Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Zero Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero Defects (or ZD) was a management-led program to eliminate defects in industrial production that enjoyed brief popularity in American industry from 1964 to the early 1970s. Quality expert Philip Crosby later incorporated it into his "Absolutes of Quality Management" and it enjoyed a renaissance in the American automobile industry—as a performance goal more than as a program—in the 1990s. Although applicable to any type of enterprise, it has been primarily adopted within supply chains wherever large volumes of components are being purchased (common items such as nuts and bolts are good examples).

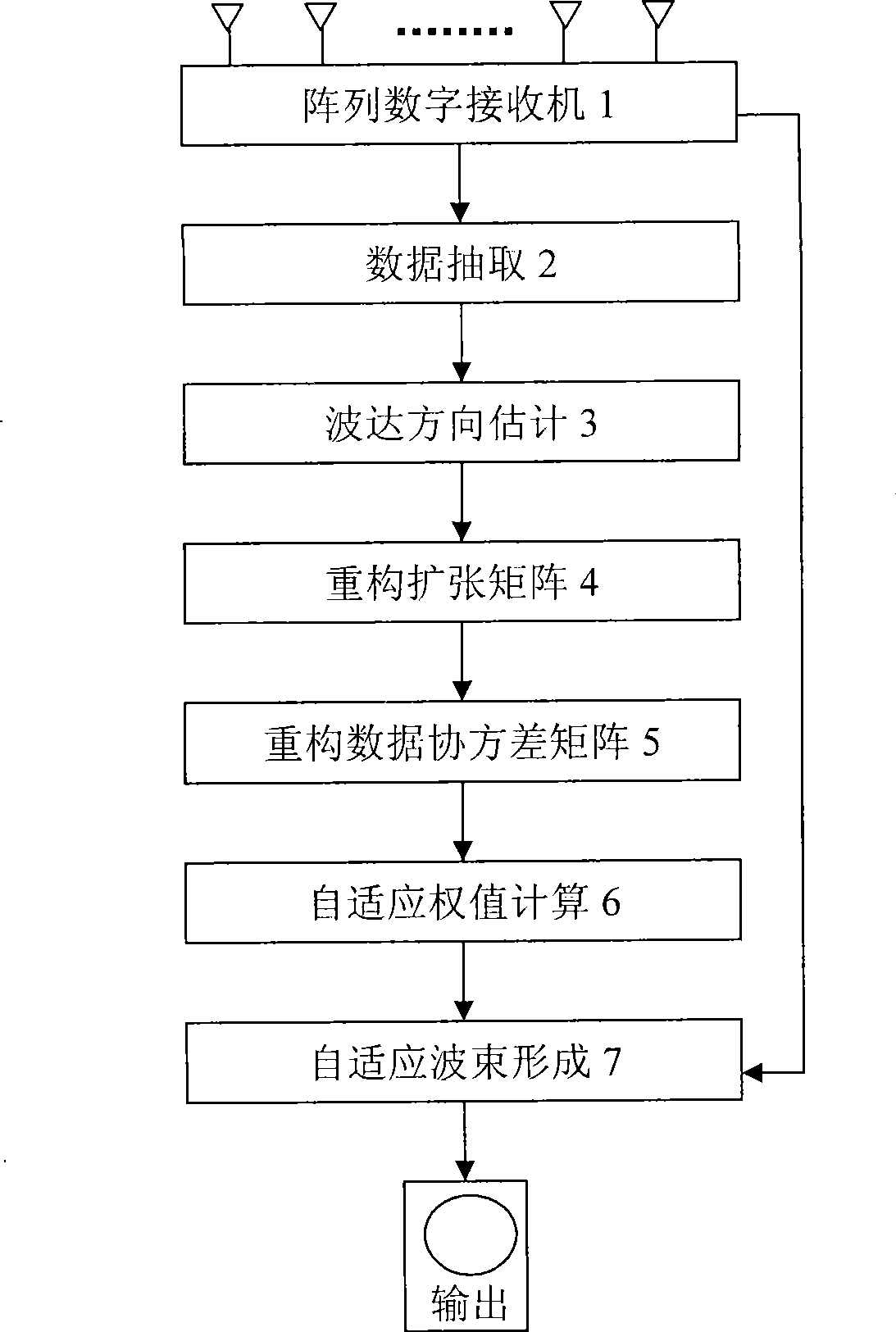

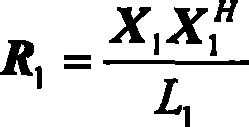

Self-adapting special interference restraint technology for phased array radar

InactiveCN101482610AEnhanced inhibitory effectSuppress complex interferenceWave based measurement systemsRadarAnalog signal

The invention discloses a self-adapting special interference suppressing technology aim at phased array radar. The conventional phased array radar can suppress the noise to inhibit the interference by self-adapting, firstly the interference data received by the radar receiver can be learned then to form a zero point on the interference direction. The zero point depth and width generated by the conventional processing method all can be influenced by the array error and are not suitable for the special interferences, such as the dense cheating interference, the movement interference, the fast transforming clearance type interference or the composite interference and so on complicated interference forms. Adopting the ultra-lower secondary lobe aerial is the most effective anti-interference method, but under the present technology and technological level, the over-high secondary lobe requirement for the phased array aerial is impractical. The invention can implement the estimations of the interference source number and the orientation by the space spectrum estimating technology firstly, and then can construct the interfering data covariance matrix by using the analog signals, then can obtain the self-adapting minor lobe cancellation weight vector calculated by the self-adapting method, thereby forming the wide zero point and deep zero defect self-adapting directional diagram to inhibit the complicated interferences. The technology of the invention can be used for the signal processing system of the phased array radar, the implementing is simple, and the invention has wide practical application prospects.

Owner:PLA AIR FORCE RADAR COLLEGE

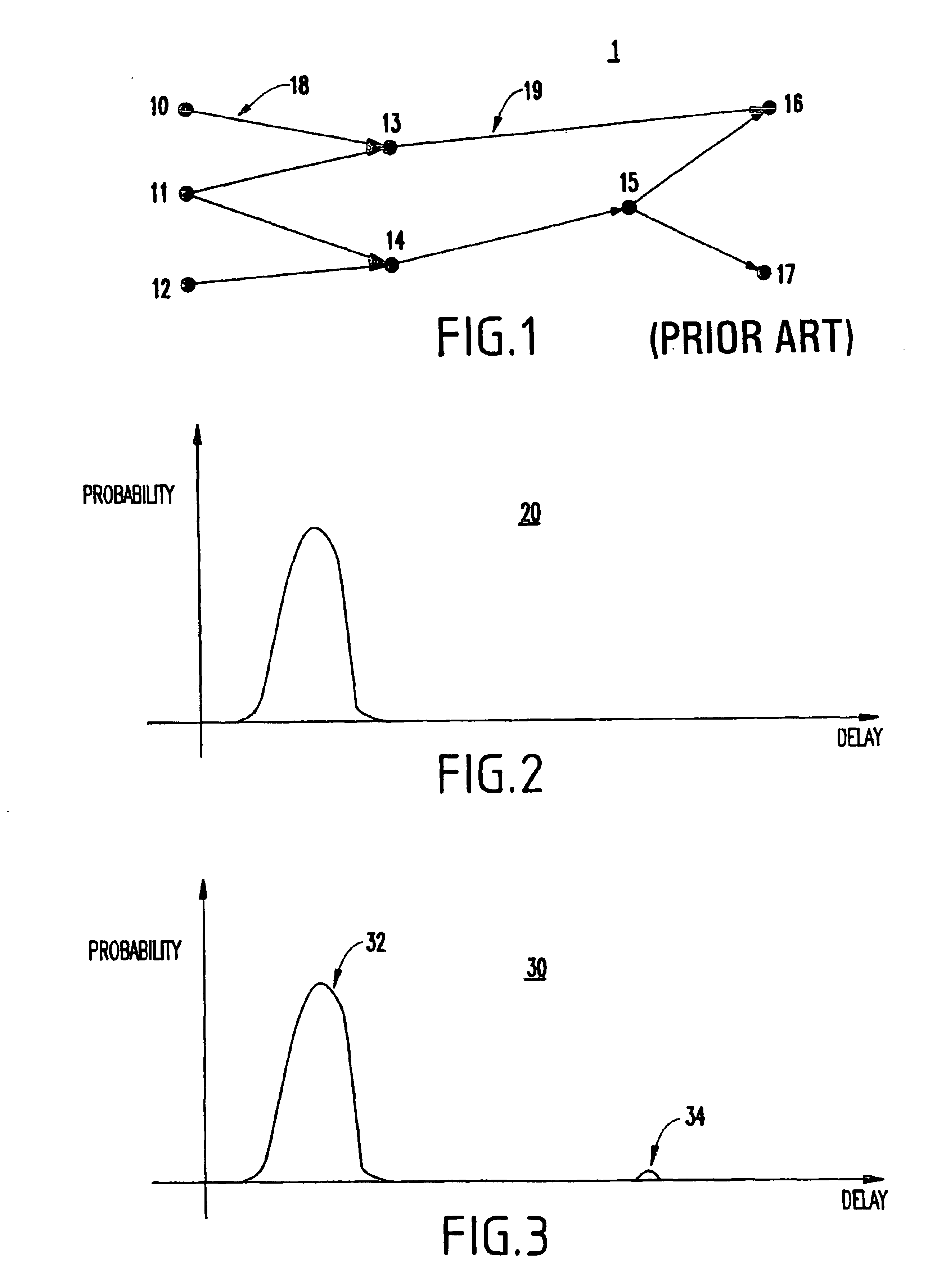

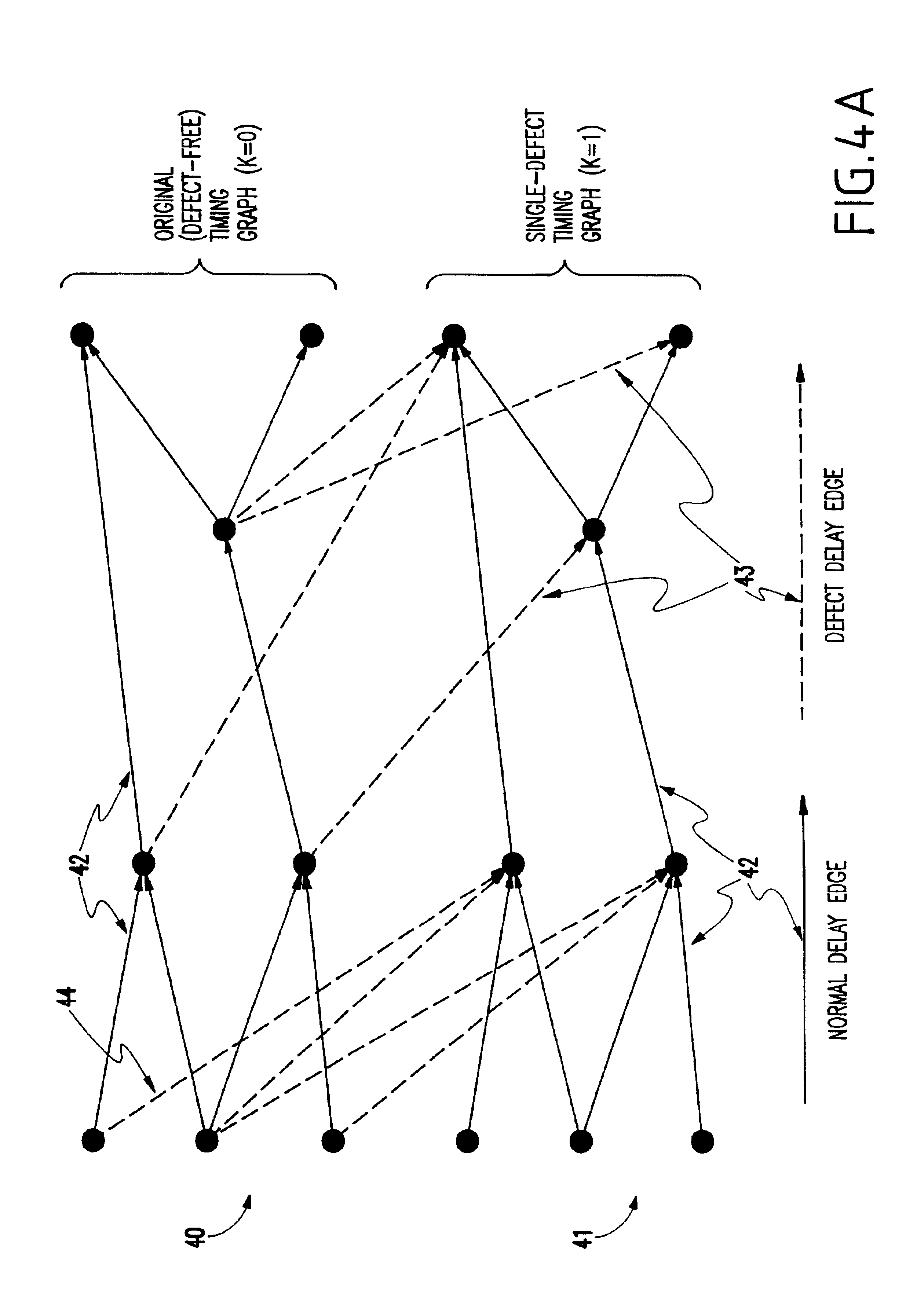

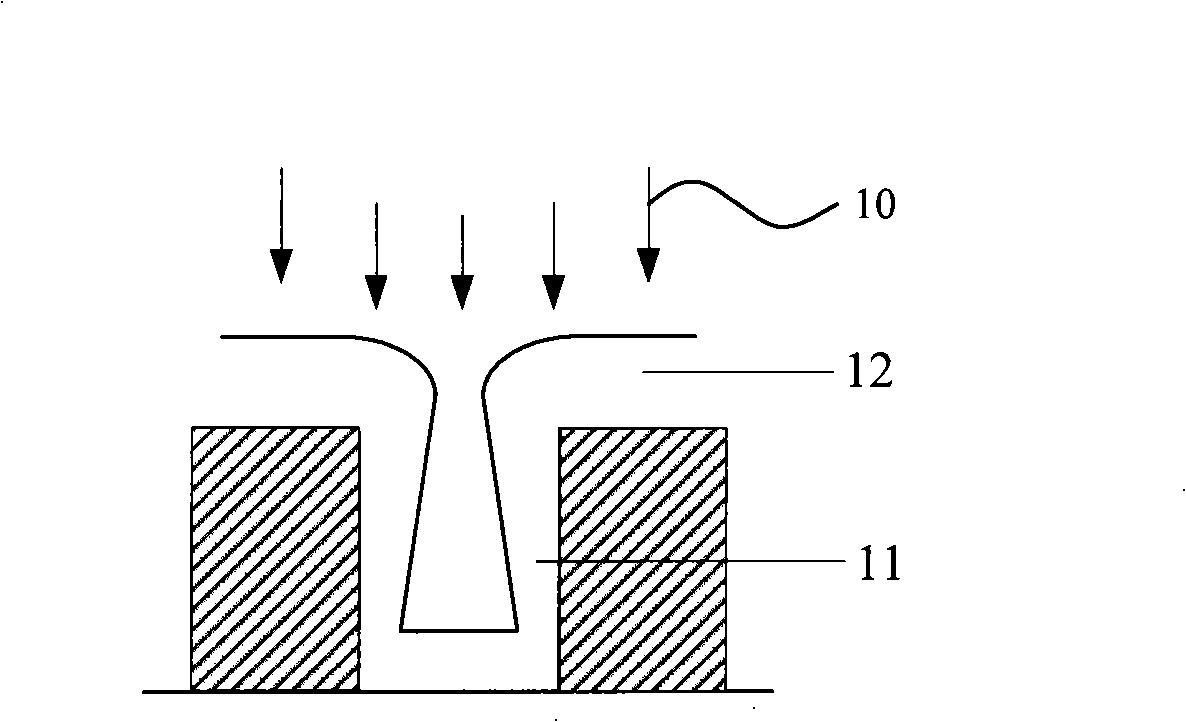

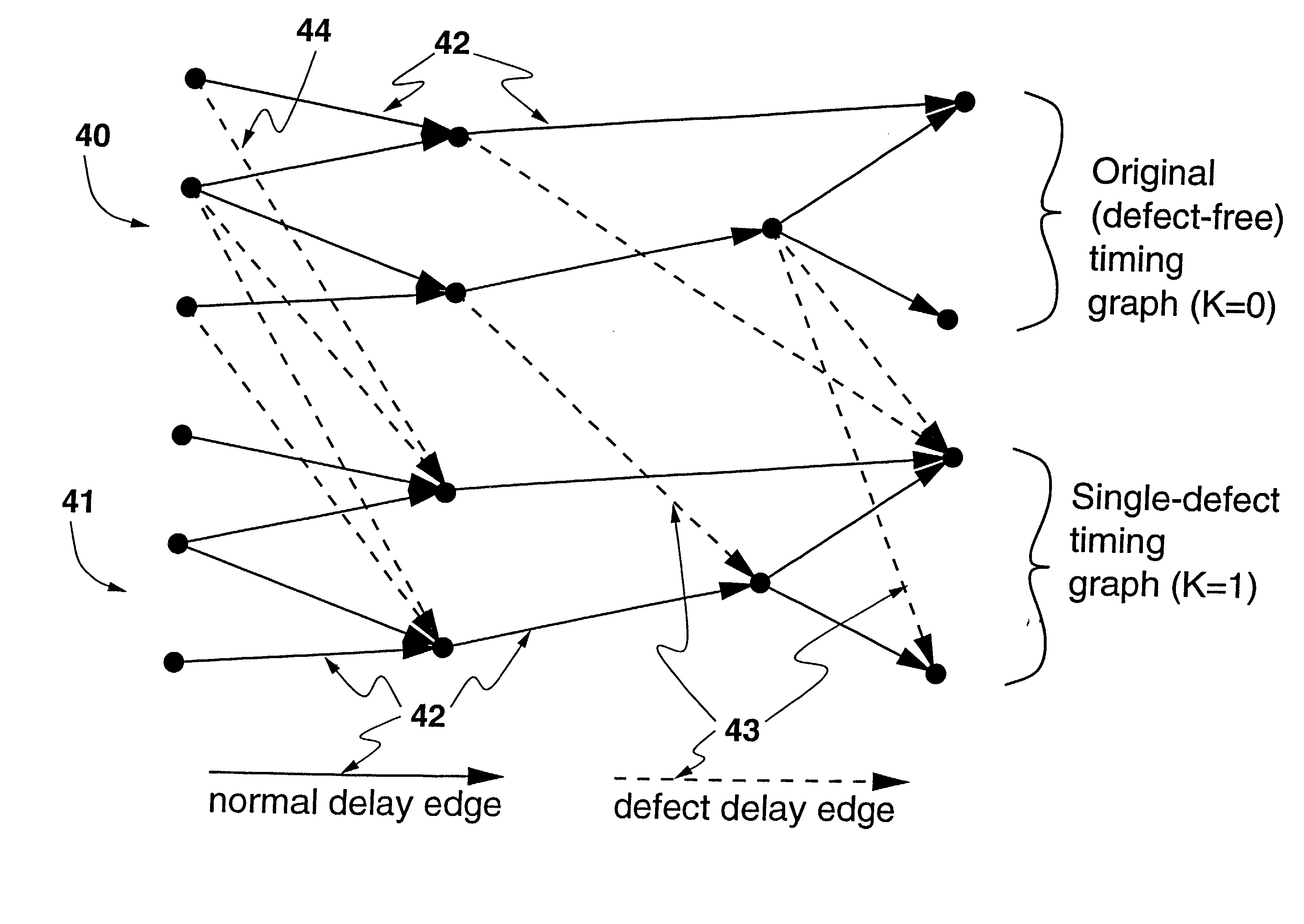

Method and system for fault-tolerant static timing analysis

Owner:GLOBALFOUNDRIES U S INC

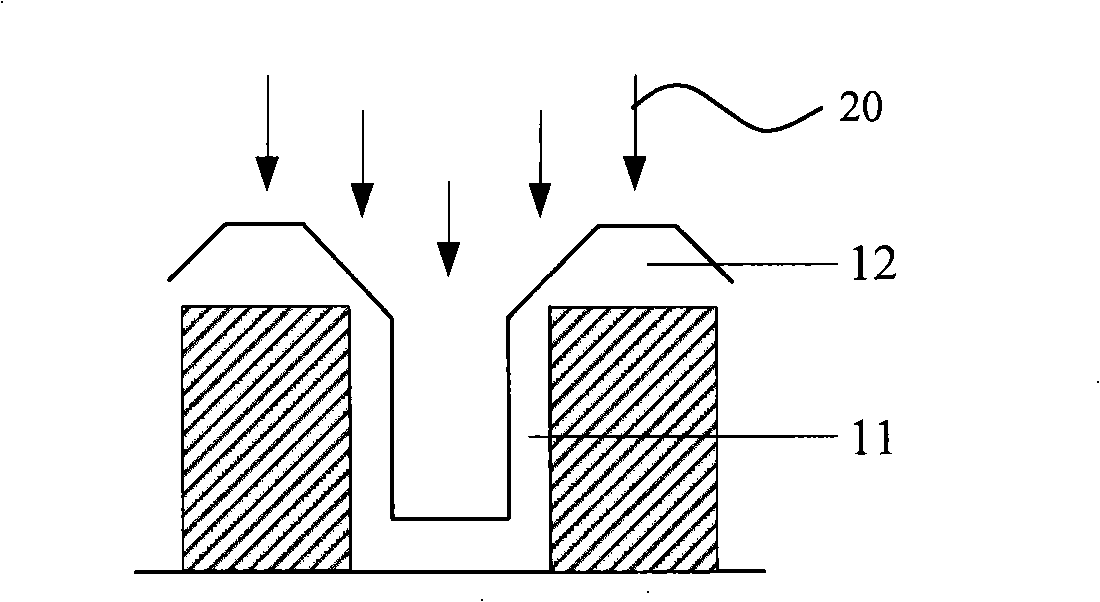

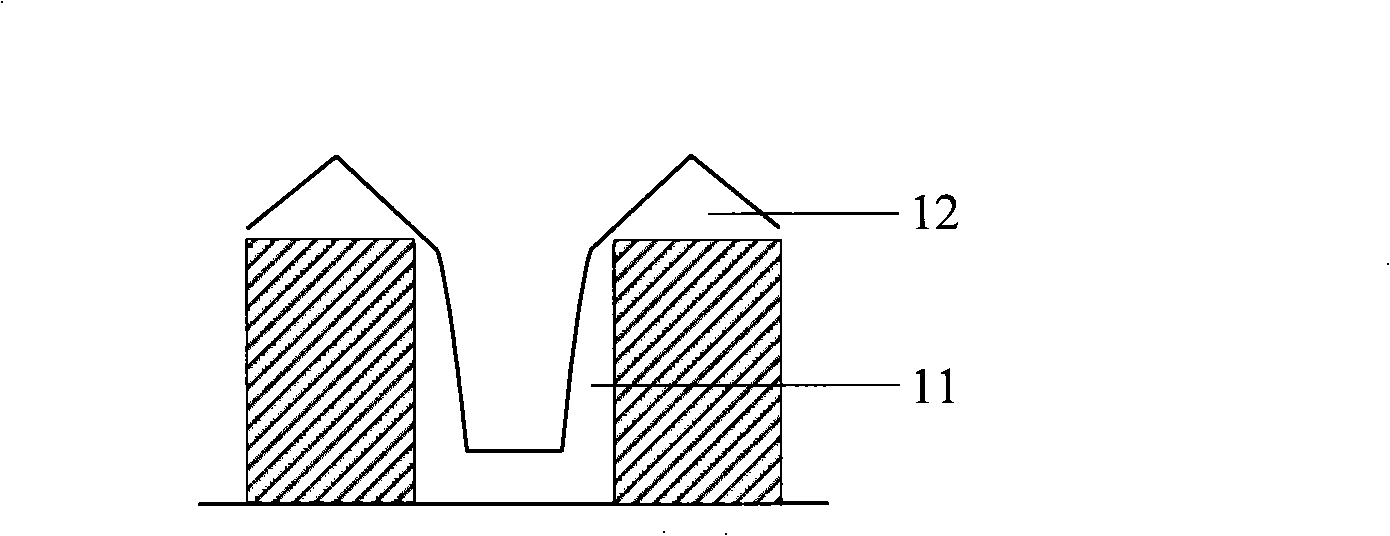

Isolation structure of shallow plough groove and manufacturing method thereof

InactiveCN101330035AImprove compactnessImprove uniformitySemiconductor/solid-state device manufacturingElectrical conductorGas phase

