Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Foreign technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

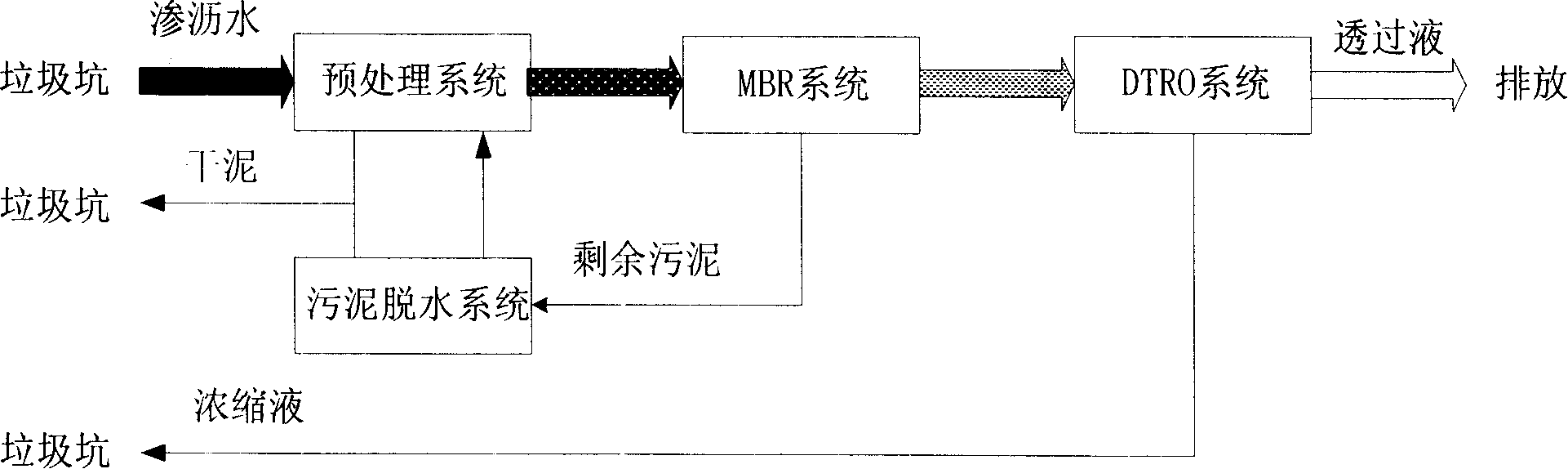

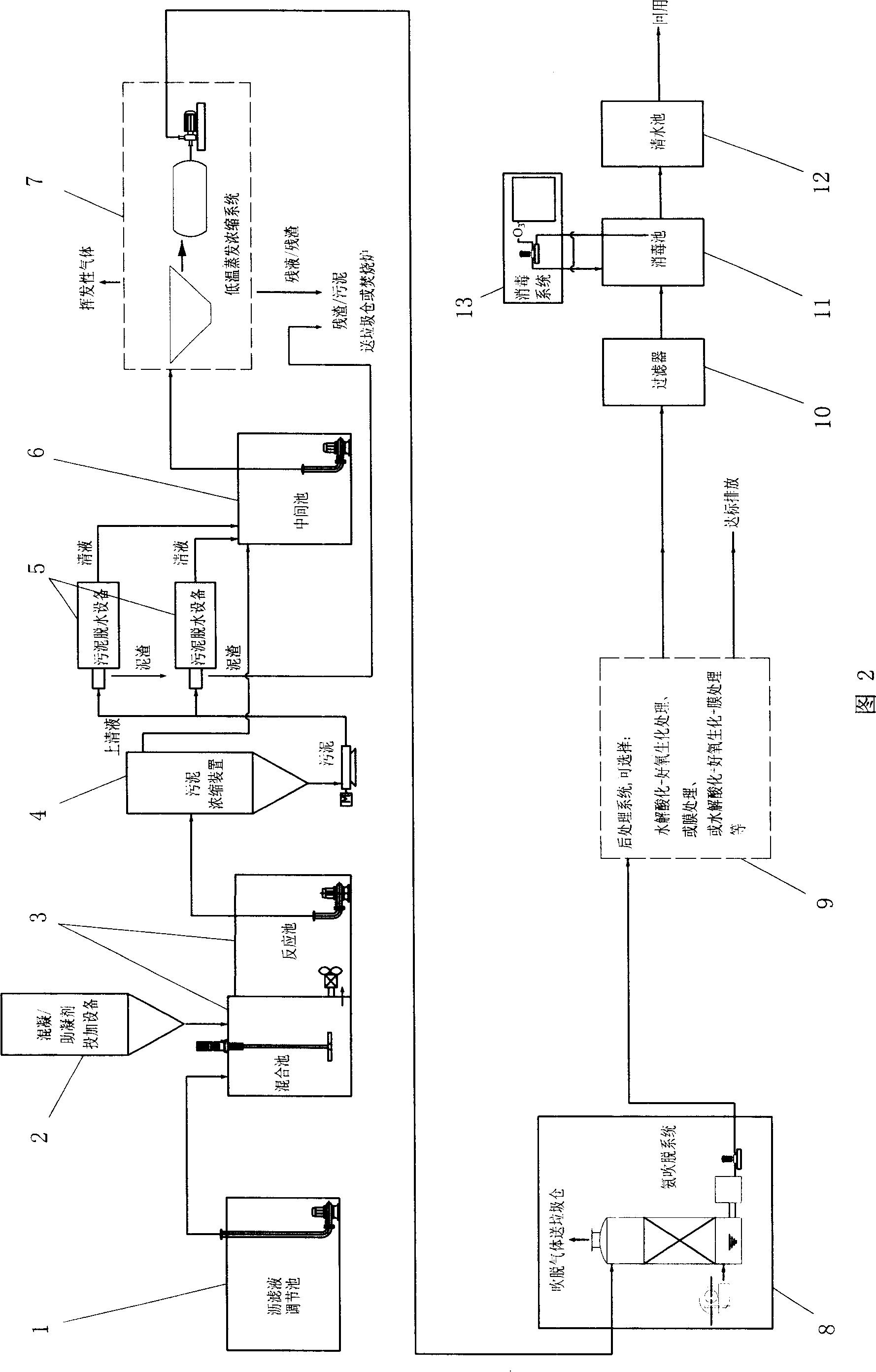

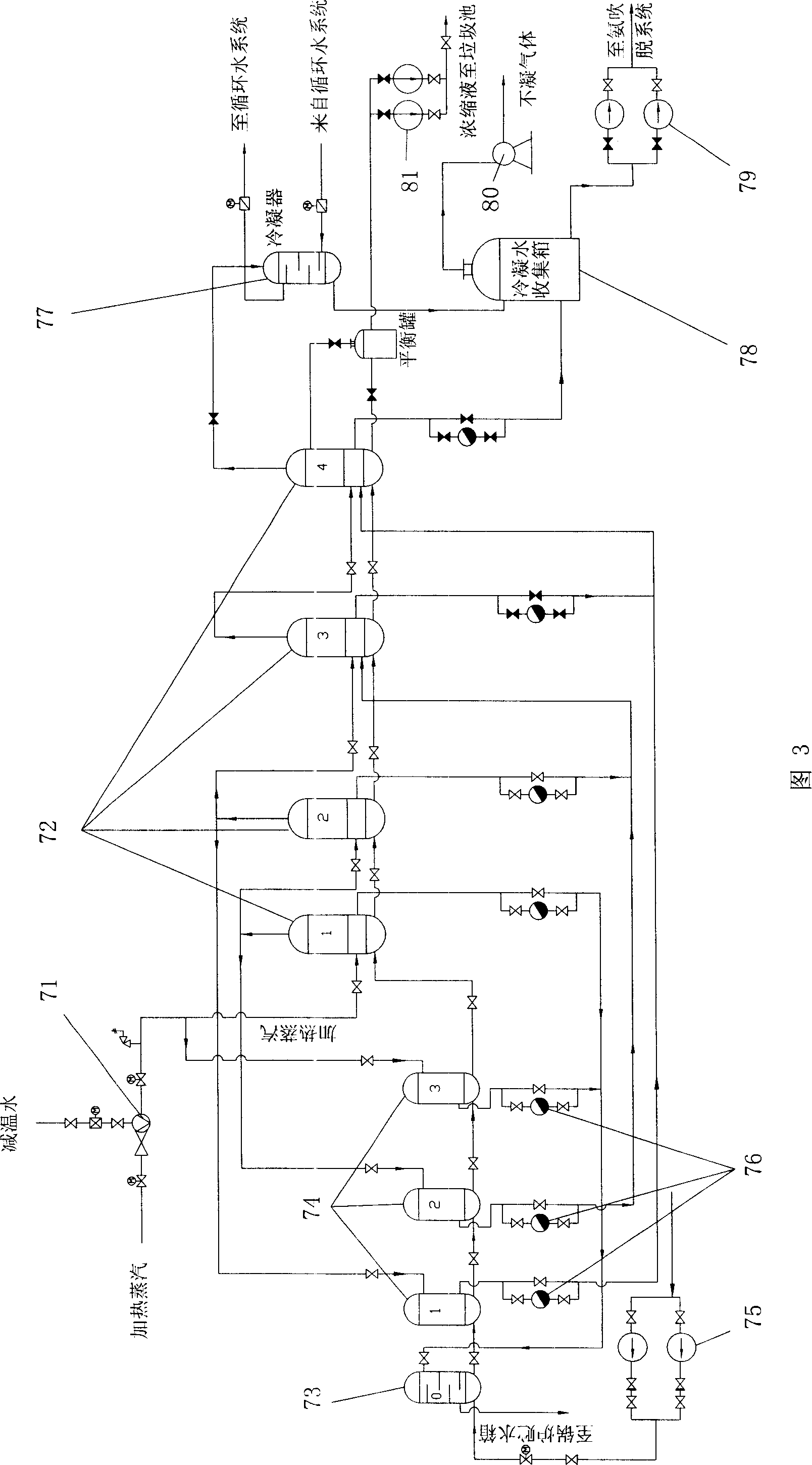

Method and system for processing leachate of garbage burning factory

ActiveCN101209881AImprove water qualityLow investment costTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisHigh concentrationForeign technology

The invention relates to a treatment method and a system of leachate of a garbage incineration plant. The method comprises that: a coagulant is added into the leachate to carry out coagulative precipitation pretreatment and to remove suspended matter; after the pretreatment, evaporation and concentration treatment are carried out on the leachate to obtain condensate water, and residue and raffinate of contaminants are removed; ammonia stripping treatment is carried out on the condensate water to remove ammonia and nitrogen; after ammonia stripping treatment, after-treatment is carried out on the condensate water to meet the environmental discharge standard. The system comprises a pretreatment system, an evaporation and concentration system, an ammonia stripping system and an after-treatment system which are connected in sequence. The invention is applicable to treating various garbage leachates with high concentration, including leachate with low content of biochemical contaminant, and can reach national primary discharge standard; heat energy of garbage incineration is used for treating leachate, thus realizing the purpose of treating waste with waste without secondary pollution; the invention has the advantages of low cost of investment and operation, energy saving, and long-term operational feasibility and load and impact resistance which are superior to prior art; the performance and operation of the invention are not restricted by foreign technology.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

