High-speed train connecting sleeper beam

A technology for high-speed EMUs and corbels, applied in railway car body parts, bogies, transportation and packaging, etc., can solve problems such as increasing production costs, stress damage to corbels, shortening service life, etc., and achieves air tightness. Good, light weight, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

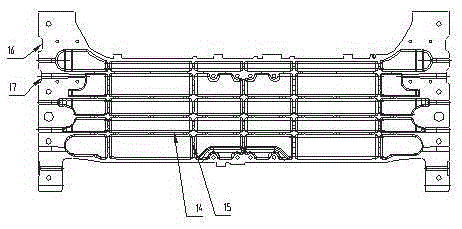

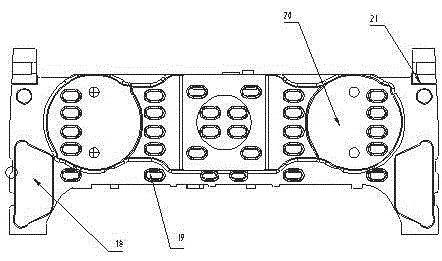

[0013] refer to figure 1 , The contact bolster is a thin-walled multi-cavity casting with a complex structure, many parts with different wall thicknesses and large length dimensions. The entire box bears the load of the vehicle body, and the inner cavity is an additional air chamber for the air spring. The reinforcing ribs on the upper plane of the contact corbel and the cast transverse ribs and cast longitudinal ribs in the inner cavity jointly realize the strength guarantee of the main body of the contact corbel, and the reinforcing ribs in the middle are longer than the reinforcing ribs on both sides. The cavity can store gas, and all the cavities communicate with each other. At the same time, the side beams provide interfaces for secondary suspension components such as anti-snake shock absorbers and anti-roll torsion bars. The force of the anti-serpentine shock absorber and the force of the secondary vertical shock absorber. The side beams are respectively equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com