Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201results about How to "Simplify the welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

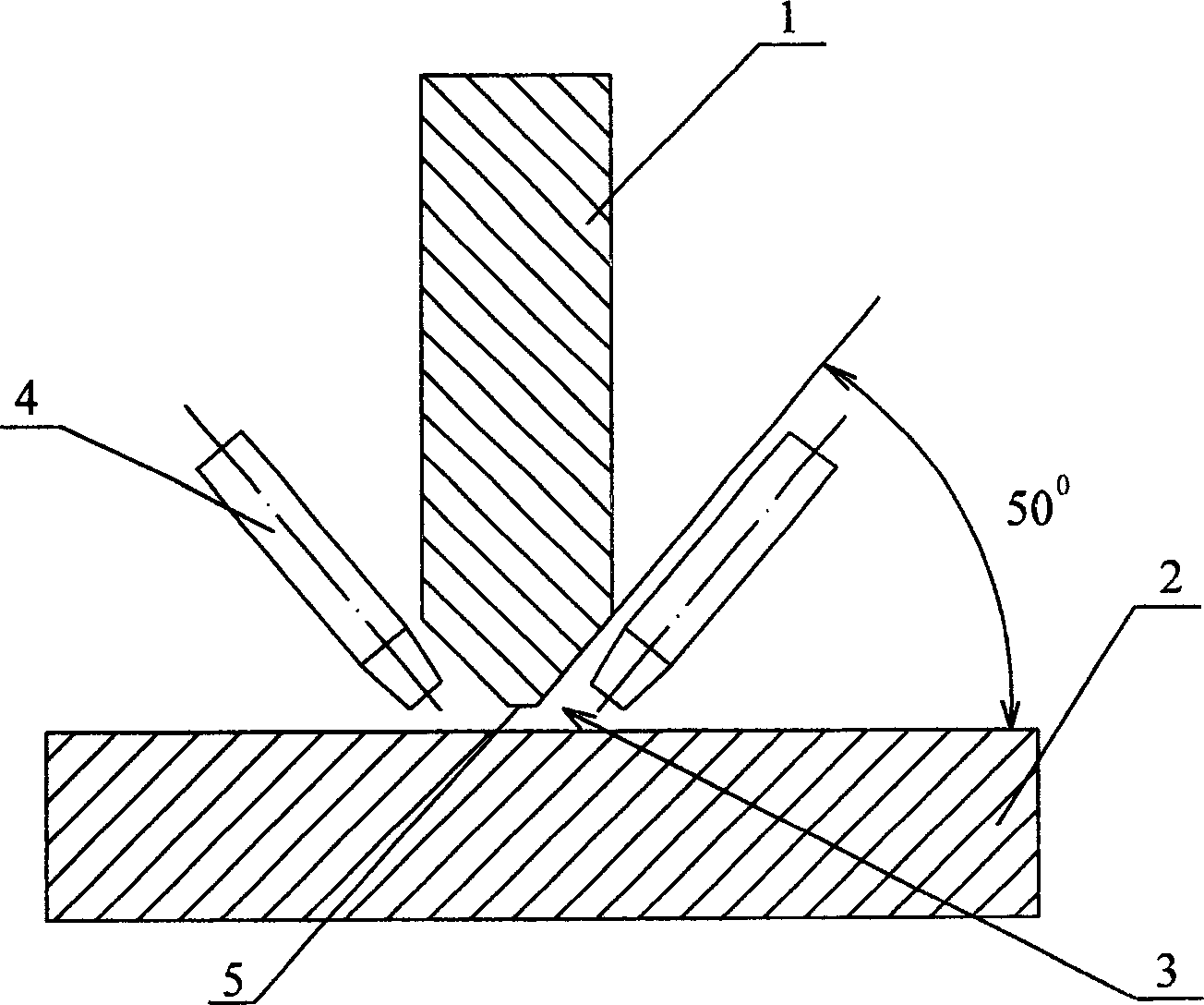

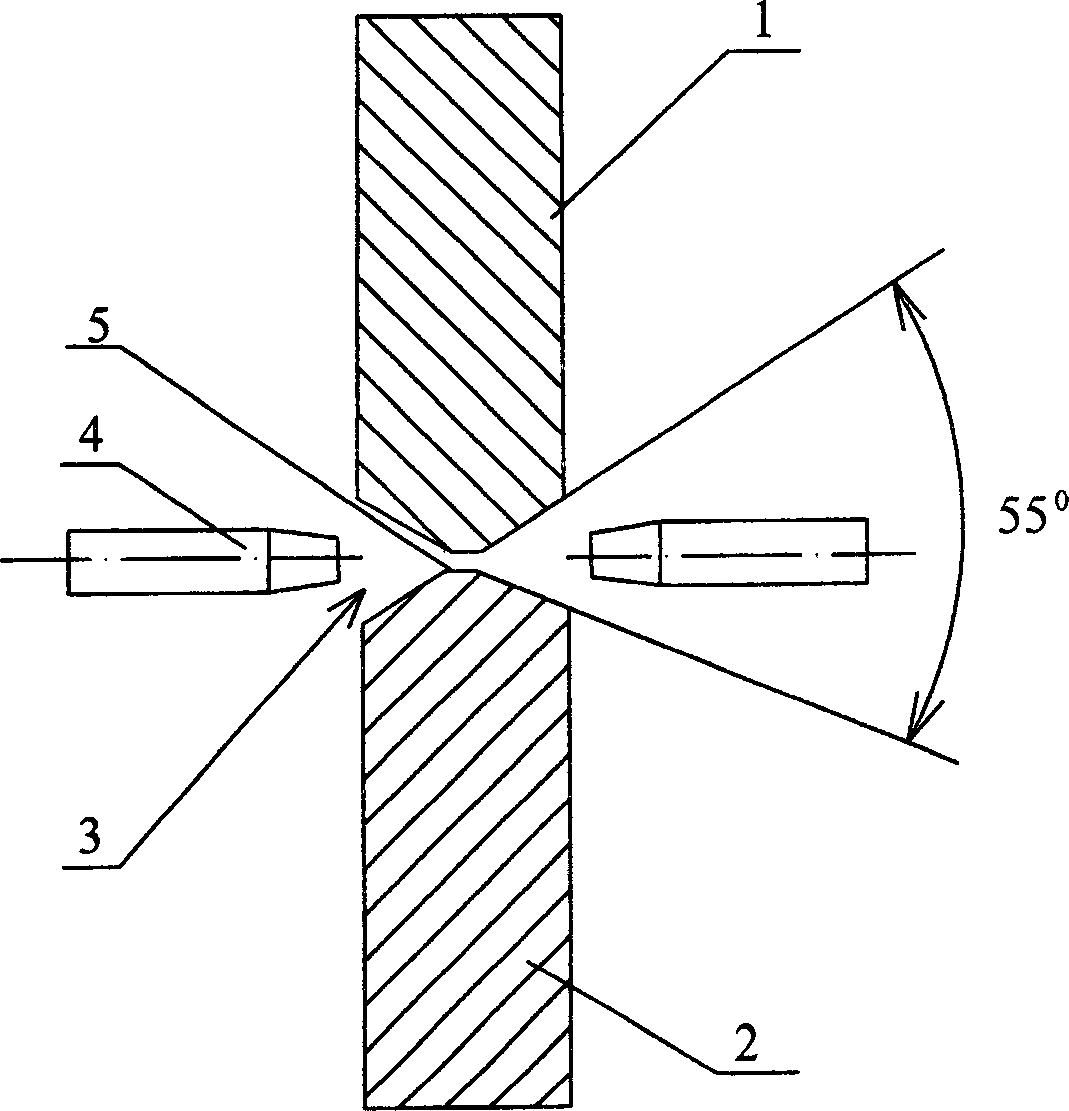

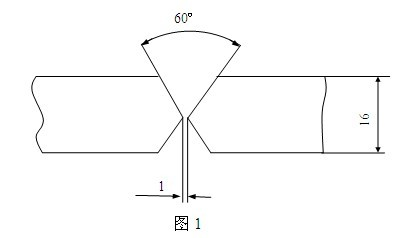

Double sides double arc welding method

ActiveCN1603045AReduce stressGuarantee welding qualityArc welding apparatusWorkpiece edge portionsJoint stressWelding deformation

The invention relates to a double side dual-arc welding method. It includes the following steps that the work-piece connection part waited for welding is made both sides welding groove; the both sides welding groove and its both sides surface is ground and cleaned out before the welding; the two independent electric arcs elicited by two welding guns of the two welding machines are conducted both sides dual-arc symmetry bottoming welding respectively at the both sides welding groove; after the bottoming welding, the two independent electric arcs are conducted both sides dual-arc filling welding respectively at the both sides welding groove. The invention avoids the carbon arc-air gouging back gouging process, simplifies the welding process, so that the automation welding can be realized. It avails to practice gas shielded welding, ensure the welding quality, reduce the welding deformation, and decrease joint stress. The method can apply to important metal structural parts welding.

Owner:渤海造船厂集团有限公司

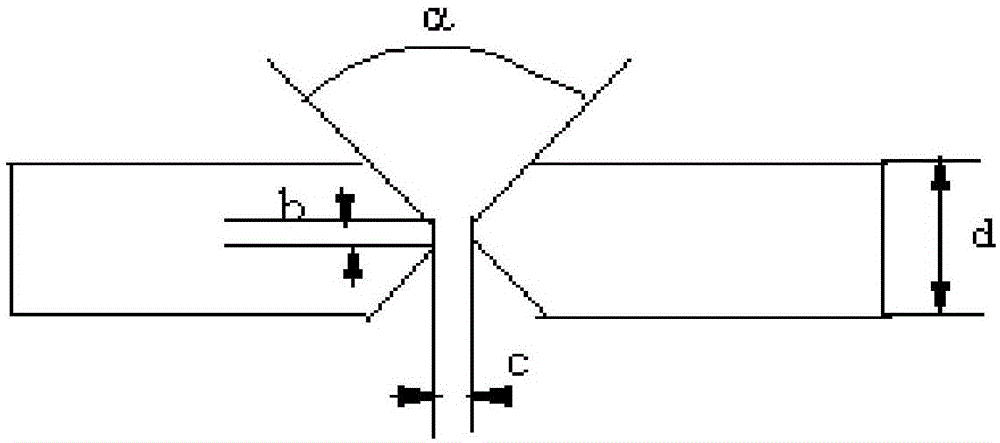

Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

InactiveCN105149786ASimplify the welding processPrecise control of single layer fill heightWelding/soldering/cutting articlesMetal working apparatusLaser processingThick plate

The invention belongs to the technical field of laser processing, and particularly relates to a narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials. The method aims at solving the problems that in the thick plate welding process, wire filling is difficult, and molten drop transition is not stable. According to the narrow-gap laser-scanning multi-layer self-melting welding method based on a prefabricated filling layer, a laser scanning welding technology and narrow-gap multi-layer filled welding are skillfully combined, therefore, a laser wire filling multi-layer welding mode for thick plate structure parts is converted into a laser self-melting multi-layer welding mode, and the single-layer filling height of a weld joint in a narrow-gap groove can be precisely controlled; due to the fact that the prefabricated filling layer can prevent the weld joint from shrinking, welding deformation can be further reduced, the thick plate welding process is greatly simplified, and the welding efficiency and the welding quality are improved. The method is suitable for narrow-gap laser welding of thin plates or thick plates of different thicknesses.

