Method for detecting atypical electronic components

A technology of electronic devices and detection methods, applied in the direction of electrical testing/monitoring, instruments, measuring electricity, etc., can solve the problems that are not enough to achieve zero defects, cannot guarantee the removal of devices, obstacles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

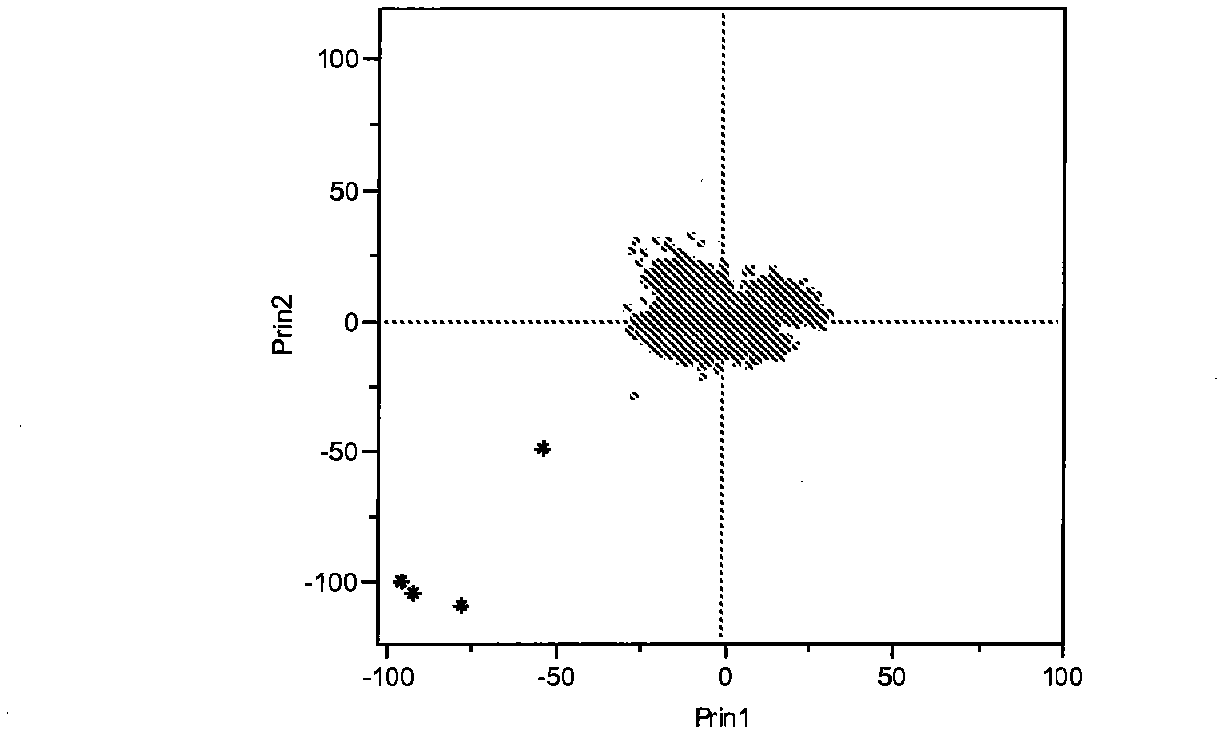

Examples

Embodiment Construction

[0057] The invention is implemented by computer software executing on a microcomputer or other standard type of computer.