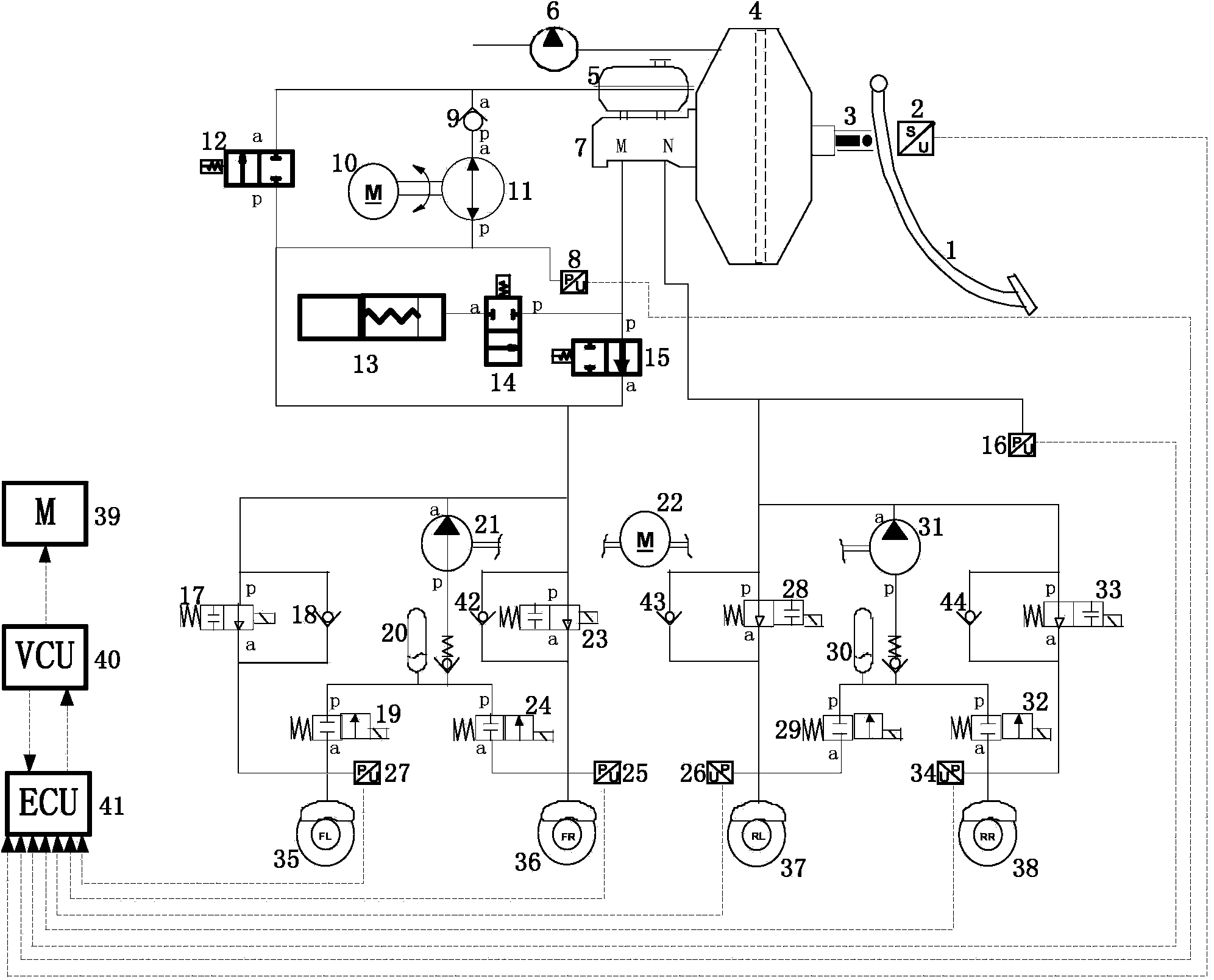

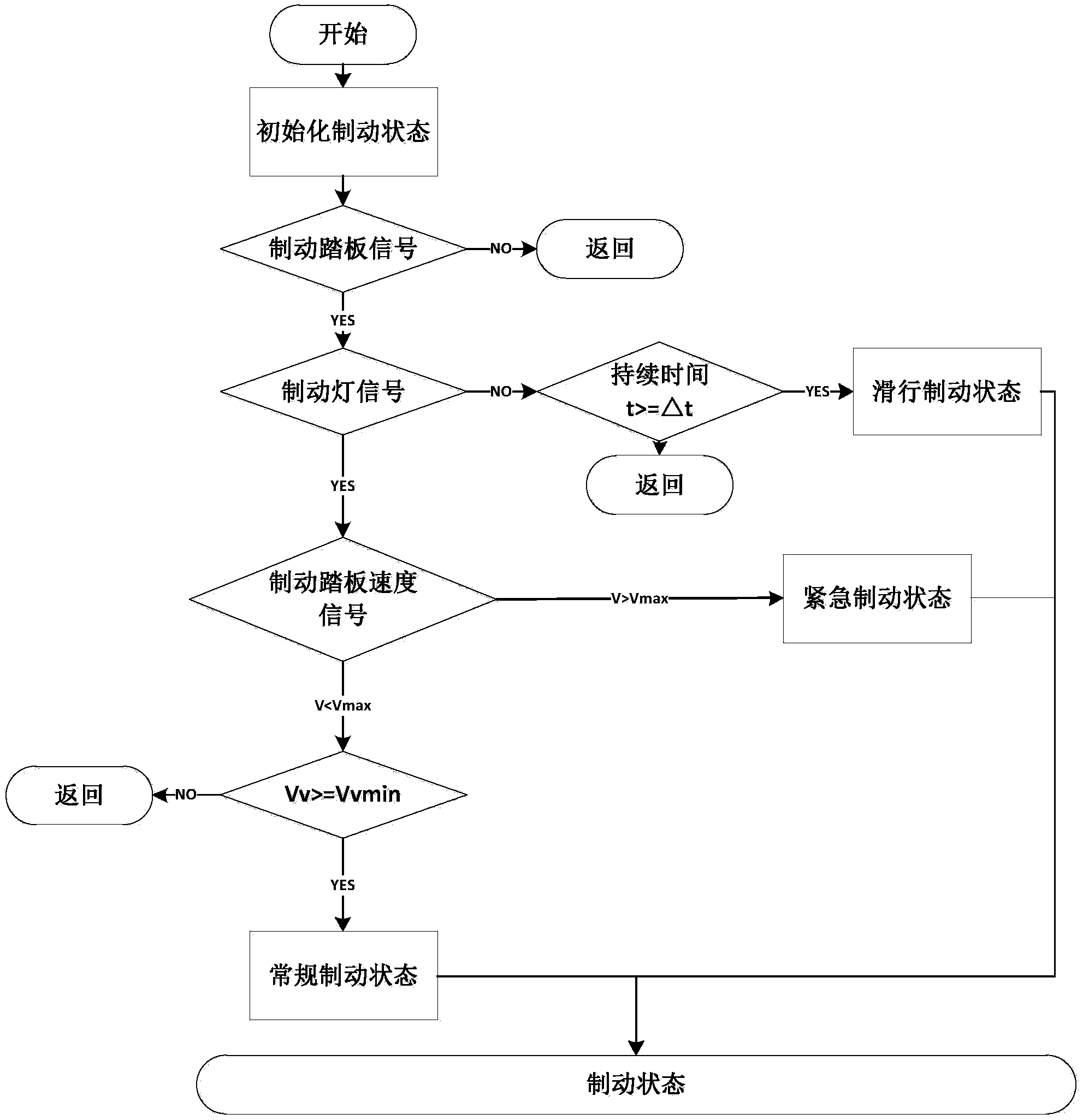

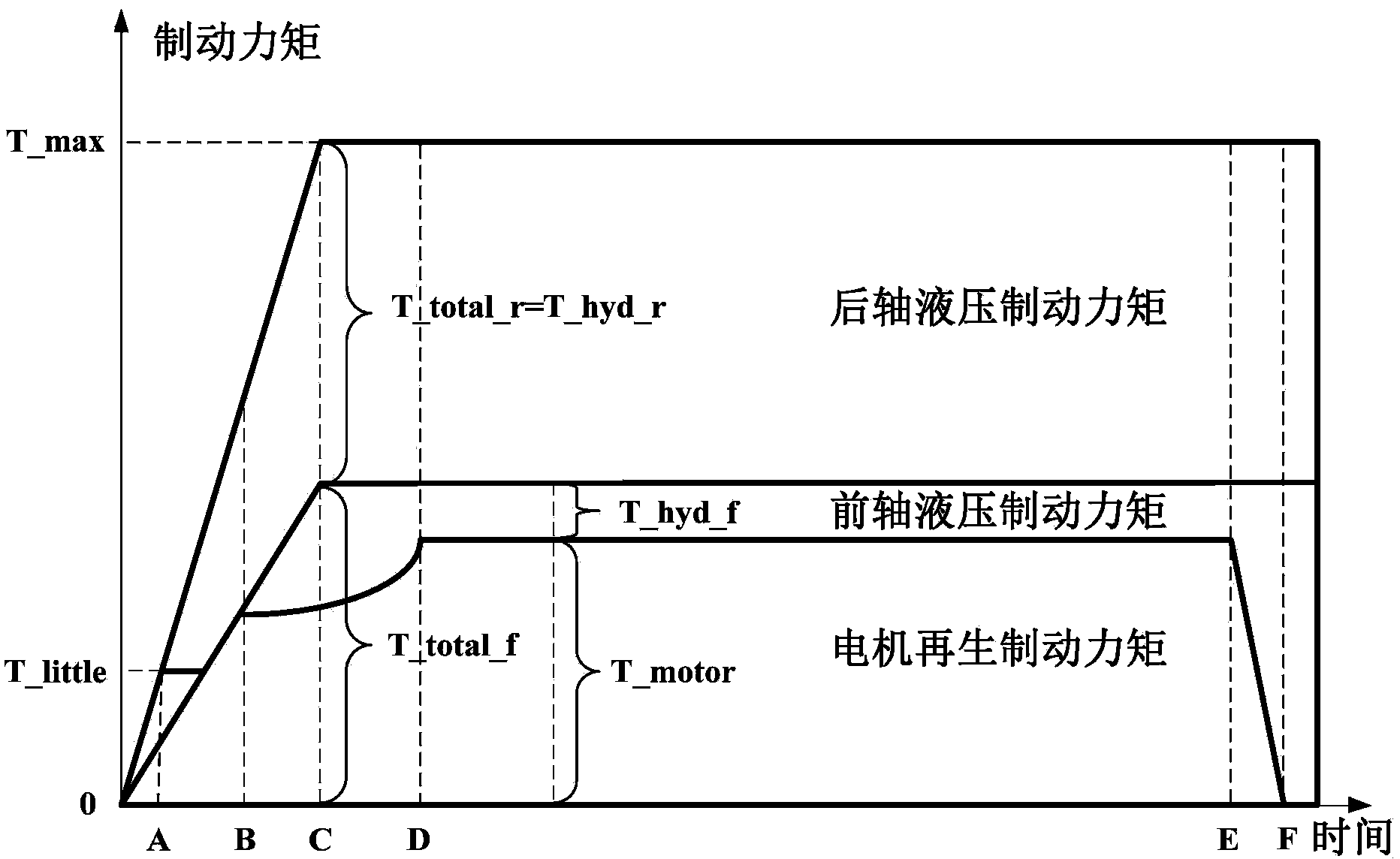

Hydraulic device for automobile braking energy recovery

InactiveCN103895634AImprove work efficiencySimplification reducesElectrodynamic brake systemsFluid braking transmissionHydraulic control unitForeign technology

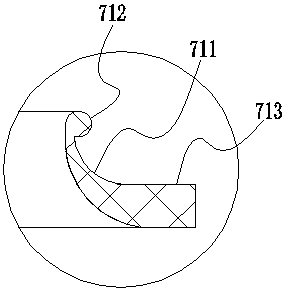

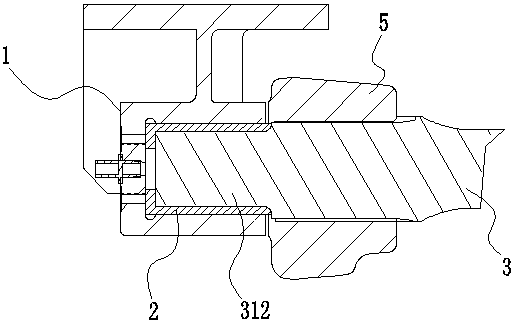

The invention discloses a hydraulic device for automobile braking energy recovery. The hydraulic device aims at solving the problems that in the prior art, the structure is complex, cost is high, and the foreign technology is depended. The hydraulic device for automobile braking energy recovery comprises a main cylinder vacuum booster assembly, a braking energy recovery hydraulic control unit, an ABS hydraulic control unit and an electronic control device. The main cylinder vacuum booster assembly comprises a braking pedal, an oil pot (5) and a braking main cylinder. An opening N of the braking main cylinder is connected with a pipe of an opening p of a left back wheel oil inlet electromagnetic valve of the ABS hydraulic control unit, an opening p of a normally-open electromagnetic valve of the braking energy recovery hydraulic control unit is connected with an opening M of the braking main cylinder through a pipe, an opening a of the normally-open electromagnetic valve and an opening p of a normally-closed linear electromagnetic valve are connected with an opening p of a right front liquid inlet electromagnetic valve of the ABS hydraulic control unit through a pipe, an opening a of the normally-closed linear electromagnetic valve is connected with the oil pot (5) through a pipe, and the electronic control device and the braking energy recovery hydraulic control unit are connected with the ABS hydraulic control unit through pipes.