Owner:HARBIN INST OF TECH

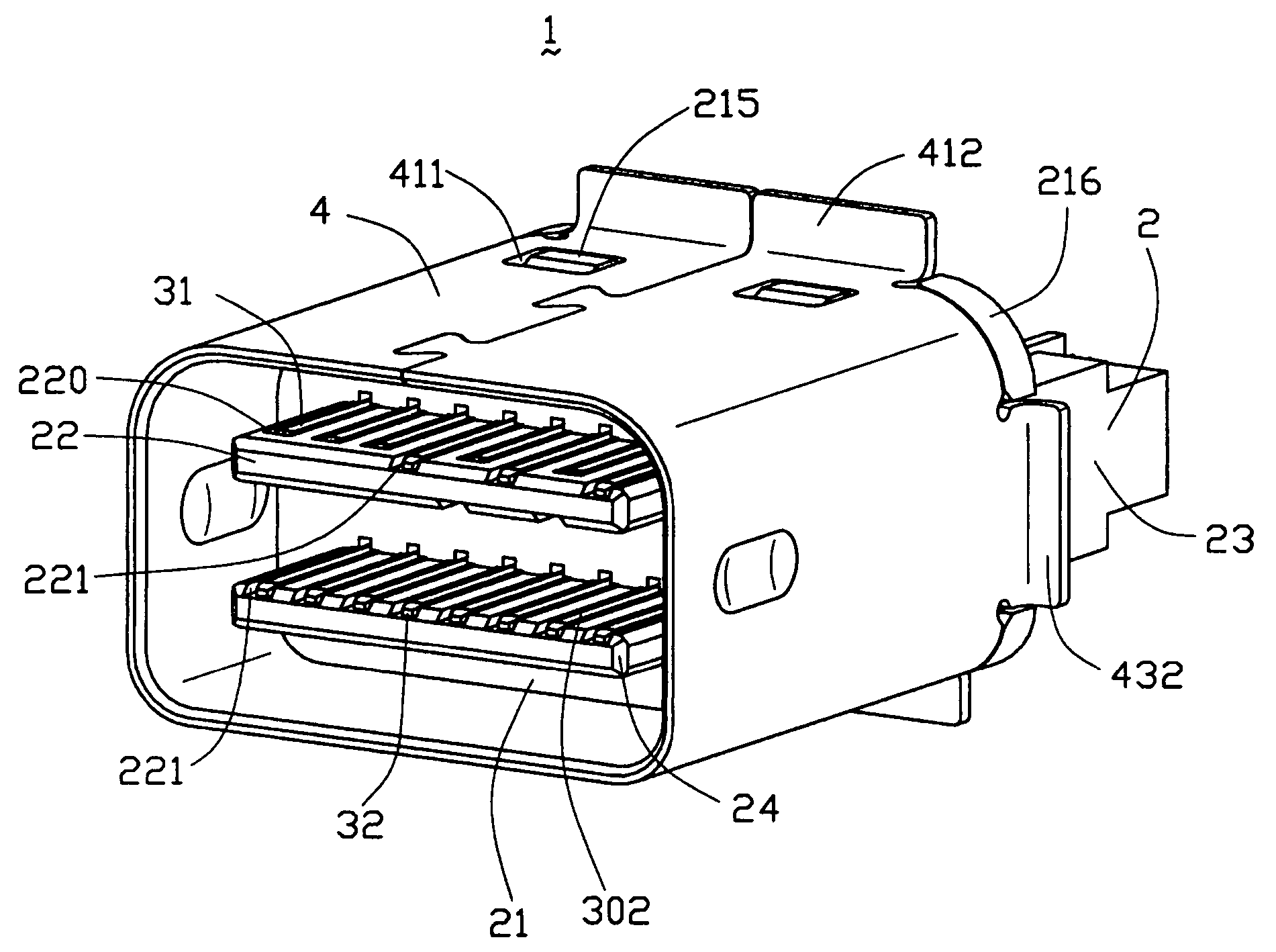

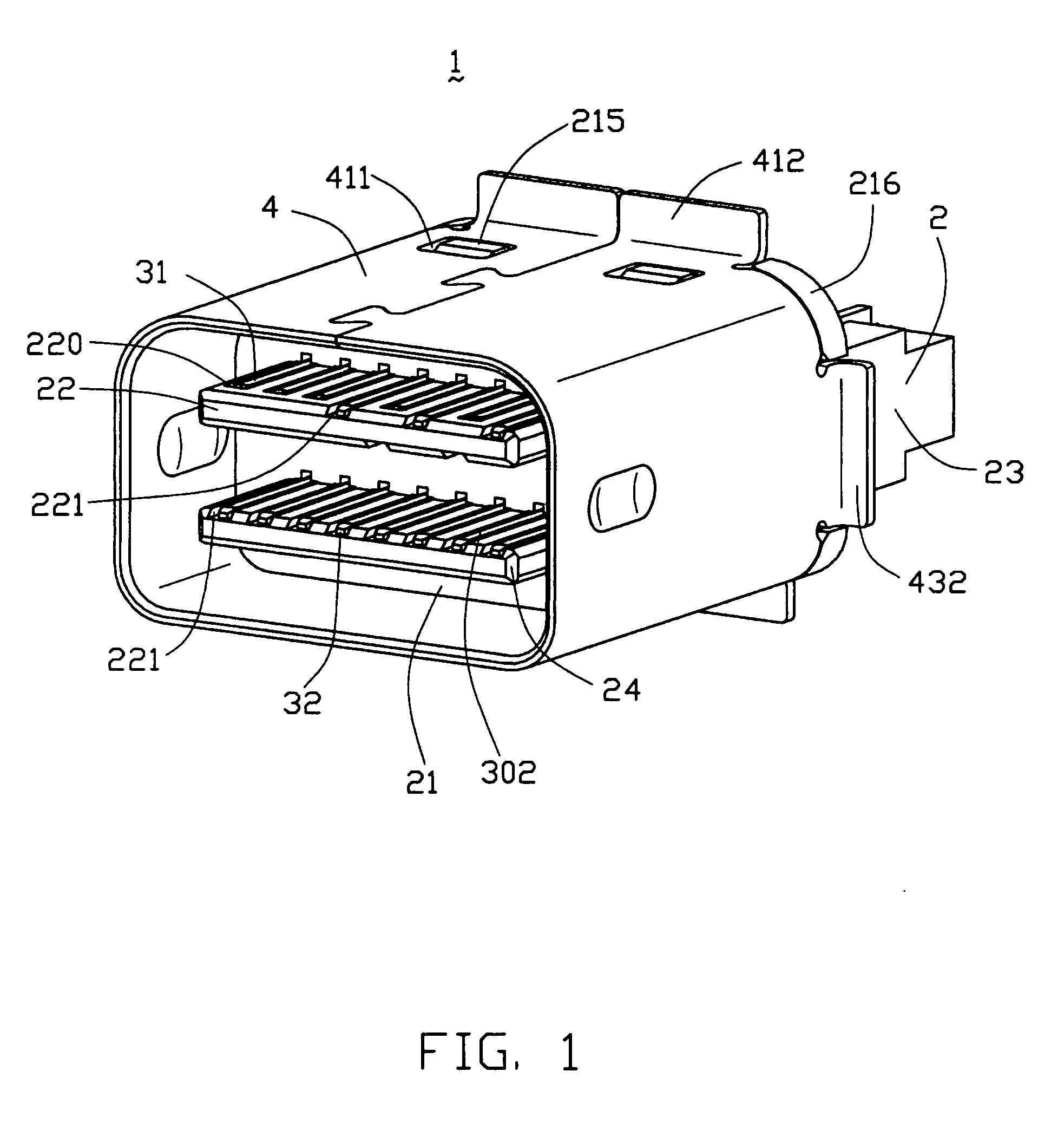

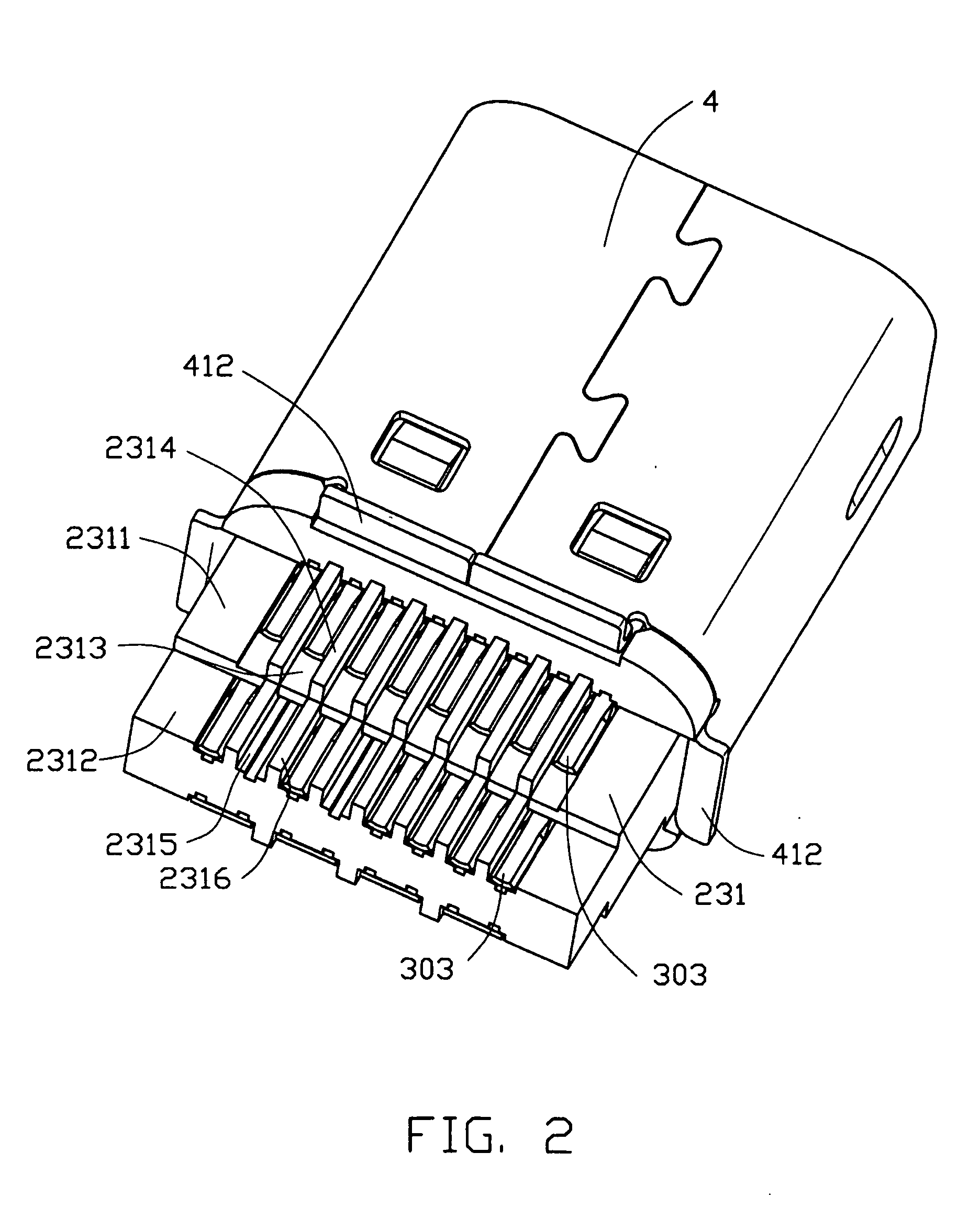

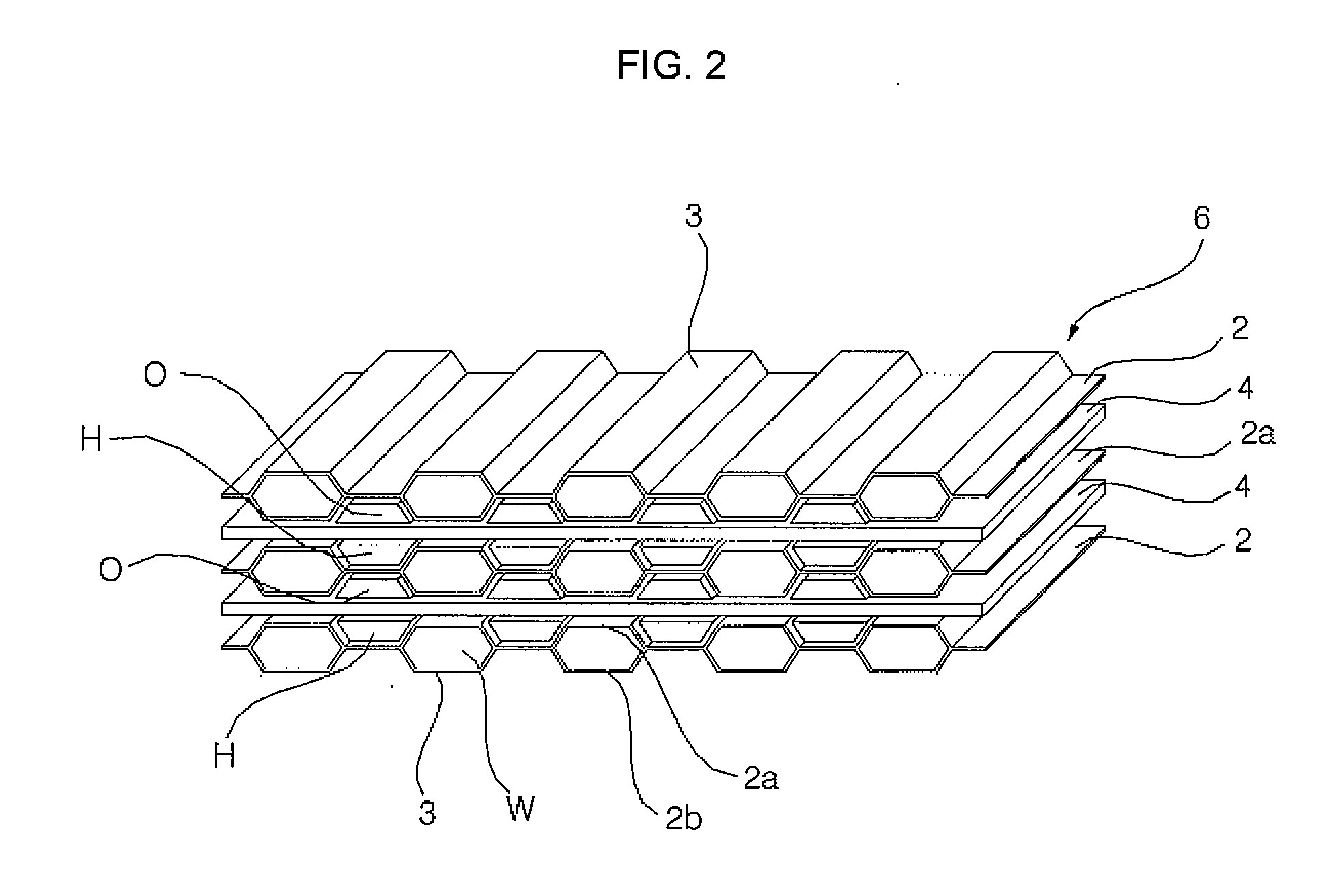

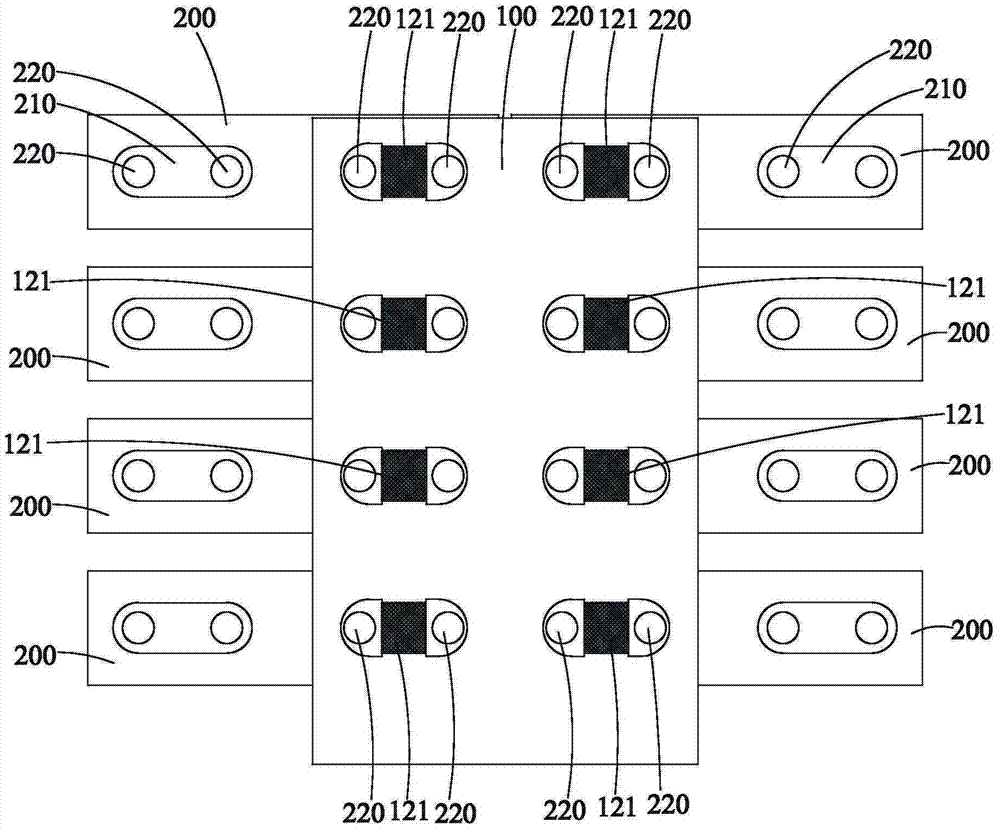

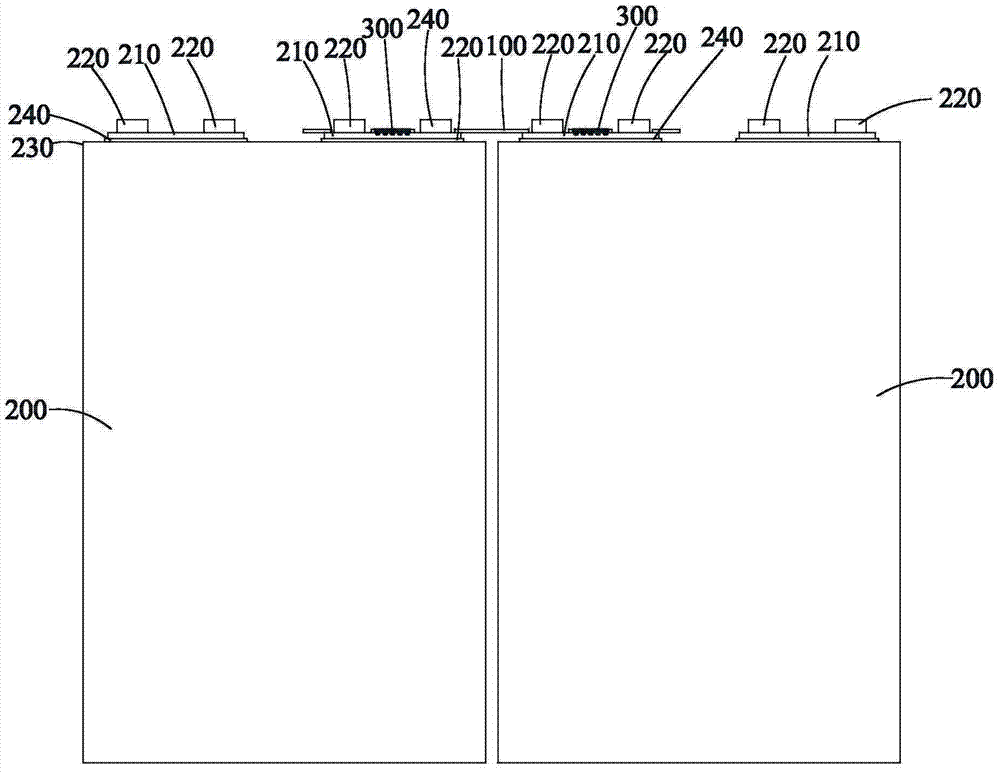

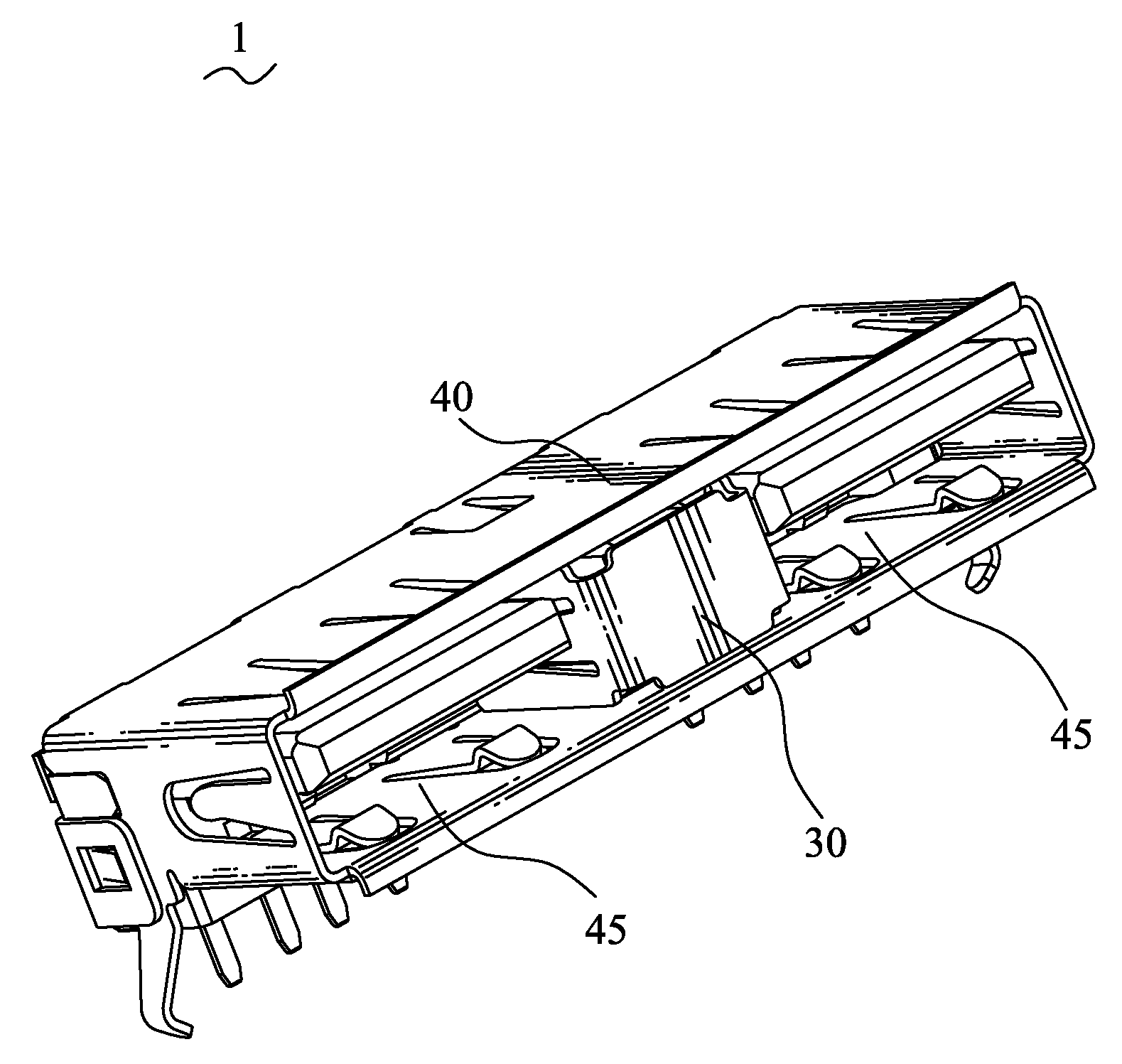

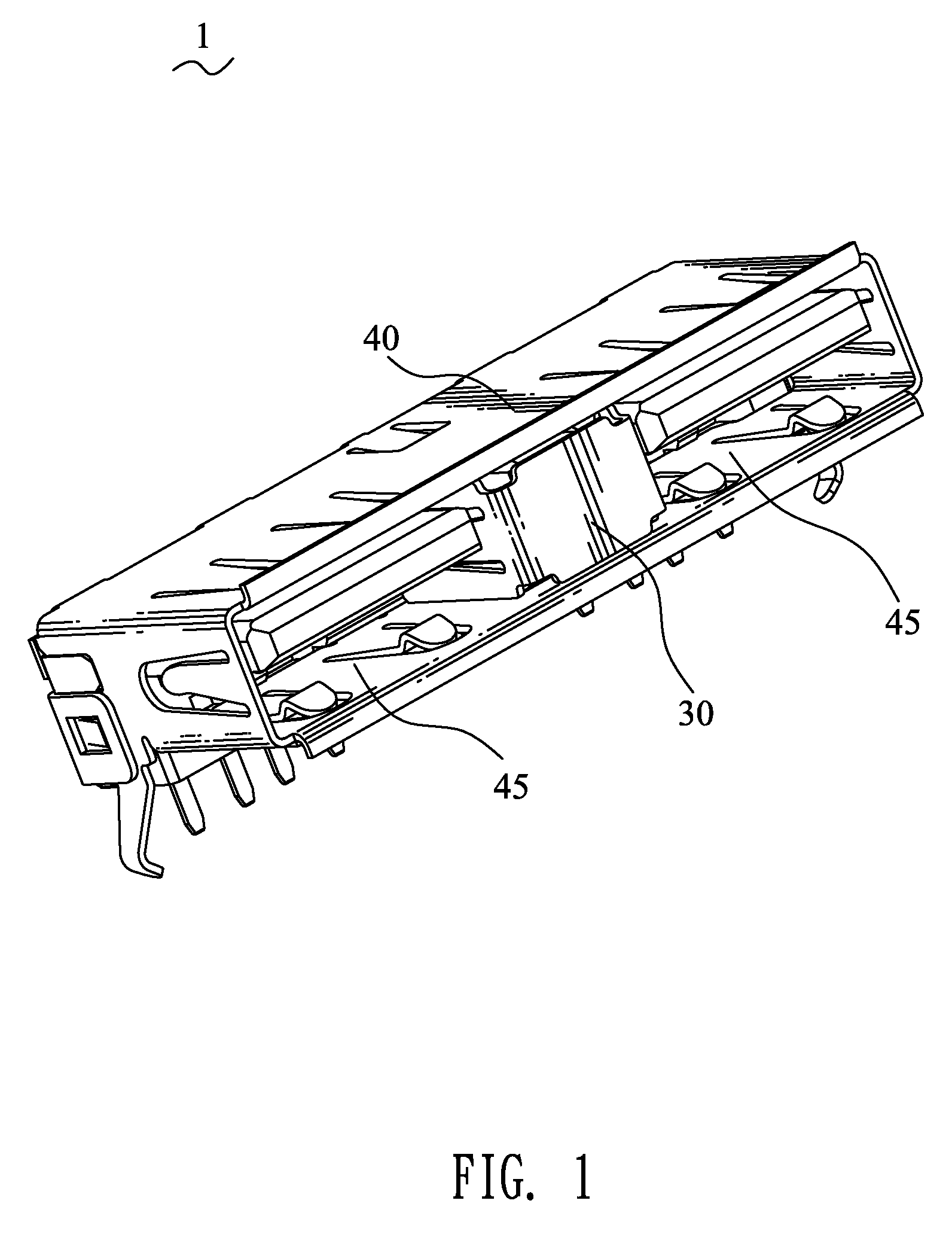

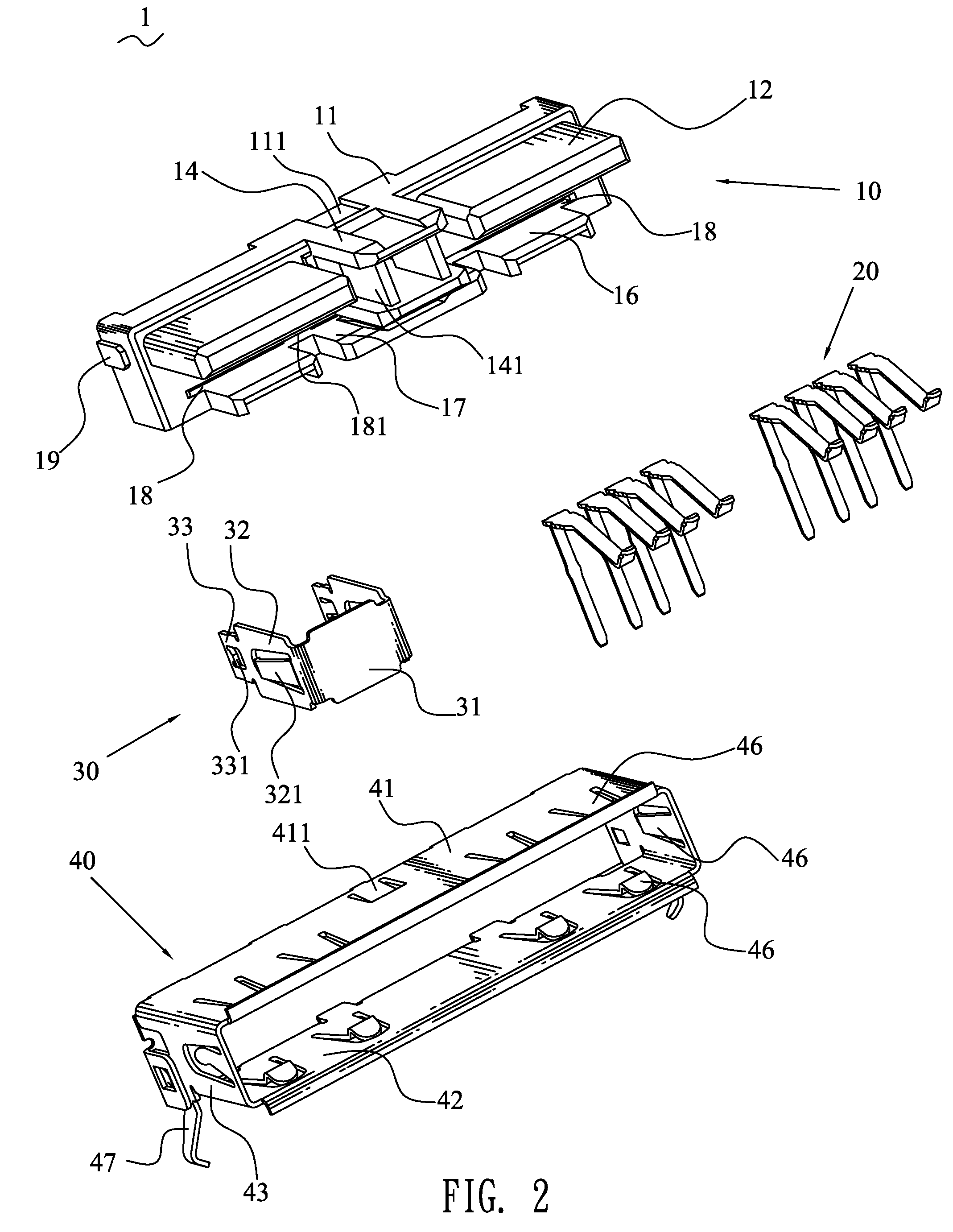

