Arc extinguishing system and contactor

An arc extinguishing and arc extinguishing chip technology, applied in relays, electromagnetic relays, electromagnetic relay detailed information and other directions, can solve the problems of low installation efficiency and high scrap rate, to improve installation efficiency, reduce scrap rate, and prevent arcs from escaping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

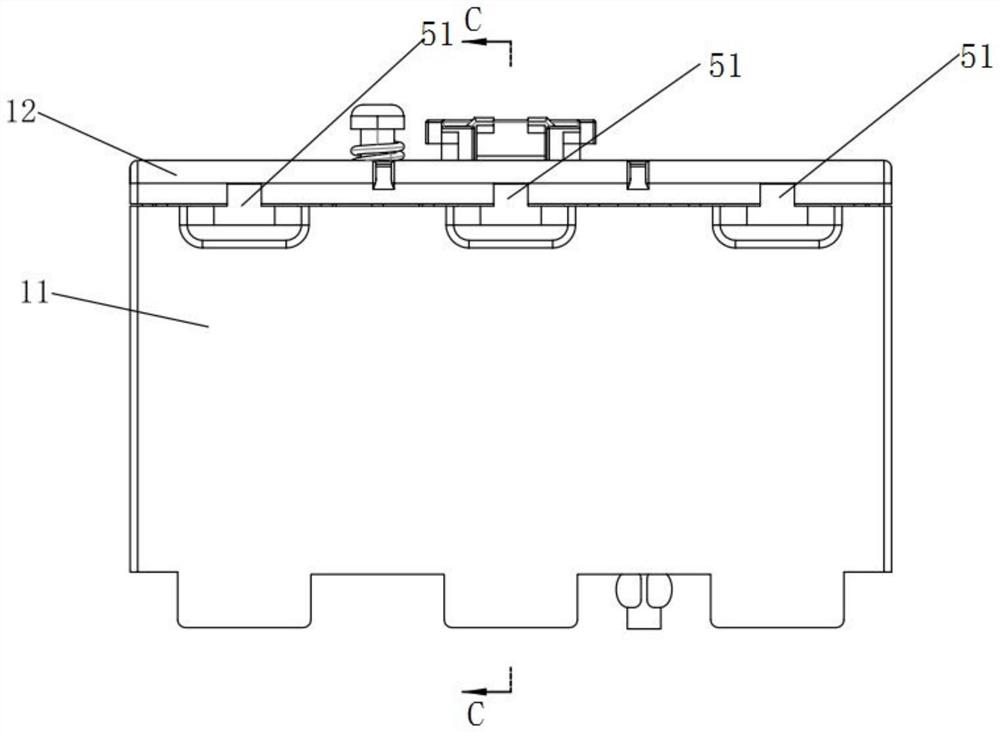

[0061] For the arc extinguishing system of this embodiment, see Figure 1 to Figure 13 As shown, it includes an arc extinguishing cover assembly 1 and an arc extinguishing blade assembly 2 . The arc extinguishing cover assembly 1 is provided with at least one arc extinguishing chamber 10 , and the arc extinguishing chamber 10 is provided with at least two mounting parts 13 arranged at intervals. The arc extinguishing plate assembly 2 includes at least one first arc extinguishing plate 21 and one second arc extinguishing plate 22, the first arc extinguishing plate 21 and the second arc extinguishing plate 22 are adapted to be respectively installed in the installation part 13, the first arc extinguishing plate The sheet 21 is arranged close to the movable contact 8 , and the second arc extinguishing sheet 22 is arranged away from the movable contact 8 . The space between two adjacent first arc extinguishing plates 21 and between the second arc extinguishing plate 22 and its ad...

Embodiment 2

[0068] The contactor of this embodiment, such as Figure 9 to Figure 13 As shown, it includes base assembly 7, base assembly 6 and the arc extinguishing system in Embodiment 1. Specifically, such as Figure 9 and Figure 11 As shown, the base assembly 7, the base assembly 6 and the arc extinguishing system are arranged in sequence from bottom to top. like Figure 10 As shown, the base assembly 6 includes a base, a contact assembly (not shown) and a contact support 61 disposed in the base. The base assembly 7 includes a base, a coil frame (not shown) and an iron core 71 disposed between the base and the coil frame, and the iron core 71 includes a yoke and a coil. The specific structure of the contact assembly is not described and limited in detail here, but it is a conventional contact structure in a contactor. Since the above-mentioned arc-extinguishing system is adopted, at least the advantages of the arc-extinguishing system of the above-mentioned embodiment 1 are obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com