Product transfer system and method based on planar auxiliary light source and machine vision

An auxiliary light source and machine vision technology, applied in general control systems, control/adjustment systems, instruments, etc., to achieve the effect of avoiding waste of raw materials, solving limitations, and improving product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

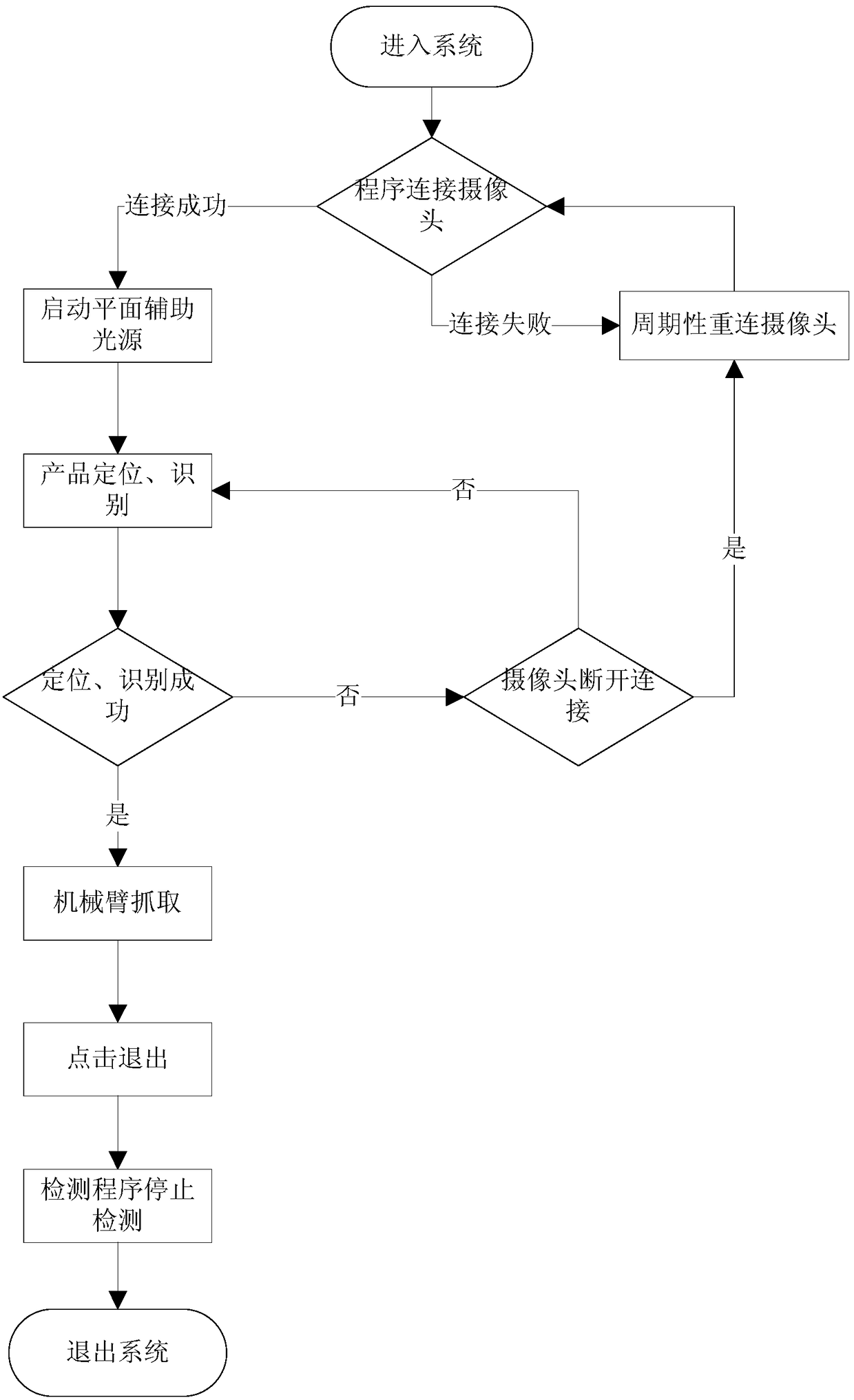

[0044] Such as figure 1 As shown, a product transfer method based on plane auxiliary light source and machine vision, including

[0045] Step 1: Install a plane auxiliary light source around the product to generate a contrast image of the product;

[0046] Step 2: collect contrast images of various types of non-defective standard products as the target image, and the target image is composed of multiple non-defective standard product contrast images using the statistical averaging method;

[0047] Step 3: Collect the angiographic image of the product to be classified on the production platform in real time as the image to be tested;

[0048] Step 4: Identify and match the image to be tested with the target image, confirm each product type, and divide it into standard products and defective products;

[0049] Step 5: Control the robotic arm to classify the products to be classified into standard products and defective products.