The invention discloses a manufacturing method of a shallow groove isolating structure, which comprises the following steps of: providing a semiconductor underlay; forming a mat oxide layer and a mat azotization layer on the surface of the semiconductor underlay; carrying out the etch of the mat oxide layer, the mat azotization layer and the semiconductor underlay so as to form grooves; carrying out the sedimentation of a first medium layer at the grooves and the surface of the underlay by a first high density plasma chemical gas deposition technology; and carrying out high-temperature thermal annealing and introduction of oxygen to form a silicon oxide layer on the surface of the first medium layer; carrying out the sedimentation of a second medium layer on the surface of the silicon oxide layer by a second high density plasma chemical gas deposition technology; carrying out rapid thermal annealing; grinding the first medium layer and the second medium layer to the mat azotization layer; and removing the mat azotization layer and the mat oxide layer. The STI isolating structure and the manufacturing method of the invention can realize void-free and zero-defect filling of a high depth-width ratio STI isolating groove.

Owner:SEMICON MFG INT (SHANGHAI) CORP

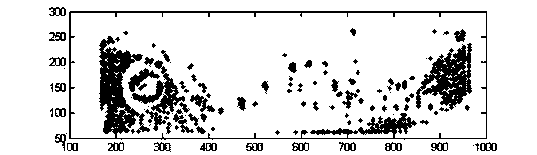

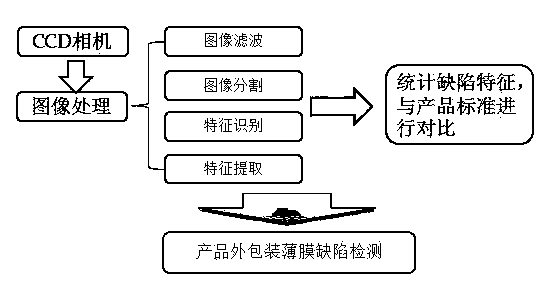

Method for detecting heat sealing defects of external packaging transparent film

InactiveCN104142349AQuality improvementFully automatedOptically investigating flaws/contaminationProduction lineImaging analysis

The invention discloses a method for detecting heat sealing defects of an external packaging transparent film. The heat sealing defects are detected through a non-contact digital image processing technology. The heat sealing face of the external packaging transparent film is converted to digital image information through a CCD camera; the image information is input to a computer for preprocessing; size adjustment and gray-scale processing are carried out, and a median filter is adopted for denoising; preprocessed images are segmented, a zero-defect original image serves as a tool image to carry out deduction operation on the segmented images, and a background image is removed; edge detection is carried out on defect characteristics in the images through a Roberts operator; an image defective region is marked through a BWlabel algorithm, and the number and area of the defect characteristics are counted through a Regionprops algorithm. The number and area of the defect characteristics extracted out according to image analysis are compared with the qualification standard, so that the effect of detecting the defects of the external packaging transparent film is achieved. The heat sealing defects of the external packaging transparent film are detected through a computer processing technology, and the method can be applied to a packaging production line for automatic detection.

Owner:中国机械总院集团云南分院有限公司

Magnetostrictive guide wave damage-free detection method

InactiveCN101126743AEasy to distinguishHigh precisionMaterial analysis using acoustic emission techniquesNon destructiveLinear relationship

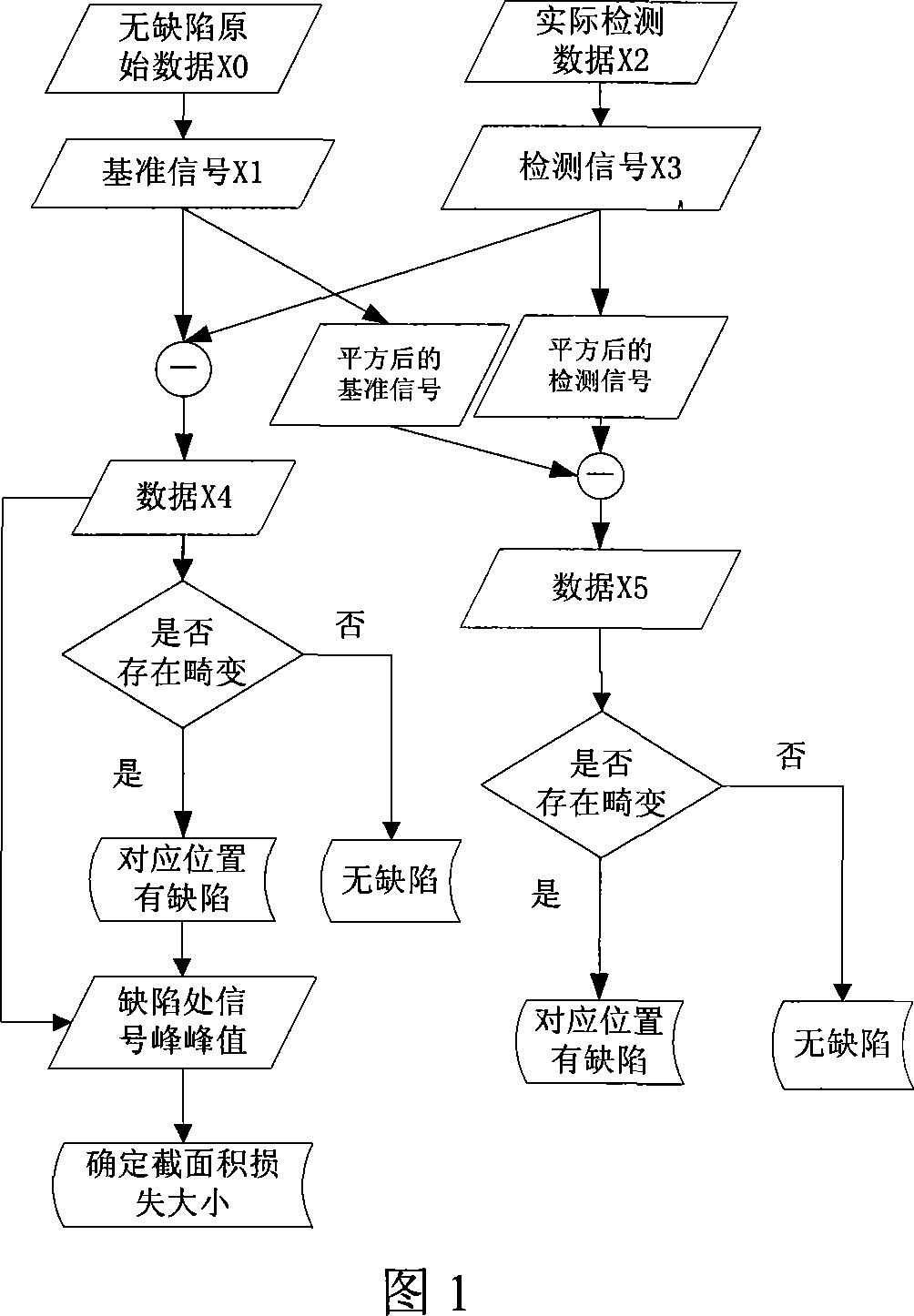

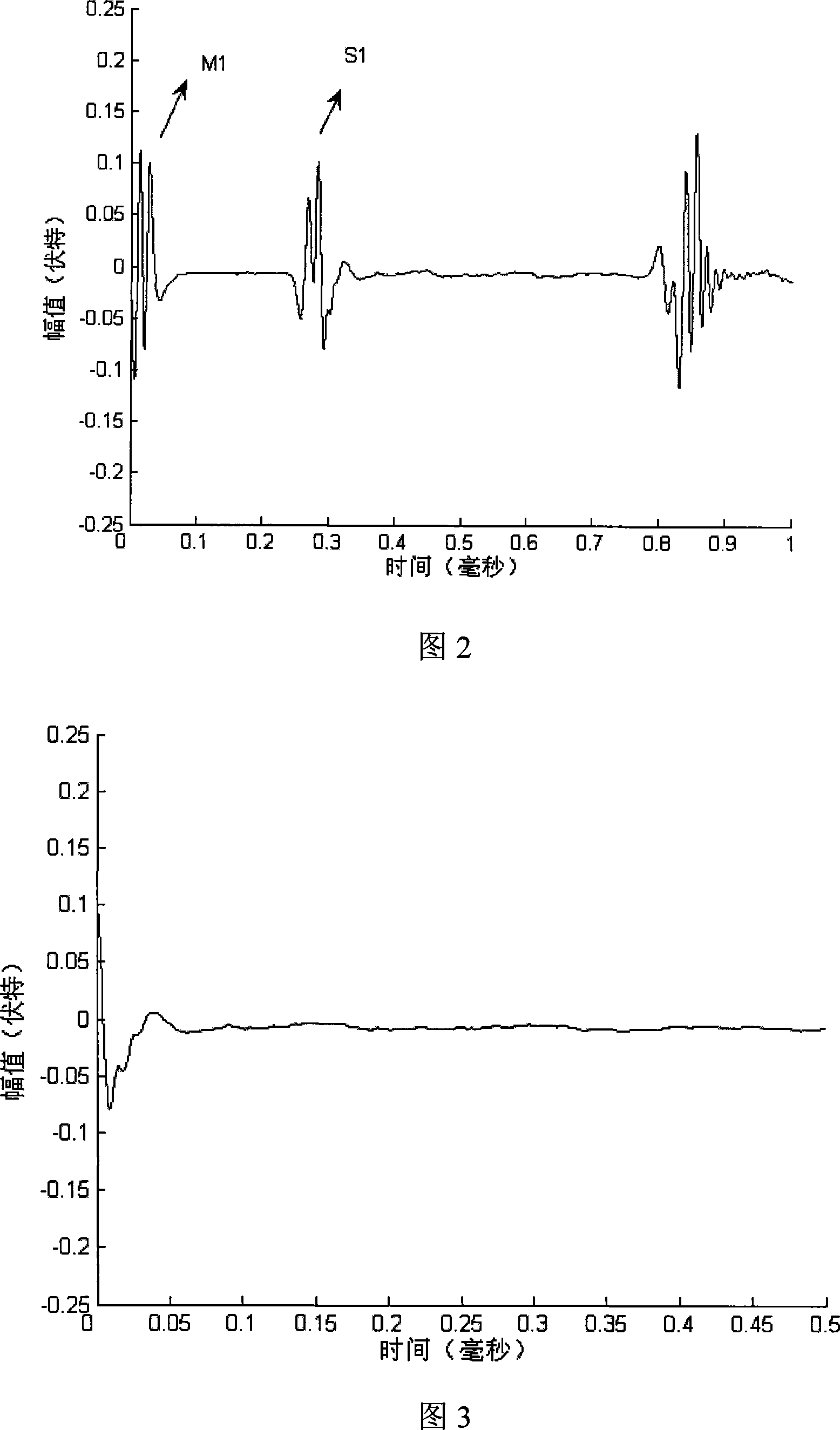

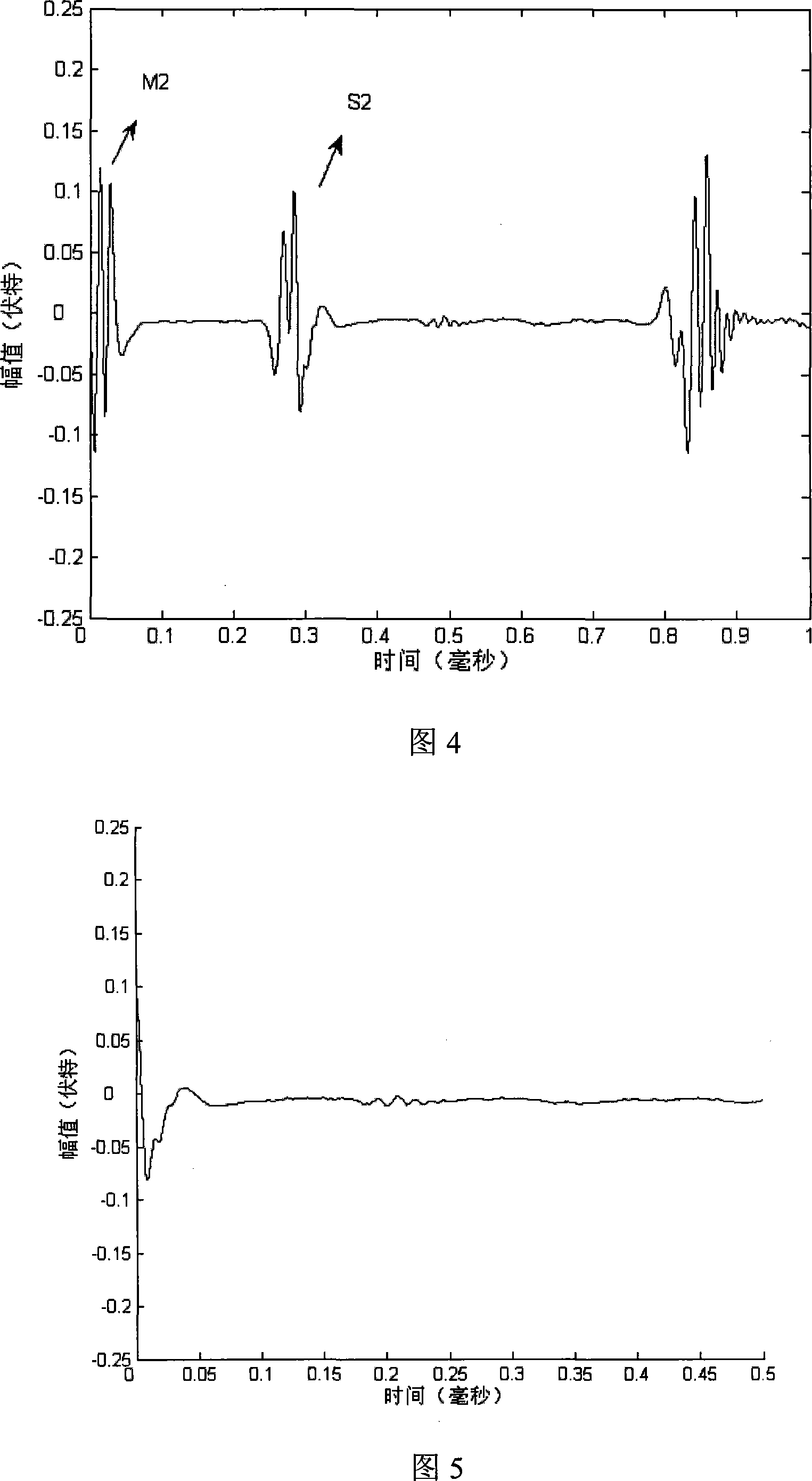

The utility model relates to a non-destructive examination method for the magnetostriction guided wave, which belongs to the technical field of non-destructive examination; wherein, a group of signals are extracted respectively from the zero defects signals of standard samples and the actual detection signals as reference signals and detection signals according to definite length and starting point of the data. The method one is that: a group of signals are acquired via the difference between the detection signals and the reference signals; defects are detected by judging whether the signals are deformed or not; the loss amounts of the section surface of tested members are measured by using the peak-to-peak value of the signals according to the linear relationship between the peak-to-peak value of the defect signals and the loss amounts of the section surface of the tested members. The method two is that: a group of signals are acquired via the difference between the square of the detection signals and the reference signals; defects are examined by judging whether the signals are deformed or not. The originally indistinguishable signals of small defects are processed into signals with easily distinguishable defects through the signal processing method, thus realizing the examination of minor defects defying examination and greatly enhancing the precision of measurement.

Owner:HUAZHONG UNIV OF SCI & TECH

Zero-defect construction method for secondary lining of tunnel

ActiveCN109026065APrevent under-thicknessPrevent voids and other defectsUnderground chambersTunnel liningNon destructivePunching

The invention discloses a zero-defect construction method for a secondary lining of a tunnel. The method comprises the following steps: S1, controlling smooth blasting quality; S2, detecting and controlling a primary lining section; S3, performing under-excavation treatment on the primary lining section; S4, hanging a waterproof board; S5, feeding window by window, vibrating layer by layer and grouting plate by plate, wherein no less than two punching holes are punched for concrete grouting of secondary lining and a two-vibration mode is adopted in which an insertion vibrator acts mainly and an adhesion type vibrator acts auxiliary for a side wall part while the adhesion type vibrator acts mainly and the insertion vibrator acts auxiliary for an arch part so as to implement concrete grouting of secondary lining; S6, performing mold grouting 2 hours after the completion of concrete grouting of second lining; S7, after mold grouting is completed, performing pipe maintenance and implementing non-destructive detection of secondary lining concrete at the same time. The invention prevents defects such as insufficient thickness and void in tunnel lining construction, guides the whole process of tunnel quality defect treatment, and ensures zero defect of lining quality.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

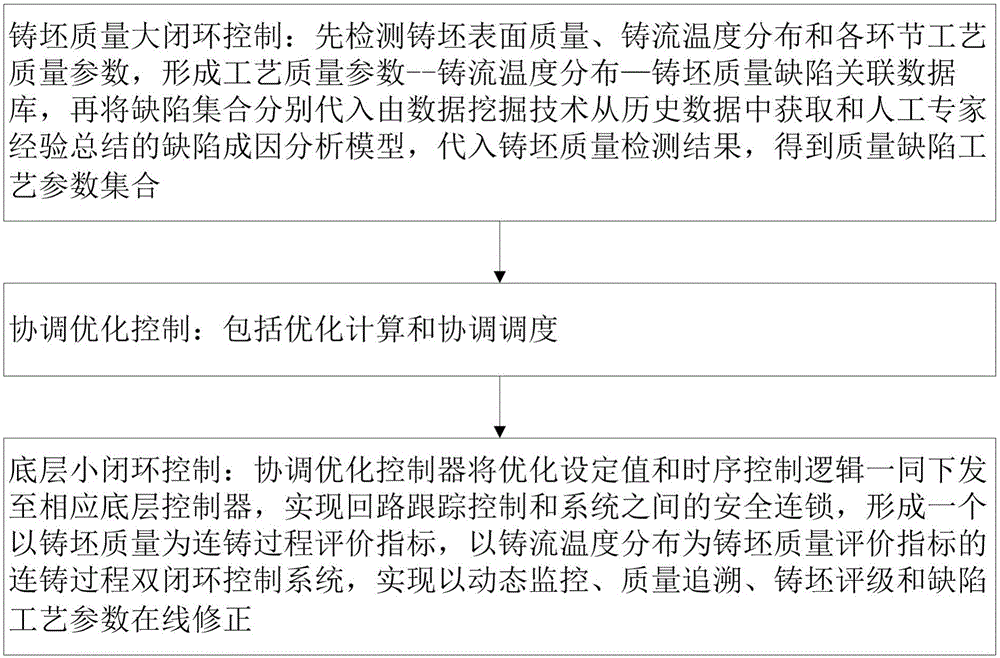

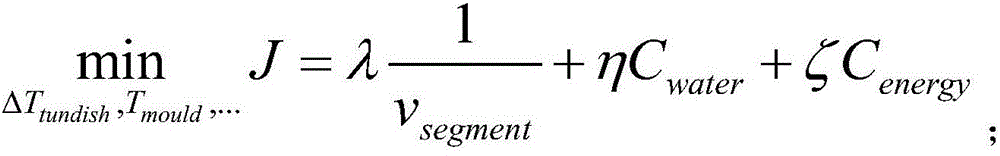

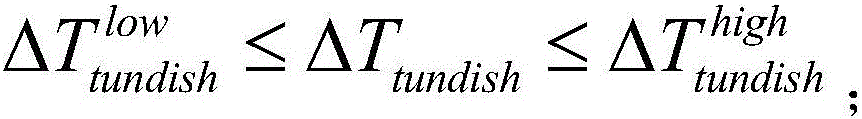

Continuous casting coordinated optimization control method

InactiveCN106077555AClear logical structureIn line with the actual production of continuous castingClosed loopEnergy consumption