Owner:JILIN UNIV

Polysilicon solar battery slice etching device

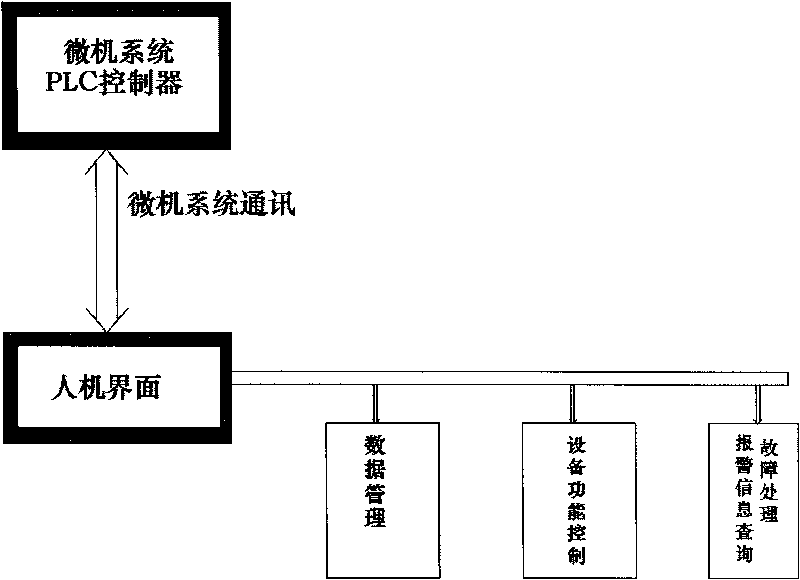

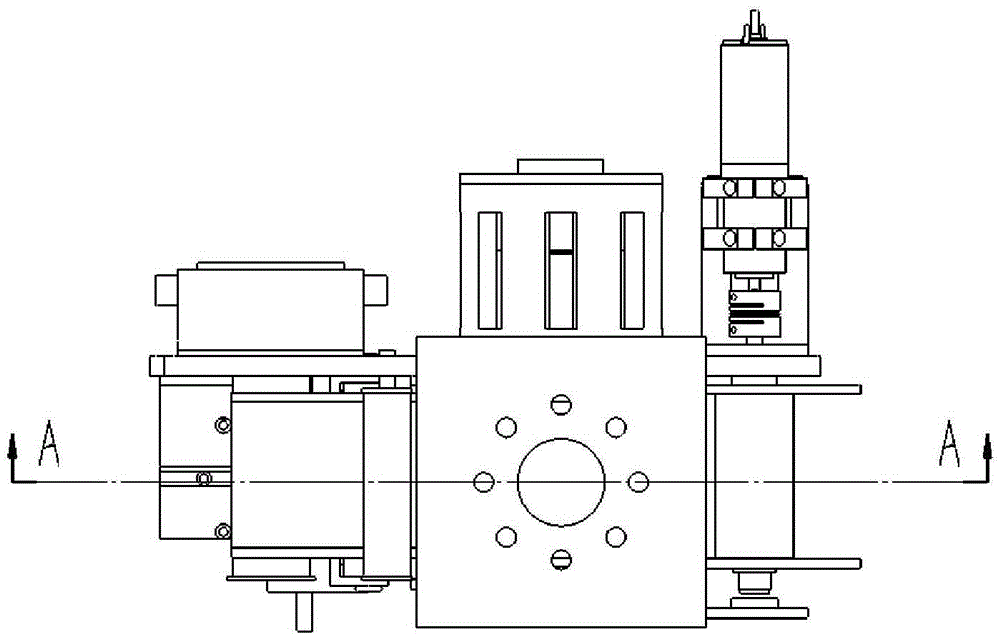

InactiveCN101719530AReduce consumptionGuaranteed constancyFinal product manufactureSemiconductor devicesControl systemForeign technology

The invention discloses a polysilicon solar battery slice etching device which comprises a polysilicon solar battery slice etching part, a polysilicon solar battery slice acid-cleaning part and a microcomputer control system, wherein the polysilicon solar battery slice etching part and the polysilicon solar battery slice acid-cleaning part are both connected to the microcomputer control system, and the microcomputer control system carries out independent control or coordinated control on the polysilicon solar battery slice etching part and the polysilicon solar battery slice acid-cleaning part. The invention can reduce the secondary pollution, improves the working environment and the production efficiency, breaks down the monopoly of foreign technologies and provides conditions for the application of domestic equipment.

Owner:上海科伟达超声波科技有限公司

Method for manufacturing high-elongation nodular cast iron QT700-7 by using steel scraps

InactiveCN104313233ASimple production processLow costProcess efficiency improvementFoundryForeign technology

The invention discloses a method for manufacturing high-elongation nodular cast iron QT700-7 by using steel scraps. Furnace burden comprises 60-85% of steel scrap Q235 and 15-40% of ductile cast iron foundry returns according to weight percentage; the method comprises the following steps: wire feeding type spheroidizing treatment, first wire feeding type inoculation treatment, second pour-over inoculation treatment and third stream inoculation treatment are carried out through alloying base iron in a furnace; casting, cooling, cleaning, tensile test and elongation rate calculation are carried out. Through the adoption of the method disclosed by the invention, as the steel scraps are adopted for production, the elongation rate reaches more than 7% while the tensile strength of the QT700 reaches more than 700 MPa; the problem that the elongation rate of the traditional nodular cast iron QT700-2 is low is solved; the requirement of high strength and high elongation rate of the nodular cast iron QT700 required for a high-requirement product is satisfied; a gap of the domestic and foreign technologies for manufacturing the high elongation nodular cast iron QT700-7 is filled; the cost is low; the economic benefits of manufacturing enterprises are obviously increased.

Owner:罗建华

Dense phase pneumatic conveying system of high-efficiency energy-saving heavy material

The invention relates to a dense phase pneumatic conveying system of a high-efficiency energy-saving heavy material, which has the main technical characteristics: (1) upward guide discharge is adopted, and an umbrella-type discharge hole device is arranged at the end of a discharge tube; (2) a discharge tube in a communicating pump body below a discharge valve is a double casing pipe; (3) bottom fluidization components which is connected by flanges are coaxially arranged at the bottom of the pump body. The invention has small volume and low requirement on the pressure of an air source, and compressed air of 0.8MPa can meet the requirement; the invention is controlled by a programmable controller, and therefore, the degree of automation is high, the running is stable and the operation is convenient; the floor area of the system can be greatly reduced, the investment cost of foundation construction, factory construction and the like of a dedusting system is reduced, and the blank of domestic conveying equipment of the heavy material is filled; compared with the foreign technology, the system makes good for deficiency and has the advantages of small volume, small floor area, easy maintenance and the like.