[0050] Based on the SURF algorithm, the Hessi...

Embodiment 2

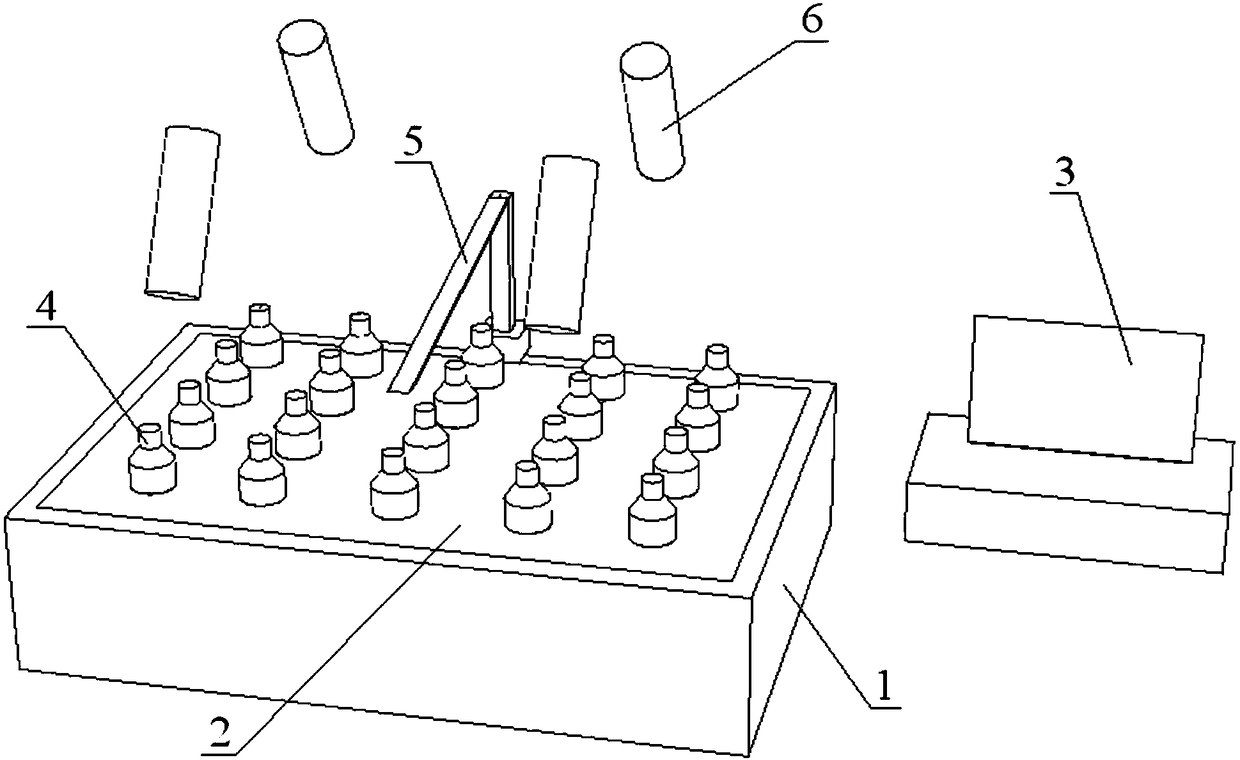

[0059] Such as figure 2 As shown, a product transfer system based on plane auxiliary light source and machine vision includes a backlight 2 arranged at the bottom 1 of the production platform, a camera 6 and a mechanical arm 5 arranged directly above the production platform 1, and the The control module 3 connected to the camera 6 and the mechanical arm 5; the camera 6 collects the contrast image of the product 4 to be classified on the backlight 2, and the control module 3 recognizes the contrast image information and matches it with the target image to confirm After the product type, control the mechanical arm 5 to carry out classification transfer.

[0060] The installation positions of the planar auxiliary light source and the camera of the product transfer system of the present invention can be adjusted according to the actual situation, and all kinds of equipment are common general-purpose equipment with simple structure and convenient installation. The control module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com