Surface composite strengthening technology for precipitation hardening stainless steel and precipitation hardening stainless steel material

A technology of precipitation hardening and surface compounding, applied in the field of surface compound strengthening of precipitation hardening stainless steel, can solve the problem of not meeting the requirements of blades, improve surface hardness and anti-cavitation performance, improve tempering resistance and high surface hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

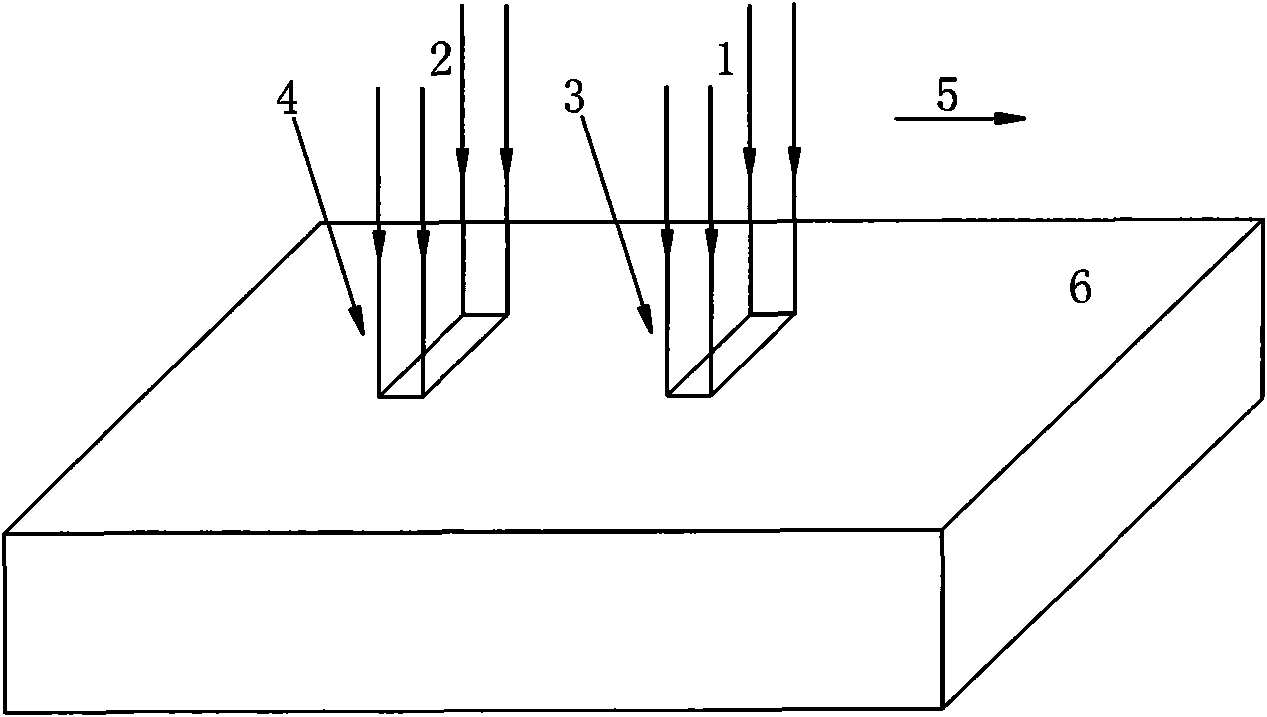

[0027] Such as figure 1 A surface composite strengthening process for precipitation hardening stainless steel is shown, in which, 1 is the first laser beam, 2 is the second laser beam, 3 and 4 are gas protection devices, 5 is the moving direction of the laser beam, and 6 is the artifact. Work piece 6 is made of 17-4PH stainless steel. After the surface is cleaned twice with 98% acetone, a layer of alloy coating with a width of 16mm and a thickness of 0.4mm is preset, and the composition is W6%, Cr19%, Ni10%, Fe7%. , Si1.2%, V0.8%, Re0.1%, remaining Co, after drying, carry out laser treatment.

