Preparation method of rolling bearing

A technology for rolling bearings and bearings, which is applied to bearings, bearing components, shafts and bearings, etc. It can solve the problems of non-optimal structure performance, not satisfying the shape of the bearing ring blank, and not being as good as the bearing steel blank, so as to avoid point contact fatigue damage , good comprehensive mechanical properties, the effect of improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

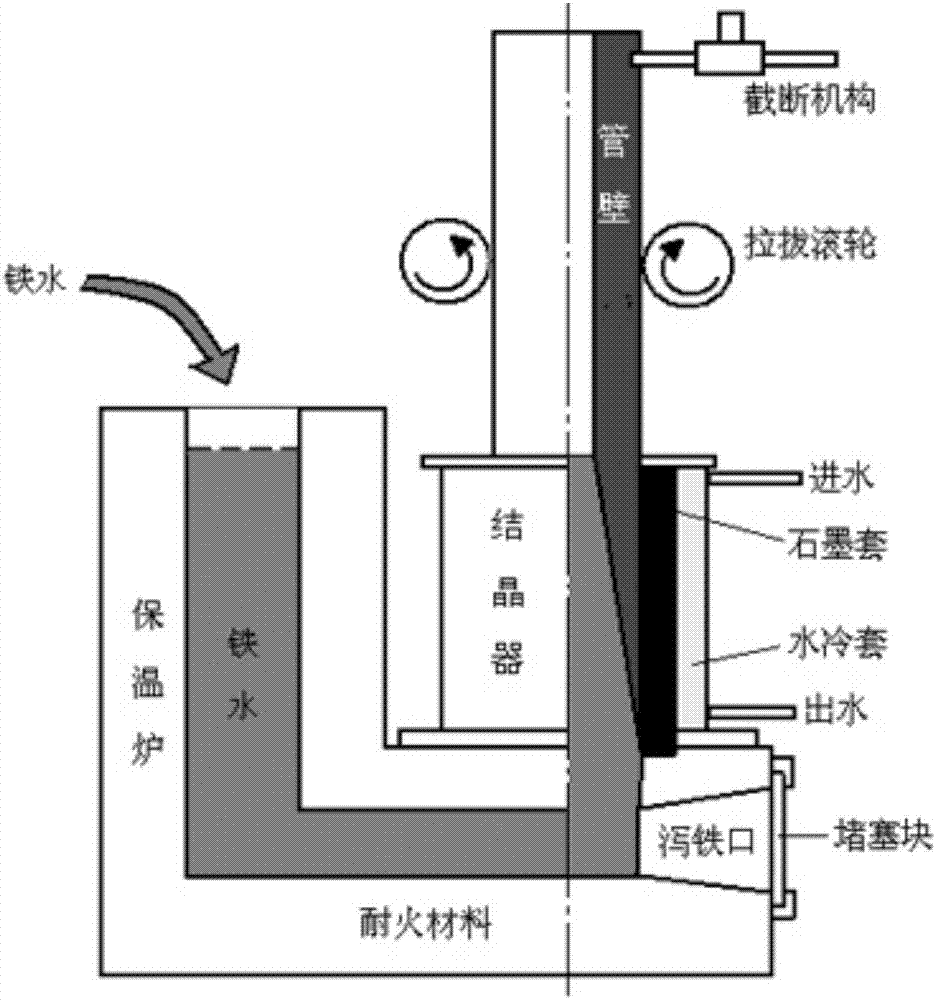

[0040] Attached below Figure 1-6 Embodiments of the present invention are described.

[0041] A material preparation and processing method for a rolling bearing, comprising the steps of:

[0042] 1) Preparation of tube blank material for inner and outer rings of bearings: use medium frequency induction furnace to melt molten iron, the initial composition (%) of molten iron is: C: 3.4-3.7, Si: 1.3-1.7 (adjusted according to the required grade of ductile iron), Mn: 0.2 -0.7, Cr: 0.1-0.3, Cu≤0.8, S≤0.05, P≤0.05, Fe: balance.

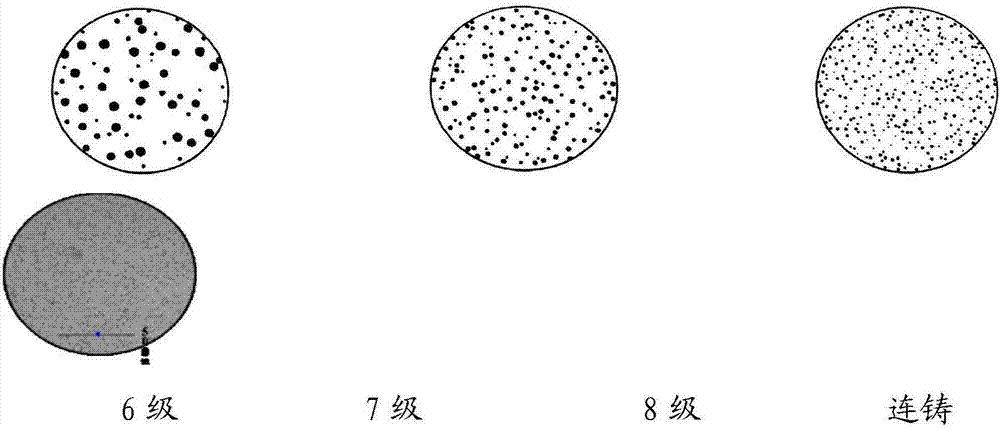

[0043] 2) Inoculation and spheroidization treatment: Use ferrosilicon inoculants for ductile iron and nickel-magnesium, nickel-copper spheroidizers to make the final silicon content of molten iron reach 2.3-2.7%, and the residual magnesium content is about 0.04%; try to avoid rare earth during operation And the incorporation of titanium in order to obtain the highest spheroidization rate.

[0044] 3) Preparation of tube blank material for bearing cage: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com