Owner:TIANJIN SHIDA ELECTRIC POWER EQUIP

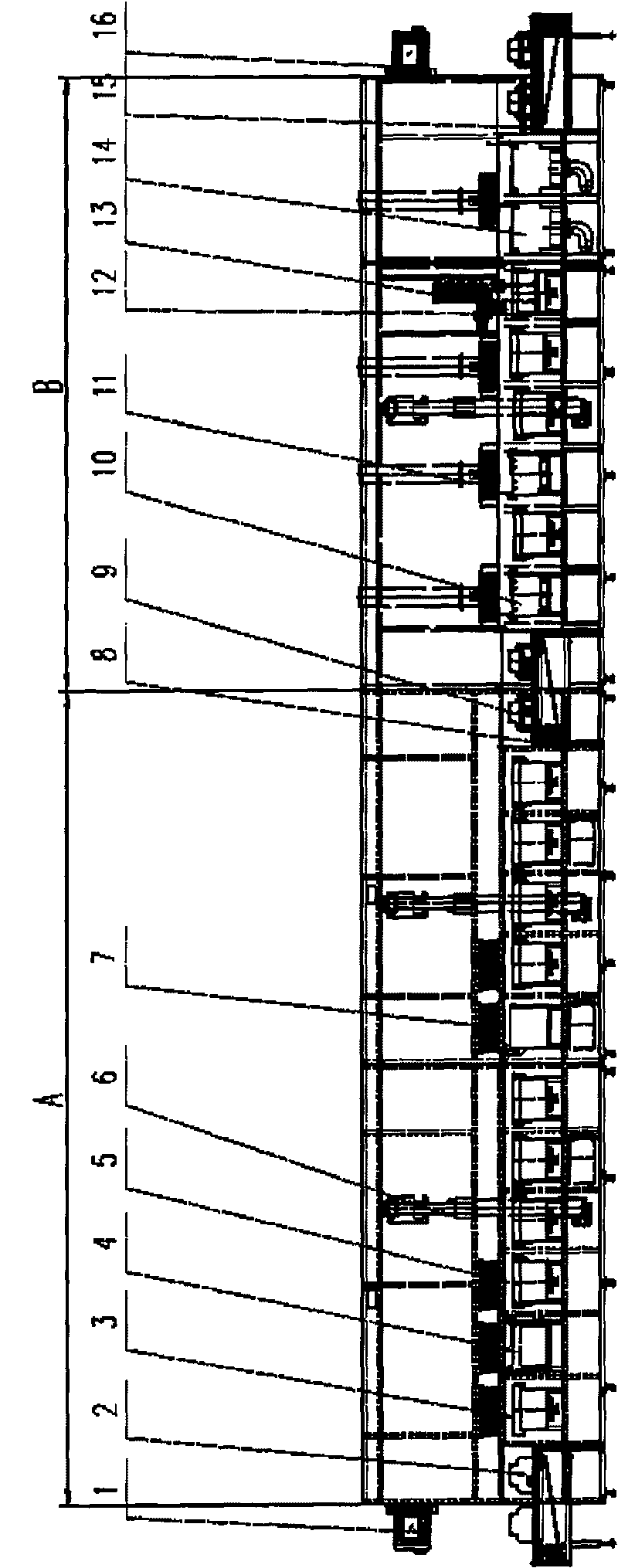

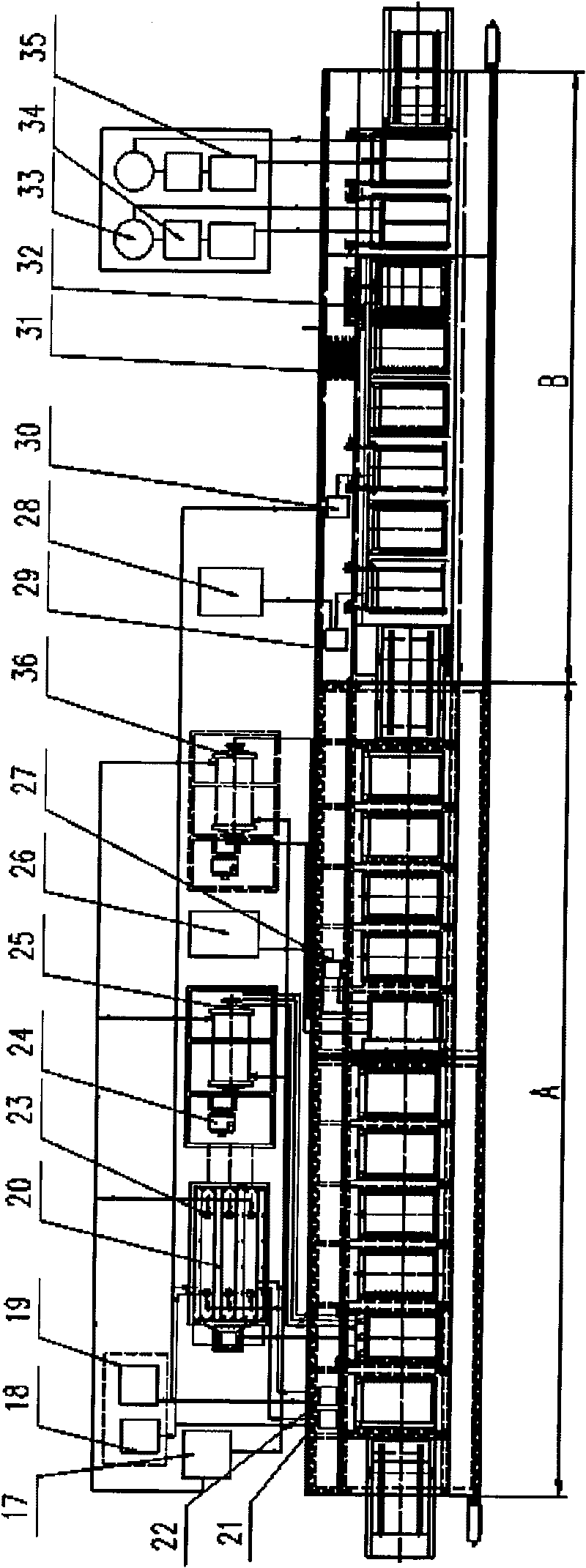

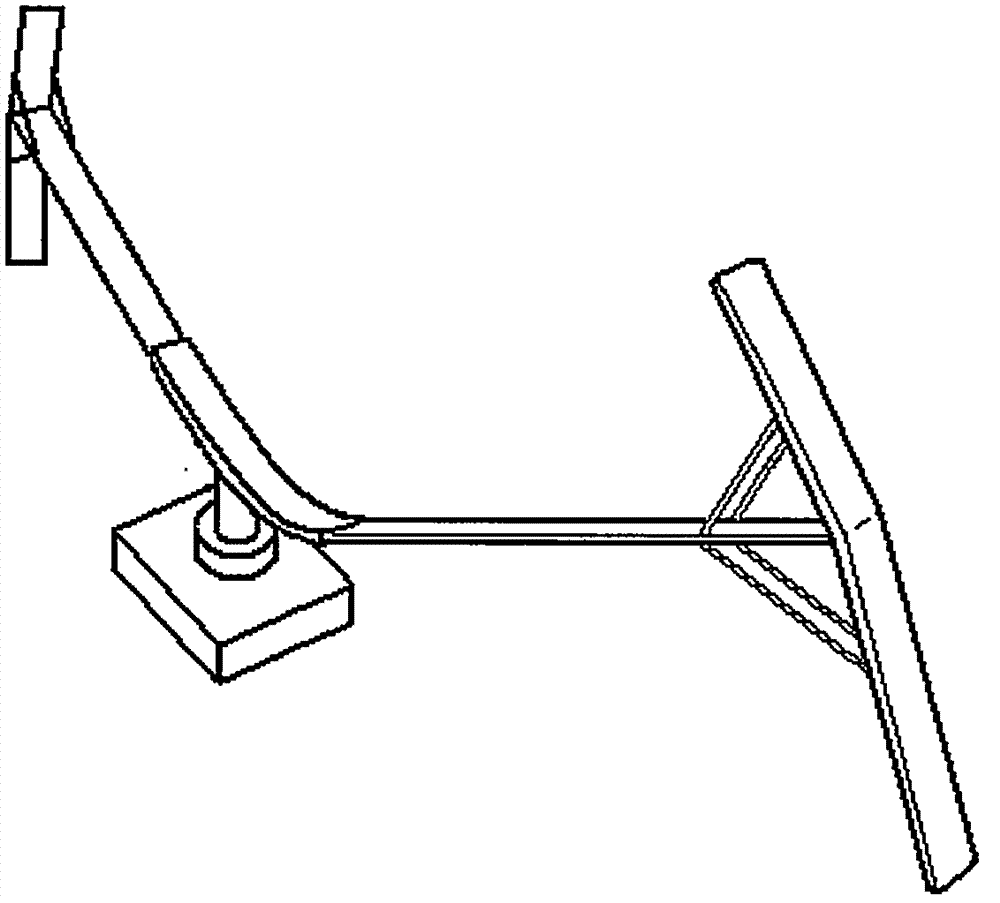

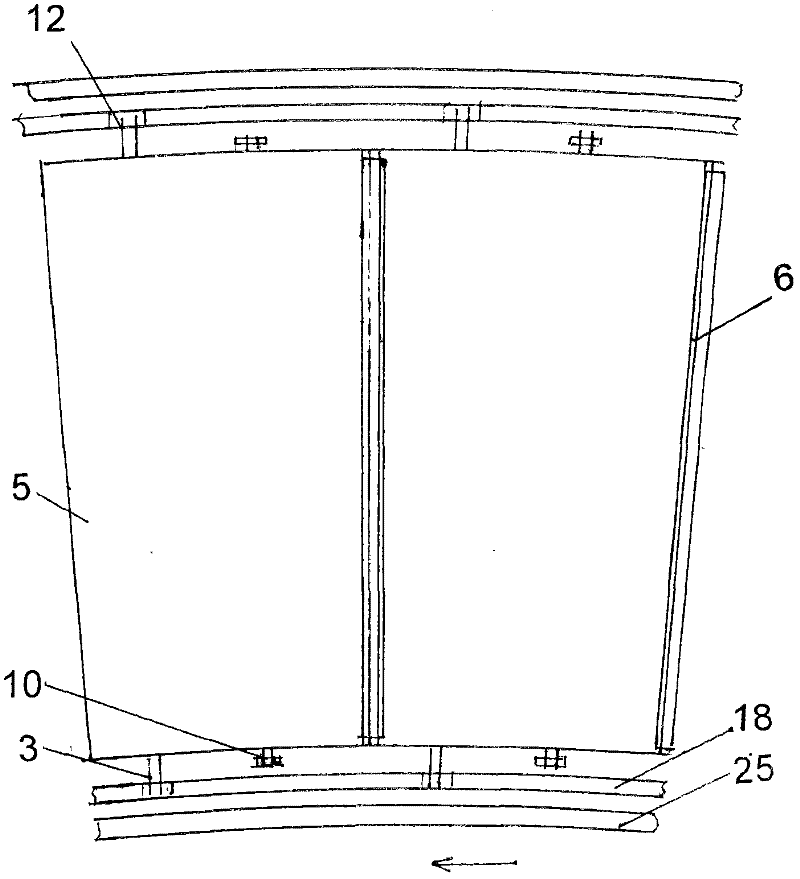

Six-shaft robot-based type automatic tape paving device and six-shaft robot based type automatic tape paving method

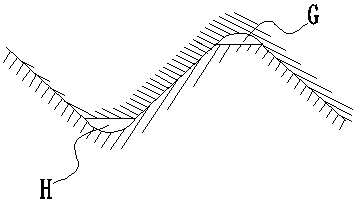

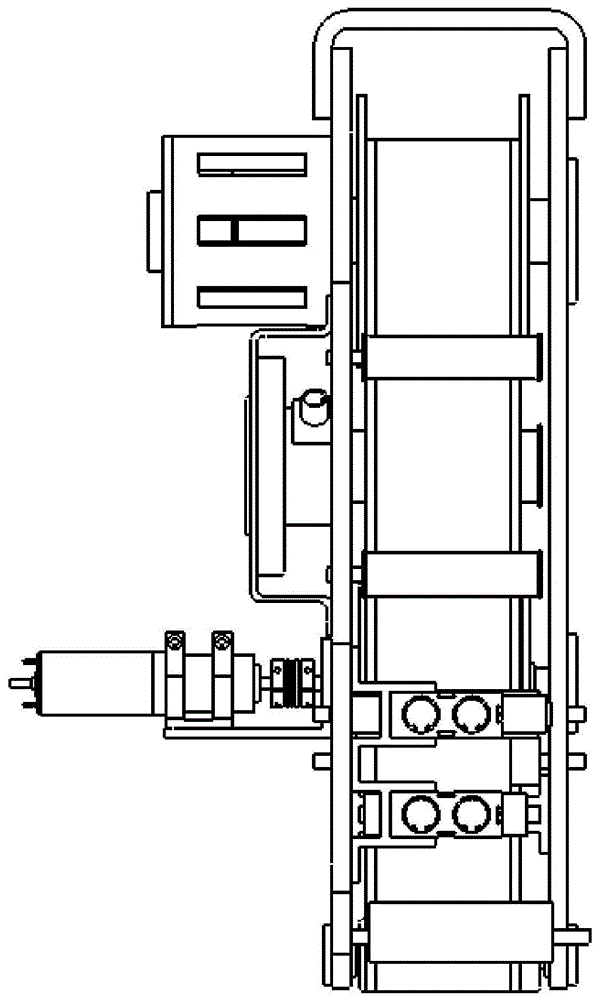

The invention discloses a six-shaft robot based type automatic tape paving device and a six-shaft robot based type automatic tape paving method. The device is applied to the field of automatic manufacturing equipment for paving a composite material fiber tape. The device comprises a belt releasing device (1), a tension detection device (2), a pressing and shearing device (3), an infrared heating device (4), a pressing mechanism (5), a lining paper collecting device (6), a rack (7) and a connection mechanism (8). The device has the function of automatically paving a composite material prepreg tape, breaks through the block of a foreign technology, and meets the requirements on manufacturing of composite materials by aerospace and aviation industries.

Owner:WUHAN UNIV

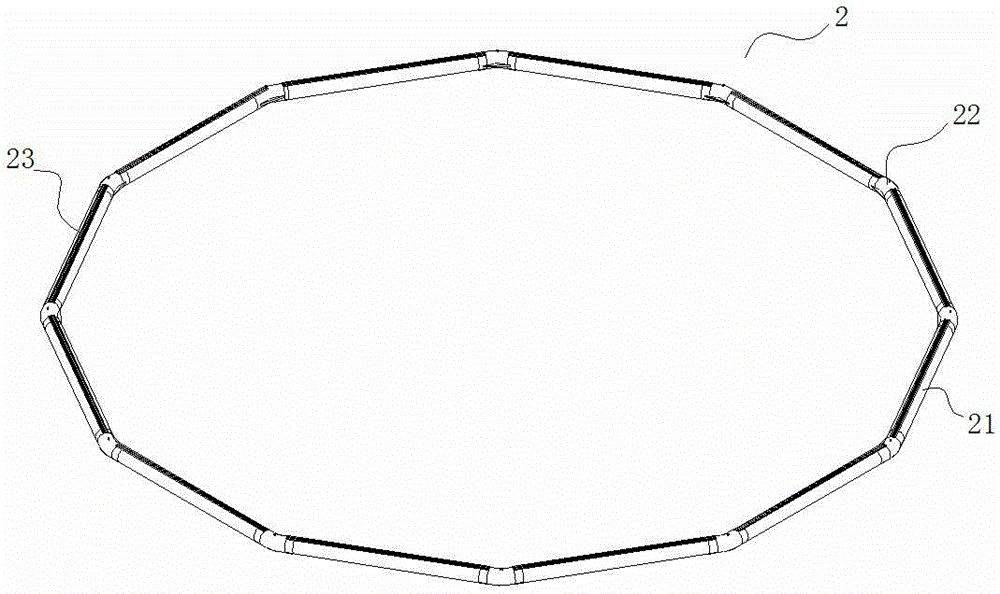

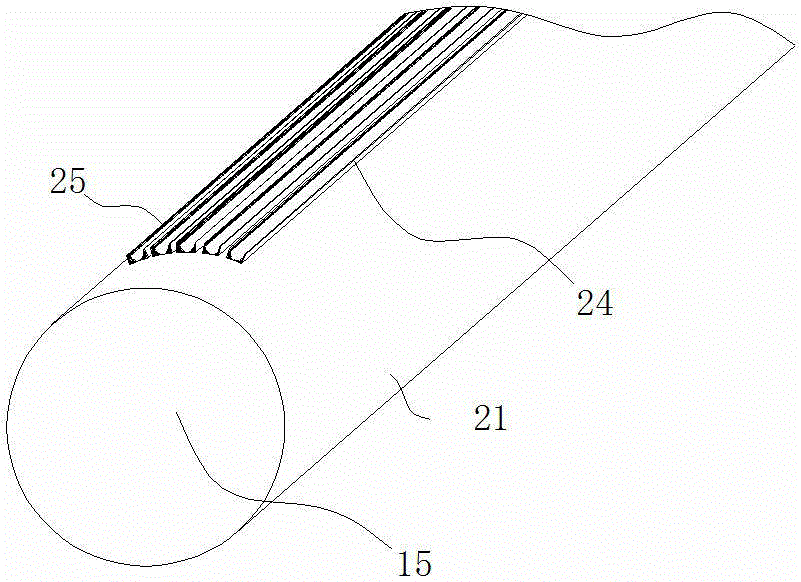

Carrying structure for aviation transient electromagnetic coil

The invention discloses a carrying structure for an aviation transient electromagnetic coil. The carrying structure comprises a polygonal frame and coil supporting cushions, wherein the polygonal frame is formed by sequentially connecting a plurality of air columns and a plurality of bent connectors, and the coil supporting cushions are arranged on the air columns. The bent connectors are of double-way structures with angles, the two ends of the bent connectors are nested with the ends of the air columns, and the angles of the bent connectors are identical to the angle of a polygon. Hanging connectors are arranged at the turning position of the bent connector. Line slots for laying electromagnetic cables are formed in the coil supporting cushions. Heat insulation layers are arranged in line slots. Regarding the characteristics that the aviation transient electromagnetic coil is huge in size, the requirement of the carrying structure for specific stiffness is high, and the requirement for materials are limited, the carrying structure for the aviation transient electromagnetic coil, wherein the carrying structure is different from the foreign technology and has the advantages of being large in size, good in rigidity, small in mass, convenient to use and maintain and the like.