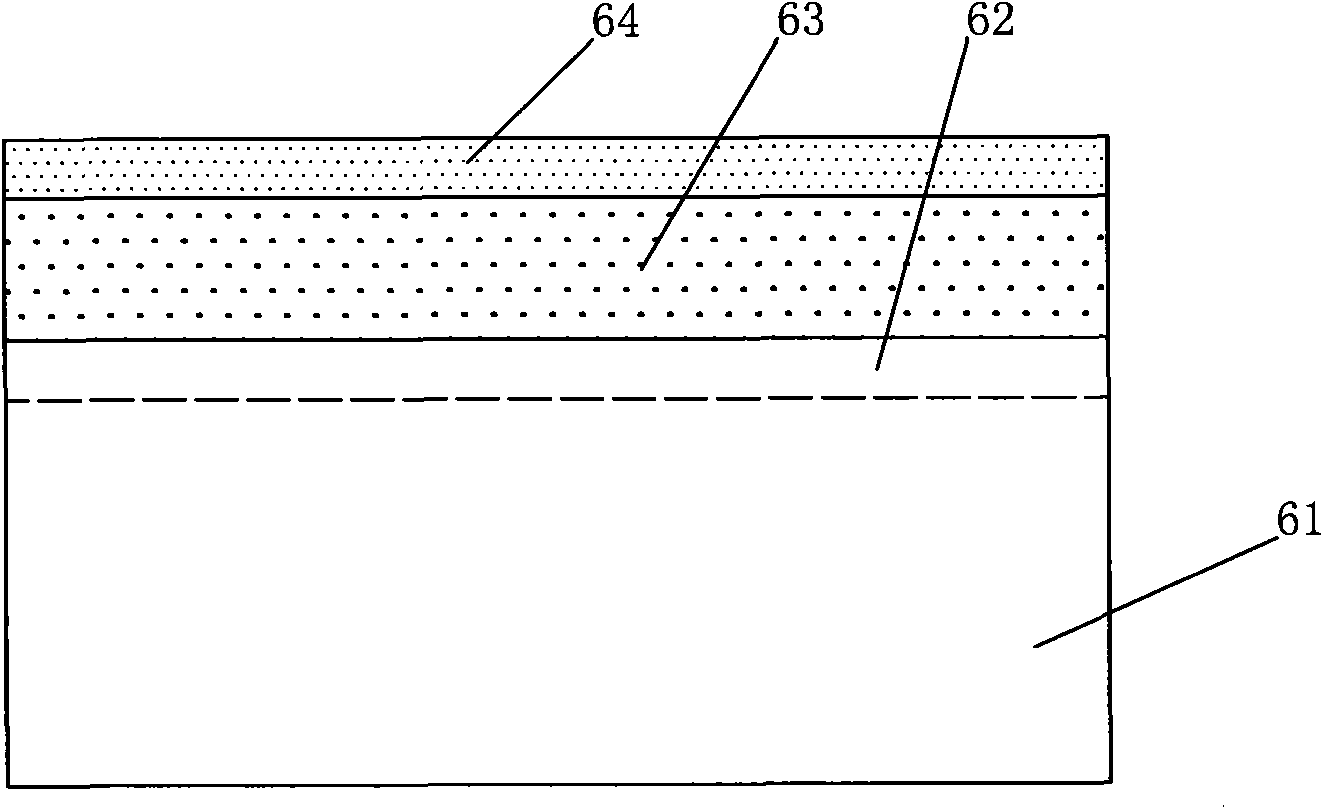

[0028] The source of the laser beam is CO 2 Laser with a wavelength of 10.6 μm and a power density of the first laser beam of 1.875 kW / cm 2 , the spot size is 16mm×10mm, and the protective medium is argon. The power density of the second laser beam is 6kW / cm 2, the spot size is 16mm×3mm, and the synchronous scanning speed is 200mm / min. Treated at 440°C / 2 hours. Finally, the highe...

Embodiment 2

[0031] Coating a layer of alloy coating with a width of 12mm and a thickness of 0.5mm on a 17-4PH stainless steel substrate, the composition is: W8%, Cr20%, Ni12%, Fe8%, Si1.5%, V0.5% , Re0.1%, Yu Co. After drying, and then laser treatment, the power density of the first beam is 1.625kW / cm 2 , The spot size is 12mm×8mm, and the cooling medium is argon. The aging temperature is 440°C, 4h; the power density of the second beam is 9kWcm 2 , the spot size is 12mm×1mm, and the synchronous scanning speed is 300mm / min. Finally, the average hardness of the alloyed surface is obtained as HV 0.2 650, the hardened layer is 150μm; the average hardness of the subsurface is HV 0.2 410, the depth of the hardened layer is 1.5mm, and the anti-cavitation performance is about 3 times higher than that of the original matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com