The invention discloses a continuous casting coordinated optimization control method. The continuous casting coordinated optimization control method comprises the steps of casting blank quality large closed-loop control, coordinated optimization control and bottom layer small closed-loop control, the design concept of optimizing control is adopted, zero defect in quality of a continuous casting billet is taken as restriction, technological parameters in a continuous casting process are optimized, sequential control logic is coordinated, and an optimization calculation result is issued to each bottom layer controller to be executed, so that optimal coordinated control of a continuous casting production process is realized, productivity is steadily improved while product quality is guaranteed, and energy consumption and water consumption are reduced at the same time.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

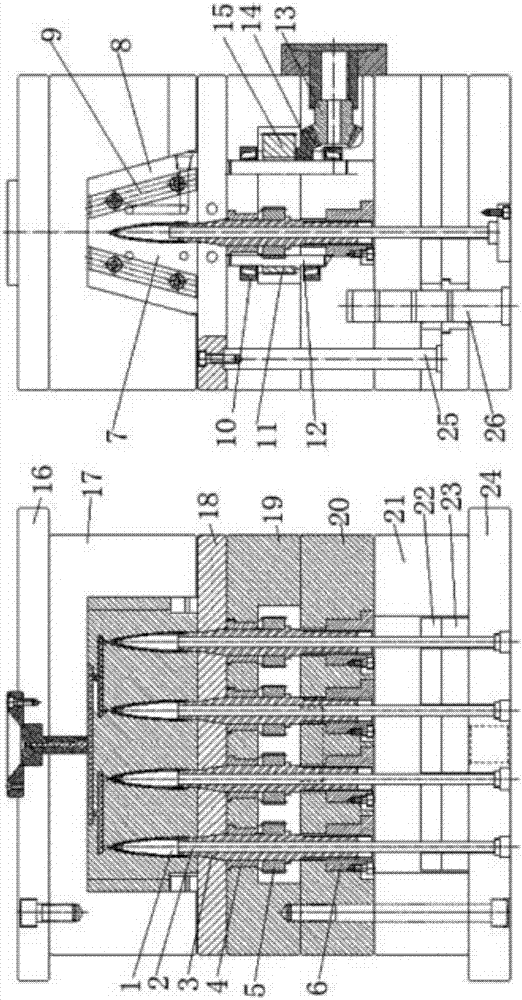

Die-casting forming method free from shrinkage cavity and shrinkage porosity defects for thick wall die-casting fitting

InactiveCN106270441ASolve the shrinkage porosity that is easy to appearSolve defects such as poresMold fillingDie casting

The invention discloses a die-casting forming method free from shrinkage cavity and shrinkage porosity defects for a thick wall die-casting fitting. By the adoption of the method, the problems of shrinkage cavity, shrinkage porosity and air hole defects which are likely to happen to a thick wall aluminum alloy die-casting fitting frequently can be solved effectively. The die-casting forming method includes the main contents that a specific pouring method with the low superheat degree is adopted, large fullness pouring with the pressure chamber fullness being 60%-70% is used, the high-pressure mold filling die-casting technique is utilized, and the internal compactness zero-defect performance of the die-casting fitting is achieved. The local pressurization structure is added in mold design, and pressurization feeding at the thick wall position far away from the position of an inner casting gate is realized. By the adoption of the method, the casting defects of the thick wall die-casting fitting can be reduced, the rejection rate of products is lowered, material wasting is avoided, cost is reduced and benefits are increased.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD +1

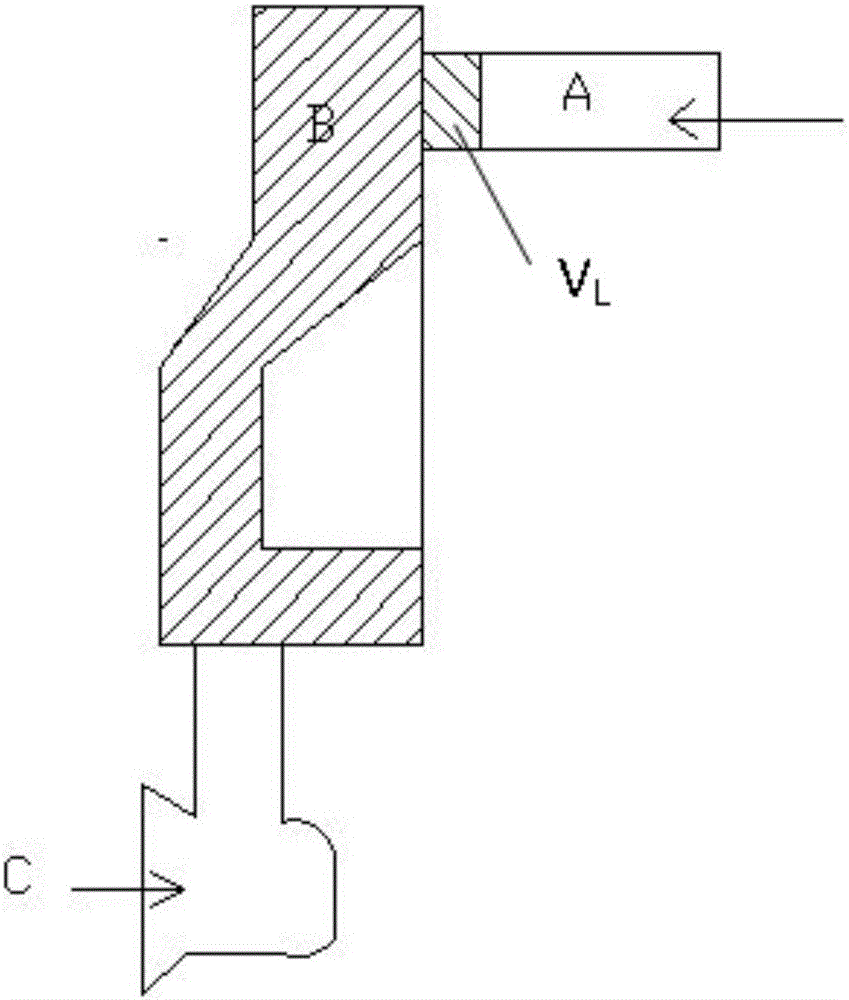

Power transmission line grounding construction method

InactiveCN105514750AAchieve zero-defect handoverMeet construction acceptance specificationsLine/current collector detailsConnection contact member materialElectrical resistance and conductanceArchitectural engineering

The invention relates to a power transmission line grounding construction method, and the method comprises the following steps: S1, digging a grounding groove; S2, laying a grounding device; S3, connecting the grounding device; S4, refilling the grounding groove; S5, measuring grounding resistance. The beneficial effects of the invention are that the method can meet the requirements of excellent standards of national construction inspection rules and quality evaluation standard rules, guarantees the zero-defect hand-over of an electric pole construction project, and avoids severe construction quality accidents and quality management accidents.