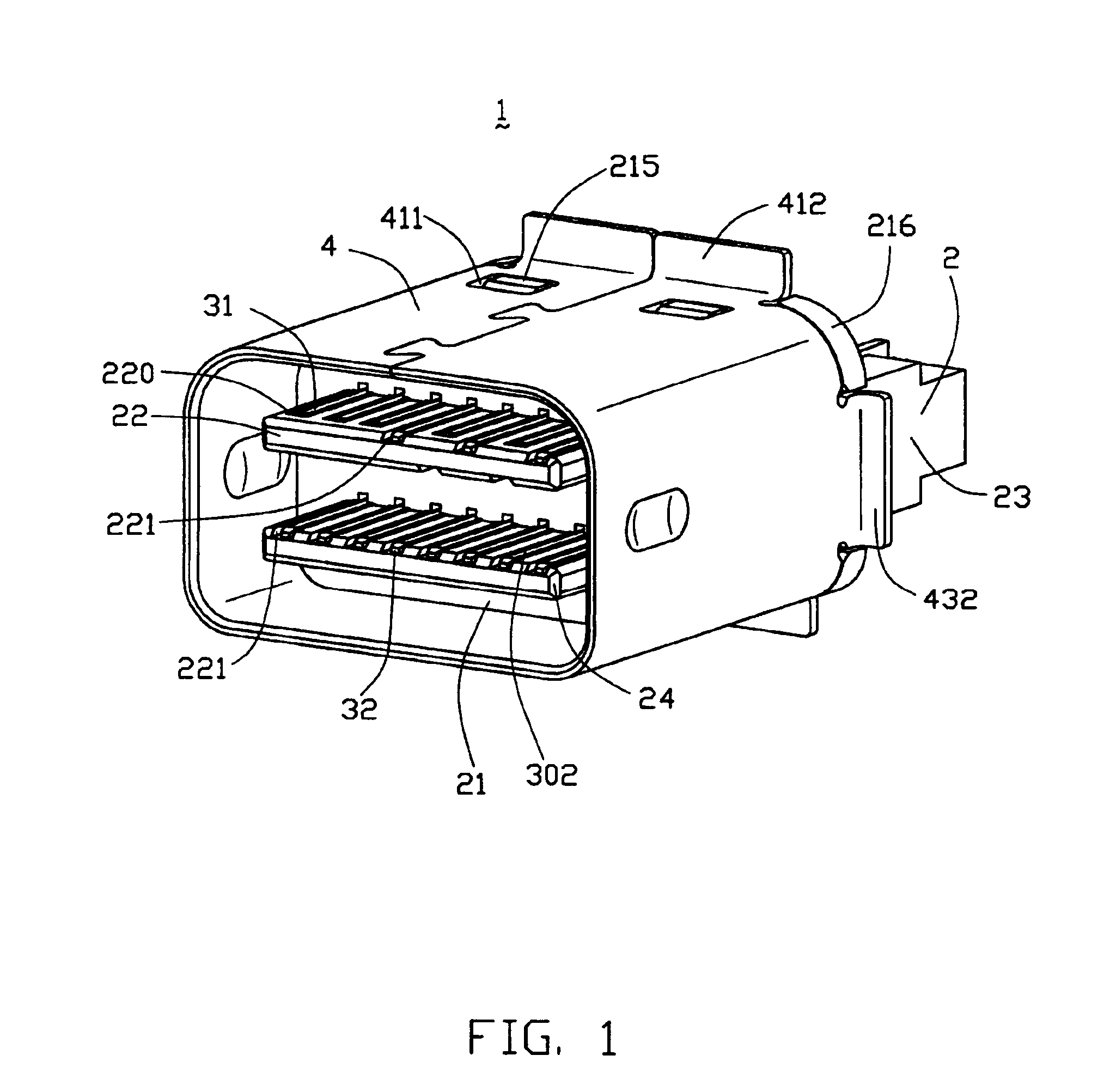

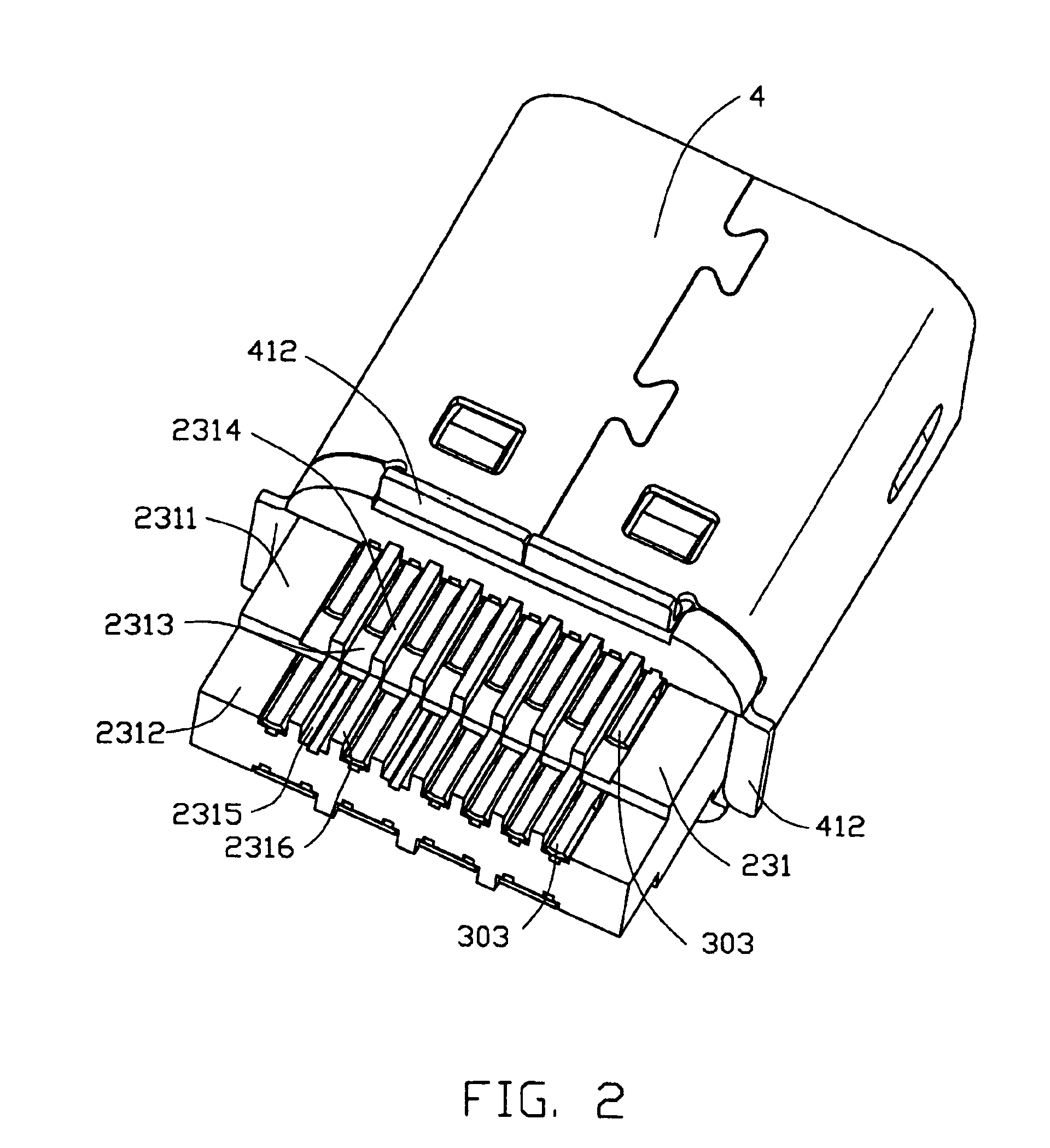

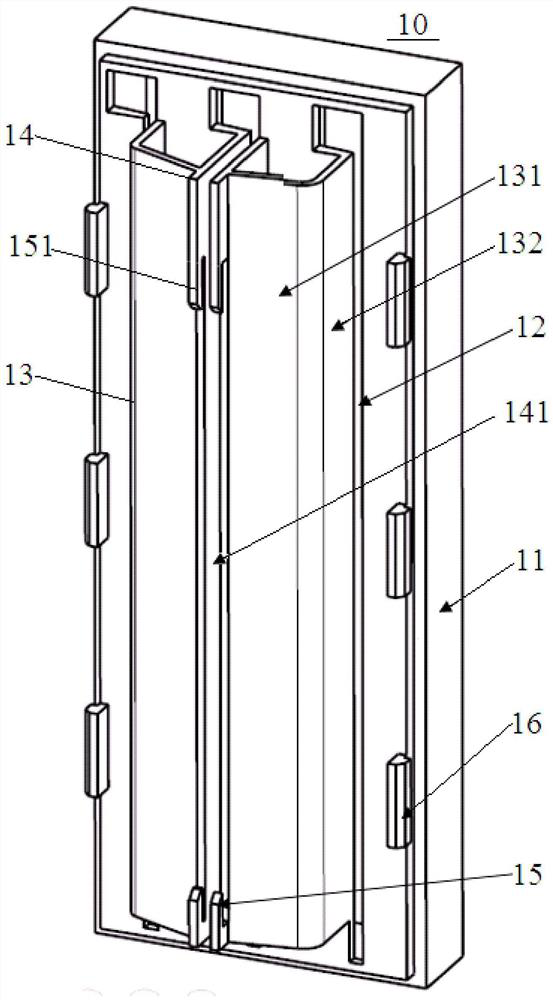

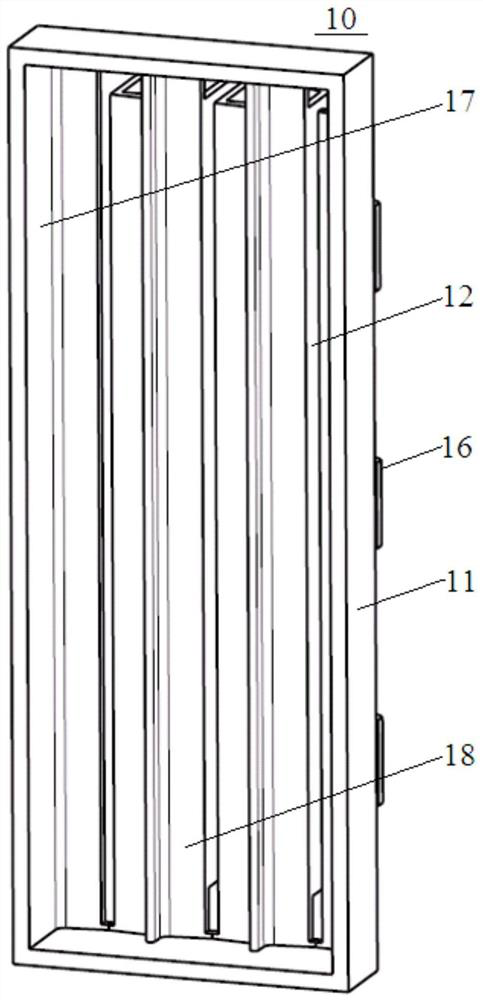

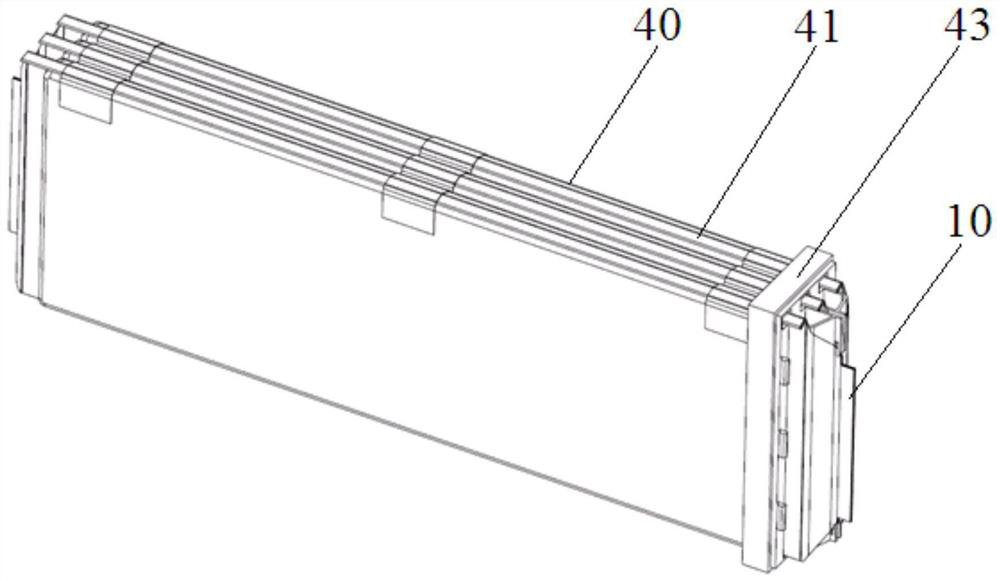

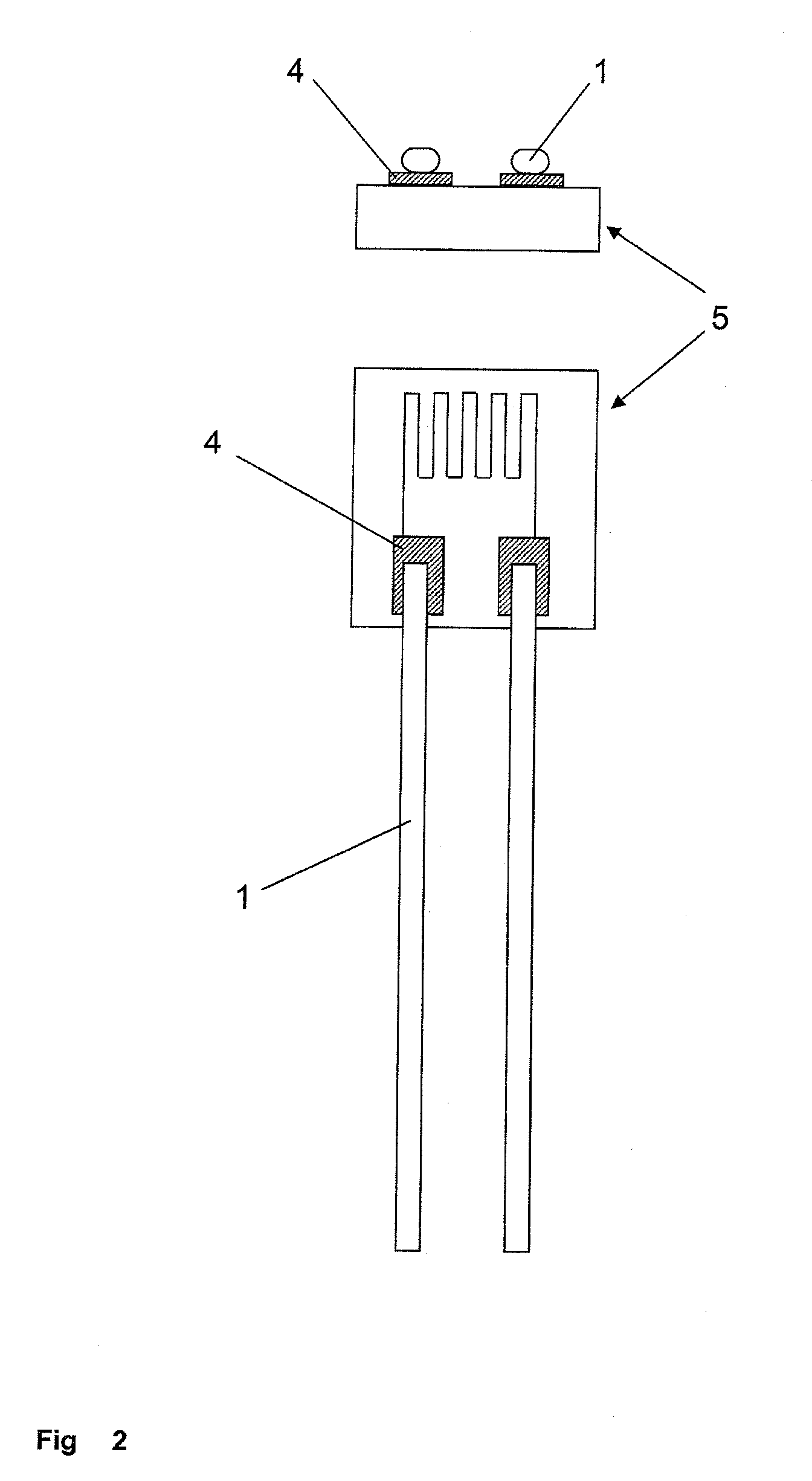

Electrical connector

InactiveUS20050014418A1Simplify the welding processElectric discharge tubesCouplings bases/casesEngineeringElectrical connector

An electrical connector (1) includes a housing (2), a number of contacts (3) received in the housing, and a shell (4) retained to the housing. The housing includes a main body (21), a first and a second tongues (22, 24) extending forwardly from the main body, and a mounting portion (23) extending rearwardly form the main body. The first and the second tongues define a number of passageways extending rearwardly throughout the main body. The mounting portion has a first and a second faces (2311,2312) on a first side (231), a third and a fourth faces (2321, 2322) on a second side (232), and a number of channels on the first, the second, the third and the fourth faces and communicating with the passageways. The second and the fourth faces are behind and offset from the first face and the third faces respectively.

