Pure argon gas shielded welding mig flux-cored wire and mig arc welding method

A technology of flux-cored welding wire and welding wire, used in arc welding equipment, welding/welding/cutting items, welding medium, etc., can solve problems such as solidification cracks, achieve high static tensile strength and fatigue strength, and suppress slag and smoke. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

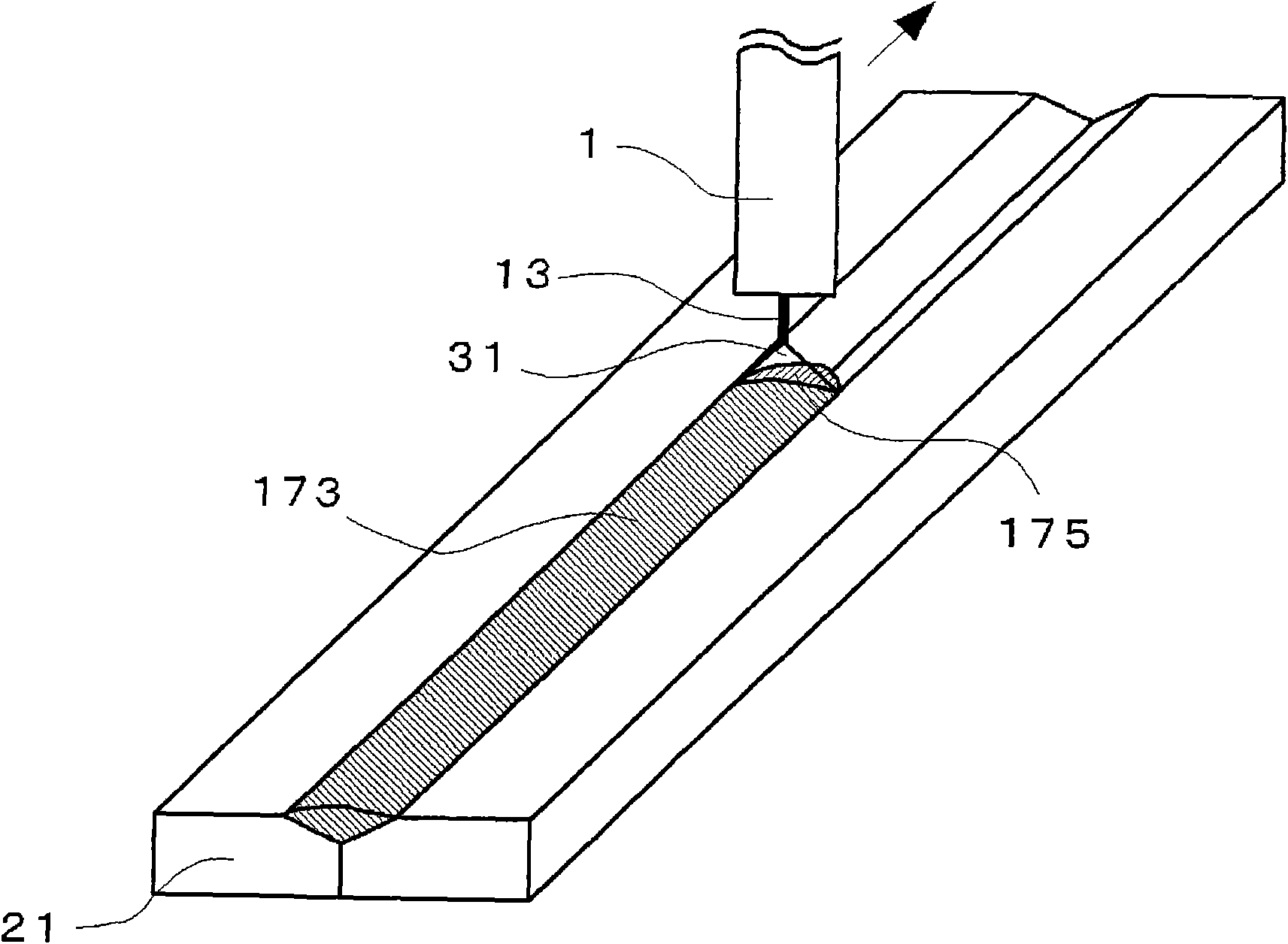

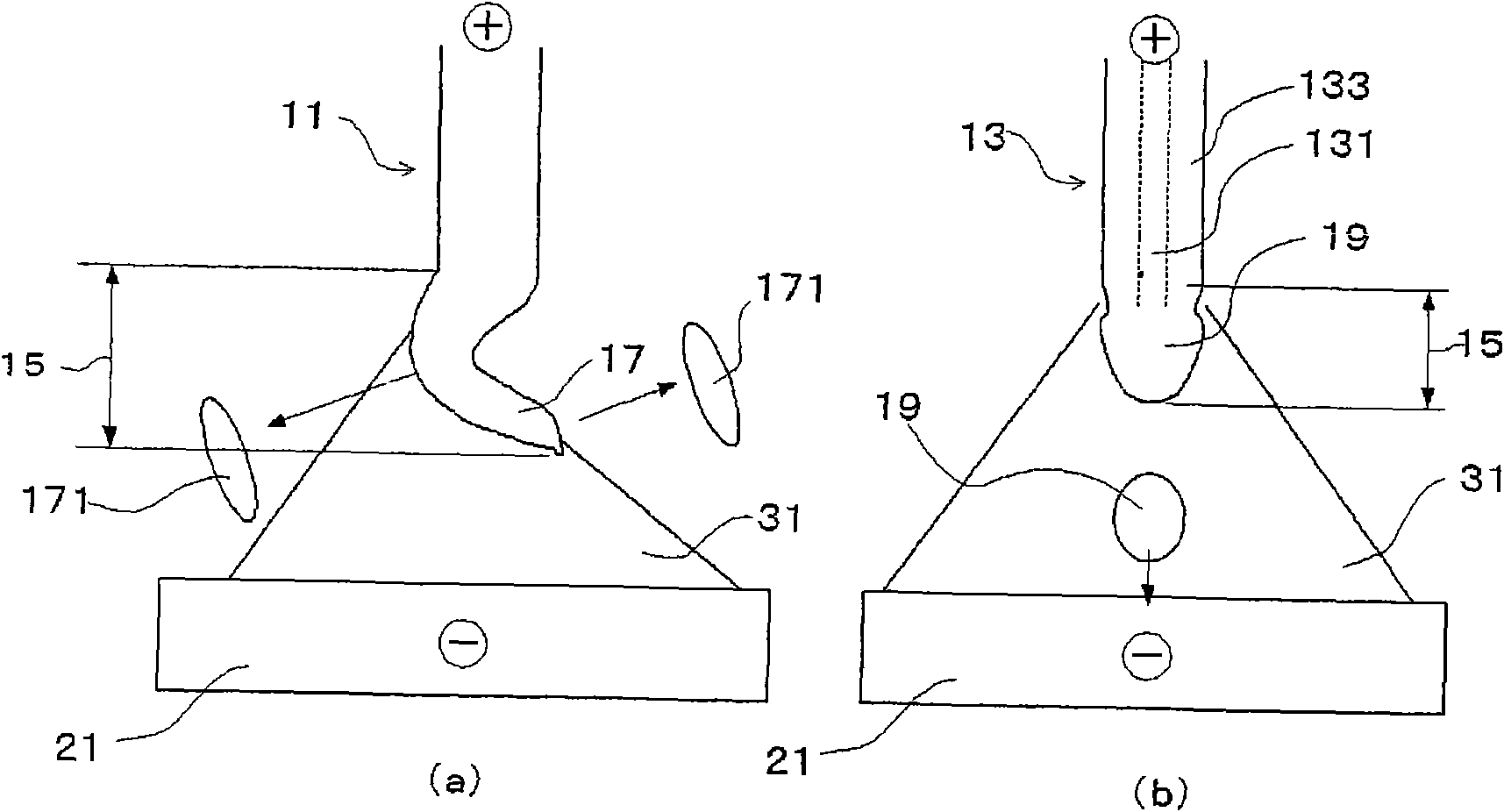