Owner:STATE GRID CORP OF CHINA +2

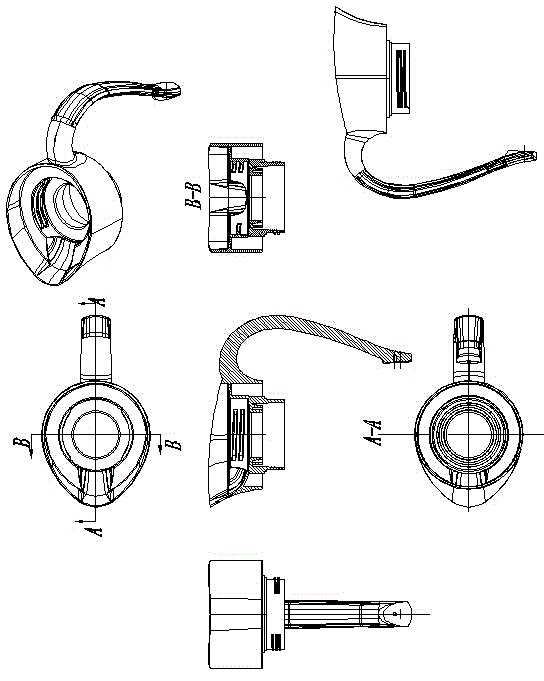

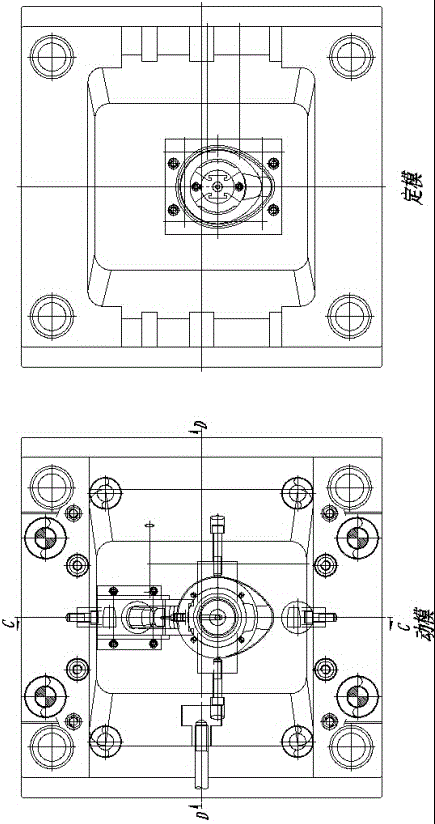

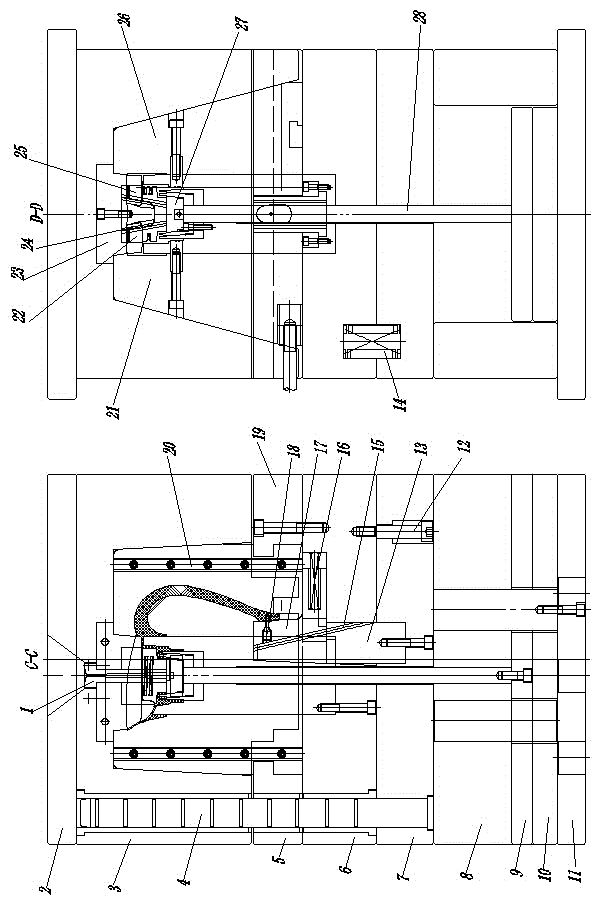

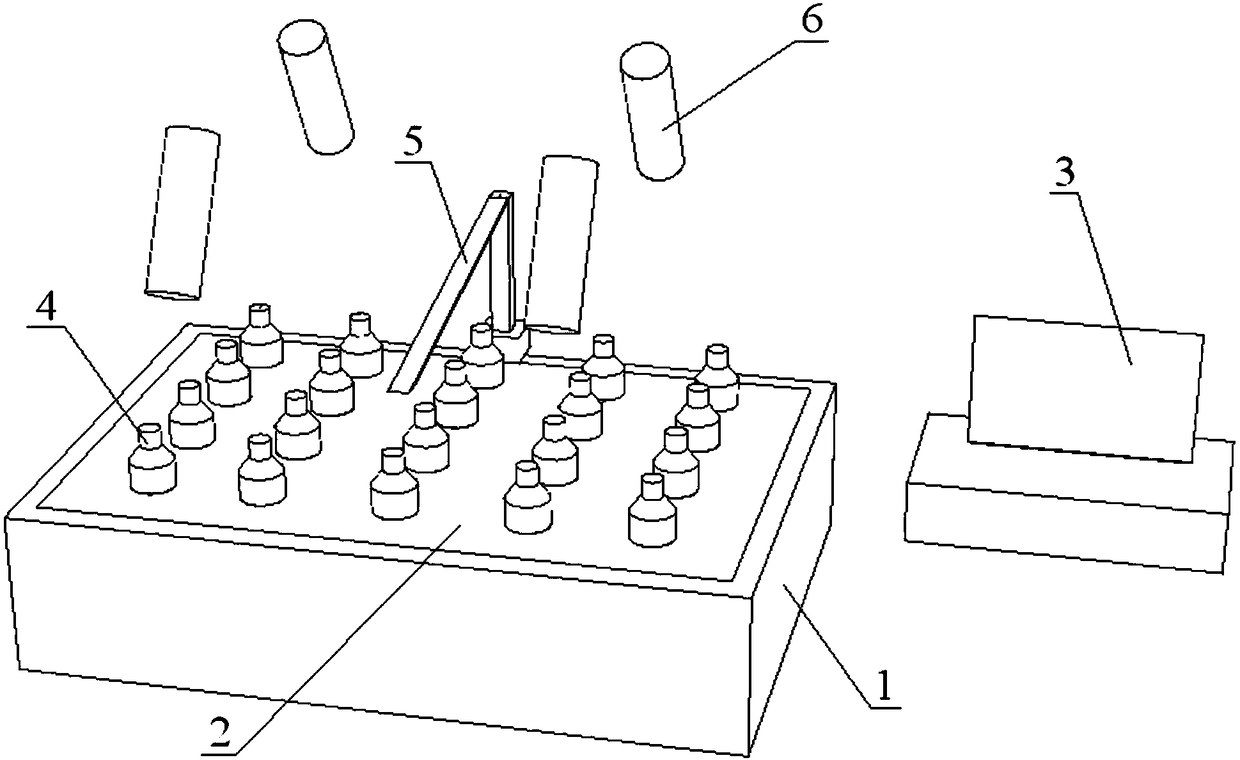

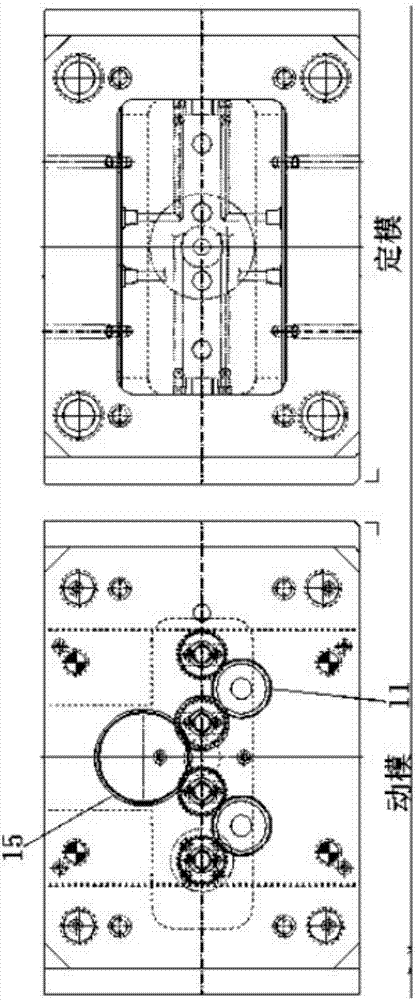

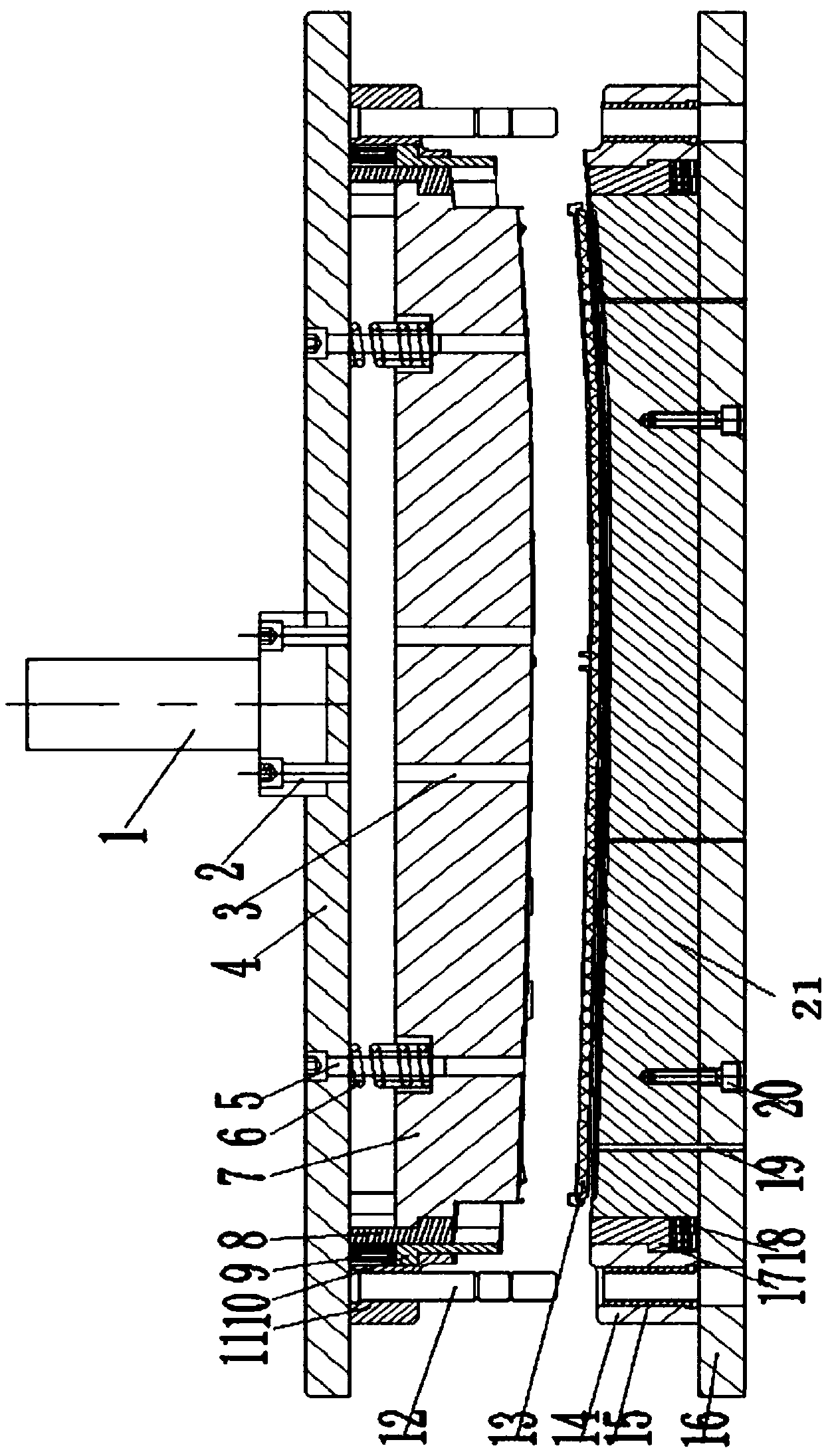

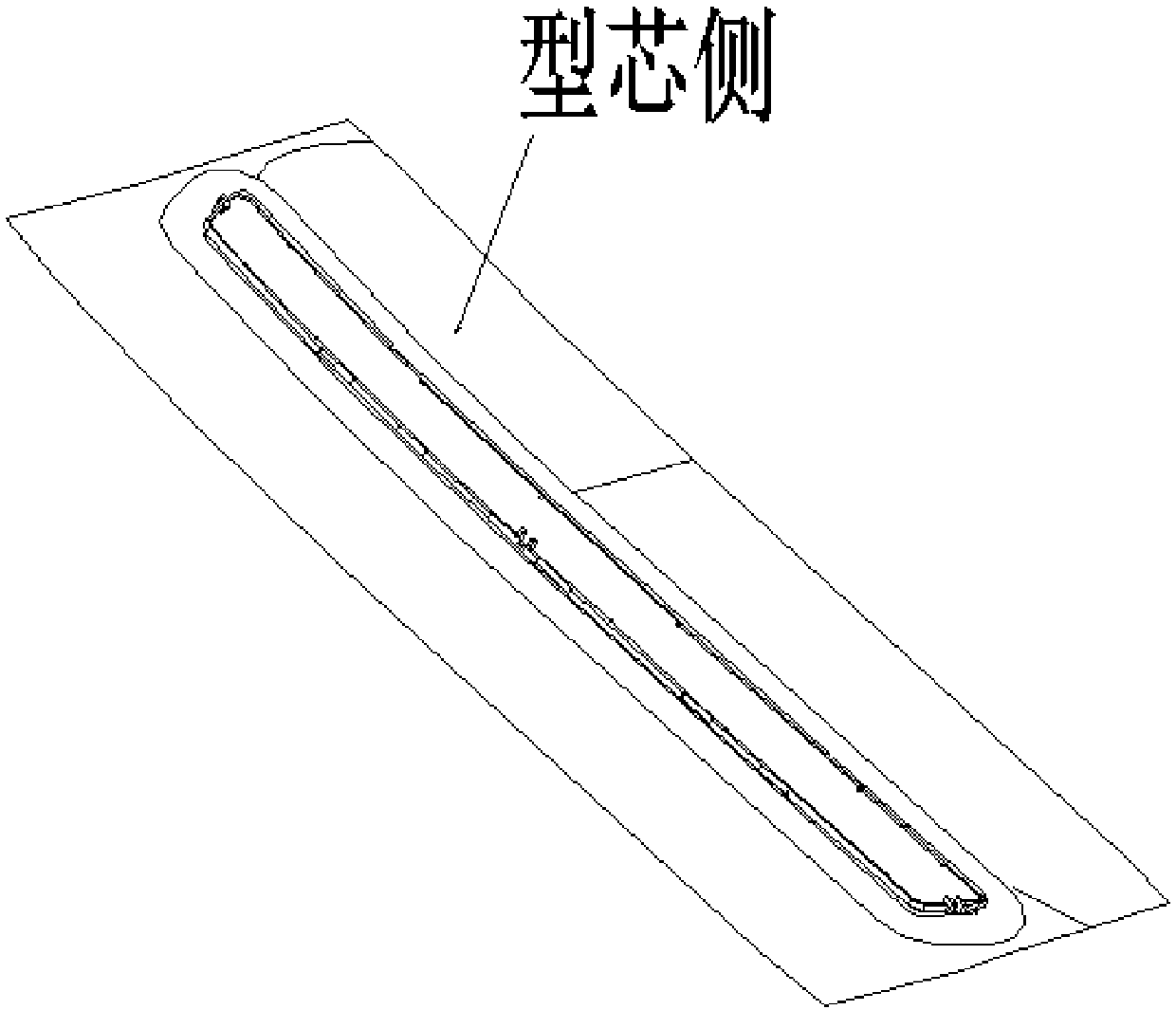

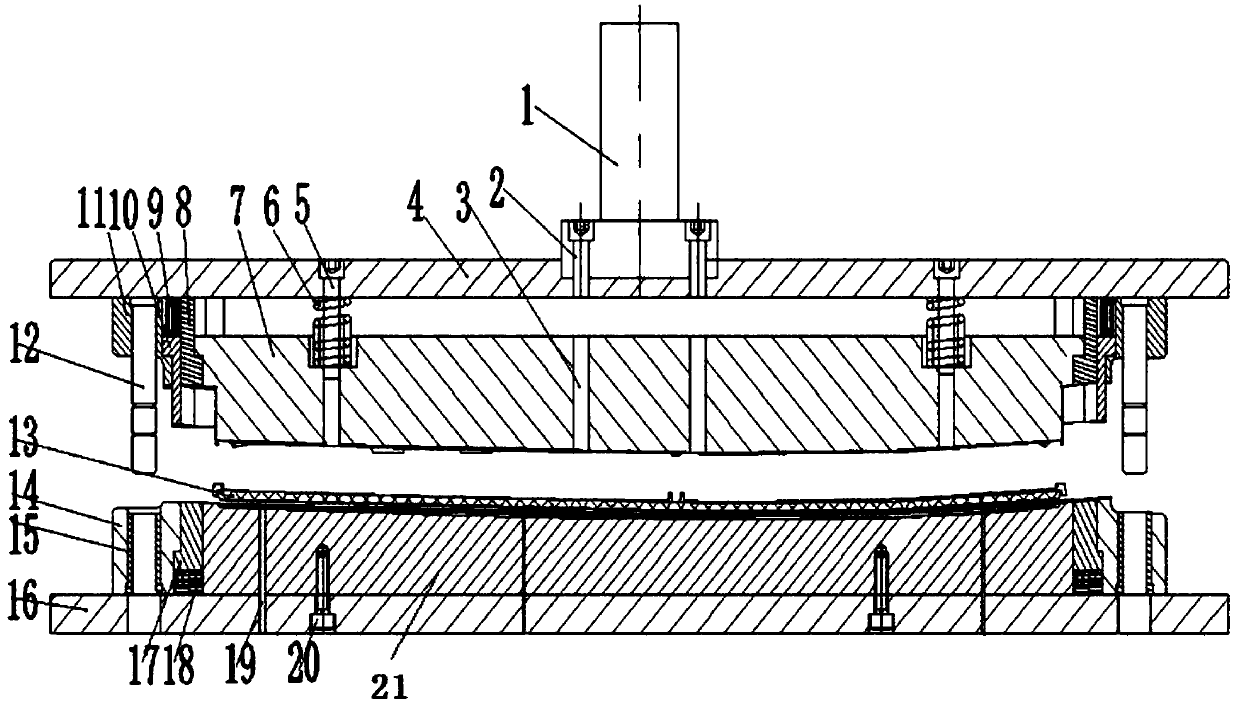

Demolding mechanism and injection mold for cup handle

The invention provides a demolding mechanism and injection mold for a cup handle. The demolding mechanism and injection mold comprises a mold base structure assembly, a forming assembly, an upper internal core-pulling mechanism assembly, a side core-pulling demolding mechanism assembly, a lower internal pulling mechanism assembly and a primary parting control assembly, wherein the mold adopts two times of parting mold opening; the mold adopts the layout of one cavity per mold; a pouring system adopts a cold runner injection molding mode. With adoption of the technical scheme, the mold overcomes the defects that a mold design mechanism has design difficulty, the actual processing and manufacturing difficulties are large, sufficient filling cannot be guaranteed by the forming and pouring modes, the forming quality is affected by more flash of products and the like in a molding and injection molding process of cup handle products, zero-defect automatic molding production of the products is realized with simple mechanisms, the product forming quality is guaranteed effectively, and the mold is reasonable in structural design, compact in structure, stable in work, safe and reliable.

Owner:湖南省蓝山县博亿农业开发有限公司

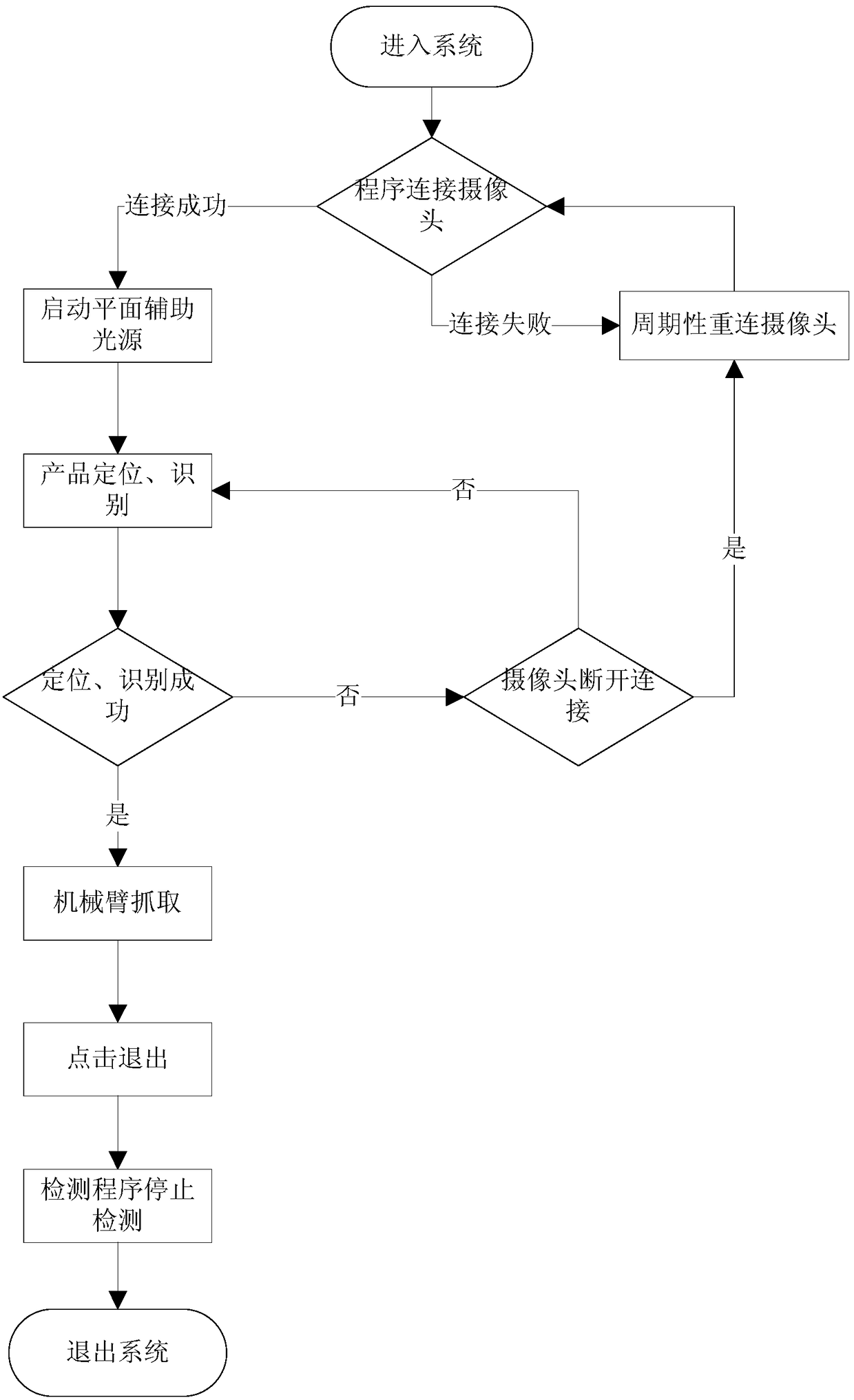

Product transfer system and method based on planar auxiliary light source and machine vision

InactiveCN108508844AOvercome limitationsReduce and avoid wasteProgramme controlComputer controlMachine visionTransfer system

The invention discloses a product transfer system and method based on a planar auxiliary light source and machine vision. The transfer method comprises the steps that the planar auxiliary light sourceis installed around products and used for producing contrast images of the products; contrast images of various types of zero-defect standard products are acquired to serve as target images; the contrast images of the products to be classified on a production platform are acquired in real time to serve as images to be detected; the images to be detected and the target images are identified and matched, and the type of each product is determined; a control mechanical arm classifies the products to be classified. The transfer system comprises the planar auxiliary light source installed around products, a camera and the mechanical arm arranged above the production platform, and a control module connected with the camera and the mechanical arm. The camera acquires contrast images of the products on the planar auxiliary light source, the control module identifies contrast image information, matches the information with the target images and controls the mechanical arm to perform classification after the types of the products are confirmed.

Owner:SICHUAN UNIV

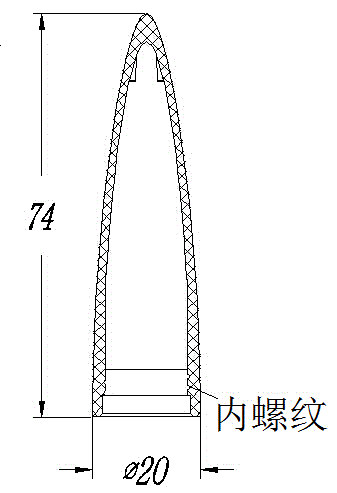

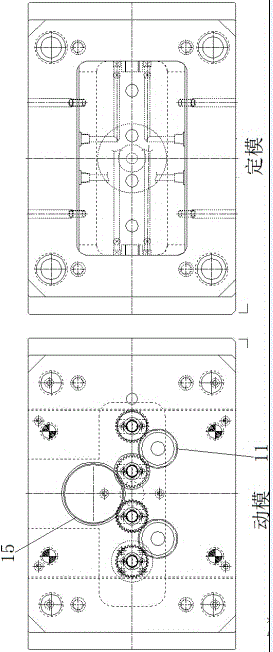

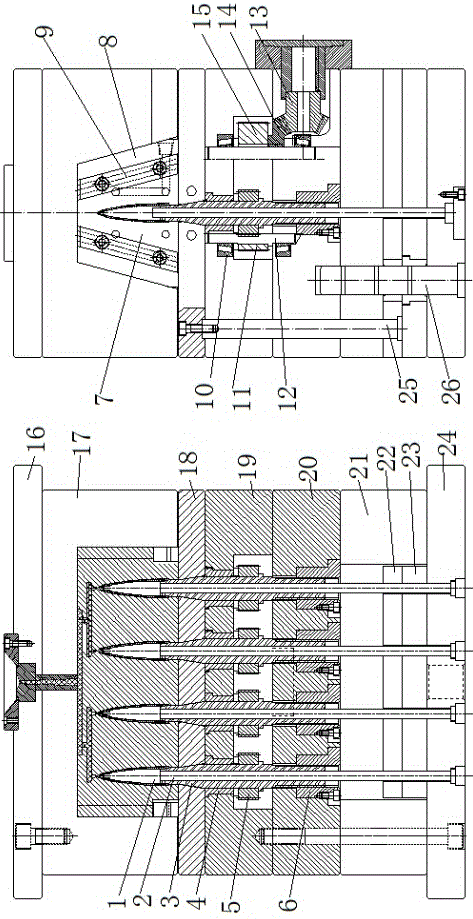

Pen cap thread injection mold

InactiveCN104924549AGuarantee molding qualityReasonable structural designScrew-threads articlesShell moldingEngineering

The invention provides a pen cap thread injection mold which comprises a mold frame structure assembly, a forming assembly, a thread releasing mechanism assembly and a mold ejecting out mechanism assembly. According to the structure layout of the mold, four cavities are formed in the mold, and a central point pouring gate mode is adopted as the gate mode. Halves of runners and halves of pouring gates are arranged on left sliding blocks and right siding blocks respectively, the mode of arranging pouring channels on the sliding blocks is adopted, and the overall pouring channels are formed by petal combination of the left sliding blocks and the right sliding blocks. By means of the technical scheme, the pen cap thread injection mold solves the practical production problems that in the technology of injection molding of pen cap product molding, product pouring gates are difficult to form, trimming is much, filling is not full; the zero-defect automatic molding production of the products can be achieved through a simple mechanism, and the product forming quality is effectively ensured. The structure design is reasonable, the structure is compact, and safety and reliability are achieved.