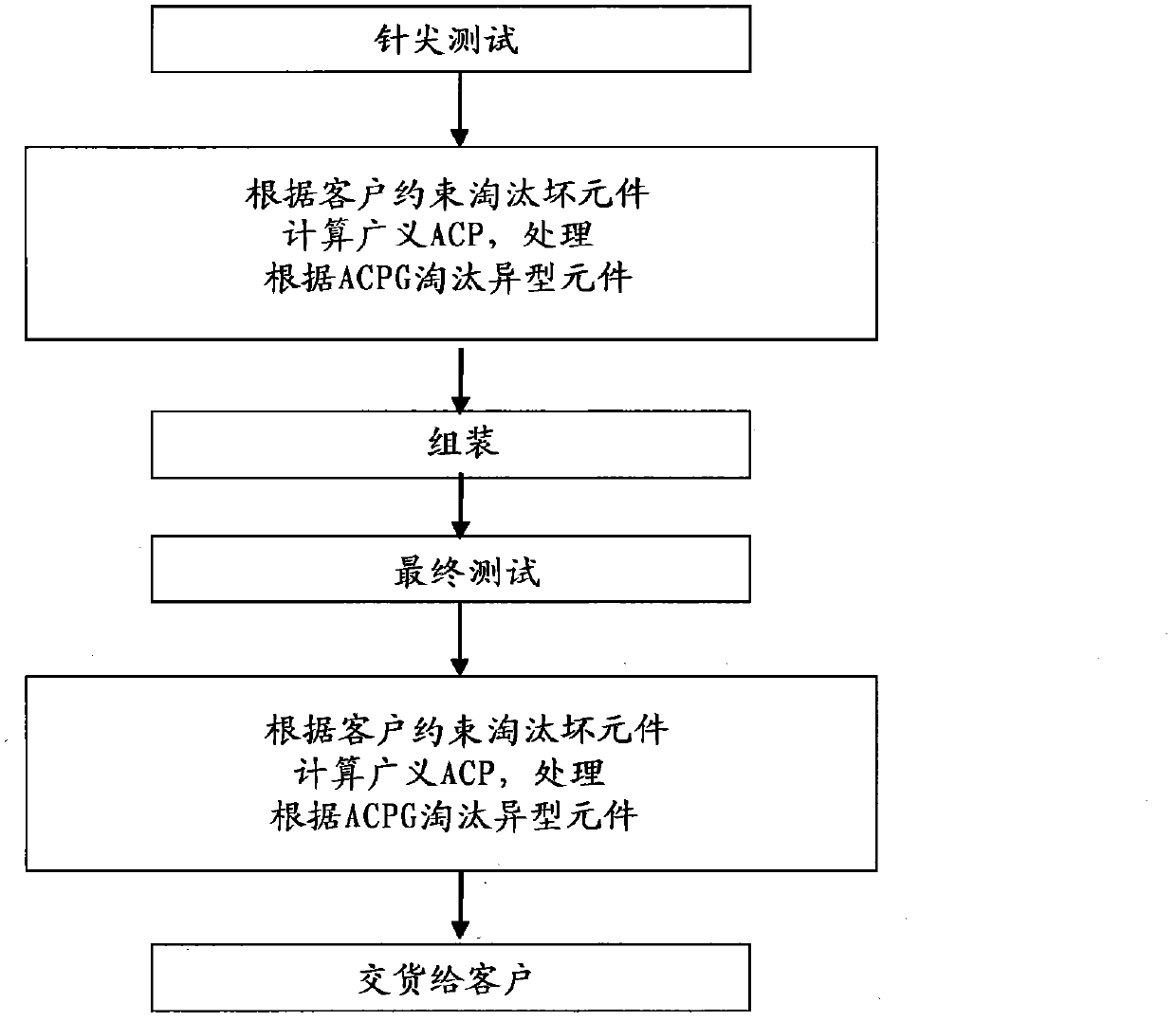

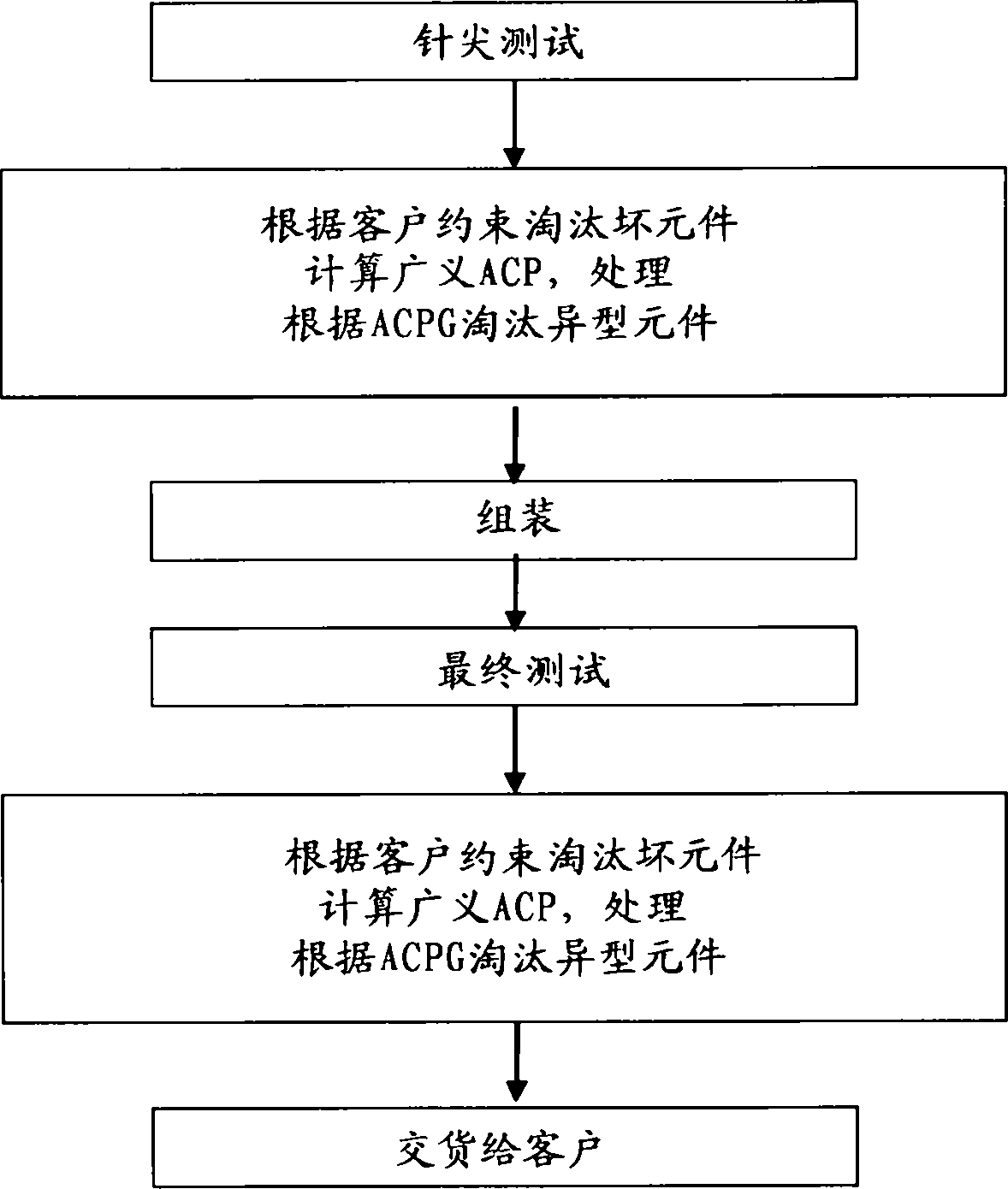

[0058] The present invention is intended to be used in the quality control of electronic device manufacture, and the specific opportunity of using the present invention is:

[0059] 1 / At the end of a needle-point (probe) test consisting of a plurality of electronic measurements and referred to as the first group of tests, i.e. at least one response to at least one test belonging to this first group of tests in the After the electronics outside the scope of the specification constraints have been discarded

[0060] 2 / Subsequently, at the end of the tests (second set of tests) performed after assembling the correct electronic device, ie the electronic device that has passed the pinpoint test and the test according to the method of the invention inside the enclosure.

[0061] The method according to the invention can be used in different ways after the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com