Owner:湖南航天远望科技有限公司

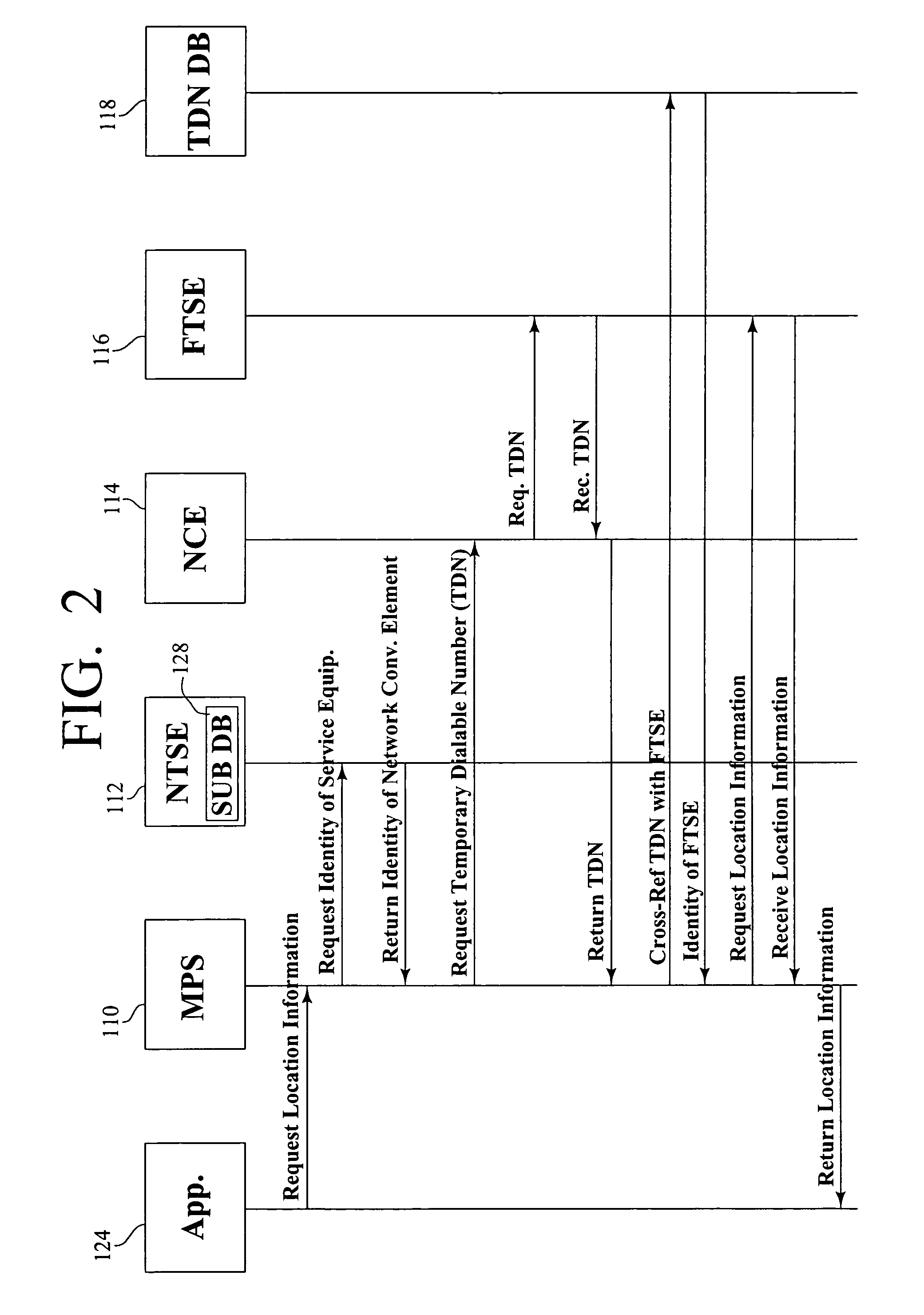

Location-based services for a multi-technology wireless device operating in a foreign technology mode

InactiveUS7272393B1Radio/inductive link selection arrangementsWireless commuication servicesForeign technologyMobile location

An existing network conversion element built to an existing standard is used to obtain the information needed to perform location-based services for a multi-technology wireless device operating in a foreign technology mode. A system includes a database relating temporary dialable numbers with corresponding equipment serving those numbers and a mobile position server in communication with the database. The mobile position server is operative to request and receive a temporary dialable number for a multi-technology wireless device operating in a foreign technology mode, utilize the database to obtain the identity of the equipment serving the wireless device from the temporary dialable number, and initiate appropriate location signaling to the serving equipment. Also, a method includes utilizing the temporary dialable number to determine the identity of the equipment serving the wireless device and obtaining the location of the device directly from the serving equipment.

Owner:CINGULAR WIRELESS II LLC

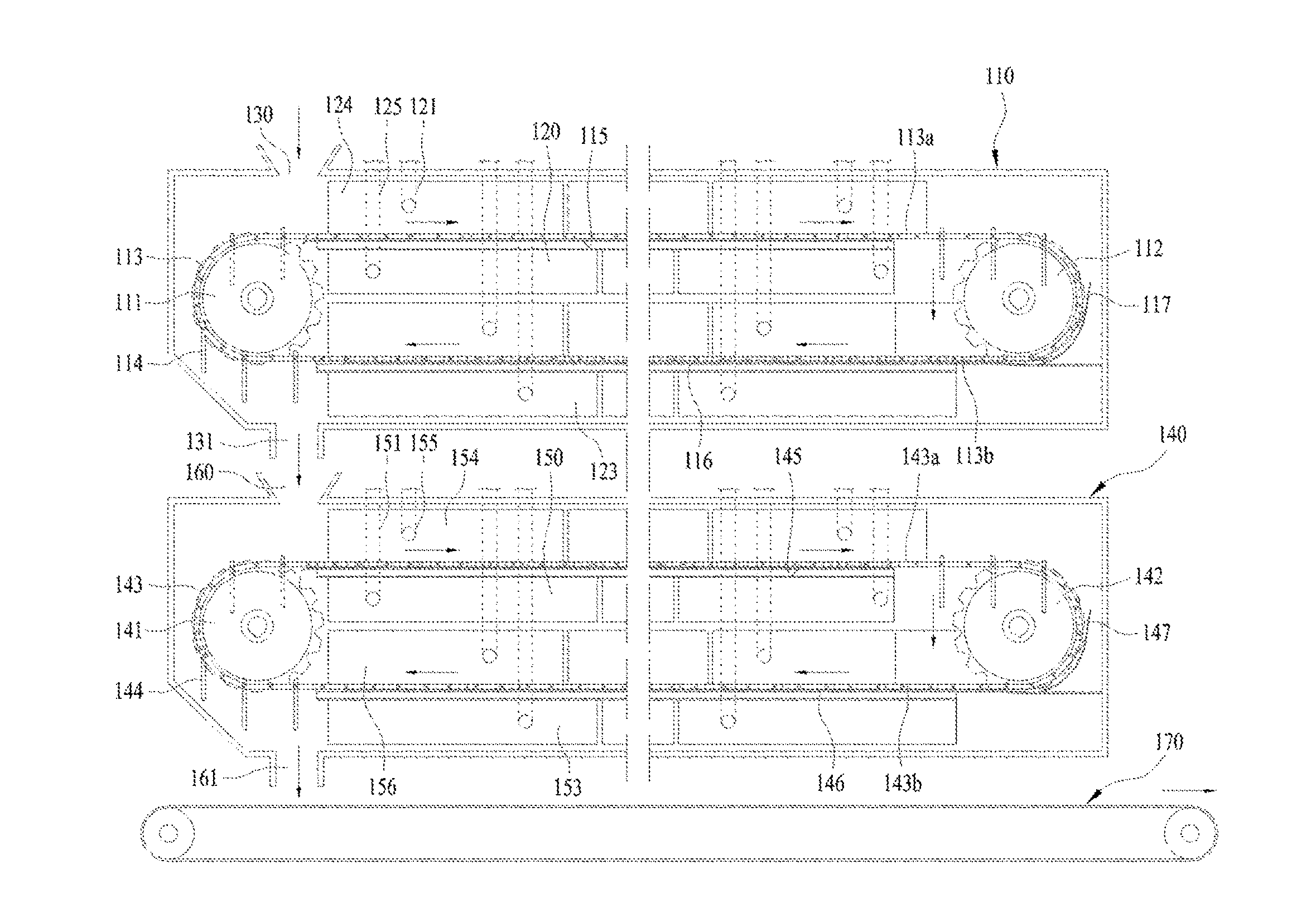

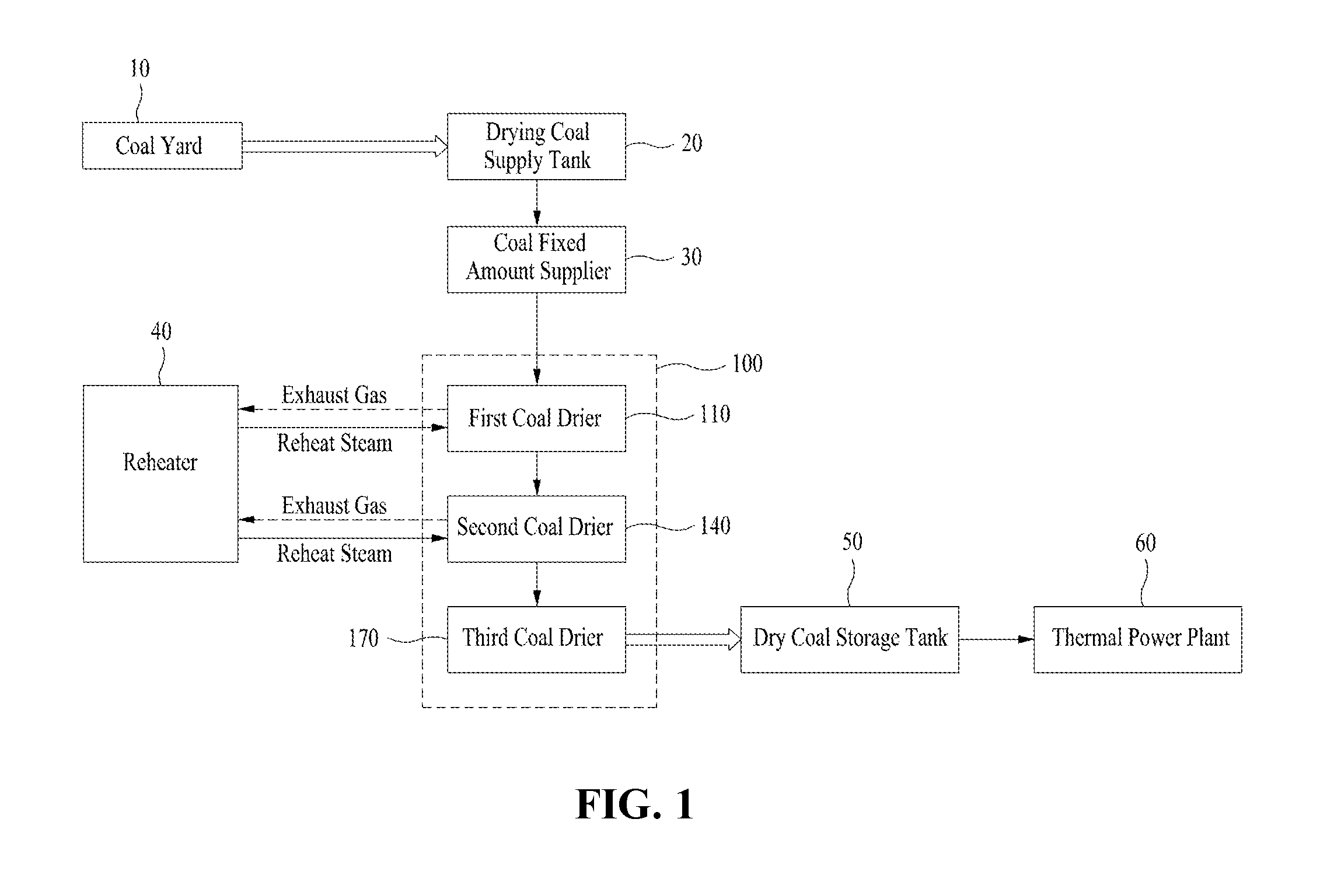

Apparatus for drying coal using reheat steam

InactiveUS20160264896A1High calorific valueCorrosion of the system is preventedDrying solid materials with heatSolid fuelsSpontaneous combustionForeign technology

The present comprises: a first coal dryer; a second coal dryer; and a third dryer, by removing moisture remaining inside and outside of coal, which is used for fueling thermal power plants, in the multiple coal dryers using reheat steam at a high temperature, incomplete combustion of coal can be prevented, thereby enhancing heat capacity of the coal, minimizing release of pollutants, preventing corrosion and enhancing the durability of a system, reducing the rate of spontaneous combustion due to reduced moisture, improving crushing efficiency of a coal pulverizer and heat distribution of a power boiler when coal is combusted, resolving the issue of clogging of a moving pathway when coal is transported, and improving coal supply stability by increasing utilization of low-quality coal for which demand is low. Furthermore, the following advantages can be provided: use of low heat capacity coal which is more affordable than high heat capacity coal; savings in fuel cost and manufacturing cost by reduced coal importation; reduction of waste, pollutants, and carbon dioxide generated from exhaust gas by relative reduction of coal consumption, and the advantages of replacement of foreign technology and exportation of equipment to foreign markets could be anticipated.