Owner:佛山天翊机械模具有限公司

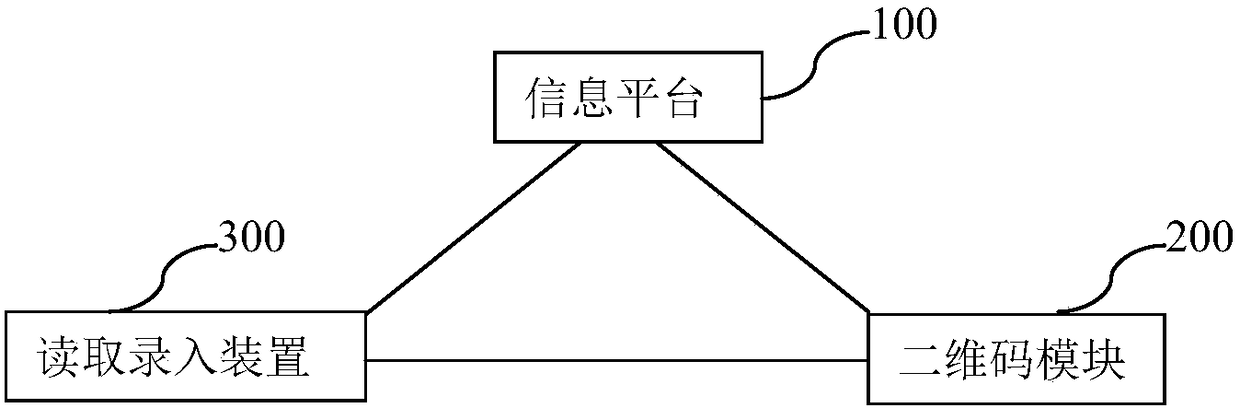

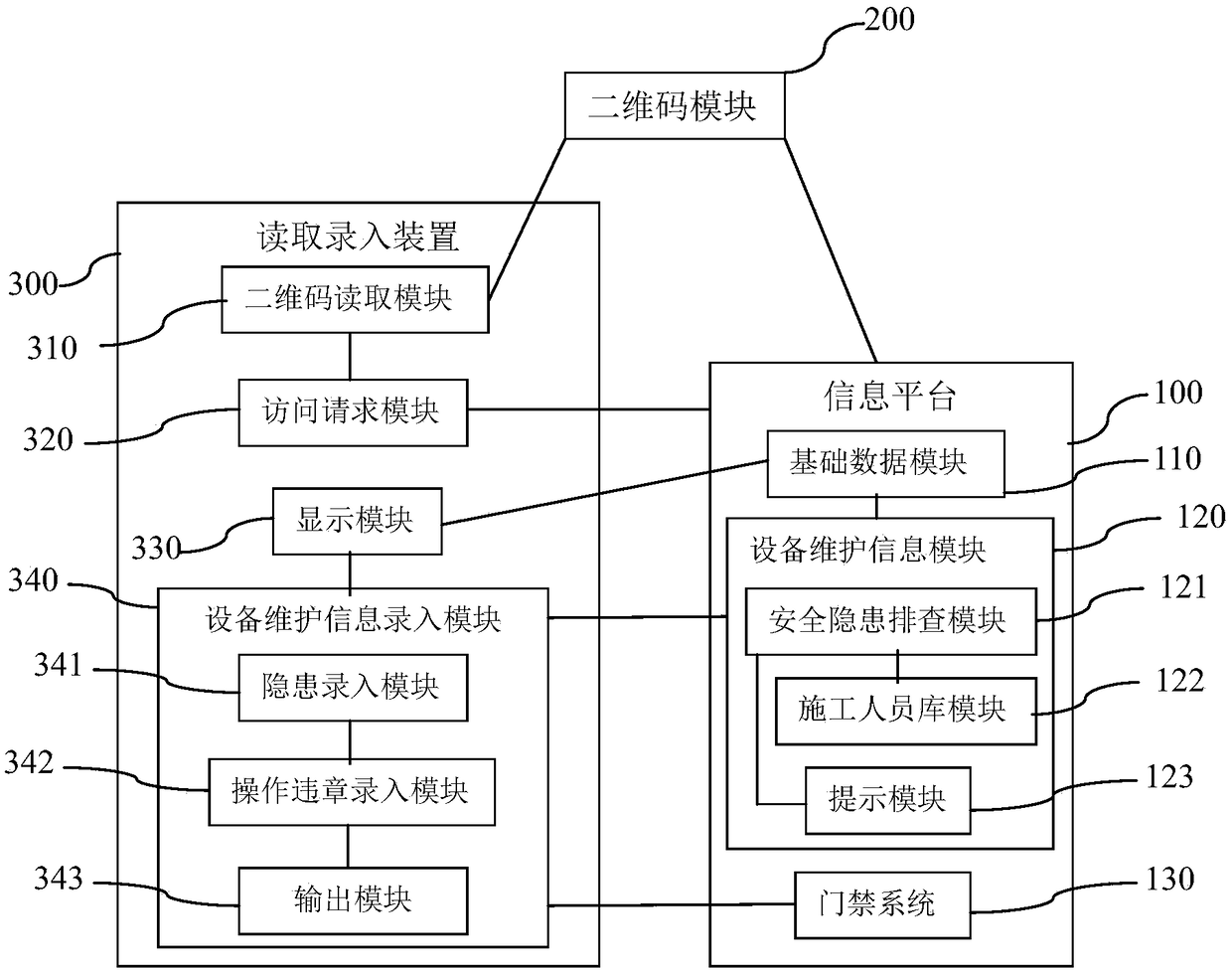

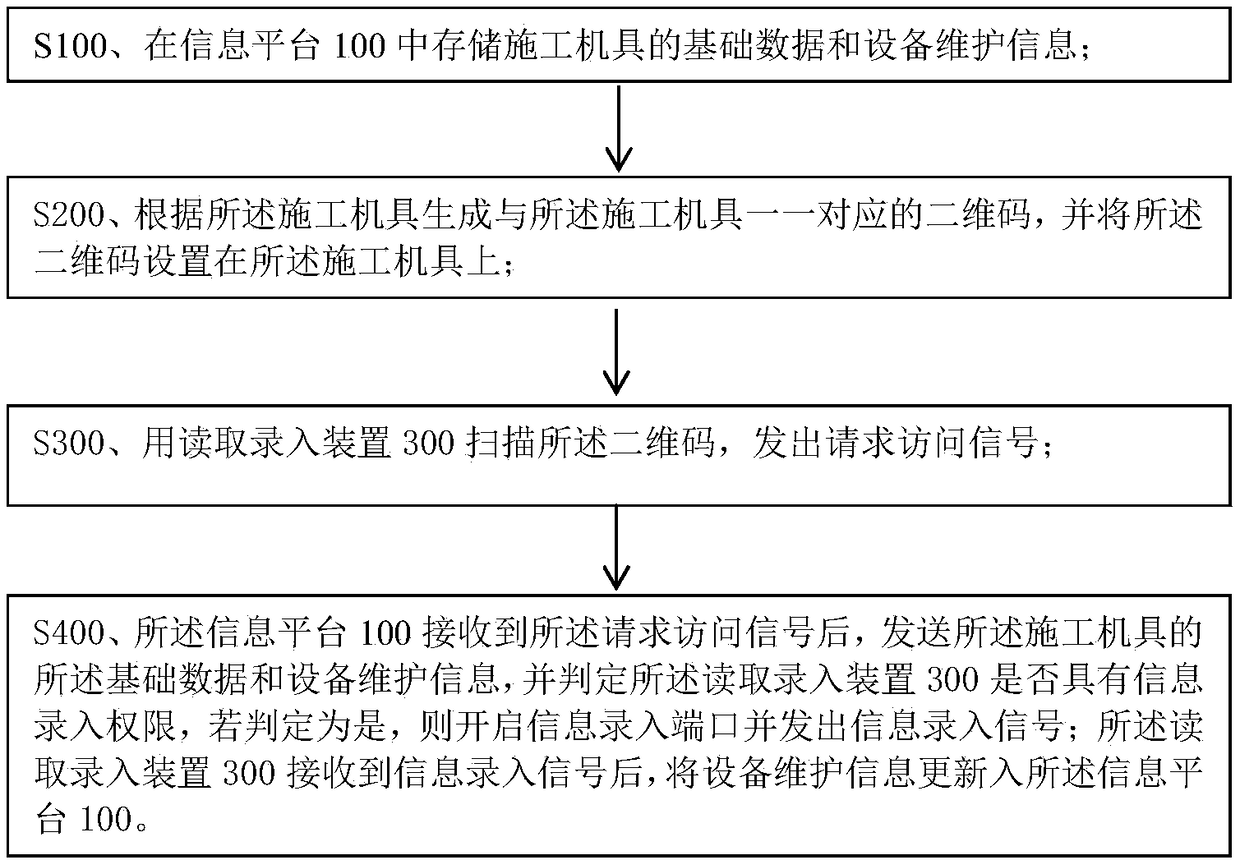

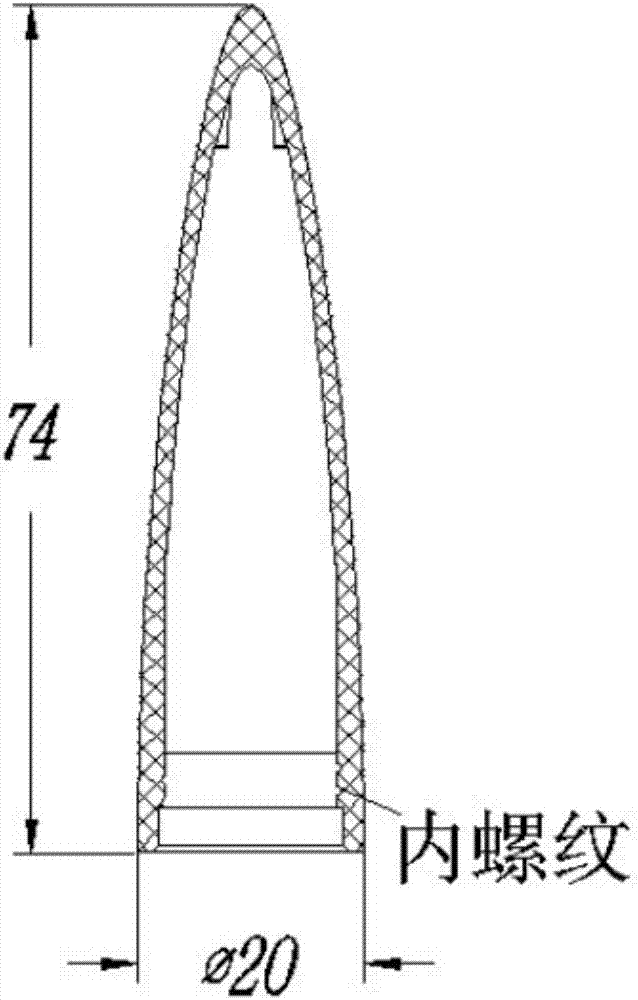

Safety information management system and method of construction equipment of nuclear power plant

InactiveCN108108782ARead in real timeAccess anytime, anywhereData processing applicationsCo-operative working arrangementsCode moduleNuclear power

The invention discloses a safety information management system and method of construction equipment of a nuclear power plant. The system comprises an information platform used for storing basic data and equipment maintenance information of the construction equipment, a quick response code module arranged on the construction equipment and used for generating a quick response code corresponding to the construction equipment according to the construction equipment, and a reading input device used for scanning the quick response code and sending a request access signal to the information platform;the information platform receives the request access signal, sends the basic data and the equipment maintenance information of the construction equipment to the reading input device, determines whether the reading input device has an information input permission, and opens an information input port and sends an information input signal if the reading input device has the information input permission; and the reading input device receives the information input signal and updates the equipment maintenance information into the information platform. According to the system and method, the informationization of safety management of the construction equipment of nuclear power engineering is realized, and the achievement of goals of zero damage and zero defect of equipment management can be ensured.

Owner:中广核工程有限公司 +1

Threaded injection mold for pen cap and use method of threaded injection mold

InactiveCN106881834AGuarantee molding qualityReasonable structural designScrew-threads articlesShell moldingEngineering

The invention provides a threaded injection mold for a pen cap and a use method of the threaded injection mold. The threaded injection mold comprises a mold base structure component, a molding component, a thread relieving mechanism component and a mold ejection mechanism component; a one-mold four-cavity layout is adopted, and a casting mode is a central pin-point gate mode; half of a runner and half of a sprue are arranged on a left slider and a right slider, the mode that pouring gates are arranged on the sliders is adopted, and the overall pouring runner consists of the left slider and the right slider which are combined together. By adopting the technical scheme, the practical production problems that a product sprue is difficult to form, many flanges exist and filling is not full in the pen cap product injection molding process are solved, zero-defect automatic molding production of a product can be realized through simple mechanisms, and the product molding quality is effectively guaranteed; the threaded injection mold is reasonable in structural design and compact in structure and is safe and reliable.

Owner:URUMQI JIUPIN SESAME INFORMATION TECH CO LTD

Method and device for linear pre-coding of communication system

InactiveCN102957502AEasy to getNo limitSpatial transmit diversityError preventionCommunications systemEngineering

The invention discloses a method and a device for linear pre-coding of a communication system. The method comprises the following steps of: setting an initial value of a receiving beam forming matrix RBFM of the current sub-carries according to channel characteristics of sub-carries which are related to a current sub-carrier of ith user equipment; determining an equivalent combined channel compensation matrix of the ith user equipment in pth iteration of the current sub-carrier according to the RBFM of the ith user equipment in (p-1)th iteration, wherein the p is a natural number; obtaining a right singular vector set of a left zero defect space of the equivalent combined channel compensation matrix and setting the right singular vector set into a transmitting beam forming matrix TBFM of the ith user equipment in the pth iteration; and setting the TBFM of the ith user equipment into a pre-coding matrix Fi of the ith user equipment according to a convergence rule. According to the method and the device disclosed by the embodiment of the invention, a pre-coding matrix can be rapidly and simply obtained, the throughput rate of the system can be increased and the system performance can be improved.

Owner:深圳市信方达科技发展股份有限公司

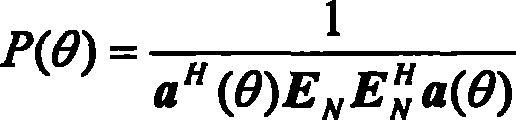

Method and system for fault-tolerant static timing analysis

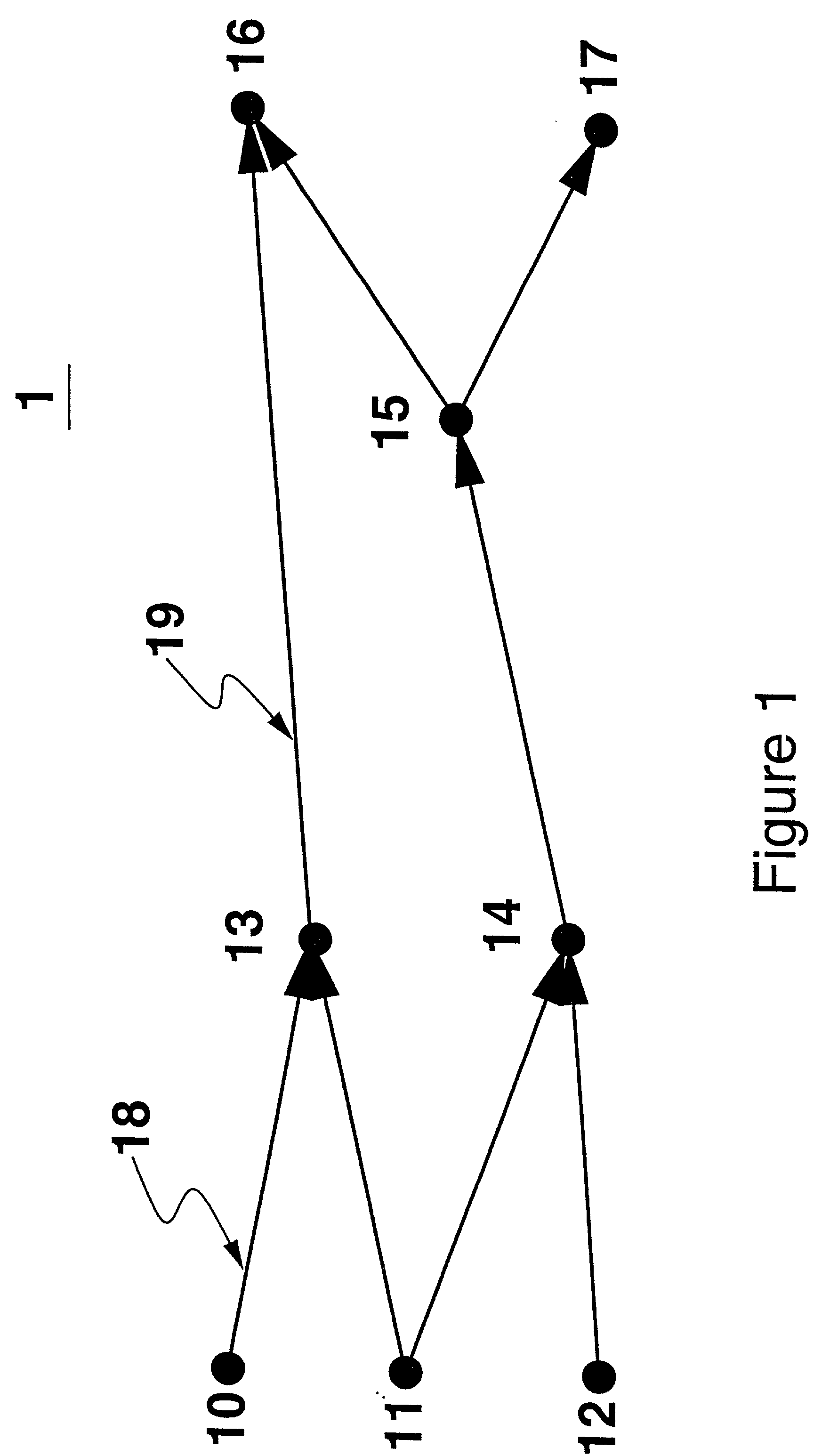

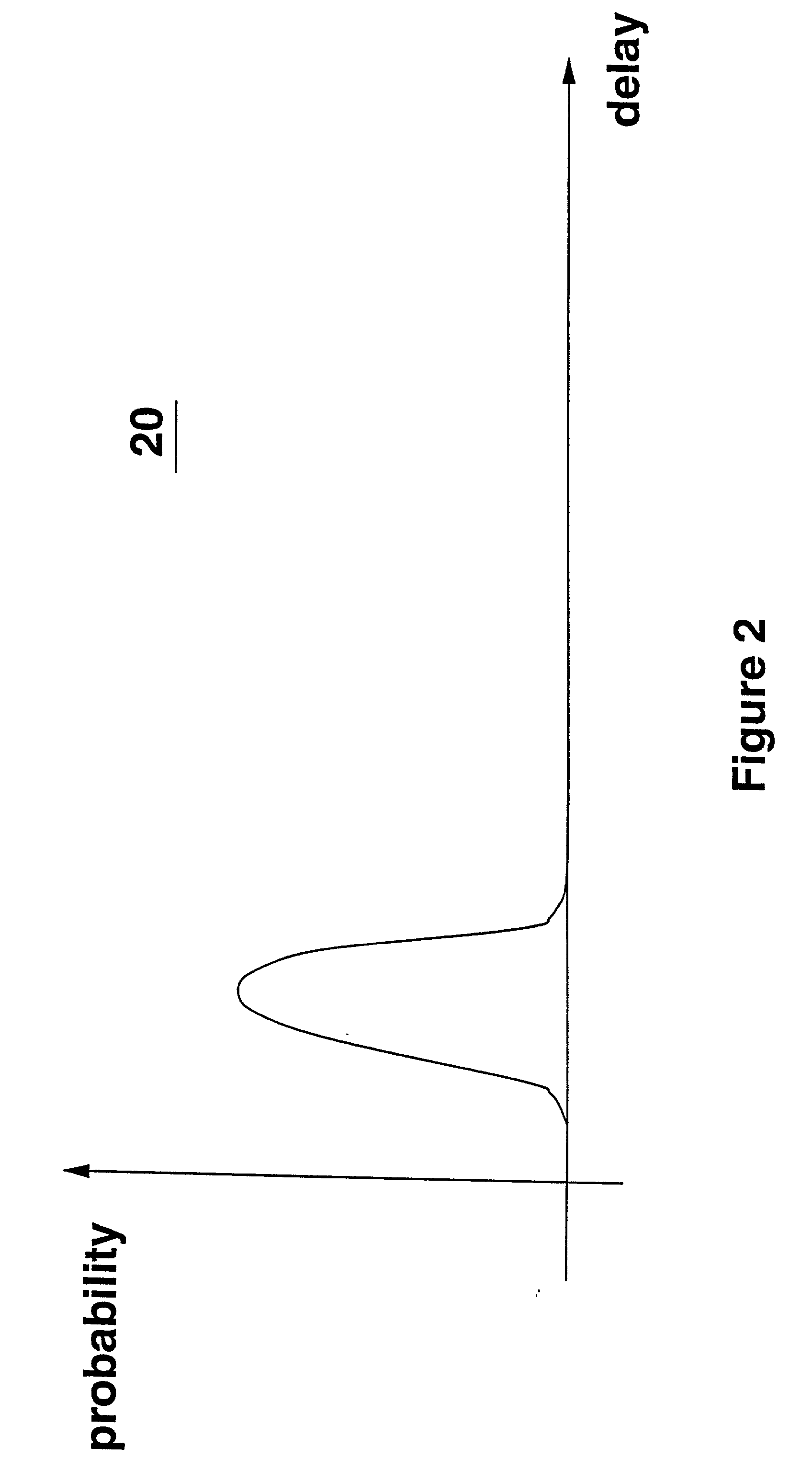

A method and system for performing fault tolerant static timing analysis for an electronic network. A composite timing graph is generated by making K+1 copies of the zero-defect timing graph of the network, where K is a predetermined maximum number of defects present on a path of the network, and static timing analysis is performed on the composite timing graph.

Owner:GLOBALFOUNDRIES US INC

Hot rolling wire rod production method for improving surface quality

InactiveCN110125177AImprove uneven deformationImprove uneven wearMetal rolling arrangementsWire rodEllipse

The invention relates to a hot rolling wire rod production method for improving the surface quality. The steps include billet preparation, heating processing, pass rolling, reducing and sizing, coil collecting and finishing. Rough rolling, intermediate rolling and pre-finish-rolling are included, the step pitch is increased during the heating processing, the box pass is adopted for billets firstly, exchange in the ellipse pass and the circle pass is then achieved, and the square billets are rolled into semi-finished products with circular fracture surfaces; the box pass, ellipse pass and circle pass combined pass is adopted for the rough rolling, the square billets are compressed under large pressure, the box pass is adopted for the first three passes of the rough rolling, box type hole base angles are increased, the ellipse pass and the circle pass are adopted for the fourth pass and the fifth pass of the rough rolling, and the circular shape is achieved after the rough rolling; and induction heating is added between the rough rolling and the intermediate rolling, and the problem that the head and tail temperature difference of red steel heads is large is solved. A spiral guide pipe is added to a lifting spiral pipe structure for the coil collecting, the circle shape of tail portions is regularized through the spiral guide pipe after the tail portions lose tension during the coil collecting, and therefore the circle shape of the tail portions is controlled and the problem that the tail portions are scratched is solved. The hot rolling wire rod production method meets the zero defect quality requirement.

Owner:WUXI XINGCHENG HUAXIN STEEL

Method for no-reference quantitative inspection of panel thinning defect based on Lamb wave

InactiveCN106153724AThe result is accurateAccuracy meetsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalThinningComputer science

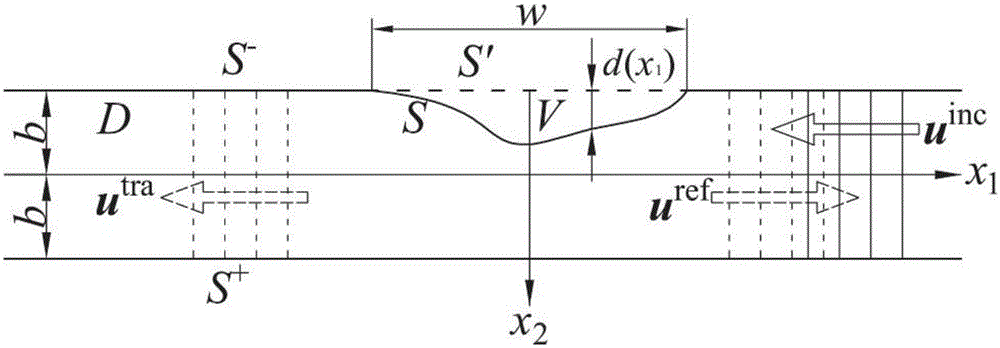

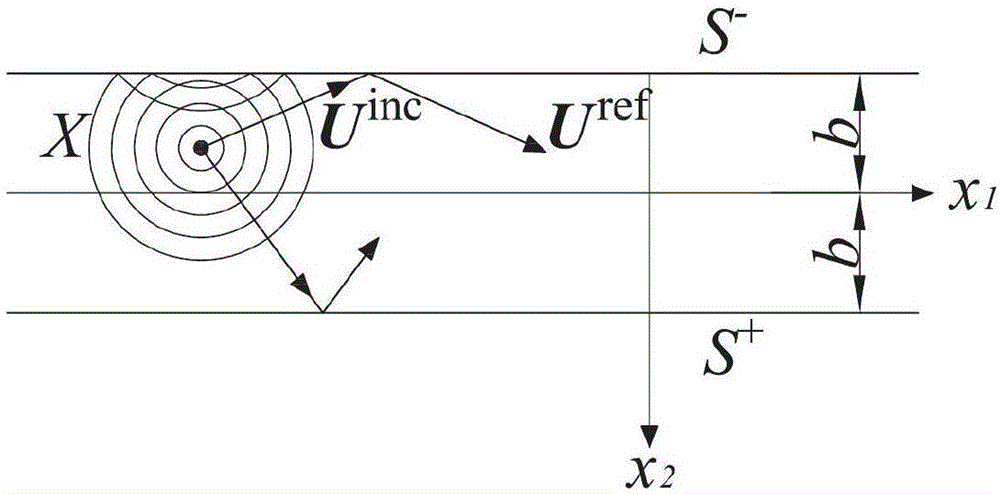

The invention discloses a method for no-reference quantitative inspection of panel thinning defect based on Lamb wave. The method comprises the following steps: solving a coefficient of the required Lamb wave reflection modal; solving a green function in a zero-defect panel; constructing a boundary integral equation by use of the dynamics reciprocal theory and far-field basic solution; substituting a reflection coefficient into the boundary integral equation and performing inverse Fourier transform to finally obtain a defect expression; and reconstructing the defect position and shape in the panel. In the invention, the problems of quantitative inspection of panel thinning defect are effectively solved, the panel defect is reconstructed by directly using the reflection information of Lamb wave without referring to any condition in advance, and an efficient and accurate method is provided for engineering quantitative detection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

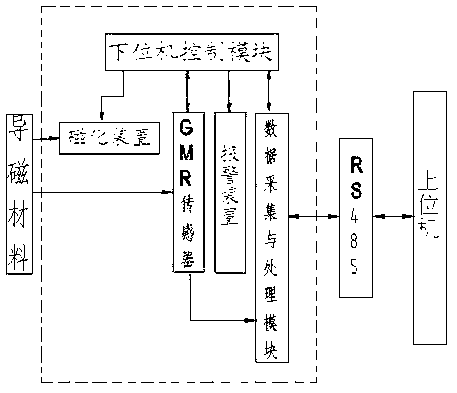

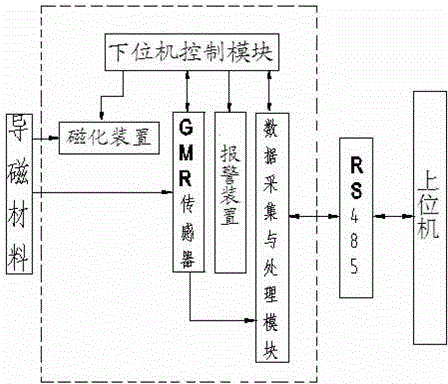

Lossless real-time detecting method and system for magnetic conductive material

InactiveCN102841133AEfficient detectionReduce testing costsMaterial magnetic variablesResistive sensorsMagnetization

The invention discloses a lossless real-time detecting method and system for a magnetic conductive material. The lossless real-time detecting method comprises the following steps of: collecting a signal of the magnetic conductive material after being magnetized by a giant magneto resistive sensor, and comparing the collected signal with a normal value of the magnetic conductive material under a zero defect state in the prior art and a typical value of reluctance change under the existence of interior defect so as to judge the flow of the inner magnetic field in the present position of the magnetic conductive material and the magnetic field diffusing state in the position of defect. A system adopted by the method comprises N sets of GMR (Giant Magneto Resistive) sensor chipsets, a lower computer control module, a magnetizing device, an alarm device, a data collecting and processing module and an upper computer, wherein the magnetizing device is used for realizing the magnetization and demagnetization of the magnetic conductive material; the sensor chipsets are used for sensing the change of reluctance change of the magnetic conductive material; and the data collecting and processing module is used for processing an analog signal collected by the sensor chipsets and then comparing with the typical value and an ideal value. The lossless real-time detecting method is low in detection cost, is used for effectively detecting a strange part and does not threaten a human body.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