Owner:HON HAI PRECISION IND CO LTD

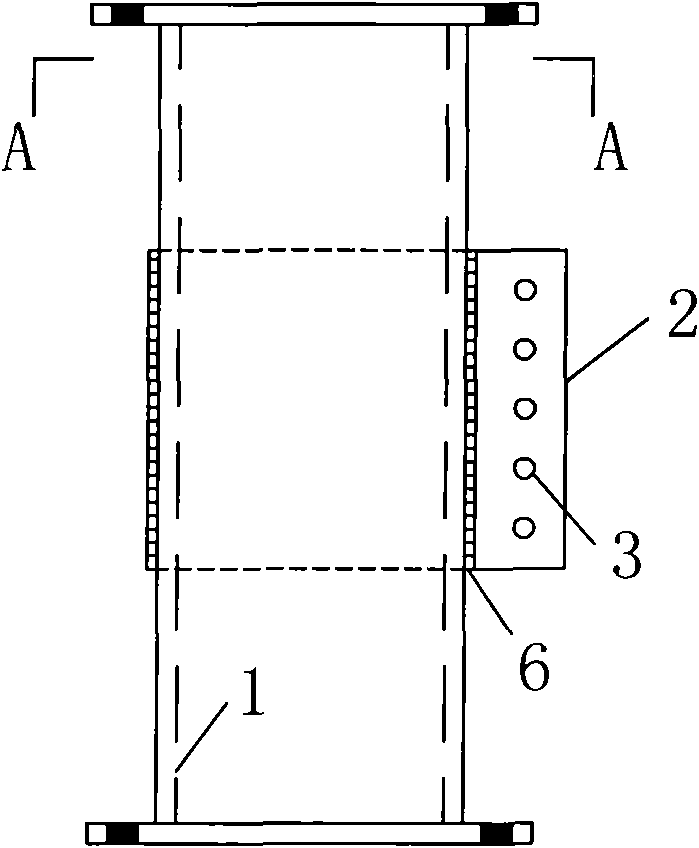

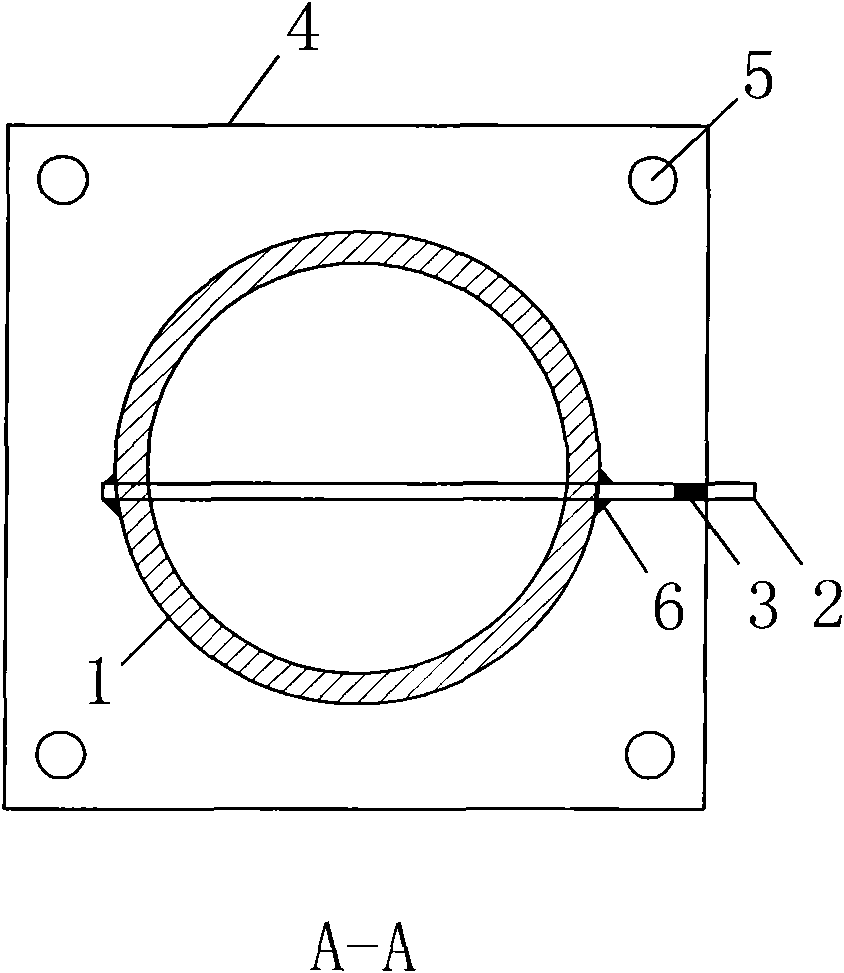

Standardized node connector of steel structure

InactiveCN101922183ADifficulty of SimplificationIncrease productivityBuilding constructionsCarrying capacityAgricultural engineering

The invention discloses a standardized node connector of a steel structure, comprising a steel column and a connection board. The connection board is fixedly connected on the side surface of the steel column; the free end of the connection board is a bolt connector; both ends of the steel column are fixedly connected with a flange on which a connection hole is arranged; the steel column is provided with a vertical through seam matched with the connection board; the connection board penetrates through the vertical through seam; and the connection board is fixedly welded with the penetrated part of the steel column. The invention has standard structure and convenient use as well as strong carrying capacity, can be applied in industrialized production and is very beneficial to promotion and application.

Owner:HENAN AUSPIC TECH

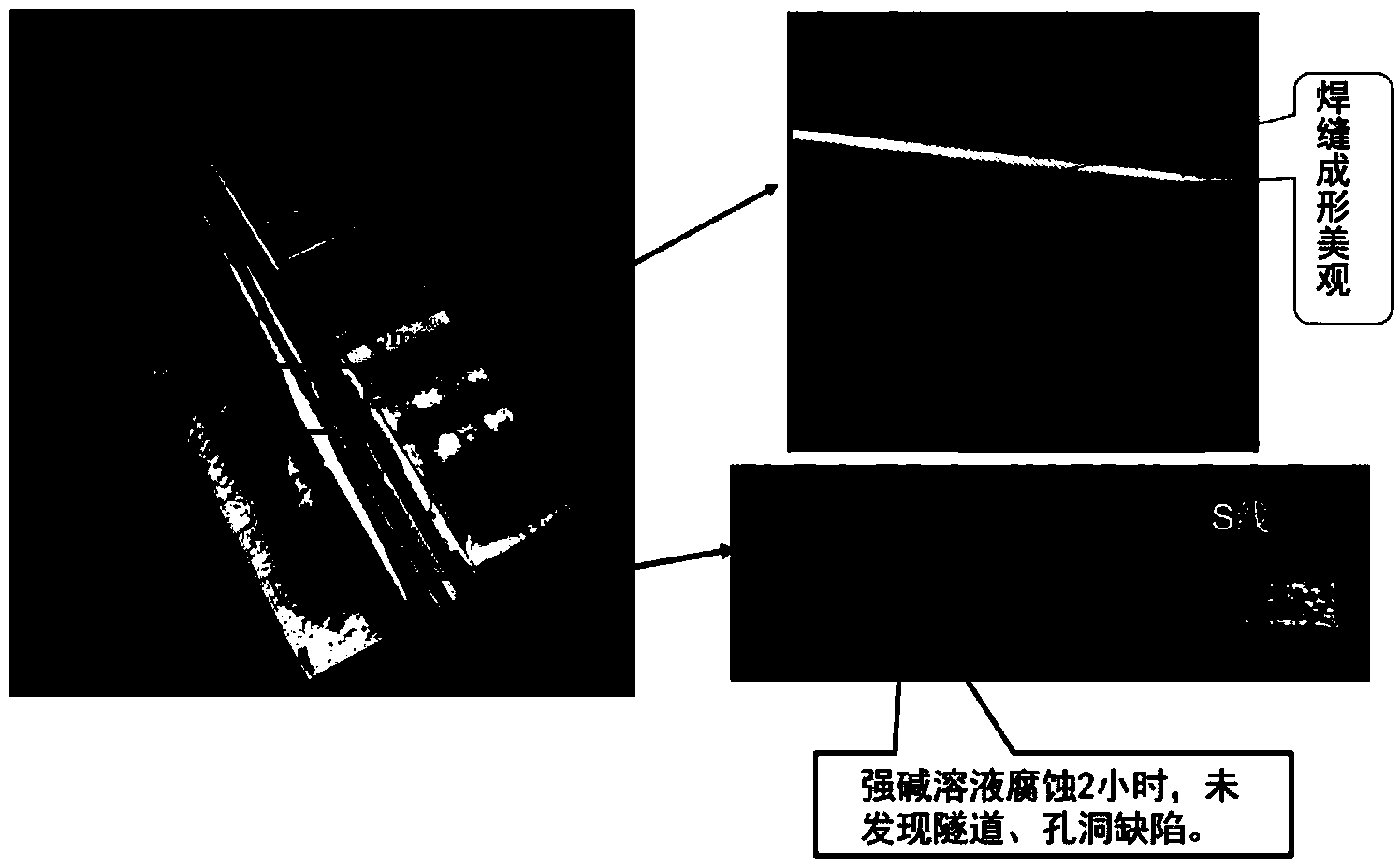

Argon-enriched mixed gas protection welding method for high-strength abrasion-resistant steel

InactiveCN102049597AIncreased sensitivity to cold crackingImprove toughnessArc welding apparatusWelding/cutting media/materialsButt weldingCrack resistance

The invention discloses an argon-enriched mixed gas protection welding method for high-strength abrasion-resistant steel, which comprises the following steps: adopting high-strength abrasion-resistant steel plates the hardness grades of which are the same, and combining and butting the steel plates the thicknesses of which are the same; adopting mixed gas containing 80% of Ar and 20% of CO2 and BHG-3 welding wires; eliminating iron rust and greasy dirt around welding seams before welding; when the fixed point butt welding and backing welding on the steel plate the thickness of which is 32mm or below 32mm is carried out, preheating to 75 DEG C before welding, and continuously welding, wherein the temperature among the welding beads of filing and cap welding seams is not lower than 60 DEG C, and the welding heat input quantity is controlled at 10-15 Kj / cm in the welding process; and when the fixed point butting welding and backing welding on the steel plate the thickness of which is 40mm is carried out, preheating to 100 DEG C before welding, and continuously welding, wherein the temperature among the welding beads of the filing and cap welding seams is not lower than 75 DEG C, and the welding heat input quantity is controlled at 10-15 Kj / cm in the welding process. By the invention, welding joints have higher strength, and the welding seams have excellent crack resistance.