Owner:HANKOOK TECH

Simulated low-emission organic waste liquid pyrolysis incineration suspending liquid formula and preparation method thereof

ActiveCN105161154AImprove stabilityReduce the amount of sedimentIncinerator apparatusRadioactive decontaminationLiquid wasteActive agent

The invention relates to a simulated low-emission organic waste liquid pyrolysis incineration suspending liquid formula and a preparation method thereof and relates to the field of low-emission waste liquid treatment. The formula comprises a component A, a component B and a component C, wherein the component A is simulated low-emission organic waste liquid and comprises, according to volume ratio, 20-30% of tributyl phosphate, 70-78% of aviation hydrogenated kerosene and 0-2% of dibutyl phosphate; the component B is calcium hydroxide suspending liquid and comprises, according to mass ratio, 25-30% of phosphorus fixation agent calcium hydroxide, 32-40% of active agent and 30-40% of deionized water; and the component C is an additive which is analytical pure magnesium carbonate. According to the formula, the shortcomings in the prior art are overcome, the suspending liquid prepared according to the formula is good in stability, small in precipitation capacity, low in viscosity and easy to convey; the active agent and the phosphorus fixation agent in the formula are domestic, and the barrier problem of introducing a foreign technology is solved.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

Method for extracting and separating high-purity curcumin with low heavy-metal residues from turmeric

InactiveCN102603505AQuality improvementImprove the safety control standard systemCarbonyl compound separation/purificationForeign technologySafety control

The invention discloses a method for extracting and separating high-purity curcumin with low heavy-metal residues from turmeric. The method comprises the following steps of: firstly cleaning, drying and crushing turmeric into turmeric powder, and mixing the turmeric powder with an extraction solvent proportionally, heating, stirring and extracting; mixing extractive solutions, filtrating and separating, removing the filter residue to obtain filtrate, and concentrating the filtrate; cooling the remaining concentrated liquid, mixing the liquid with a crystallization solvent proportionally, and carrying out static crystallization in a suitable temperature range and filtrating the mixture to obtain wet crystal product; and finally mixing the crystallization solvent with water proportionally to prepare a mixed solvent, mixing the wet crystal product with the mixed solvent proportionally and recrystallizing, and separating to obtain high-purity curcumin with low heavy-metal residues. The technology provided by the invention can reduce the heavy metal content as much as possible while retaining effective natural ingredients of traditional Chinese medicine at the same time, and the technology has significant meaning in improving the standard system of safety control for traditional Chinese medicine, breaking the foreign technical barriers and really pushing traditional Chinese medicine to go onto the world market.

Owner:徐宏永

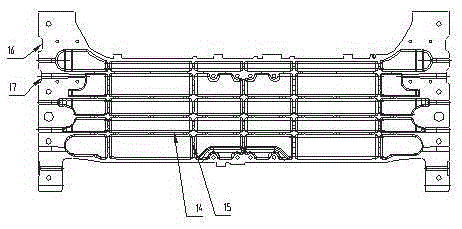

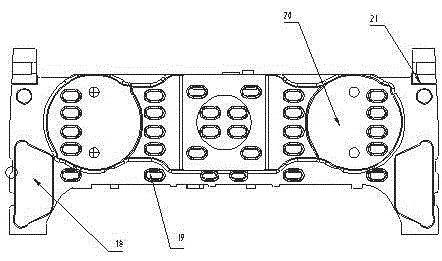

High-speed train connecting sleeper beam

A high-speed train connecting sleeper beam comprises an anti-S-shaped damper base and an anti-lateral-twisting pull rod base. Square pins and round pin positioning guiding installing holes, all of which are connected with a train body are formed in end side beams. The high-speed train connecting sleeper beam is characterized in that the connecting sleeper beam is of an integral casting box structure, an integral cavity is formed in the middle of the connecting sleeper beam and serves as an additional air chamber for air springs, strengthening ribs are arranged on the upper plane, and the inner cavity of the connecting sleeper beam is composed of transverse casting bars and longitudinal casting bars. According to the connecting sleeper beam, the strength of the connecting sleeper beam is guaranteed, manufacturability and air tightness are good, the weight is low, and the strength is high. The simplicity of mounting and dismounting of a bogie and the train body is achieved, the monopoly from the foreign technology is broken, and cost is reduced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

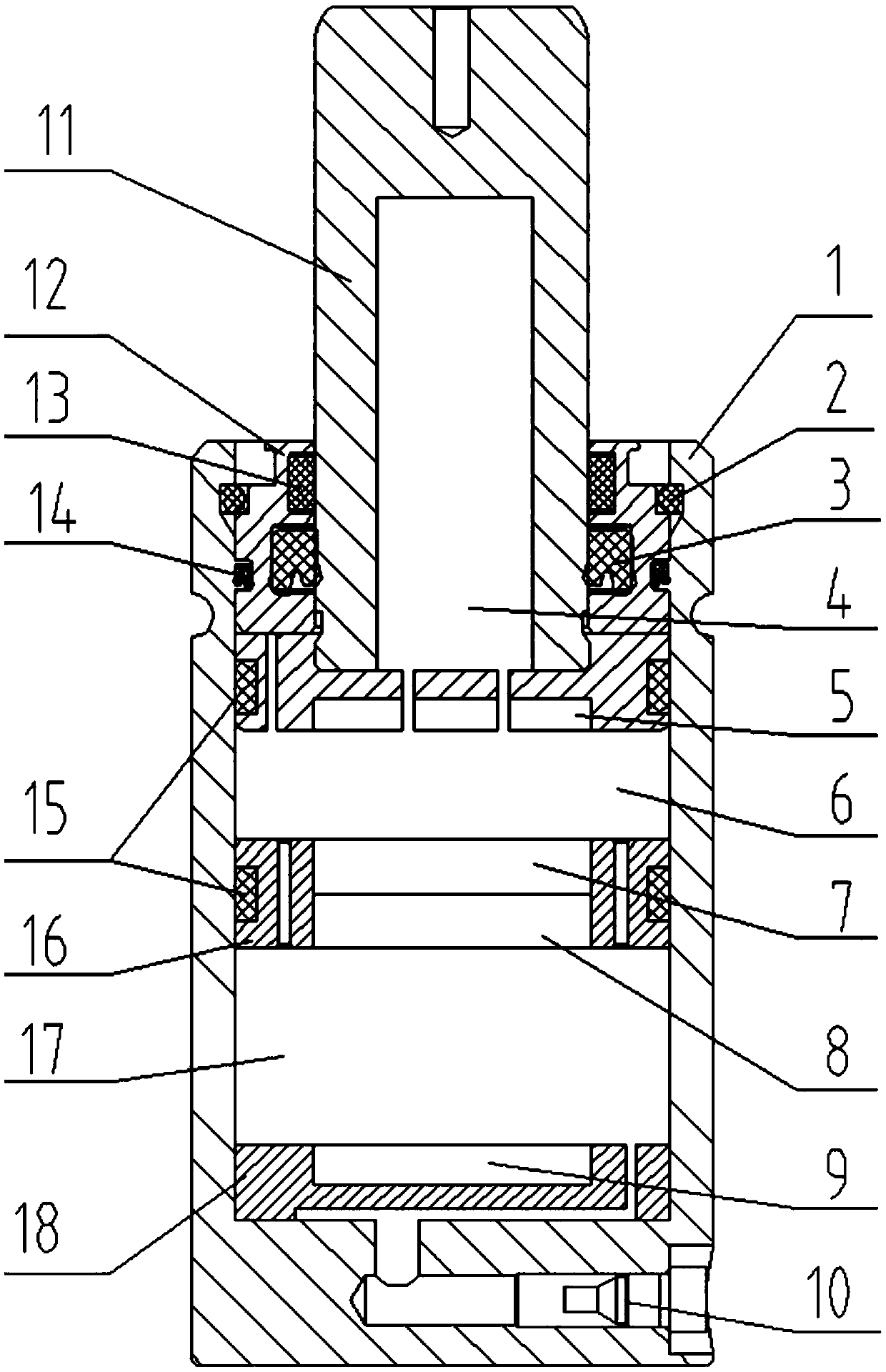

Permanent magnet high pressure nitrogen spring

The invention discloses a permanent magnet high pressure nitrogen spring which comprises a cylinder body, a permanent magnet A, a permanent magnet B, a permanent magnet C, a permanent magnet D, a gas charging valve, a rod piston, an upper end cover, a rodless movable piston and a lower end cover. A cavity A is formed in a piston rod. The permanent magnet A is installed at the bottom of a piston body. The piston body and the permanent magnet A are provided with a gas walking hole A. The permanent magnet B and the permanent magnet C are installed inside the rodless movable piston. The rodless movable piston is provided with a gas walking hole B. A cavity B is formed between the rodless movable piston and the piston body. The top of the lower end cover is provided with the permanent magnet D. The lower end cover is provided with a gas walking hole C. A cavity C is formed between the lower end cover and the rodless movable piston. The permanent magnet high pressure nitrogen spring overcomes defects in domestic and foreign technology and has the very important significance in improving safety, stability and buffering capacity of the nitrogen spring in industries such as mold manufacturing, saving energy, improving the product quality and reducing the product cost.

Owner:李长鸿

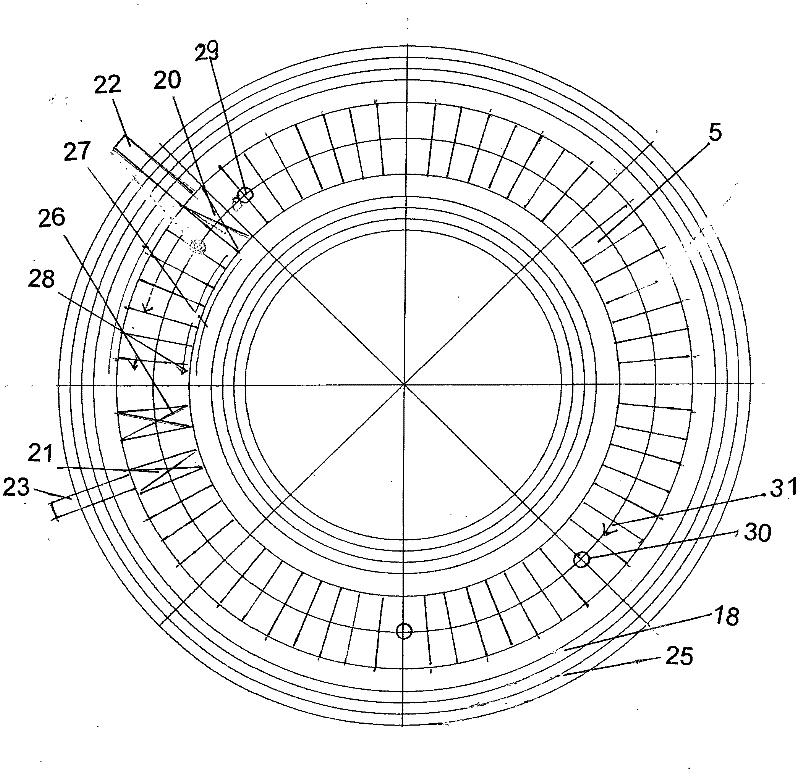

Improved extra-large vertical-axis wind-driven turbine power generator system

ActiveCN104747375ALarge starting torqueStarting torque balanceEnergy industryRenewable energy generationWind drivenForeign technology

The invention discloses a technology for an extra-large vertical-axis wind-driven turbine power generation unit. The technology for the extra-large vertical-axis wind-driven turbine power generation unit has the advantages that a turbine is an extra-large unit with the power level higher than or equal to 10MW, double-blade and single-arm AerogeneratorX designs of a British Arup company are improved to obtain double-blade and double-arm triangular designs from the perspective of structural mechanics, and accordingly the shortcoming of low structural strength due to high shear stress of cantilever beams can be overcome; starting torque can be increased by the aid of the additional Savonius turbine, driving torque is stable owing to the additional Savonius turbine, and output power of the unit can be increased; a novel power generator and a novel motor converter technology are matched with each other, so that a large wind power system can be formed and becomes the extra-large vertical-axis wind power generation unit with integrated novel domestic and foreign technologies and high industrial implementation degrees.