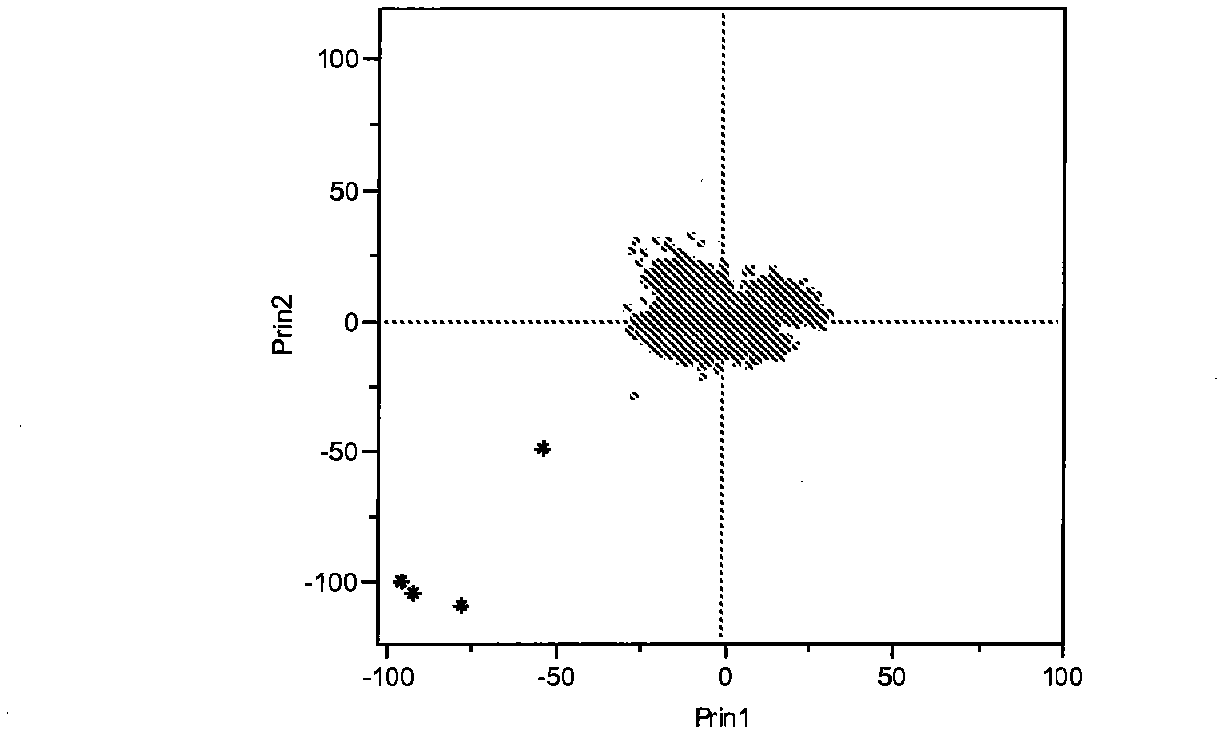

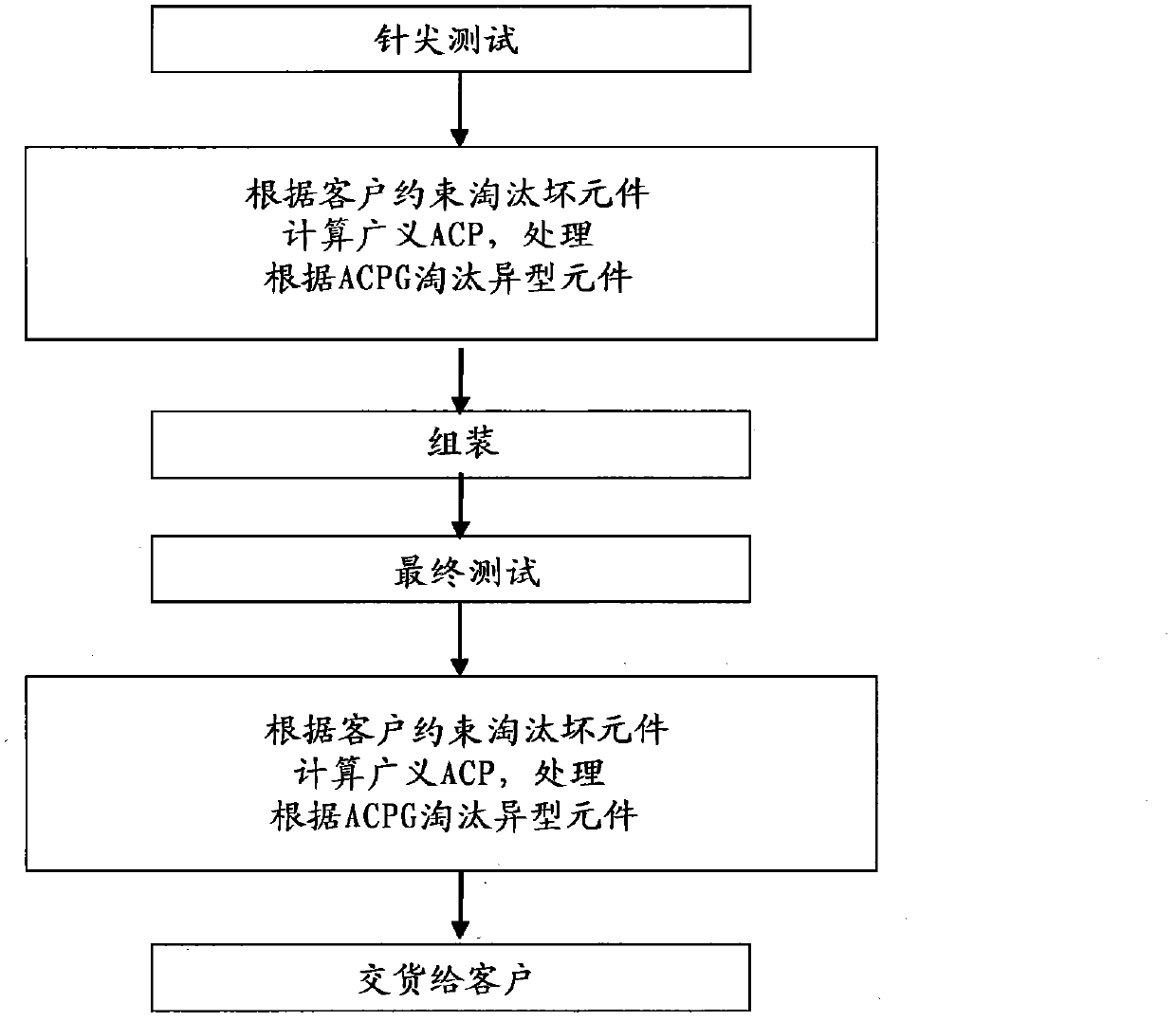

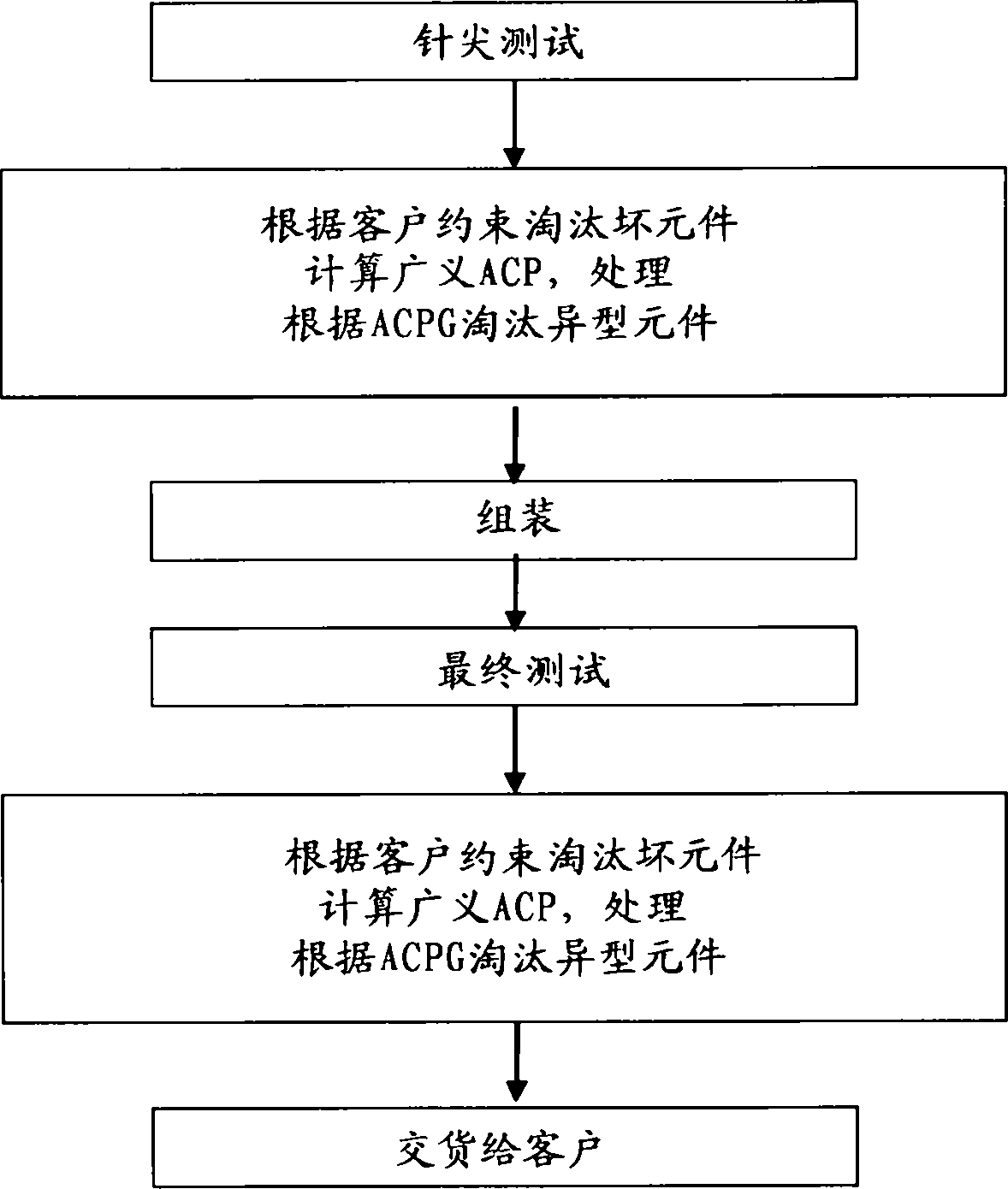

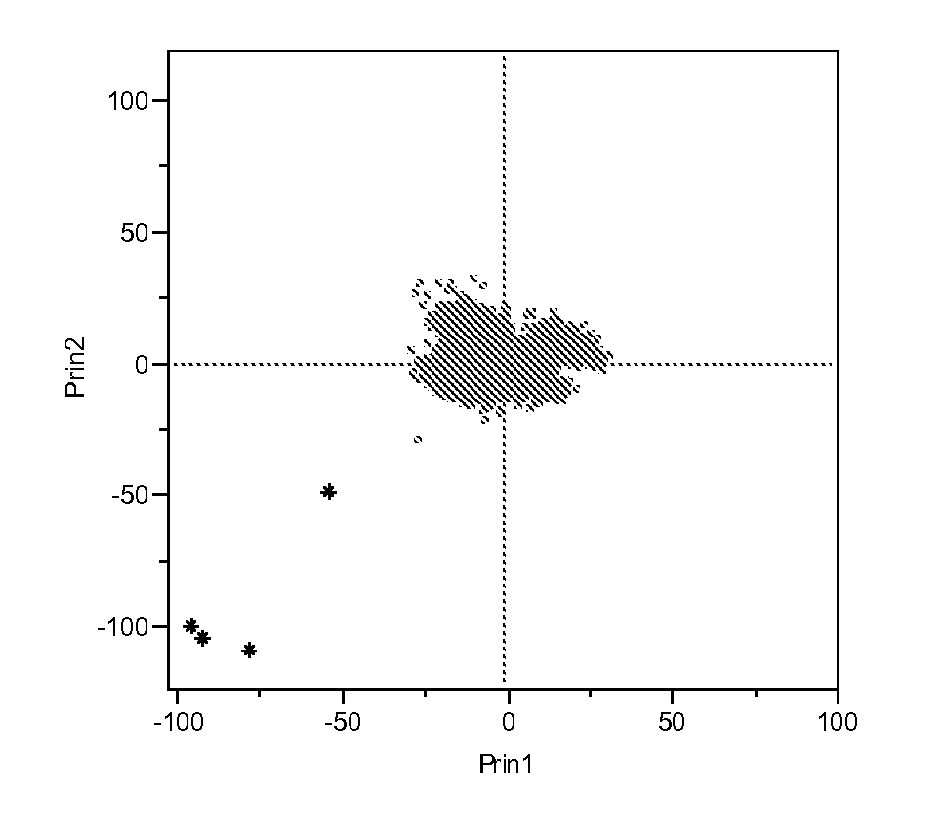

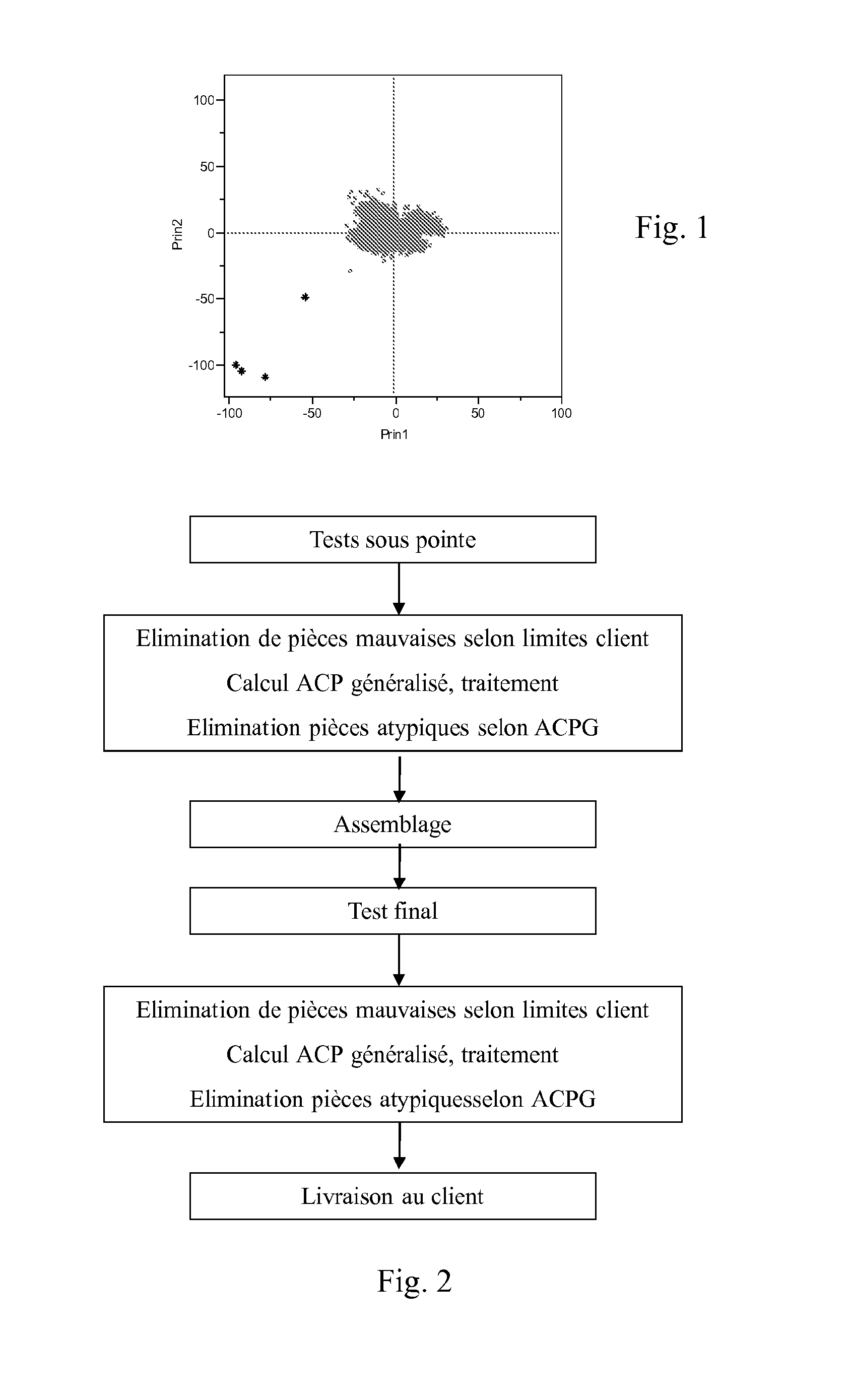

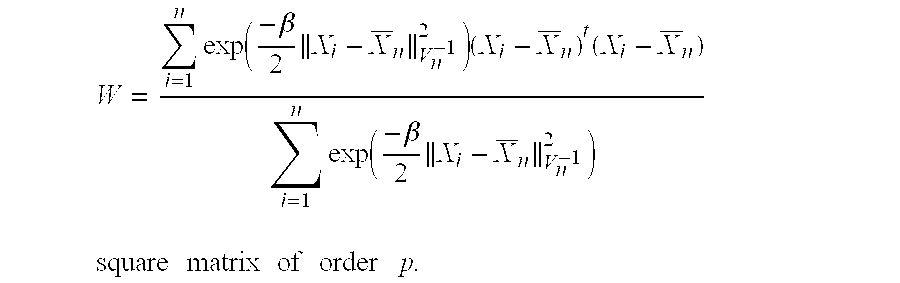

Method for detecting atypical electronic components

InactiveCN102388347ASolve the problem of setting the centerResolve differencesElectrical testingElectric testing/monitoringDigital dataPrincipal component analysis

The invention relates to a method for detecting atypical electronic components for the quality control of n electronic components at the end of the manufacturing process, said components being subjected to a number p of unit tests providing digital data, said set of n components including electronic components having a response to each of the p unit tests that lies within predetermined limits particular to each of the p tests, wherein the method comprises using the multi-dimensional information of the p dimension responses of said n electronic components. The method uses a generalised principal component analysis for detecting atypical parts in the semiconductor field, or in the fields including modules assembled using electronic components (e.g. an ABS module, a smart card, etc.). The aim of the method is to get close to "zero defect", wherein no part is detected to be substandard by the client.

Owner:IPPON INNOVATION

PET membrane punching mold forming by IMR and application method thereof

InactiveCN109910103AGuarantee molding qualityReasonable structural designMetal working apparatusCompanion animalBiomedical engineering

The invention provides a PET membrane punching mold forming by IMR and a using method thereof. The problems that edge trimming is difficult to achieve automatic production for the control board products needing to adopt the IMR forming process technology, burrs are more, edge deformation and the like are even caused after edge trimming are solved. The novel membrane punching mold is designed, a membrane positioning mechanism, a membrane exhaust mechanism and an edge pressing device are additionally arranged in the mold, so that the phenomenon that the burrs are more and the membrane is deformed after punching when the membrane is punched in the IMR process is eliminated, so that the zero-defect automatic production of products is realized, the product forming quality is effectively guaranteed, the mold structure design is novel, and the mold has relatively good production and application values.