Owner:NANJING IRON & STEEL CO LTD

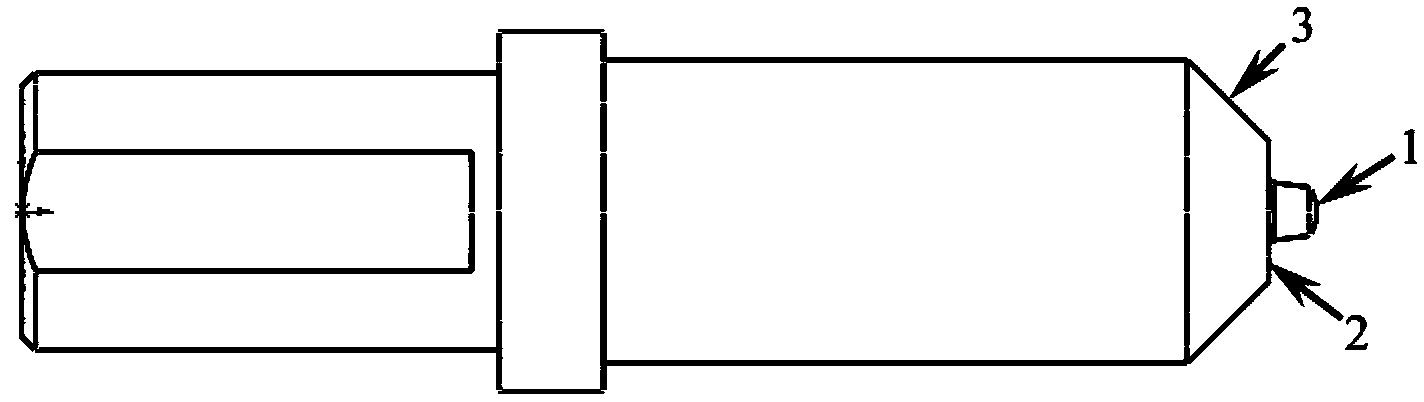

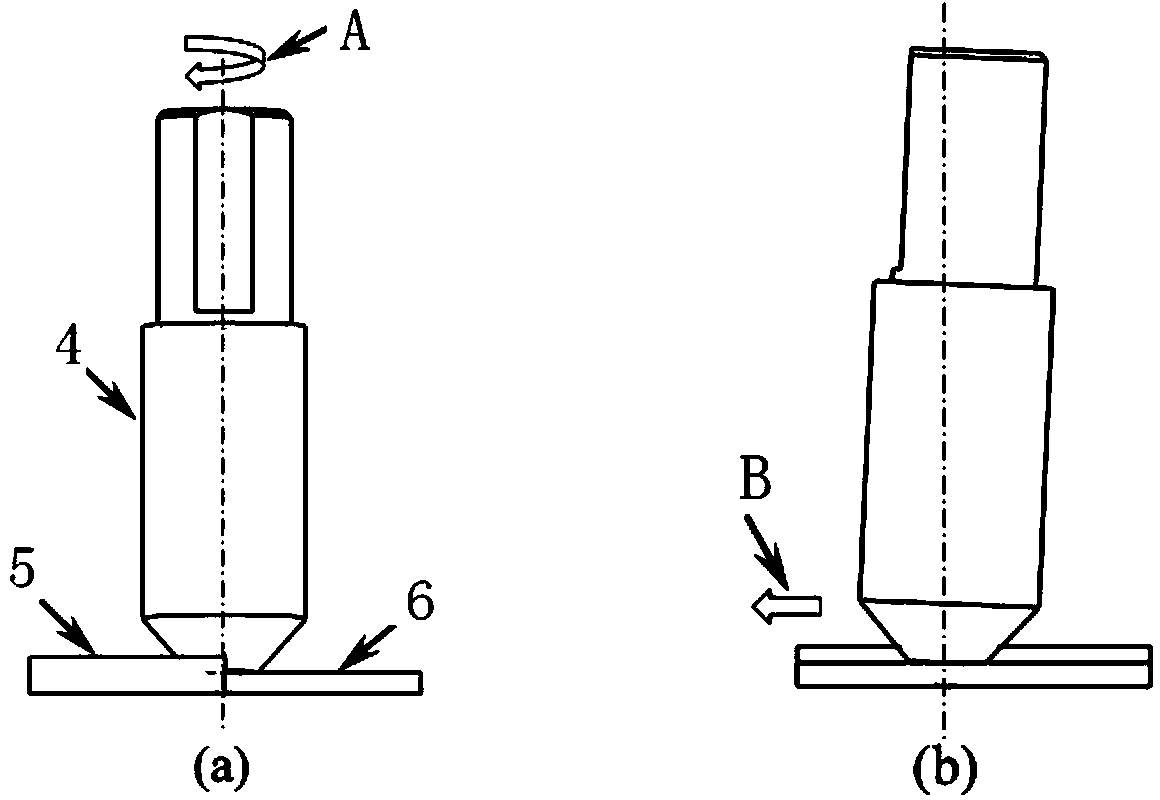

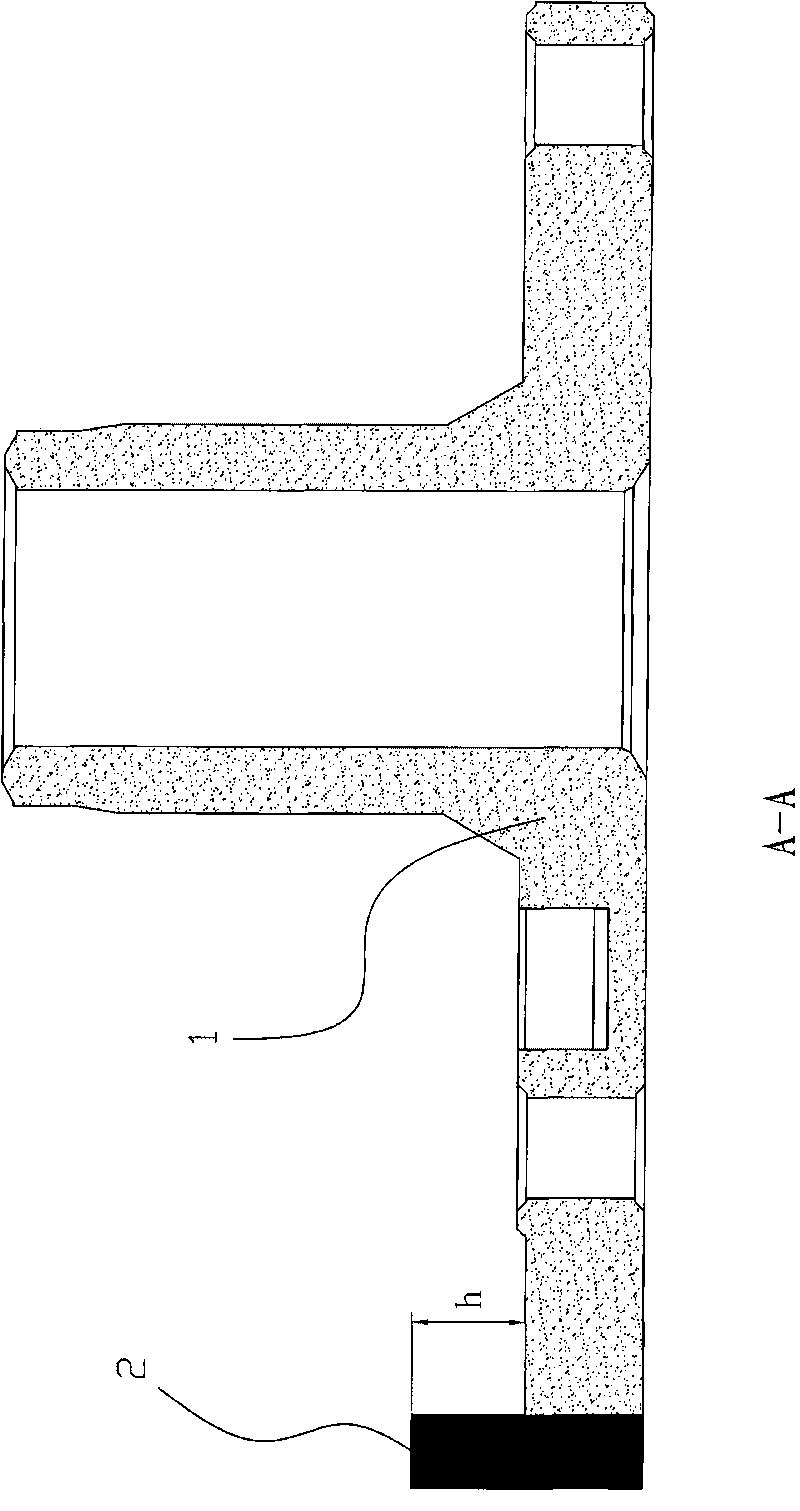

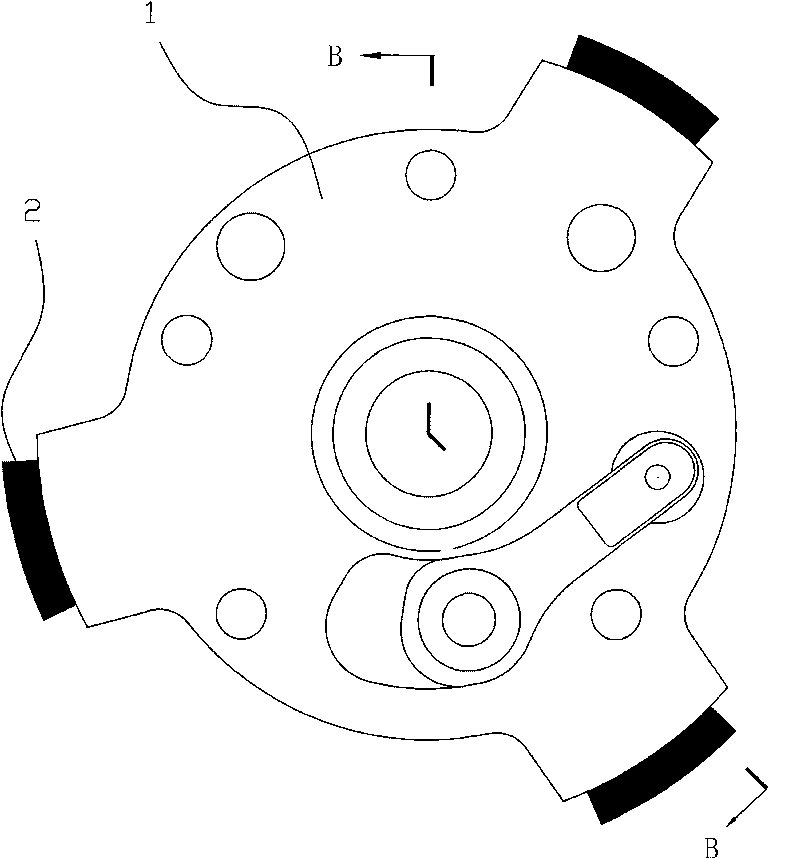

Stirring head for friction stir welding used for welding parts with different thicknesses and welding method

InactiveCN103949769AIntegrity guaranteedGuaranteed reliabilityWelding/soldering/cutting articlesMetal working apparatusEngineeringFriction stud welding

The invention relates to a stirring head for friction stir welding used for welding parts with different thicknesses and a welding method. A cutting accessory shaft shoulder is added on the basis of the existing stirring head, and the accessory shaft shoulder plays a role in cutting and removing the redundant material on the thicker side of connectors having different thicknesses to acquire a flat friction stir welding joint. The method is carried out on common friction stir welding equipment, a nose or tool of the equipment is not transformed at all, then the requirements on the equipment and the welding method are greatly simplified; in addition, in the welding process, a shaft shoulder of the stirring head and the two side surfaces of the part are parallel, so that the phenomena that metal of the connector is insufficiently extruded or damaged by shearing are not caused, the integrity and the reliability of the part are guaranteed; moreover, the accessory cutting shaft shoulder of the stirring head also plays an important role as for the part whose thickness suddenly changes, and the smooth welding process of the part is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

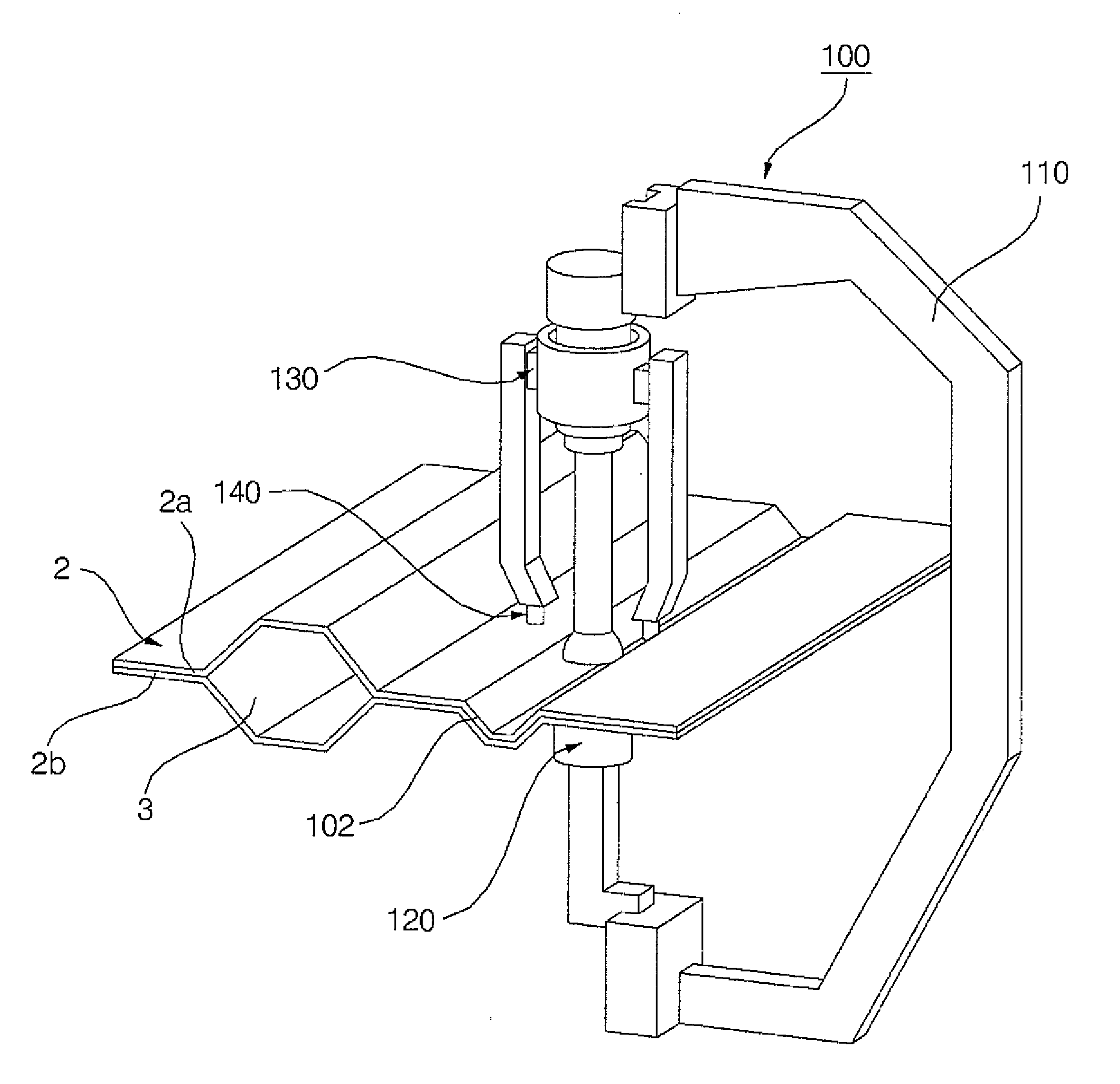

Apparatus for welding upper and lower plates of metal separating plate of fuel cell

InactiveUS20090014497A1Simple structurePrevent thermal deformationWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationEngineering

Provided is an apparatus for welding upper and lower plates of a metal separating plate of a fuel cell which can simplify the welding of a separating plate, improve welding and watertight performance, and prevent the thermal deformation of a separating plate. The apparatus includes a supporting unit which is disposed below a main body and on which the metal separating plate is safely seated; a friction stir unit which faces the supporting unit, and welds the metal separating plate using a friction stir welding method; and a temperature control unit which is disposed either at the friction stir unit or at the supporting unit, measures a temperature of at least a portion of the metal separating plate during the welding, and controls an operation of the friction stir unit so that the temperature of the metal separating plate can be maintained within a predetermined range.