Owner:于岳亮 +8

High recovery method of waste phosphoric acid film during electrode foil production

The invention discloses a high recovery method of a waste phosphoric acid film during electrode foil production. The method comprises a DP1 process waste acid pipeline, a DP1 waste phosphoric acid front liquid storage tank, a DP1 waste phosphoric acid standby storage tank, a DP1 waste phosphoric acid sterilization filtration system, a primary low-pressure nanofiltration membrane system, a secondary high-pressure nanofiltration membrane system, a reverse osmosis membrane system, a reverse osmosis membrane producing water storage tank, a multiple-washing high-pressure nanofiltration system, a nanofiltration membrane producing water storage tank, a reverse osmosis membrane concentrated water storage tank, a washing system producing water storage tank, a primary nanofiltration membrane concentrated water storage tank, a secondary nanofiltration membrane concentrated water storage tank, a multistage washing front liquid storage tank and a washing system producing water storage tank. The invention provides the high recovery method of the waste phosphoric acid film during electrode foil production, an equipment utilization process adopting a domestic nanofiltration membrane to replace an imported nanofiltration membrane is completed by continuous exploring and verifying through experiments, the overall equipment domesticization is realized, and the limitation by foreign technology monopoly and a long post-service period is avoided, so that not only is the cost greatly reduced, but also the method can be continuously perfected and continuously improved.

Owner:新疆智诚同欣环保科技有限公司

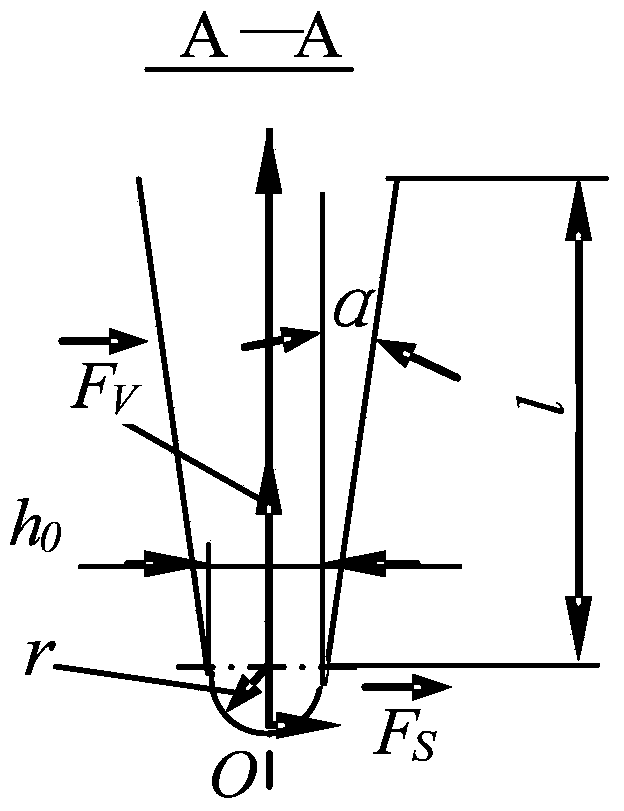

Method for determining width and angle of blade of disc cutter of whole-section tunnel boring machine

The invention belongs to the technical field of disc cutter design, and particularly relates to a method for determining the width and the angle of a blade of a disc cutter of a whole-section tunnel boring machine. The method for determining the width and the angle of the blade of the disc cutter of the whole-section tunnel boring machine comprises the steps of (1) selecting manufacturing materials of the disc cutter, and determining allowable pressure stress [sigma y], (2) determining the diameter of the disc cutter, determining extreme abrasion loss l, further determining maximum thrust Fv of the disc cutter, (3) determining a central angle theta corresponding to the arc-shaped section of the rock breaking blade of the disc cutter, (4) calculating the width and the angle of the blade of the disc cutter on a cutterhead of the whole-section tunnel boring machine according to the parameters and a given formula. According to the method for determining the width and the angle of the blade of the disc cutter of the whole-section tunnel boring machine, self-dependent design can be carried out according to the conditions of engineering geology, the requirement for the construction period, cutter ring materials and the like of China, blind imitation of foreign products is avoided, development of the disc cutter technology of China can be effectively promoted, limitation of the foreign technology can be broken through, a path of self-dependent innovation can be broken, and huge economic benefit can be created.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

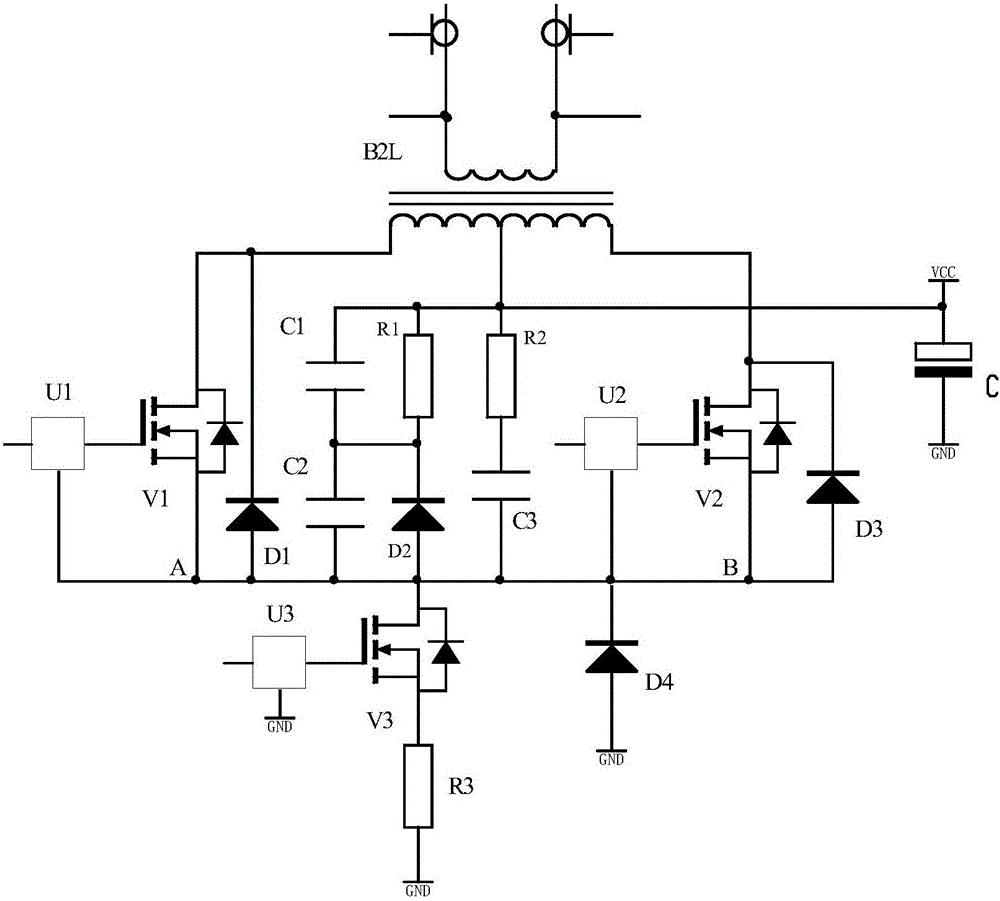

Spot welder pulse output control circuit adopting transformer to output direct current pulses

The invention discloses a spot welder pulse output control circuit adopting a transformer to output direct current pulses. The spot welder pulse output control circuit comprises an MCU automatic control circuit, a constant-current constant-voltage control circuit, the pulse transformer B2L, an energy-storage capacitor C, a first power switch V1, a second power switch V2, and a third power switch V3, wherein the pulse transformer B2L, the first power switch V1, the second power switch V2, the third power switch V3 and a fourth power switch V4 form a Y-shaped welding pulse output drive circuit, so that the spot welder pulse output control circuit has a function of switching positive pulse output, negative pulse output or alternate positive-negative direct current pulse output fast at any time, the amplitude and the width of output positive pulses and negative pulses can be adjusted freely as required, and can be different, the polarity of direct current pulses output by the transformer can be switched fast at any time, and the amplitude and the width of the pulses can be adjusted freely. According to the invention, the domestic technology blank that output polarity switching of direct current pulses in the field of spot welders is monopolized by foreign technologies is filled.

Owner:ZHONGSHAN VIHAN ELECTRONICS EQUIP

Aluminum alloy strip material for computer support, and preparation method thereof

The invention discloses an aluminum alloy strip material for a computer support, and a preparation method thereof. The aluminum alloy strip material for the computer support comprises the following components in percentage by mass: 0.01%-0.10% of Si, 0.03%-0.08% of Fe, 0.01%-0.10% of Cu, 0.02%-0.05% of Mn, 2.4%-3.4% of Mg, 0.01%-0.10% of Cr, 0.01%-0.02% of Zn, 0.01%-0.03% of Ti, and the balance Aland inevitable impurities, wherein the content proportion of FeMnAl6 in an intermetallic compound is not greater than 0.01%. According to the aluminum alloy strip material for the computer support, and the preparation method thereof, by controlling the chemical components of the alloy and optimizing the production parameters of casting and hot-rolling processes, the preparation method of the aluminum alloy strip material for the computer support has the advantages of being high in anodic oxidation quality, level in shape, high in forming performance, and the like, and breaks the monopoly of foreign technologies in the aspect.

Owner:CHINALCO RUIMIN

Patent supermarket or system for managing technique conversion platform

InactiveCN101303748AConvenient to find in ChinaEasy to findResourcesIntellectual propertyMulti language

The invention relates to a patent supermarket or technology transformation platform management system which includes entering a display module for three icons of welcome with a busy market background from a patent supermarket or technology transformation platform display module, then entering a display module with at least two languages, entering an interface display module of a trading hall for various languages, respectively entering a patent management display module or a display case display module from the interface display module of the trading hall for various languages and entering a display module for the relevant content of the patent from the display case display module. The patent supermarket or the management system can be convenient for a patentee or a technology demanding enterprise, which fast and effectively improves the transformation of the patent or the technical achievements; is convenient for a foreign patentee and a foreign technology demanding enterprise that come to China to search business opportunities by adopting multi-language displaying; in order to match with the implementing of the national intellectual property strategy, the patent supermarket or the management system not only abstracts the patentee, but also abstracts an investment enterprise; besides, the transparency and the public trust of the patent supermarket or technology transformation platform is improved.

Owner:殷亮

Design method for realizing high-speed data bus by optical fiber channel

InactiveCN104796199AImprove reliabilityImprove data transfer bandwidthBus-type electromagnetic networksAviationForeign technology

The invention relates to a design method for realizing a high-speed data bus by an optical fiber channel, comprising an Ethernet passive optical network configuration method, a three-layer exchange mechanism, a topology of optical fiber bus design, a bus controller, an access unit, a photoelectric conversion module, a light splitter, and an optical fiber. Before the invention, technologies related to an optical fiber high-speed data transmission bus use foreign standards, and as the technologies and chips for realizing the technologies belong to the scope of embargo of the west to China, China could not directly use the standards. According to the invention, a new method is used to replace a similar foreign technology, and an optical fiber high-speed data transmission bus product standard system of our own is established, so that the optical fiber high-speed data transmission bus technology can be widely applied to spaceflight, aviation, war industry, electronic industry and other fields.

Owner:KANGYUXING TECH BEIJING

Ethernet data encryption and decryption processing method based on national cryptographic algorithm

InactiveCN110401532AIndustry security and controllableKey distribution for secure communicationForward error control useEffective solutionForeign technology

The invention discloses an Ethernet data encryption and decryption processing method based on a national cryptographic algorithm. An encryption and decryption algorithm used in a system in MACSec and / or 802.1 X is replaced with the national cryptographic algorithm; an SM2 national cipher or higher-level asymmetric algorithm is adopted as an algorithm for protecting the symmetric cipher in key interaction so as to ensure that the symmetric cipher is not illegally acquired in the transmission process, and an SM4 or SM9 or higher-level national cipher encryption and decryption algorithm is adopted as an encryption and decryption algorithm in data transmission so as to ensure that sensitive data is not illegally read. Compared with an encryption and decryption algorithm dominated by European and American countries, the method is controllable in industry security, gets rid of excessive dependence on foreign technologies and products, and provides an effective solution for constructing an autonomous controllable network security environment.

