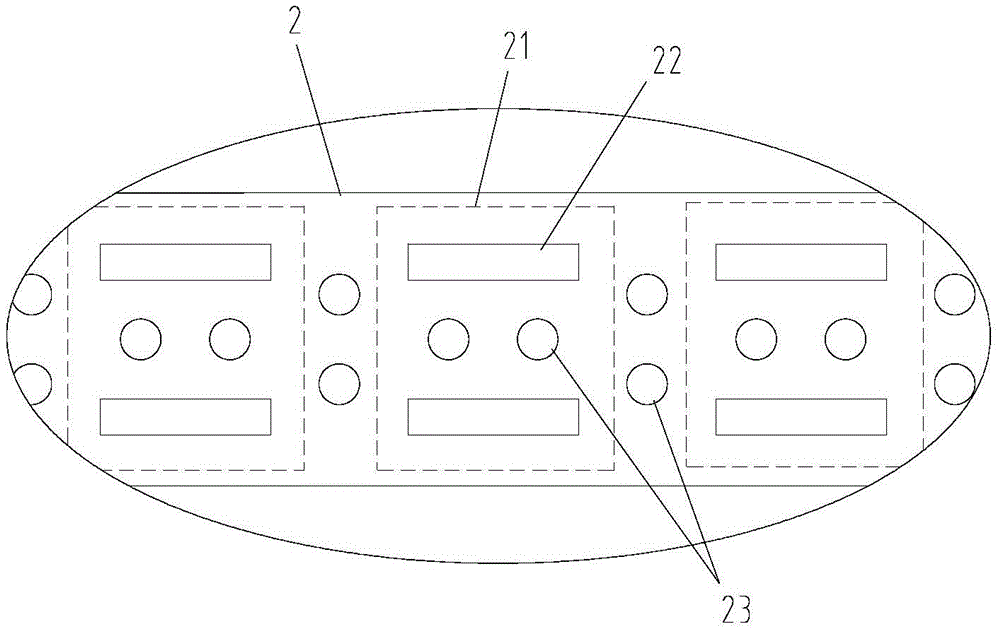

Gas burner

The invention discloses a gas burner. The gas burner comprises a body frame and a plurality of burning fire grates. The multiple burning fire grates are arranged at the upper end of the body frame at intervals and in the same column. The upper end surface of each burning fire grate is provided with a plurality of flaming arrays. The multiple flaming arrays are arranged to be in at least one line in the length direction of the corresponding burning fire grate. Each flaming array comprises two first nozzles and at least one second nozzle. The first nozzles can generate horizontal flame towards all around. The second nozzles can generate longitudinal flame upwards. The two first nozzles of each flaming array are arranged oppositely. The length direction of each first nozzle corresponds to the length direction of the corresponding burning fire grate. The second nozzles are arranged between the two corresponding first nozzles. The lower end of the body frame is provided with an air inlet adjusting plate which is used for controlling air ventilation. The gas burner is higher in burning efficiency and has the characteristics of being higher in energy use efficiency and lower in cost.

Owner:GUANGZHOU DEVOTION HOME ENVIRONMENT TECH CO LTD

Preheat treatment process for super-strong high-toughness carburizing steel bar and forge piece

PendingCN114317897AImprove hardenabilityImprove temper resistanceFurnace typesHeat treatment furnacesTemperingHeat conservation

The invention belongs to the field of material processing, and relates to a preheat treatment process for a super-strong high-toughness carburizing steel bar and a forge piece, which comprises the following steps of: firstly, carrying out primary high-temperature tempering on the bar and the forge piece which are subjected to thermoplasticity forming at the heating temperature of 670-710 DEG C and the heat preservation time of 8-20 hours, and carrying out furnace cooling or air cooling to room temperature; then incomplete annealing is conducted, the heating temperature ranges from 950 DEG C to 1000 DEG C, the heat preservation time ranges from 1 h to 3 h, and furnace cooling or air cooling is conducted to the room temperature; and finally, secondary high-temperature tempering is conducted, the heating temperature ranges from 670 DEG C to 710 DEG C, the heat preservation time ranges from 8 h to 20 h, and furnace cooling or air cooling is conducted to the room temperature. Through the pre-heat treatment, the structure inheritance caused by high-temperature heating before the super-strong high-toughness carburizing steel bar and the forge piece are subjected to plastic forming is eliminated, fine crystal grains are obtained after final heat treatment, the hardness of the bar or the forge piece is reduced, the residual stress is eliminated, and the cutting machining performance is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Roll surface repair material of wrapper roll and laser cladding remanufacturing method of wrapper roll

ActiveCN111378897AImprove heat strengthImprove high temperature wear resistanceMetallic material coating processesRepair materialHigh wear resistance

The invention provides a roll surface repair material of a wrapper roll and a laser cladding remanufacturing method of the wrapper roll, and belongs to the technical field of repair of wrapper rolls.The roll surface repair material of the wrapper roll has high wear resistance, high temperature resistance and corrosion resistance, the roll surface repair material is clad on the surface of the wrapper roll by wide-band laser cladding, the cladding efficiency can be improved, the remanufactured wrapper roll has higher hardness, high temperature resistance, wear resistance and corrosion resistance, and the service life of the remanufactured wrapper roll is greatly prolonged; and meanwhile, surface cracking of the wrapper roll and the problem of hard and soft strip in the using process of theremanufactured wrapper roll can be avoided, and the uniform wear of a cladding layer is achieved.

Owner:合肥九州龙腾科技成果转化有限公司

Manufacturing method of high-performance 42CrMo gear

PendingCN112077247AImprove flowMeet the use requirementsFurnace typesForging/hammering/pressing machinesFiberTempering

The invention belongs to the technical field of gear machining, and particularly relates to a manufacturing method of a high-performance 42CrMo gear. The method comprises the steps that a technological process is determined, numerical simulation and optimization are performed on die-forging forming technological parameters in the determined technological process, and then specified raw materials are adopted and subjected to blank heating, die-forging forming, normalizing heat treatment, rough turning, hardening and tempering treatment and finish turning treatment to obtain the high-performance42CrMo gear. The gear manufactured by adopting the process has the advantages that (1) by adopting loose tooling forging forming, a good macroscopic fiber flow direction can be obtained in a gear body, and the internal structure of the gear is compact and uniform; (2) before water-cooling quenching and tempering treatment, nondestructive testing is carried out on the gear to ensure that the internal and surface quality conditions of the gear meet the use requirements; and (3) water-cooling quenching and tempering treatment is adopted, so that the tempering resistance of the gear body is higher, and the wear resistance is better.

Owner:SHANDONG IRAETA HEAVY IND

High-strength torsion resistant steel and preparation method thereof

The invention discloses a high-strength torsion resistant steel, and relates to the technical field of metal smelting. The high-strength torsion resistant steel comprises, by mass, 0.22%-0.49% of C, 1.25%-1.38% of Co, 0.88%-1.34% of Ni, 4.57%-5.45% of Cr, 0.96%-1.35% of Mo, 0.53%-0.59% of Al, 0.58%-0.78% of Ti, 0.16%-0.19% of Si, 0.09%-0.14% of V, 0.13%-0.16% of W, 0.06%-0.09% of Nb, 0.004%-0.009%of Ca, 0.12%-0.26% of Mn, 0.06%-0.09% of styrene-butadiene-styrene block copolymer, 1.66%-2.53% of rare earth elements and the balance Fe and inevitable impurities. The invention further discloses apreparation method of the high-strength torsion resistant steel, and the strength and toughness of the steel can be improved effectively; and the phenomenon that the steel is liable to be twisted offby external force is avoided.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com