Owner:高勇勇

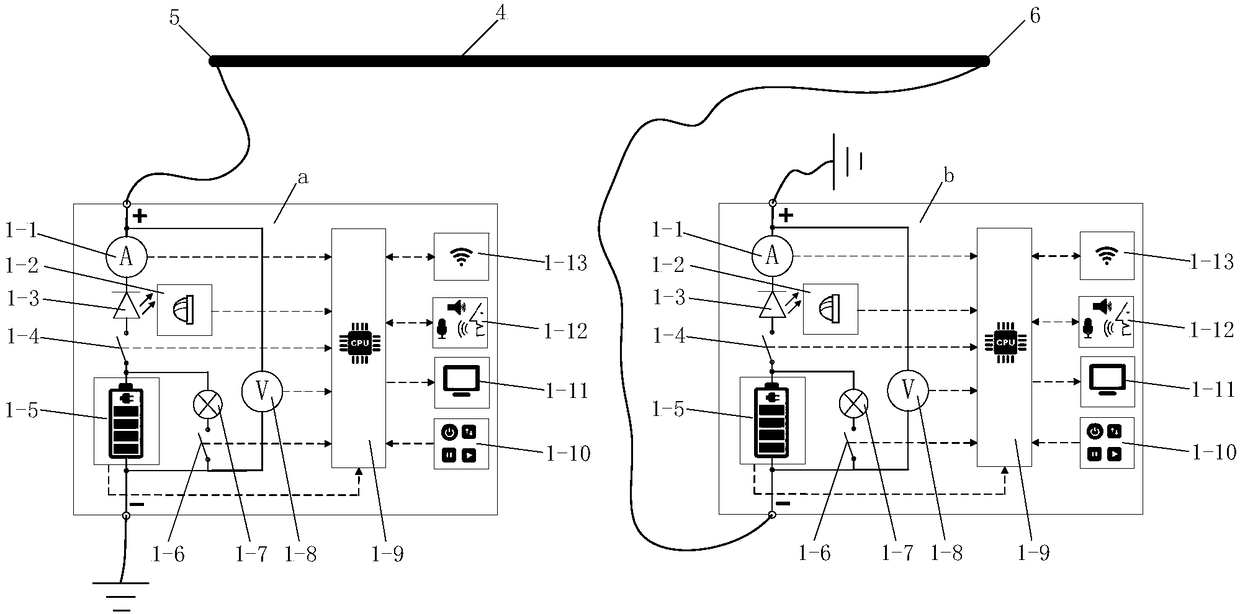

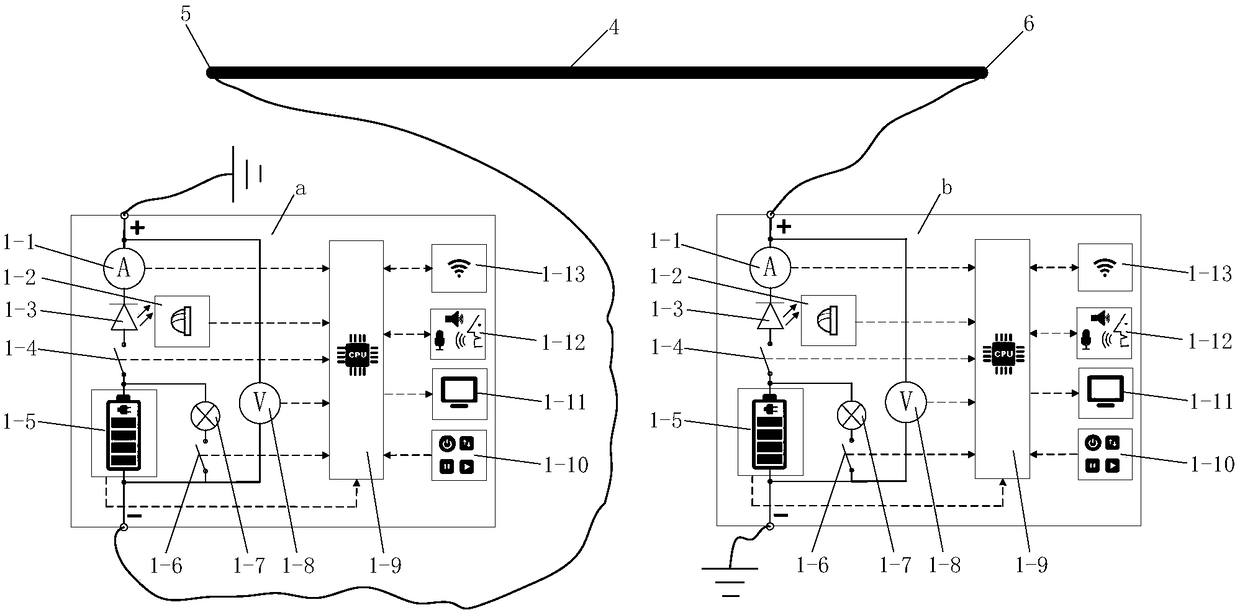

Manual and automatic integrated wire calibrating system and method of electrical equipment

PendingCN108362972AImprove accuracyImprove efficiencyElectrical testingElectrical resistance and conductanceCost burden

The invention relates to a manual and automatic integrated wire calibrating system and method of electrical equipment. Wire calibration is conducted by combining light, current and resistance as wellas information technologies, so that accuracy degree and credibility of wire calibration are improved, on-site use is facilitated, heavy wire calibration and cost burdens are reduced for workers, andfoundation is laid for zero-defect commissioning of the subsequent electrical equipment. The system comprises a first wire calibration module and a second wire calibration module which are the same; the positive or negative polarity output port of the first wire calibration module is connected to a to-be-calibrated wire on the same side of the electrical equipment; the rest other polarity output port of the first wire calibration module is connected with a ground wire; the second wire calibration module selects the opposite polarity output port connected with the first wire calibration moduleand the to-be-calibrated wire to be connected to the opposite side of the to-be-calibrated wire of the electrical equipment; the rest other polarity output port of the second wire calibration module is connected with the ground wire; the first wire calibration module and the second wire calibration module perform instruction and signal transmission as well as information sharing through the own wireless transmission modules and crossly judge the correctness and the integrity of the to-be-calibrated wire of the electrical equipment.

Owner:XIAN THERMAL POWER RES INST CO LTD

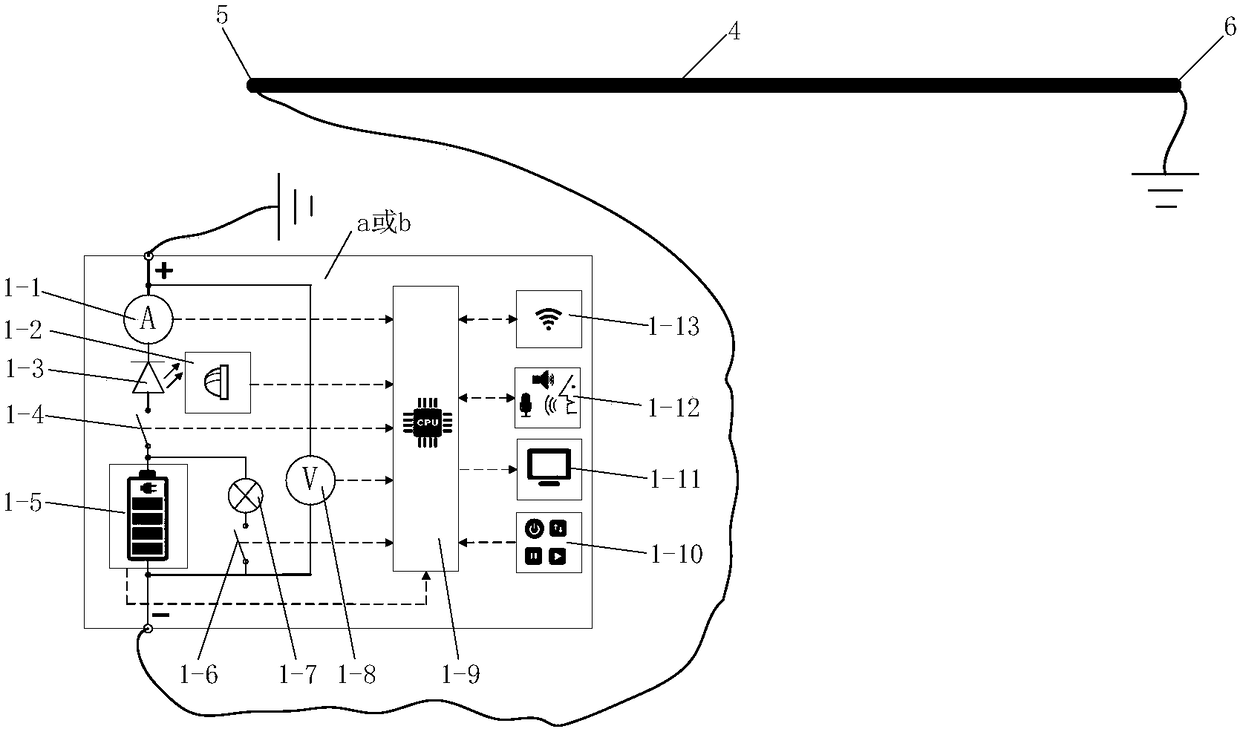

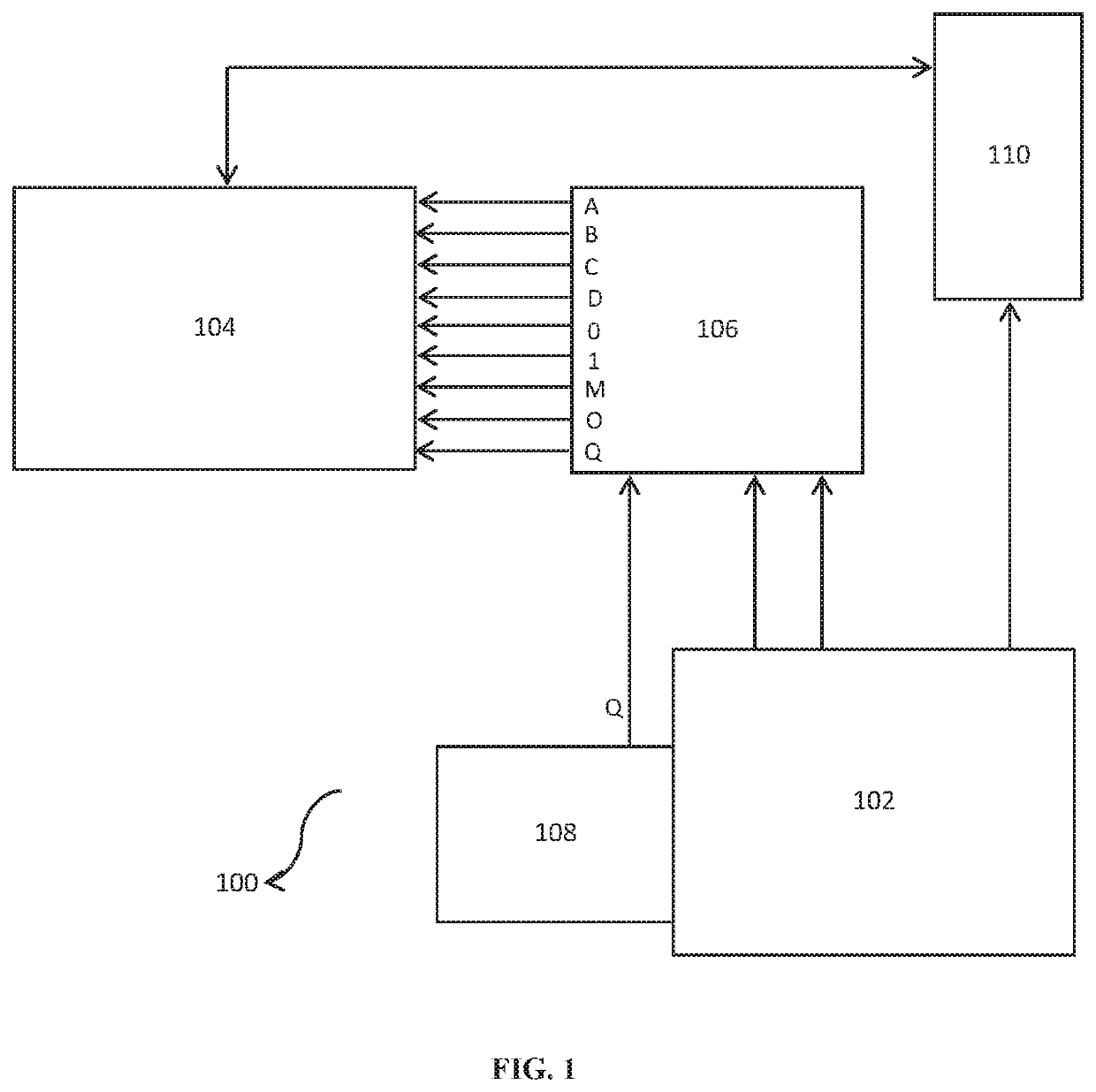

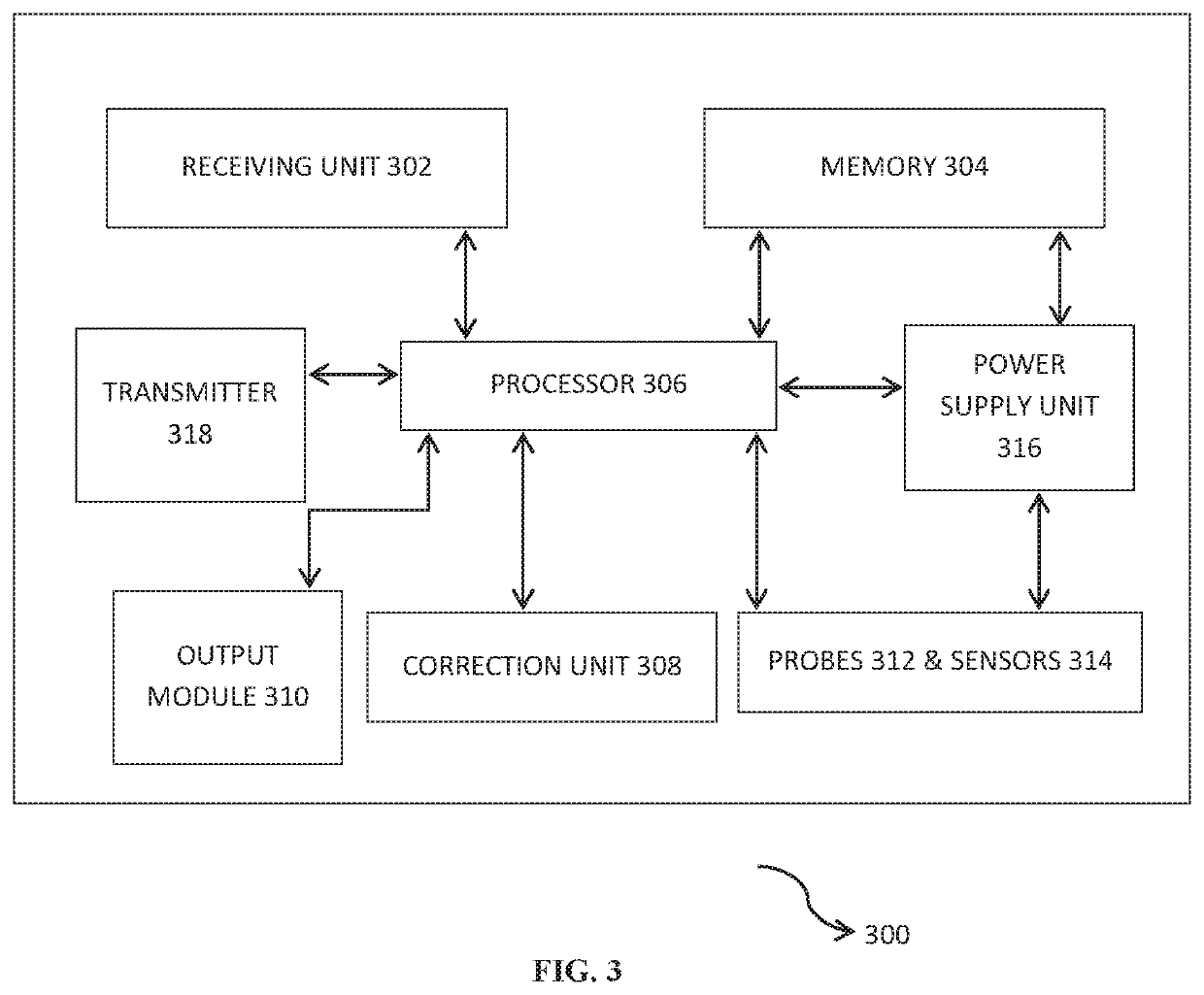

System and a Method to Enable Zero Defect Production

Embodiments of the present invention provide a comprehensive system that integrates automatically gauging and correcting stations operating in a machine environment with a universal machine monitoring for detecting defective articles, quarantining the defective articles, ensuring the defective articles are safely quarantined, analyzing the machine and article related data for providing contextual information for the defective articles produced, predicting one or more necessary actions to be taken for minimizing defects in future and achieving near zero defect quality in machine production. The comprehensive system provides such contextual information about the defects / faults in the article or the machine operations in real time and locally and remotely to any human resource.

