Method and system for processing leachate of garbage burning factory

A waste incineration and treatment method technology, applied in the direction of combustion method, aerobic process treatment, sustainable biological treatment, etc., can solve the problems of high operating cost, large power consumption, high engineering cost and high operating cost, and achieve steam consumption Less, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

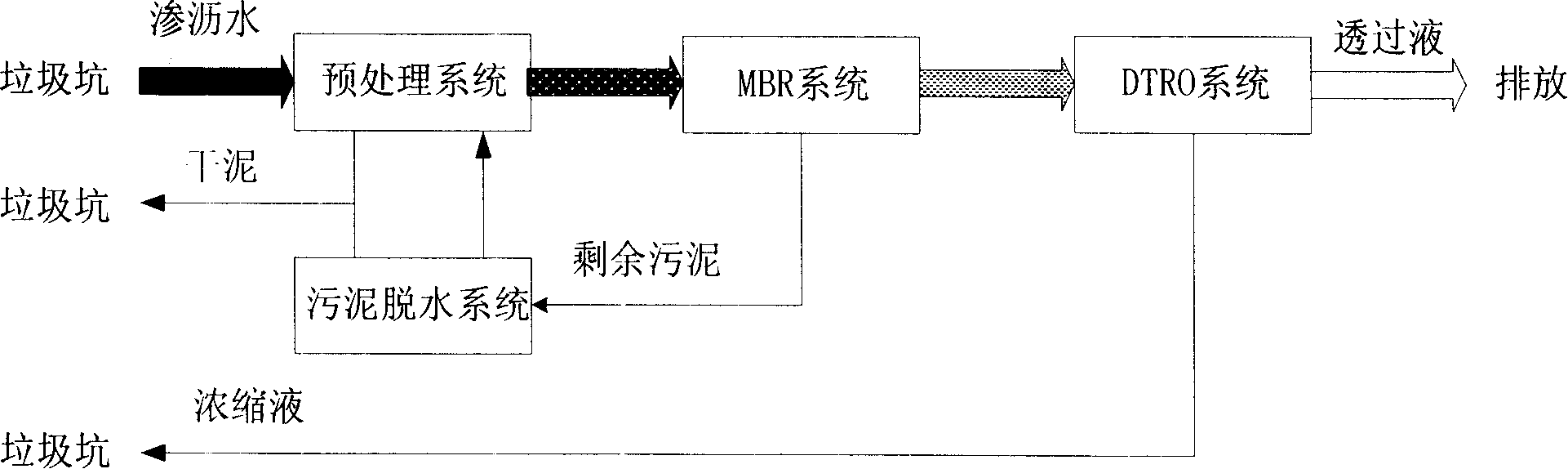

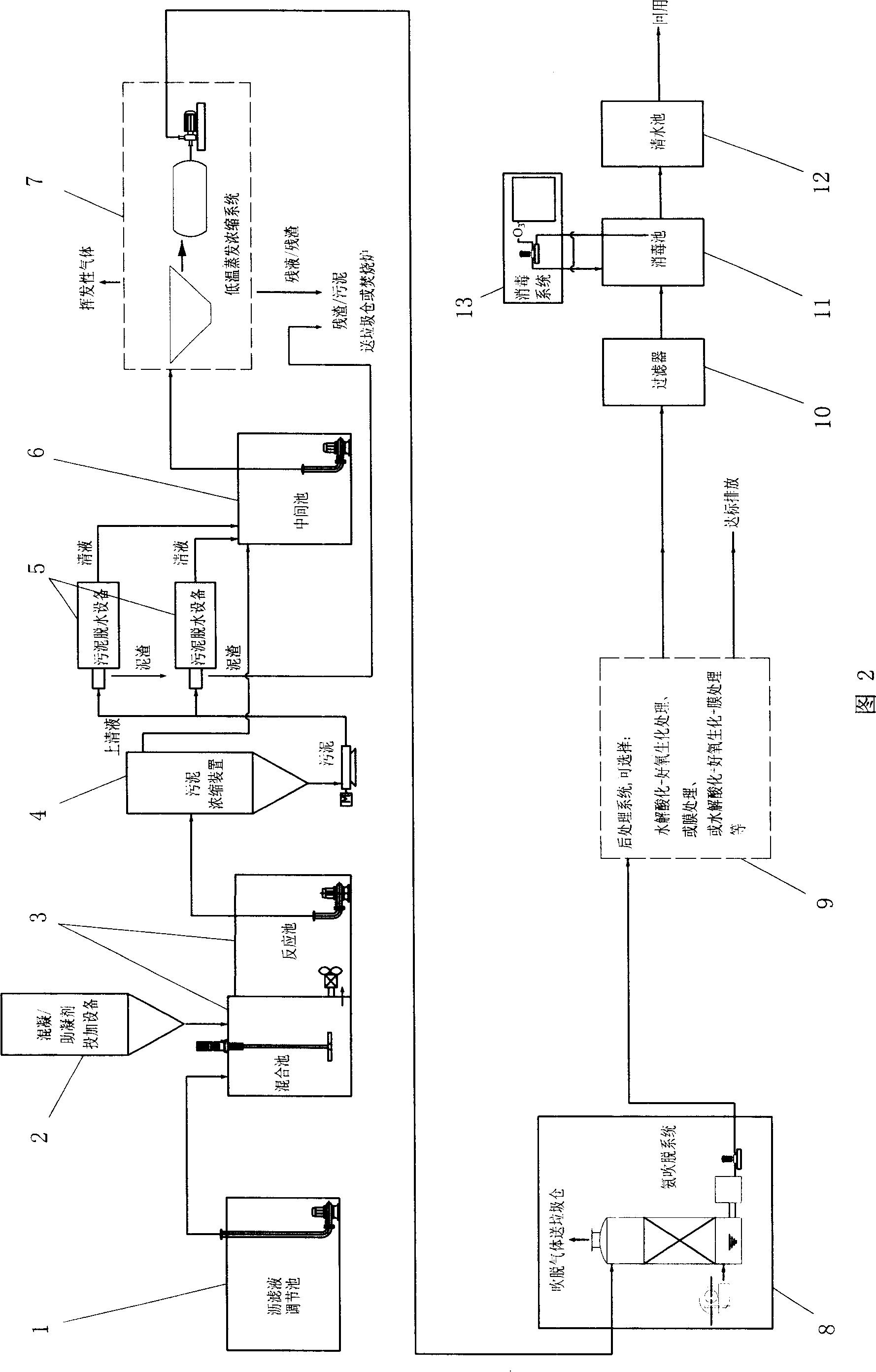

[0058] As shown in Figure 2, the leachate treatment method of the garbage incineration plant of the present invention includes a pretreatment process, an evaporation concentration treatment process, an ammonia stripping treatment process and a post-treatment process, and each process is described in detail below;

[0059] The pretreatment process is a common coagulation and sedimentation treatment in the sewage treatment process, that is, adding a coagulant to the garbage leachate (available coagulants include caustic soda (NaOH), quicklime (CaO), slaked lime (Ca(OH) 2 )Wait. In order to speed up the precipitation, a coagulation aid can also be added), and the leachate is fully stirred, so that the coagulant / coagulant aid reacts with the pollutants in the leachate, and the suspended matter in the leachate is precipitated to form sludge. The sludge is dehydrated and removed, and the precipitated supernatant and detached water are sent to the next step for processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com