Demolding mechanism and injection mold for cup handle

A demoulding mechanism and injection mold technology, which is applied in the field of injection mold mechanism design, can solve the problems of difficulty in ensuring full filling, mold design mechanism design, and processing and manufacturing, so as to achieve compact structure and ensure molding Reasonable effect of quality and structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

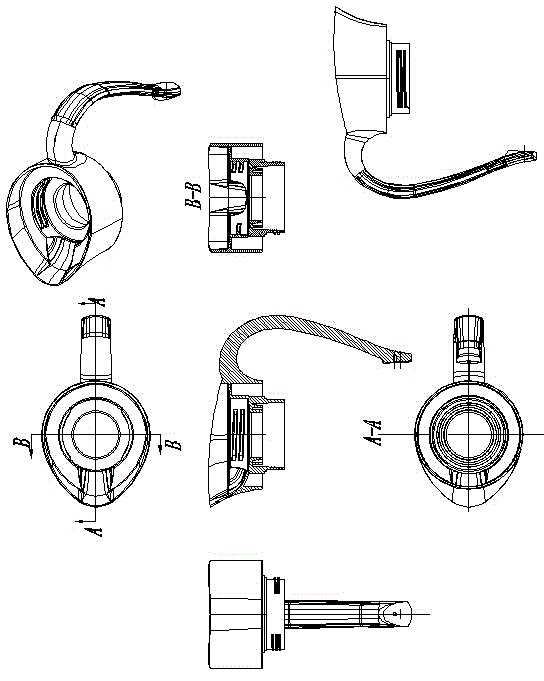

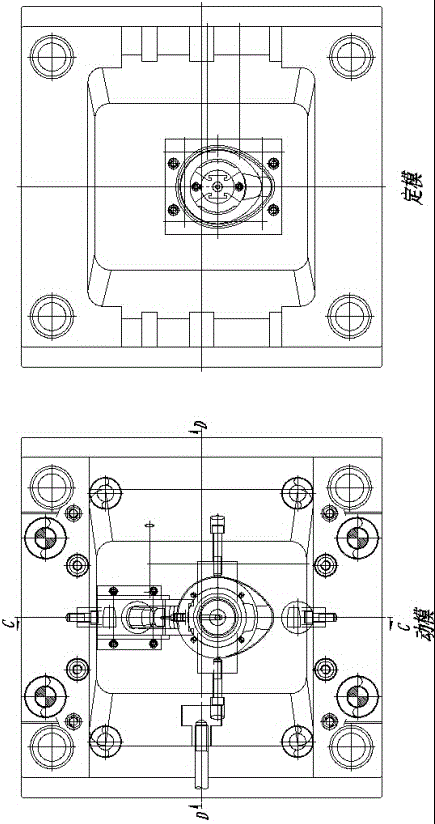

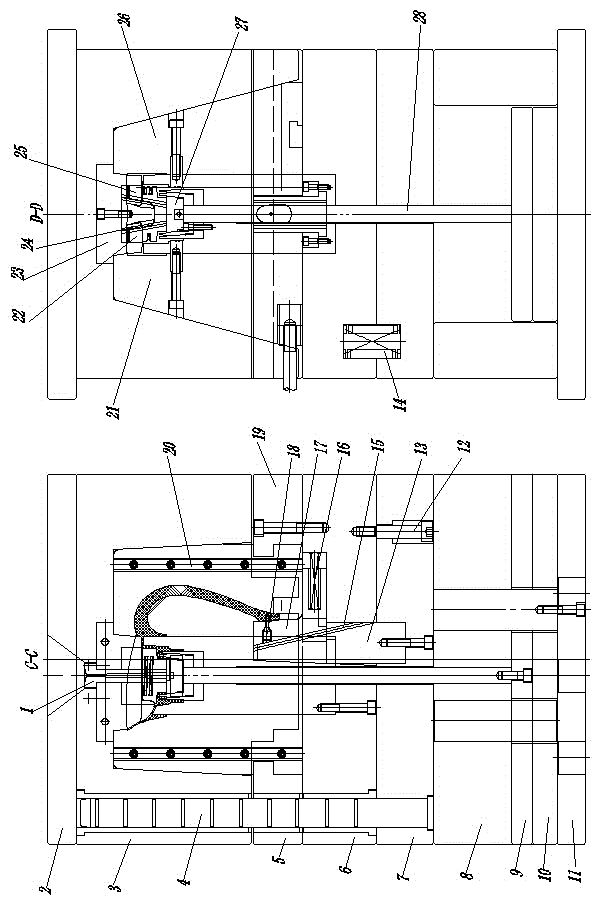

[0016] Figure 1-4 Shown is the relevant explanatory diagram of the present invention; A cup handle demoulding mechanism and its injection mold include a positioning ring 1, a panel 2, a fixed mold fixing plate 3, a guide post 4, a slider plate 5, a core fixing plate 6, Moving mold backing plate 7, spacer block 8, thimble cover plate 9, thimble push plate 10, lower mold seat plate 11, backing plate pull rod 12, inner pumping pressure block 13, backing plate separation spring 14, inner pumping T-shaped groove 15, Inner slider spring 16, inner slider 17, inner needle 18, Haval slider bezel 19, Haval slider guide strip 20, left Haval slider 21, left upper inner slider 22, upper inner core pressure Block 23, upper inner pumping block T-shaped groove 24, upper right inner pumping slider 25, right Harvard slider 26, central top block 27, central ejector rod 28, such as figure 2 , image 3 shown.

[0017] The mold frame structure assembly includes a positioning ring 1, a panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com