Continuous casting coordinated optimization control method

A technology of coordinated optimization and control methods, applied in the field of advanced industrial manufacturing control, can solve the problems of technical complexity, difficulty, frequent quality incidents, etc., and achieve the effect of clear logic structure, reduced energy and water consumption, and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

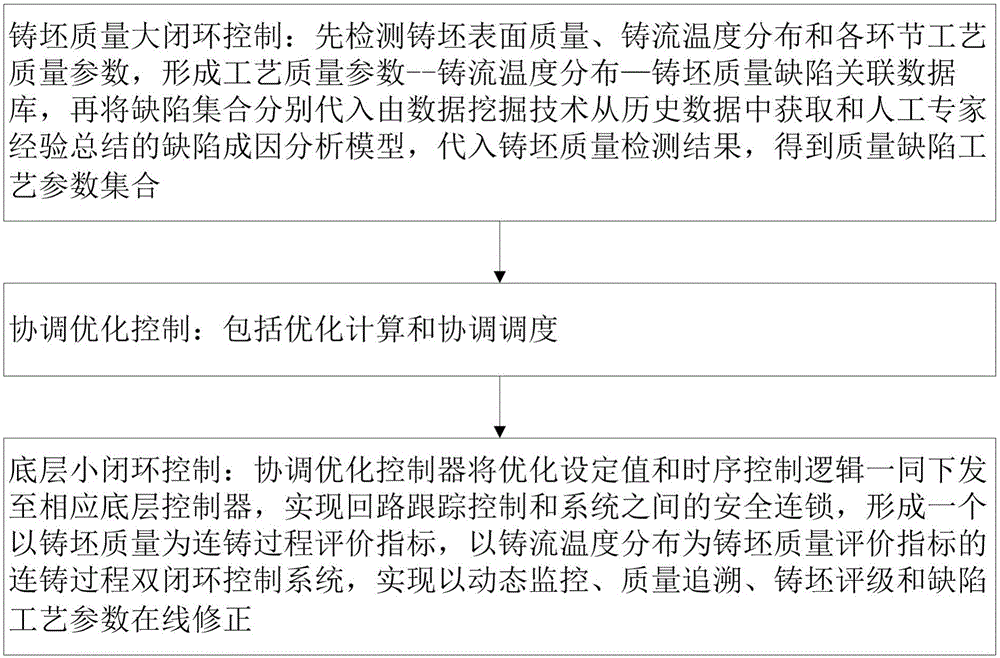

[0022] see figure 1 , the present invention provides a continuous casting coordinated optimization control method, comprising the following steps:

[0023] S1. Large closed-loop control of slab quality: first detect the surface quality of slab, temperature distribution of casting strand and process quality parameters of each link, form process quality parameters-strand temperature distribution-slab quality defect correlation database, and then collect defects Substituting the defect cause analysis model obtained from historical data by data mining technology and summarizing the experience of artificial experts, respectively, substituting the results of slab quality inspection to obtain a set of process parameters for quality defects;

[0024] S2. Coordinated optimization control: including optimized calculation and coordinated scheduling;

[0025] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com