Zero-defect test method for numerically-controlled machine tool processing

A defect inspection and CNC machine tool technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of not being able to effectively reduce the scrap rate, reduce production costs, solve high scrap rates, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below.

[0036] The invention advances the detection of parts processing to the detection of the panel of the numerical control machine tool before processing, improves the processing precision and greatly improves the yield of finished products.

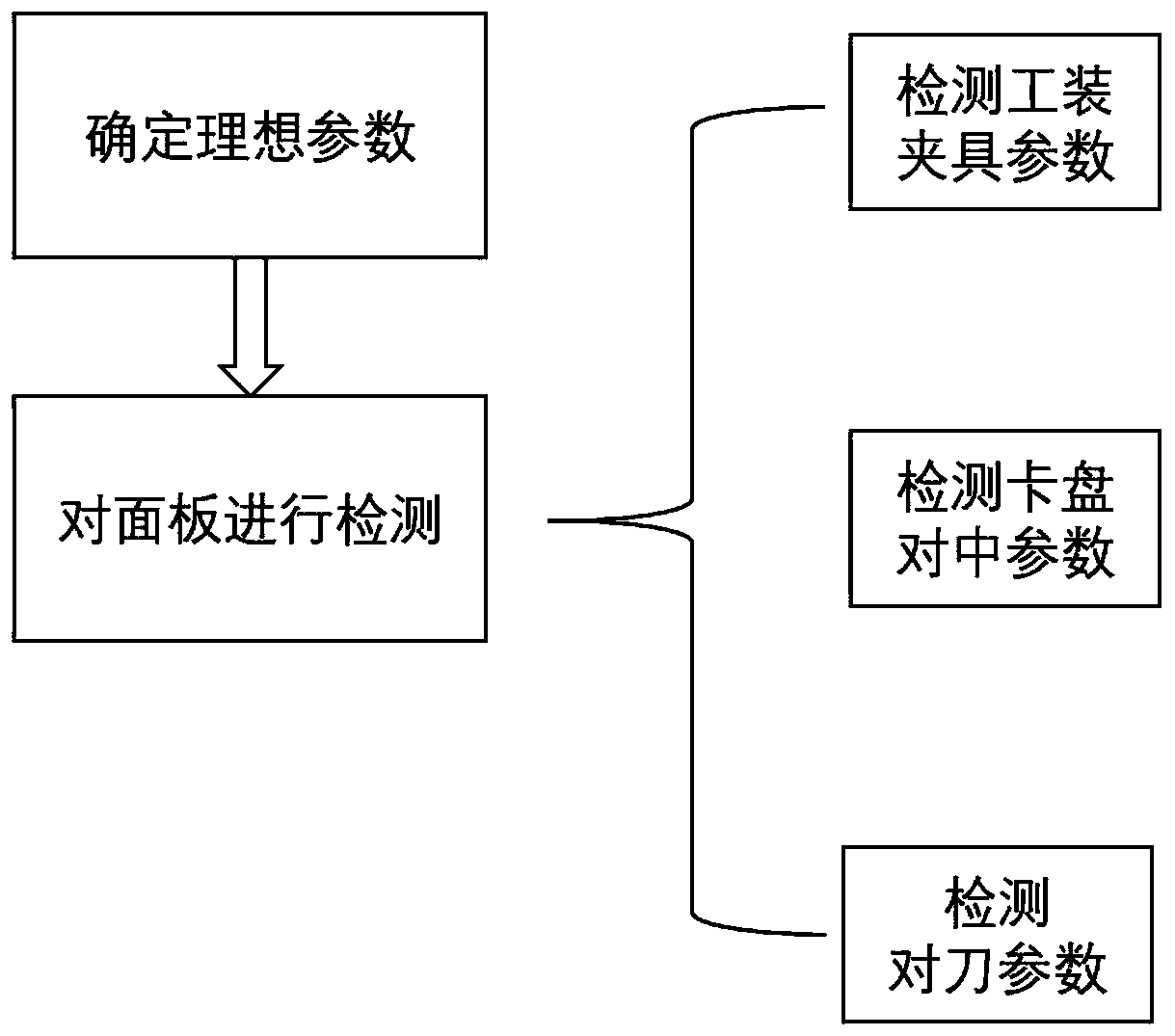

[0037] The inventive method specifically comprises the following steps

[0038] Step 1. Determine the ideal parameters of the machine tool panel through trial production of samples and traditional testing of the samples;

[0039] The ideal parameters include: fixture parameters, chuck centering parameters, and tool setting parameters.

[0040] Step 2. After determining the ideal parameters, record the parameters, and inspect the panel before each part is processed to ensure that the panel parameters meet the ideal parameters required by the corresponding part.

[0041] The present invention specifically includes two specific embodiments of a turning-milling integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com