Owner:SARUP GAURAV

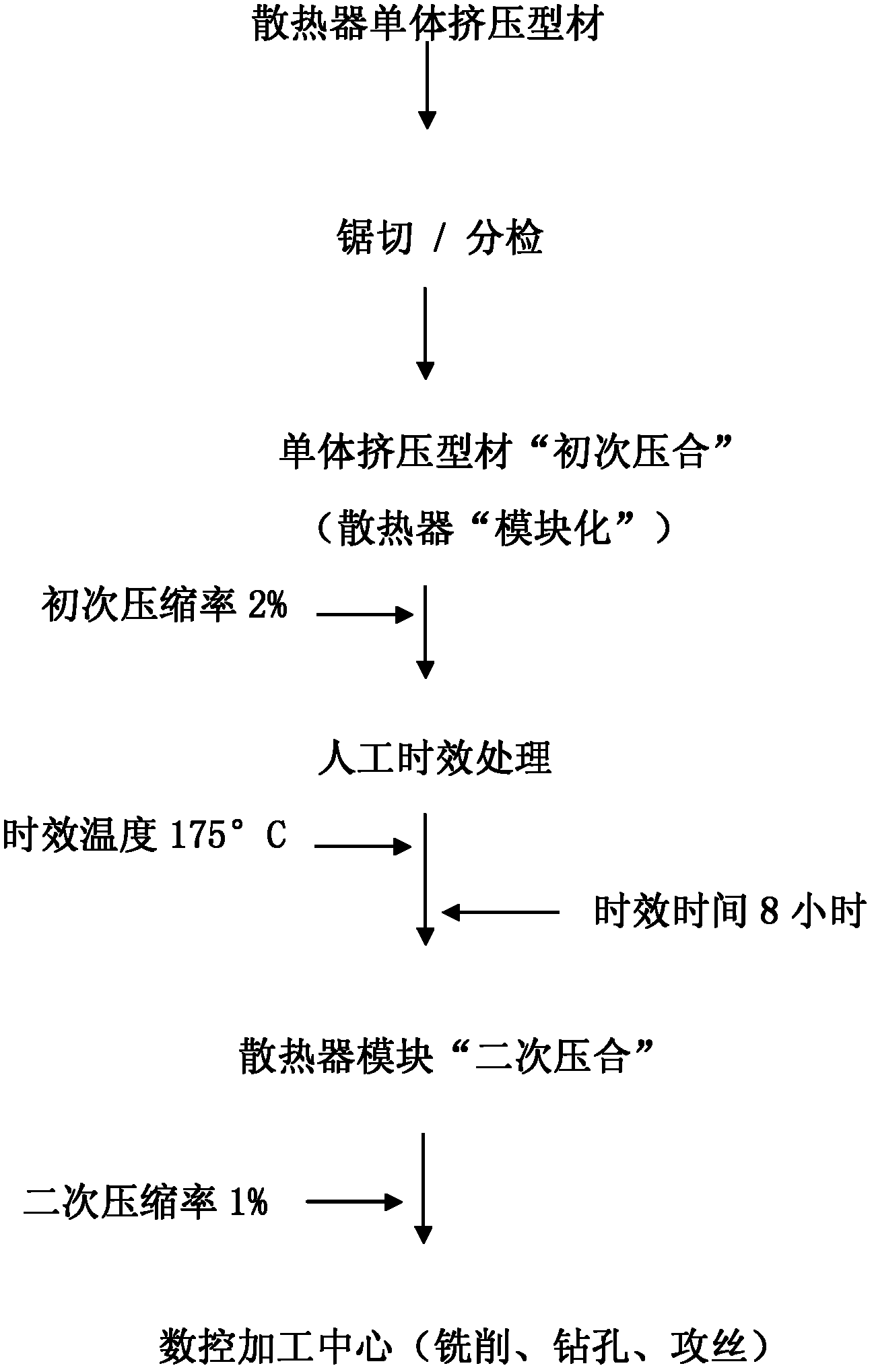

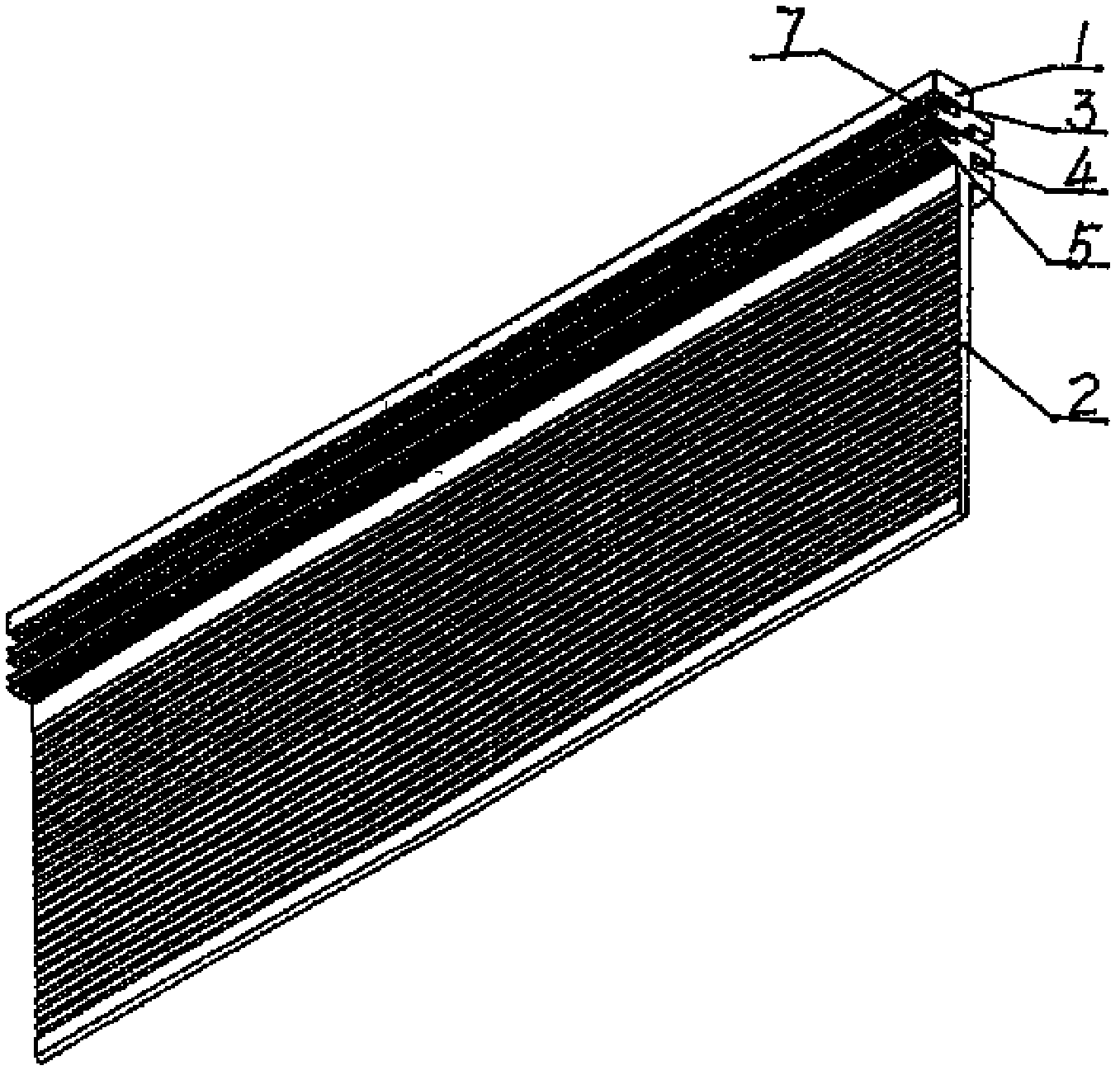

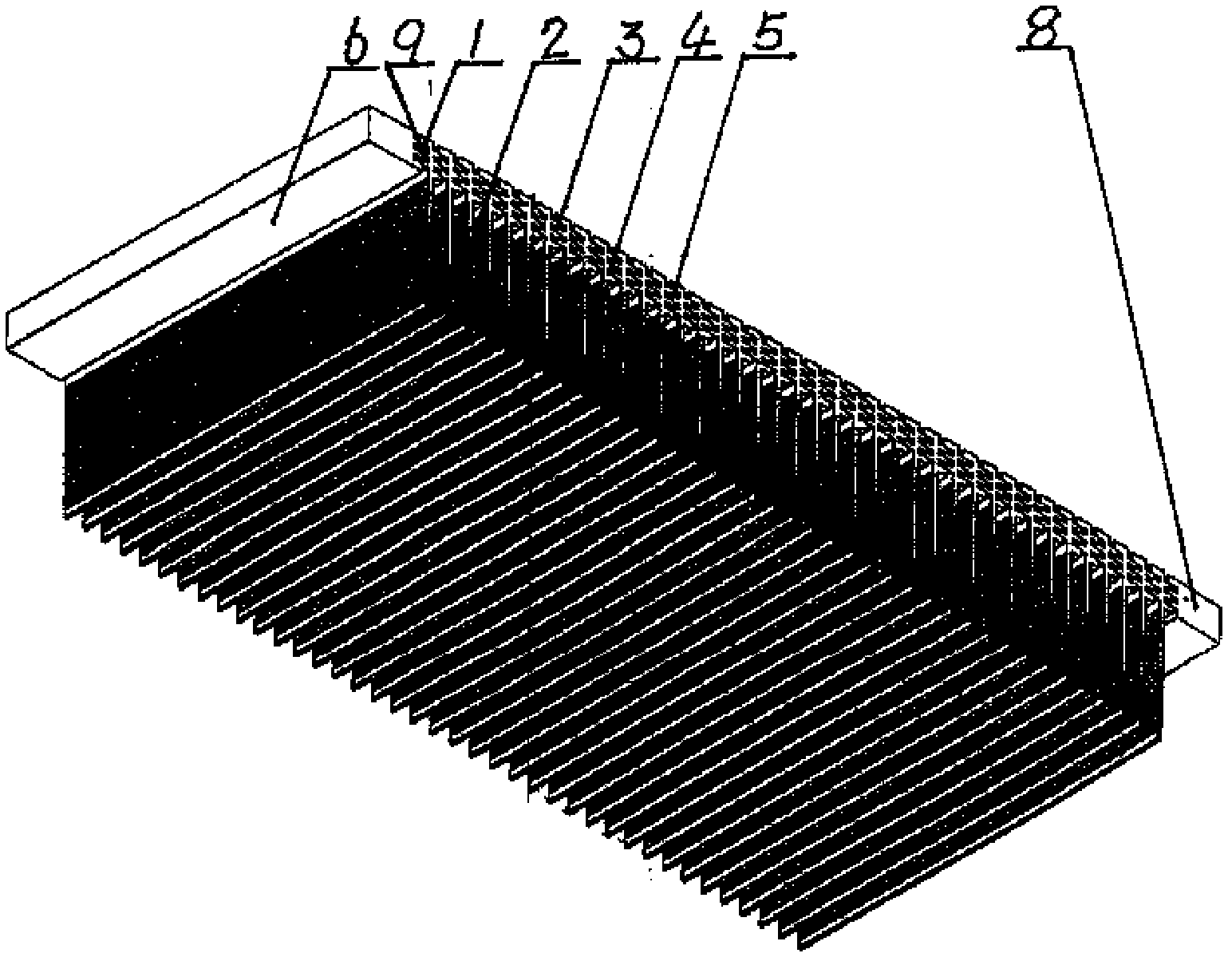

Compensation method of modular radiator manufacturing process

ActiveCN102357786AIncreased number of crystal defectsIncrease volume fractionComputer moduleProcess compensation

The invention relates to a compensation method of a modular radiator manufacturing process. The compensation method comprises the following steps: first, sawing an extruded section composed of a single heat storage substrate 1 and a fin 2, and then carrying out sorting and stacking before pressure closing; carrying out primary pressure closing on a plurality of the extruded sections composed of the single heat storage substrate 1 and the fin 2 to generate 2% compressive deformation; carrying out artificial aging treatment on a radiator module obtained from the primary pressure closing at the temperature of 175+ / -5 DEG C for 8 hours; then carrying out secondary pressure closing on the radiator module subjected to aging hardening to generate a 1% secondary compressive deformation and obtaina modular radiator; and finally entering a digital control processing center to obtain a finished product. In the invention, on the basis of maintaining a 'modular radiator manufacturing method', thebonding strength level of the 'inner boundary' of the substrate of the radiator is further improved through using a secondary pressure closing process compensation method, thus being capable of obtaining crack defects on the surface of the substrate of the radiator and dye penetrant nondestructive detection zero-defect results.

Owner:天津锐新昌科技股份有限公司

Method for detecting atypical electronic components

InactiveUS20120053877A1Easy to detectEliminateElectrical testingSpecial data processing applicationsDigital dataPrincipal component analysis

A method for detecting atypical electronic components for the quality control of a set of n electronic components at the end of the manufacturing process, the components being subject to a number p of unit tests providing digital data, this set of n components consisting of electronic components whose response to each of the p unit tests is contained within pre-defined limits specific to each of the p tests, uses the multidimensional information of the p dimension responses of these n electronic components. The method uses a generalized principal component analysis for detecting atypical items in the semiconductor field, or in fields including modules assembled using electronic components (e.g. an ABS module, a smart card, etc.). The aim of the method is to get close to “zero defect”, in which no parts are detected as non-compliant by the client.

Owner:IPPON INNOVATION

Navigation method for mounting prefabricated components of prefabricated building

PendingCN110348546AAchieving very beneficial sharingEasy to shareForecastingCo-operative working arrangementsInformation sharingRelevant information

The invention discloses a navigation method for installation of prefabricated components of a prefabricated building. The method comprises the following steps: information in RFID tag is transmitted to BIM-RFID system for judgment and processing, and a construction sequence, ca omponent transportation sequence, ta ransportation train number, transportation routes and like are pl are reasonably arranged;, and implementation of zero-defect and zero-inventory idealized targets in lean construction is facilitated. Meanwhile, relevant information such as the actual progress of the construction sitecan also be fed back to a prefabricated part production factory in real time; and the factory adjusts the component production plan according to the fed-back construction site progress information, so that the probability of waiting for work and waiting for materials is almost zero, then the factory transmits the information of the adjustment plan to the construction site, information sharing isachieved, and smooth proceeding of engineering is facilitated.

Owner:云南齐星杭萧钢构股份有限公司

Rapid drying method for cottonwood thick plate

ActiveCN102435046BHelps to moveFast dryingDrying solid materials with heatHearth type furnacesThick plateEngineering

Owner:LANDBOND FURNITURE GROUP

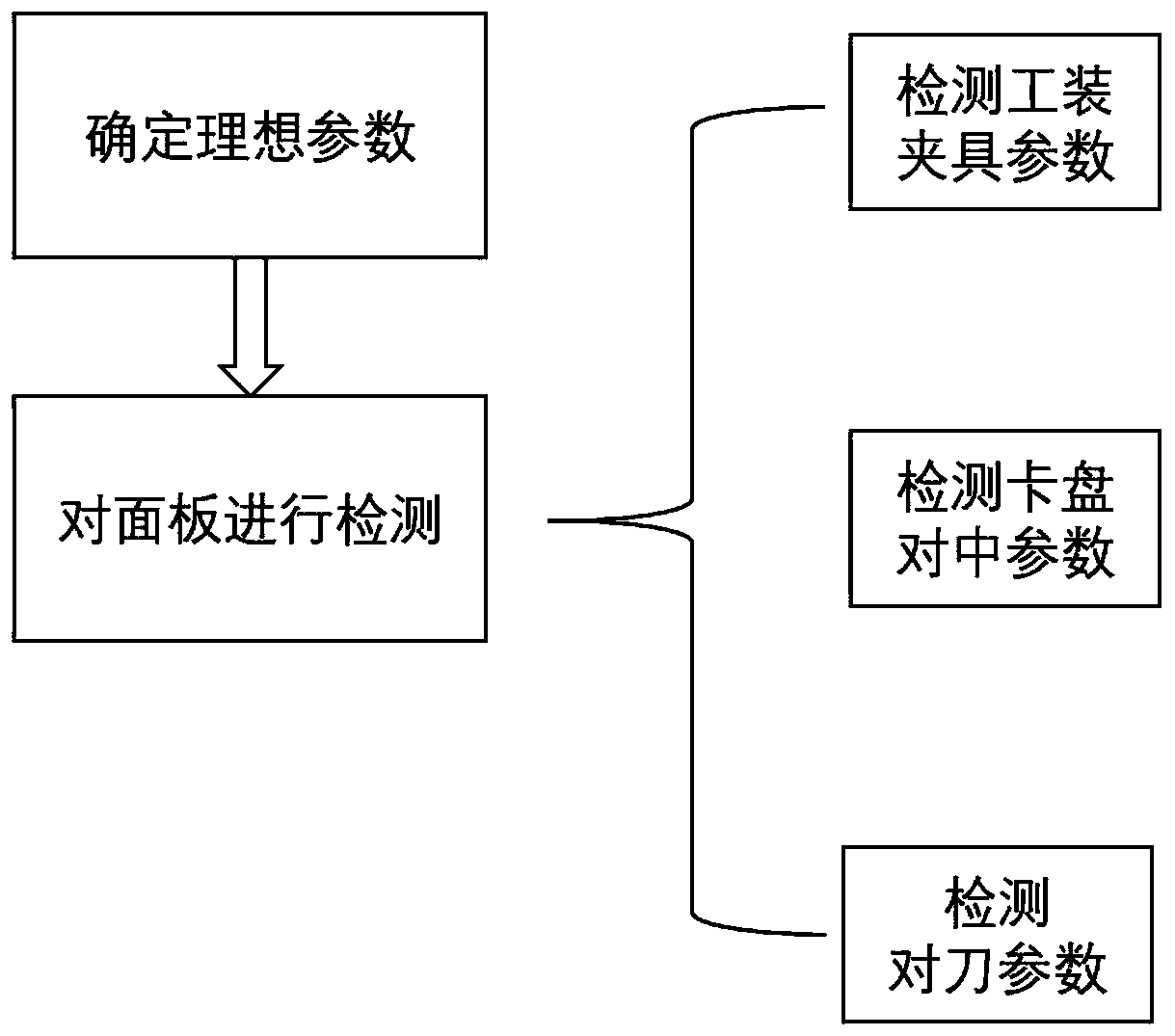

Zero-defect test method for numerically-controlled machine tool processing

InactiveCN110666586ASolve the high scrap rateRealize pre-testingMeasurement/indication equipmentsNumerical controlProcess engineering

The invention provides a zero-defect test method for numerically-controlled machine tool processing. A panel of a machine tool is detected before processing according to ideal parameters of the panelof the machine tool. The method comprises the specific following steps that step 1, a sample piece is trial-manufactured and traditionally detected to determine ideal parameters of the panel of the machine tool; step 2, the ideal parameters are determined and recorded, the panel is detected before part processing each time, and ideal parameters, required by corresponding parts, according with panel parameters are determined. According to the zero-defect test method, the detection link is brought in front of finished product processing, whether or not the panel parameters of the numerically-controlled machine tool meet the requirement is tested before processing, so that the aims of greatly lowering the rejection rate and increasing the finished product rate are achieved, the processing cost of a factory is lowered, the production efficiency is improved, and zero-defect processing is achieved.

Owner:上海临港新兴产业企业服务有限公司

Lossless real-time detecting method and system for magnetic conductive material

InactiveCN102841133BEfficient detectionReduce testing costsMaterial magnetic variablesResistive sensorsMagnetization

The invention discloses a lossless real-time detecting method and system for a magnetic conductive material. The lossless real-time detecting method comprises the following steps of: collecting a signal of the magnetic conductive material after being magnetized by a giant magneto resistive sensor, and comparing the collected signal with a normal value of the magnetic conductive material under a zero defect state in the prior art and a typical value of reluctance change under the existence of interior defect so as to judge the flow of the inner magnetic field in the present position of the magnetic conductive material and the magnetic field diffusing state in the position of defect. A system adopted by the method comprises N sets of GMR (Giant Magneto Resistive) sensor chipsets, a lower computer control module, a magnetizing device, an alarm device, a data collecting and processing module and an upper computer, wherein the magnetizing device is used for realizing the magnetization and demagnetization of the magnetic conductive material; the sensor chipsets are used for sensing the change of reluctance change of the magnetic conductive material; and the data collecting and processing module is used for processing an analog signal collected by the sensor chipsets and then comparing with the typical value and an ideal value. The lossless real-time detecting method is low in detection cost, is used for effectively detecting a strange part and does not threaten a human body.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

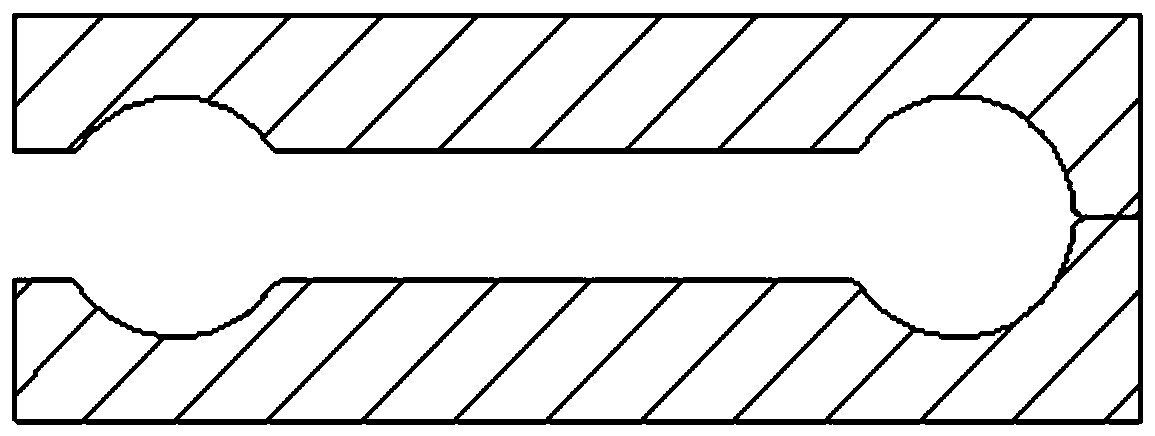

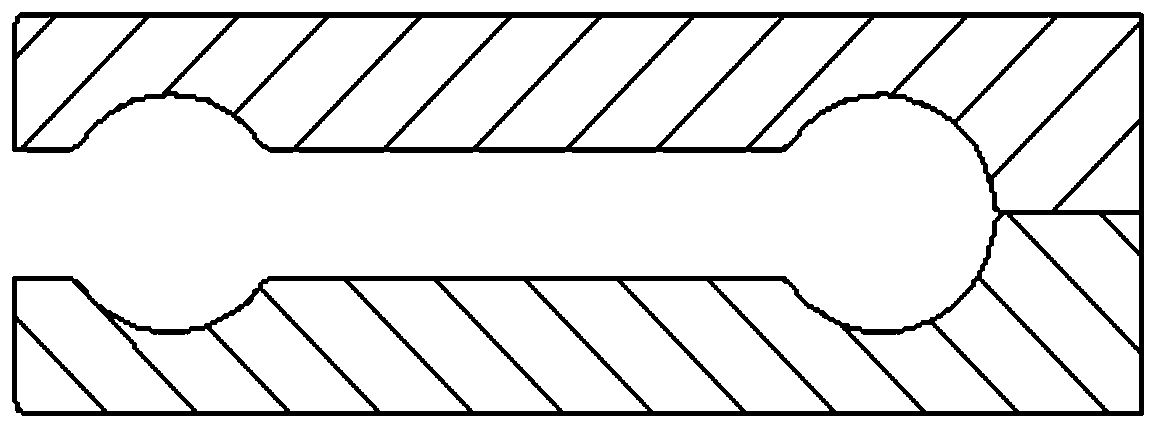

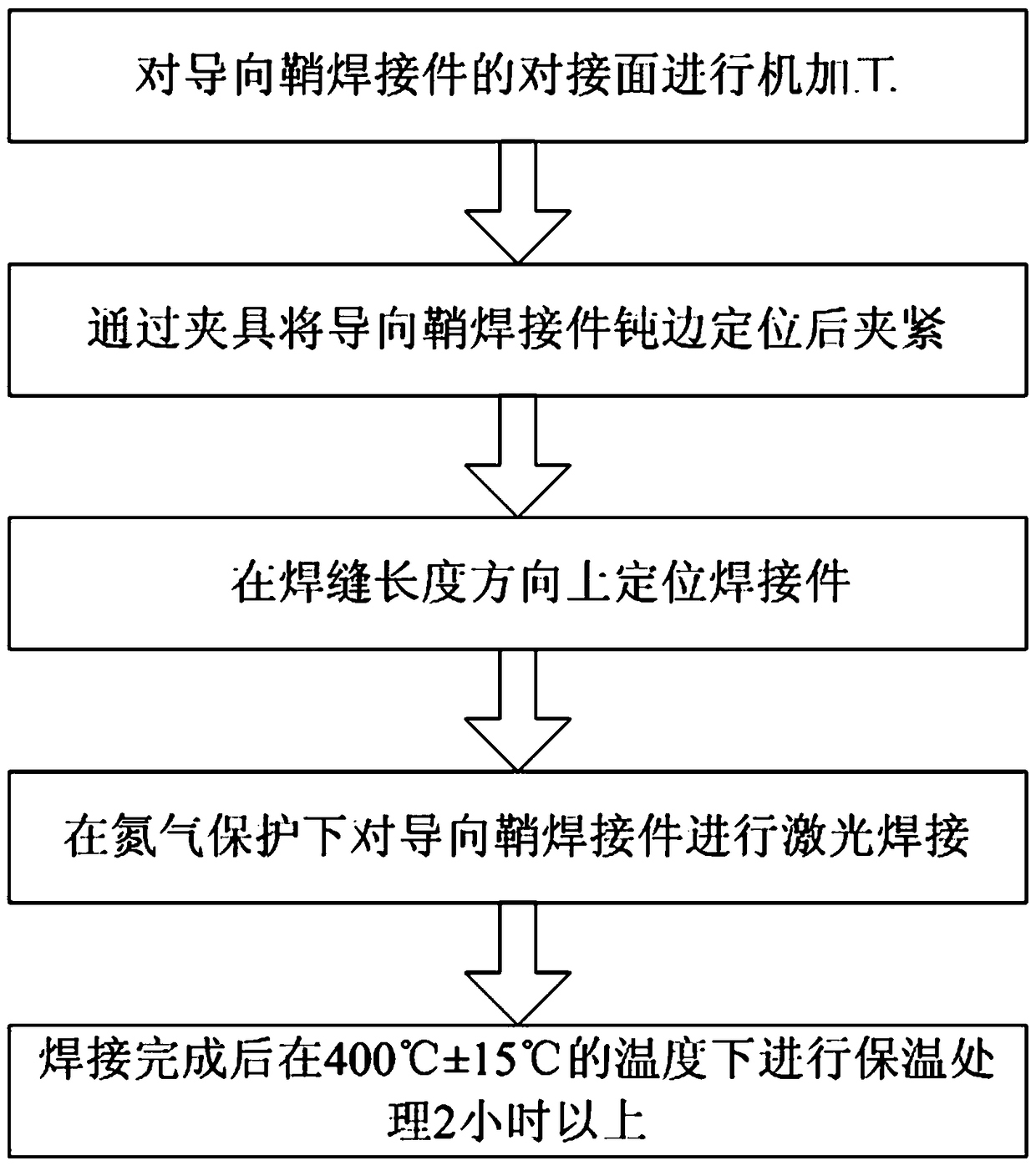

Laser Welding Method for Guide Sheath of Guide Tube in Nuclear Reactor

ActiveCN105382416BSimplify the welding processFast welding speedLaser beam welding apparatusNuclear reactor coreNuclear reactor

The invention belongs to the technical field of welding, and discloses a laser welding method of guide sheaths of a guide cylinder in a nuclear reactor. The laser welding method comprises the following steps: (1) machining butt planes of guide sheath weld assemblies until the machining precision of the butt planes reaches the degree of zero defect by visual inspection and a liquid penetration test; (2) positioning and then clamping truncated edges of the guide sheath weld assemblies through a clamp, wherein the gap between the butt planes is less than or equal to 0.02mm; (3) positioning the weld assemblies in the length direction of a welding line; (4) under the protection of nitrogen, performing laser welding on a butt joint of the guide sheath weld assemblies; (5) after the welding, performing insulation treatment at the temperature of 400+ / -15 DEG C for not less than 2 hours. According to the laser welding method provided by the invention, the welding process is simple, the welding speed is fast, the welding formation is excellent, the physical and chemical properties are excellent, the deformation is controllable, and the working environment is safe.

Owner:上海第一机床厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com