Owner:KUNGAO XINXIN MICROELECTRONICS (JIANGSU) CO LTD

Target piece for producing C-14 isotope by heavy water reactor

PendingCN113140346ARealize industrial productionSolve the production capacitySpecific isotope recoveryConversion in nuclear reactorIsotopic labelingForeign technology

The invention aims to disclose a target piece for producing C-14 isotope by a heavy water reactor, the target piece comprises a connecting rod and an end plate, a target cylinder assembly or an absorption rod assembly is arranged around the connecting rod, and the target cylinder assembly or the absorption rod assembly is fixed at the upper end and the lower end of the arrangement position of the target cylinder assembly or the absorption rod assembly through the end plate. The connecting rod is connected with the upper positioning mechanism and is used for positioning the target piece; compared with the prior art, the target piece is placed in the reactor core of the heavy water reactor, and the C-14 isotope is generated by irradiation of thermal neutrons, so that the industrial production of the C-14 isotope can be realized, the production capacity of the C-14 can be improved, the foreign technical blockade can be broken, and the discourse right of the international isotope transaction market can be obtained; and the development of industries such as domestic biological medicine, environmental protection and isotope labeling detection is promoted, and the aim is fulfilled.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +2

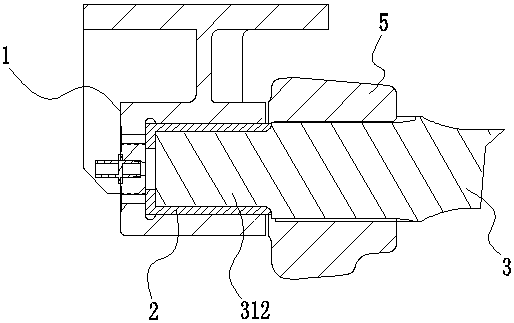

End part structure of antiroll torsion bar capable of preventing galvanic corrosion

ActiveCN108909749AReduce scrap rateAvoid Galvanic CorrosionBogiesWheel axle self-adjustmentsForeign technologyEngineering

The invention discloses an end part structure of an antiroll torsion bar capable of preventing galvanic corrosion. The structure comprises a coating sprayed on the outer peripheral surface of a torsion bar end part; after assembly, the coating is located between the torsion bar end part and a torsion bar bearing; a main sealing ring is arranged between a torsion bar end surface of a torsion bar and the end surface of the torsion bar bearing; the end surface of the torsion rod bearing is utilized so that the main sealing ring is tightly attached to the torsion bar end surface of the torsion rod; and therefore, a sealed attachment surface is formed on the end surface of the torsion rod bearing in order to prevent galvanic corrosion. During an application process, rusting corrosion at the torsion rod end part is avoided. The rejection rate of an antiroll torsion bar device is reduced. The cost of overhaul is lowered. Additionally, limits of foreign technology are removed. The maintenancemarket is automatically mastered.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Selectively passing material and preparation method thereof

ActiveCN104934091ASolving Manufacturing ChallengesExcellent selective pass performanceRadiation electrical energyNeutron irradiationForeign technology

The present invention discloses a selectively passing material and a preparation method thereof, belonging to the technical field of materials. The selectively passing material is provided with a channel used for passing of helium, the channel is formed by a release process of helium which is generated by neutron irradiation for the material. The preparation method of the selectively passing material comprises the steps of: mixing powdery metal with powdery <10>B elementary substance / compound; sintering the mixture to obtain a matrix; then performing neutron irradiation processing on the obtained matrix; and finally performing heating processing on the matrix which is subjected to the neutron irradiation processing to release the helium generated by the neutron irradiation to form the selectively passing material. According to the selectively passing material and the preparation method of the present invention, the problem of preparing a <238>Pu helium-passing plutonium-blocking material is solved, and the characteristic that <10>B reacts with neutron to generate helium is ingeniously utilized to form a specific channel for diffusion of helium atoms, excellent selectively passing performance is achieved, in addition, the condition of each step of the preparation process can be easily controlled, thereby avoiding the disadvantages of low yield and unstable quality of foreign technology, and the selectively passing material also can be used as a helium-passing window material for being popularized and applied to alpha decay isotopes besides the <238>Pu.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Method for preventing end part of antiroll torsion bar from galvanic corrosion

ActiveCN108909750AReduce scrap rateAvoid Galvanic CorrosionPretreated surfacesCoatingsForeign technologyRejection rate

The invention discloses a method for preventing an end part of an antiroll torsion bar from galvanic corrosion. The method comprises the following steps: spraying a coating on the outer peripheral surface of a torsion bar end part such that the coating is located between the torsion bar end part and a torsion bar bearing and a main sealing ring is arranged between the end part of an antiroll torsion bar and an end surface of a torsion rod bearing; during assembly, firstly enabling the main sealing ring to sleeve the torsion bar end surface of the torsion bar, enabling the torsion bar end partto insert into the torsion bar bearing, utilizing the end surface of the torsion bar bearing to compact and attach the main sealing ring onto the torsion bar end surface during an insertion process such that a sealed attachment surface is formed on the end surface of the torsion bar, thereby preventing galvanic corrosion. During an application process, rusting corrosion at the torsion rod end partis avoided. The rejection rate of an antiroll torsion bar device is reduced. The cost of overhaul is lowered. Additionally, limits of foreign technology are removed. The maintenance market is automatically mastered.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A kind of automatic tape laying device and method based on six-axis robot

The invention discloses a six-shaft robot based type automatic tape paving device and a six-shaft robot based type automatic tape paving method. The device is applied to the field of automatic manufacturing equipment for paving a composite material fiber tape. The device comprises a belt releasing device (1), a tension detection device (2), a pressing and shearing device (3), an infrared heating device (4), a pressing mechanism (5), a lining paper collecting device (6), a rack (7) and a connection mechanism (8). The device has the function of automatically paving a composite material prepreg tape, breaks through the block of a foreign technology, and meets the requirements on manufacturing of composite materials by aerospace and aviation industries.

Owner:WUHAN UNIV

Circulating cooling water low-temperature exhaust heat drying bed for large-scale power station

InactiveCN102564071AReduce the temperatureRealize zero heat pollutionDrying solid materials with heatHearth type furnacesSocial benefitsAutomatic control

The invention relates to a circulating cooling water low-temperature exhaust heat drying bed for a large-scale power station, belonging to the technical field of auxiliary machines mated with a boiler. The circulating cooling water low-temperature exhaust heat drying bed is characterized in that discarded hot circulating cooling water low-temperature exhaust heat of the power station is applied to a large-scale drying device by using an annular self-unloading device. The cost of drying materials is saved, and the requirement of recycling circulating water by reducing the temperature of the circulating water can be achieved through a drying process. A drying device manufacturing enterprise is free of a development mode of depending on the introduction of foreign technologies and mutual imitation among enterprises, the manufacture of the drying device is promoted to trend to energy saving, environment protection, automatic control and upsizing, and the competitiveness is enhanced for seizing international and domestic markets. Meanwhile, efficient utilization of circulating water exhaust heat of the power station is enabled to be more practical, standardized and scaled. The significance is achieved for reducing power generation cost and increasing economic benefit and social benefit.

Owner:张咸民 +1

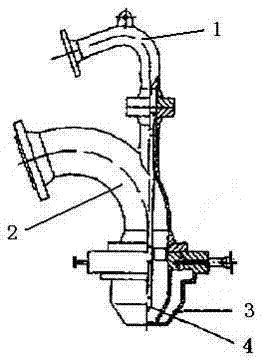

Heavy oil gasifier burner

The invention discloses a heavy oil gasifier burner, which comprises an oil bent pipe, a gas bent pipe and a spray nozzle, wherein the oil bent pipe is connected with the gas bent pipe, the spray nozzle is installed on the gas bent pipe and a spray gun is connected with the oil bent pipe and the gas bent pipe. The process technology performance and the quality of the heavy oil gasifier burner reach the level of foreign technologies; the heavy oil gasifier burner can absolutely substitute for imported burners; compared with the imported burners, the cost is saved; and a strong guarantee is provided for the continuity of production.

Owner:大连经济技术开发区水国燃烧器有限公司

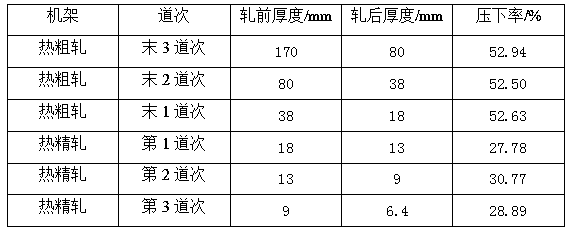

Cadmium plate special for a nuclear power plant and manufacturing technology thereof

InactiveCN101515481ALow costPromote healthy developmentNuclear energy generationRoll mill control devicesManufacturing technologyForeign technology

A cadmium plate special for a nuclear power plant and a manufacturing technology thereof are disclosed. The cadmium plate is characterized in that the size of the cadmium plate are 0.3mm-1.2mm of thickness * 500mm-1500mm of width * 1000mm-5000mm of length. The manufacturing technology thereof comprises the steps of: selecting GB zero cadmium ingot, selecting a crucible or a metal pan for melting the GB zero cadmium ingot, covering the molten liquid in the crucible or the metal pan with strong base, pouring a cadmium block at the temperature of 350-550 DEG C and lathing the cadmium block to remove oxide skins on the surface of the cadmium block, heating in a heat preservation furnace with the heating temperature of 100-320 DEG C, preserving the heat in the heat preservation furnace until the interior and exterior temperatures of the cadmium block are uniform, then performing the hot rolling and breaking to a cold-rolling blank, and afterwards, performing the cold-rolling formation gradually on a four-roller reversable rolling mill. The invention lowers the cost of the special cadmium plate and breaks the monopolization of foreign technologies, the safety and reliability completely meet the demand of nuclear power, and the invention maintains stable and reliable supply of the cadmium plate special for the nuclear power plant and promotes nuclear power industry to be soundly developed.

Owner:SHENYANG HANRUIDA TITANIUM

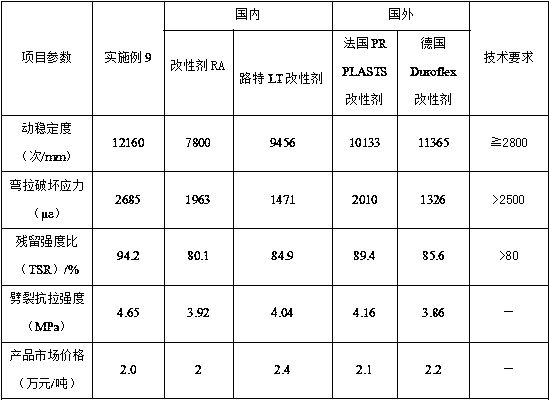

Bituminous mixture modifier and preparation method thereof

InactiveCN109320978AImprove low temperature crack resistanceImprove water damage resistanceBuilding insulationsForeign technologyRoad surface

The invention discloses a bituminous mixture modifier and a preparation method thereof. The bituminous mixture modifier is prepared from waste polyethylene, waste polypropylene, a toughening agent, aninitiator, a modifier, an anti-ageing agent, filler and pigment. According to the bituminous mixture modifier and the preparation method thereof, by adopting modification technologies of blending, grafting, toughening and the like, the industrial, agricultural and domestic recovered waste PE and PP, the other modifier, the filler and the like are mixed evenly according to a certain ratio to prepare black solid particles, according to 0.3-0.5% of total mass of a bituminous mixture, the black solid particles, pitch and mineral aggregate are stirred and mixed evenly at a mixing station under technology conditions of certain temperature, mixing time and the like, thus paving can be conducted, the rut resistance capability of a bituminous pavement can be greatly improved, and meanwhile, both the moisture damage resistance performance and the low temperature resistance performance are obviously improved. By adopting the modification technologies, not only is the cost reduced, but also the high temperature stability of the bituminous mixture can be greatly improved, the foreign technology monopoly is broken, and the bituminous mixture modifier and the preparation method thereof have profound significance in the aspects of positively responding to national waste material resource recycling and the like.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com