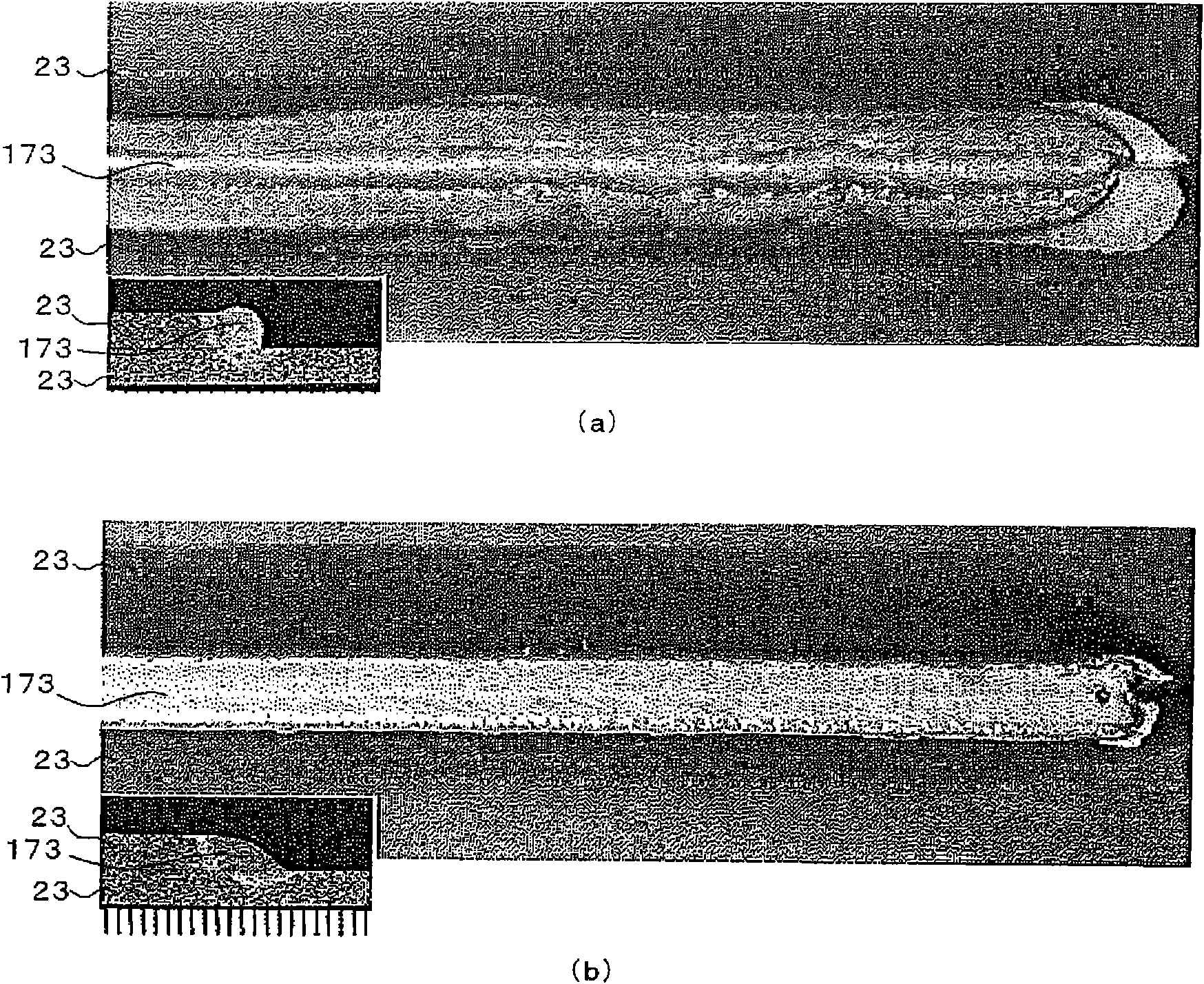

[0021] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. figure 1 It is a perspective view showing a MIG welding method using pure Ar gas according to the embodiment as a shielding gas. The welding wire 13 is continuously supplied to the welding torch 1 , and the welding wire 13 is fed out from the tip of the welding torch 1 toward the base material 21 through the center portion of the welding torch 1 . With the welding wire 13 as the positive electrode and the base material 21 as the negative electrode, a welding voltage is applied from a power supply (not shown), and an arc 31 is formed between the welding wire 13 and the base material 21 . The arc 31 melts the welding wire 13 and the base material 21 to form a molten pool 175 . At this time, if figure 2 As shown in (b), Ar gas as a shielding gas is supplied to the vicinity of the molten pool 175 formed between the welding wire 13 and the base material 21, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com