Owner:HYUNDAI MOTOR CO LTD

Surfactant for magnesium alloy TIG welding and its prepn process and usage

InactiveCN1974112AAspect ratio heightImprove welding productivityArc welding apparatusWelding/cutting media/materialsMetallic materialsSlurry

The present invention relates to one kind of surfactant for magnesium alloy TIG welding and its preparation process and usage, and belongs to the field of metal material welding technology. The surfactant consists of CdCl2 and / or ZnCl2 40-60 wt%, Cr2O3 15-25 wt%, TiO2 15-25 wt% and SiO2 for the rest. Its preparation process includes mixing the materials and the subsequent ball milling for 2-4 hr. When the surfactant is used, it is first mixed with acetone and / or alcohol to form slurry for easy applying and then spread to the surface of weld pass in the amount of 1-6 mg / sq cm, and after the coating is dried, TIG welding is performed. The surfactant can ensure the welding seam quality, obviously increase fusion depth of the welding seam, simplify the welding process, raise welding efficiency, and lower production efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for welding high-grade wear-resistant steel under protection of carbon dioxide

ActiveCN102632320AMeet different mechanical performance requirementsIncreased sensitivity to cold crackingArc welding apparatusWelding/cutting media/materialsButt weldingCrack resistance

The invention belongs to the technical field of welding steel materials and discloses a method for welding high-grade wear-resistant steel under protection of carbon dioxide. The method comprises the following steps of: utilizing a high-grade wear-resistant steel plate with the hardness grade of HB500 and the thickness of below 25mm, combining and butt jointing the steel plates with the same thicknesses; according to different requirements of a structure on mechanical property, respectively selecting CO2 gas and a welding wire with the extension strength Rm of larger than or equal to 500MPa or the extension strength Rm of larger than or equal to 690MPa; selecting the welding wire with the extension strength Rm of larger than or equal to 500MPa, pre-heating to 120 DEG C before welding when butt welding and back welding are performed on a fixed point; continuously welding, wherein the temperature of an interval between filling and cap weld welding beads is not lower than 120 DEG C and is not higher than 200 DEG C, and welding heat input amount is controlled within 8-20KJ / cm in welding; or selecting the extension strength Rm of larger than or equal to 690MPa, pre-heating to 150 DEG C before welding when butt welding and back welding are performed on a fixed point; and continuously welding, wherein the temperature of an interval between filling and cap weld welding beads is not lower than 150 DEG C and is not higher than 200 DEG C, and welding heat input amount is controlled within 8-20KJ / cm. The method for welding high-grade wear-resistant steel under the protection of the carbon dioxide, disclosed by the invention, ensures that a welding joint has higher strength so that a welding bead has excellent anti-cracking performance, the welding joint has higher low-temperature impact toughness storage and safety margin, the construction condition is modified and the production cost is reduced.

Owner:NANJING IRON & STEEL CO LTD

Method for manufacturing powder metallurgy supporting seat

The invention relates to a method for manufacturing a powder metallurgy supporting seat, which sequentially comprises the following steps: (1) pressing a supporting seat base body (1), and arranging a structure for placing a transition block (2) on the supporting seat base body (1); (2) processing the transition block (2); (3) arranging the transition block on the structure for placing a transition block (2) on the supporting seat base body (1), positioning soldering flux between the supporting seat base body (1) and the transition block (2), and then putting the supporting seat base body (1) assembled with the transition block (2) in to a sintering furnace at the temperature of 1000-1300 DEG C under the condition of vacuum or filling with assistant welding gas sintering atmosphere for sintering for 5-50min; (4) after welding, measuring the size and accuracy to determine whether machining and adjusting are needed for correcting the position of the transition block (2) on the supporting seat base body (1); and (5) carrying out steam treatment on the supporting seat base body (1) welded with the transition block (2); therefore, the manufacturing process of powder metallurgy supporting seat can be completed. Compared with the prior art, as the transition block is welded with the supporting seat base body by a powder metallurgy sintering and soldering method, the supporting seat base body has high position, accurate locating accuracy and good connecting strength; and the whole welding process is simple and easy to operate.

Owner:NBTM NEW MATERIALS GRP

Non-preheating gas shielded welding method for wear-resistant steel plate

ActiveCN105149746AHigh strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsWear resistantSteel plates

The invention discloses a non-preheating gas shielded welding method for a wear-resistant steel plate. The non-preheating gas shielded welding method comprises the following steps: adopting a high-strength wear-resistant steel plate with carbon equivalent greater than 0.48% and hardness level of HBW450; selecting a gas mixture of 20% CO2 and 80% Ar and a GHS70-2 soldering wire; adopting fixed-point welding, not preheating before welding, and controlling a temperature between welding beads of a filling and cosmetic-welding welding seam to 100-150 DEG C; adopting an arc-connected left welding method for backing welding, controlling backing welding current to 150-170 A, welding voltage to 18-22V and welding speed to 10-15cm / min, and guaranteeing good back forming; controlling welding current during interlayer and cosmetic welding to 200-230 A, welding voltage to 25-28 V and welding speed to 20-25cm / min; and controlling thermal input to 16-20kJ / cm. According to the non-preheating gas shielded welding method, a welding joint has relatively high strength, and a welding seam has excellent low-temperature toughness resistance.

Owner:SHANDONG IRON & STEEL CO LTD

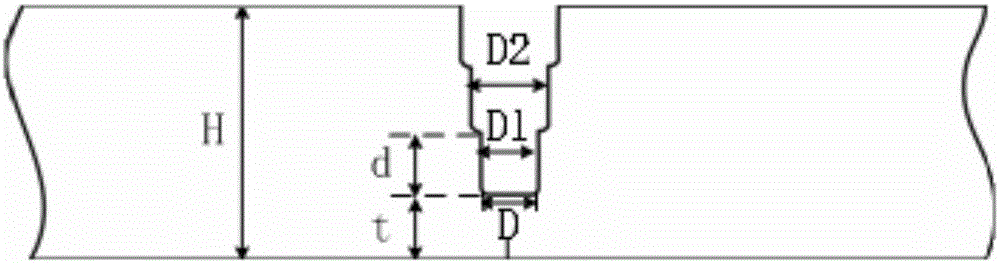

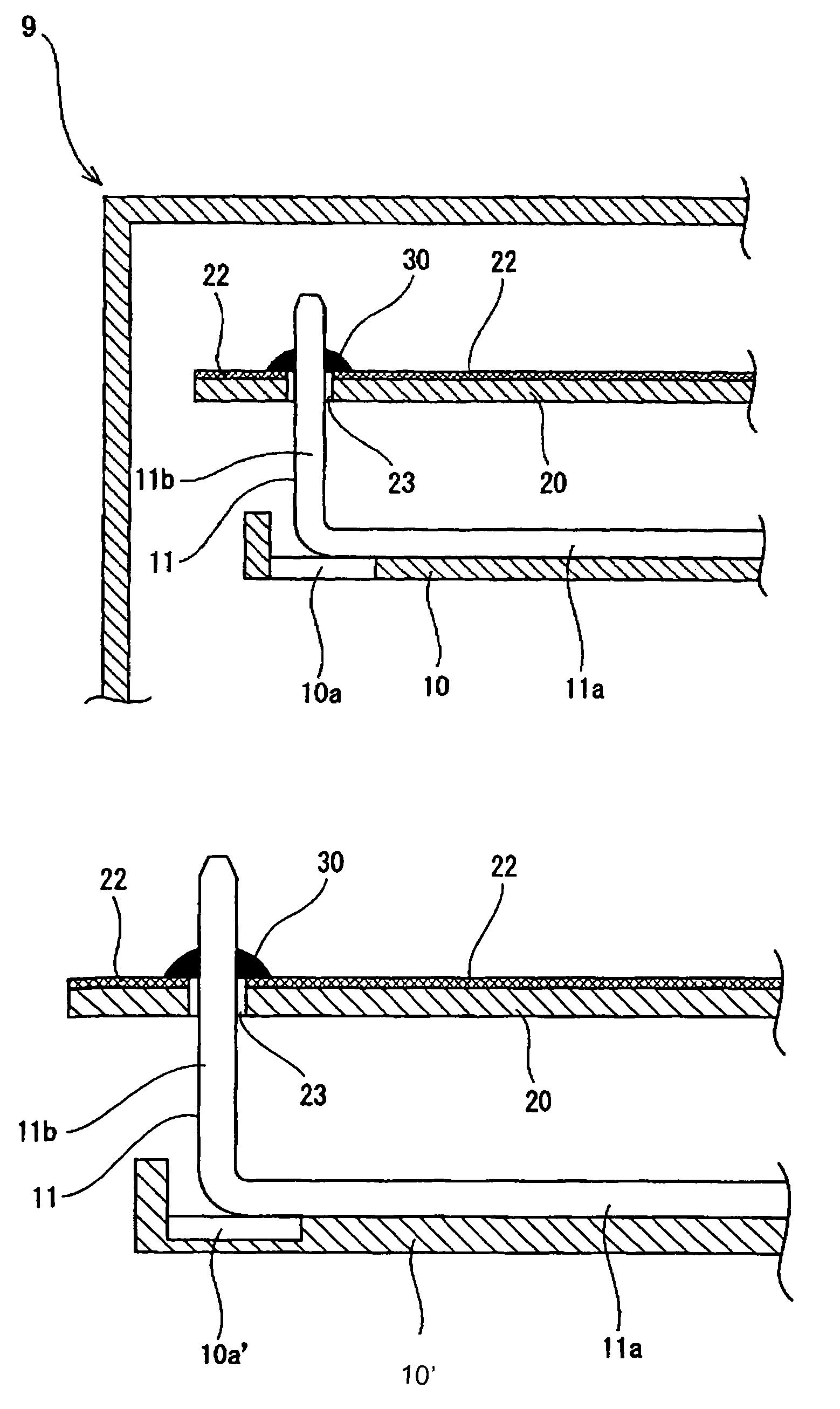

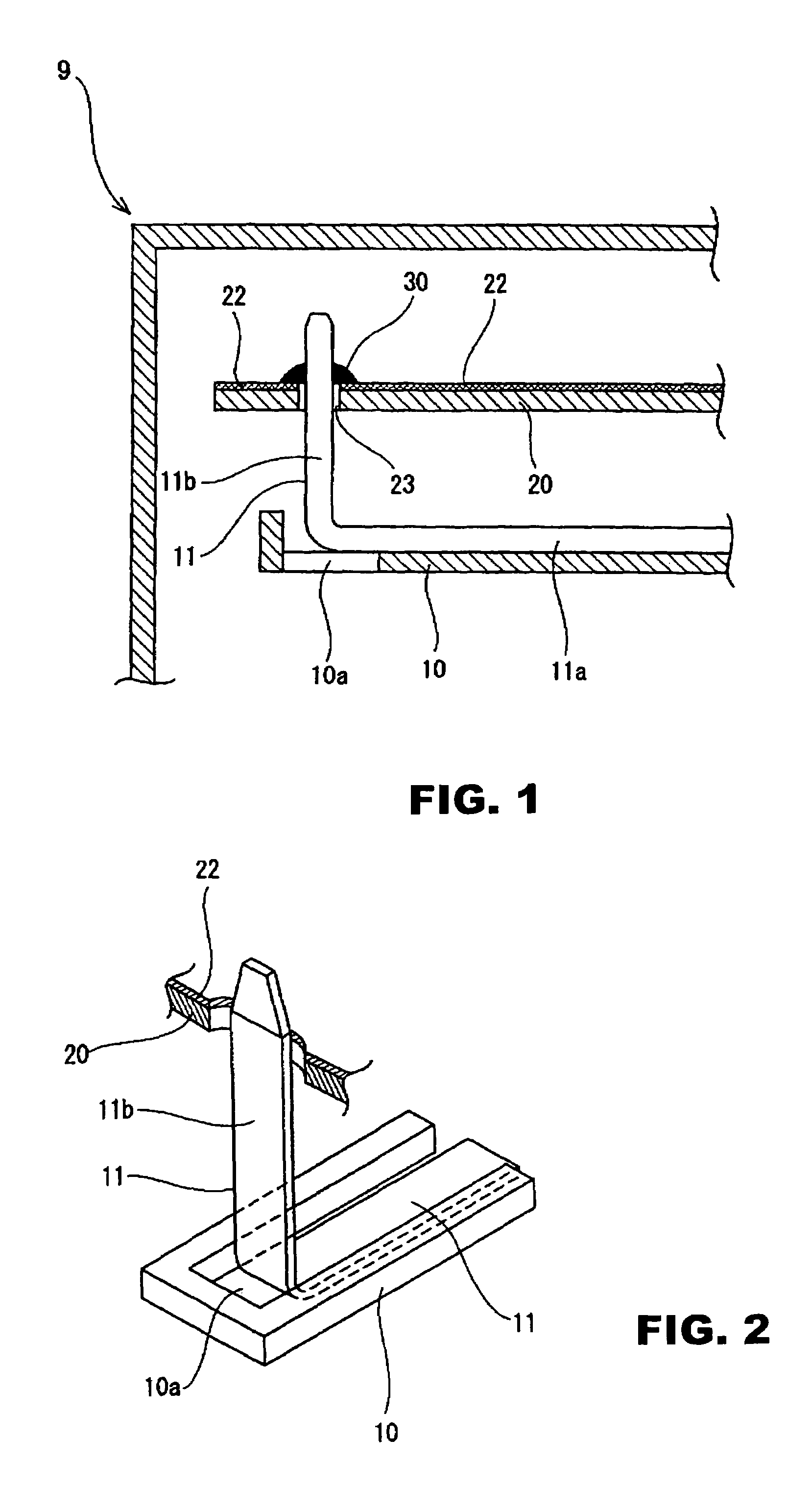

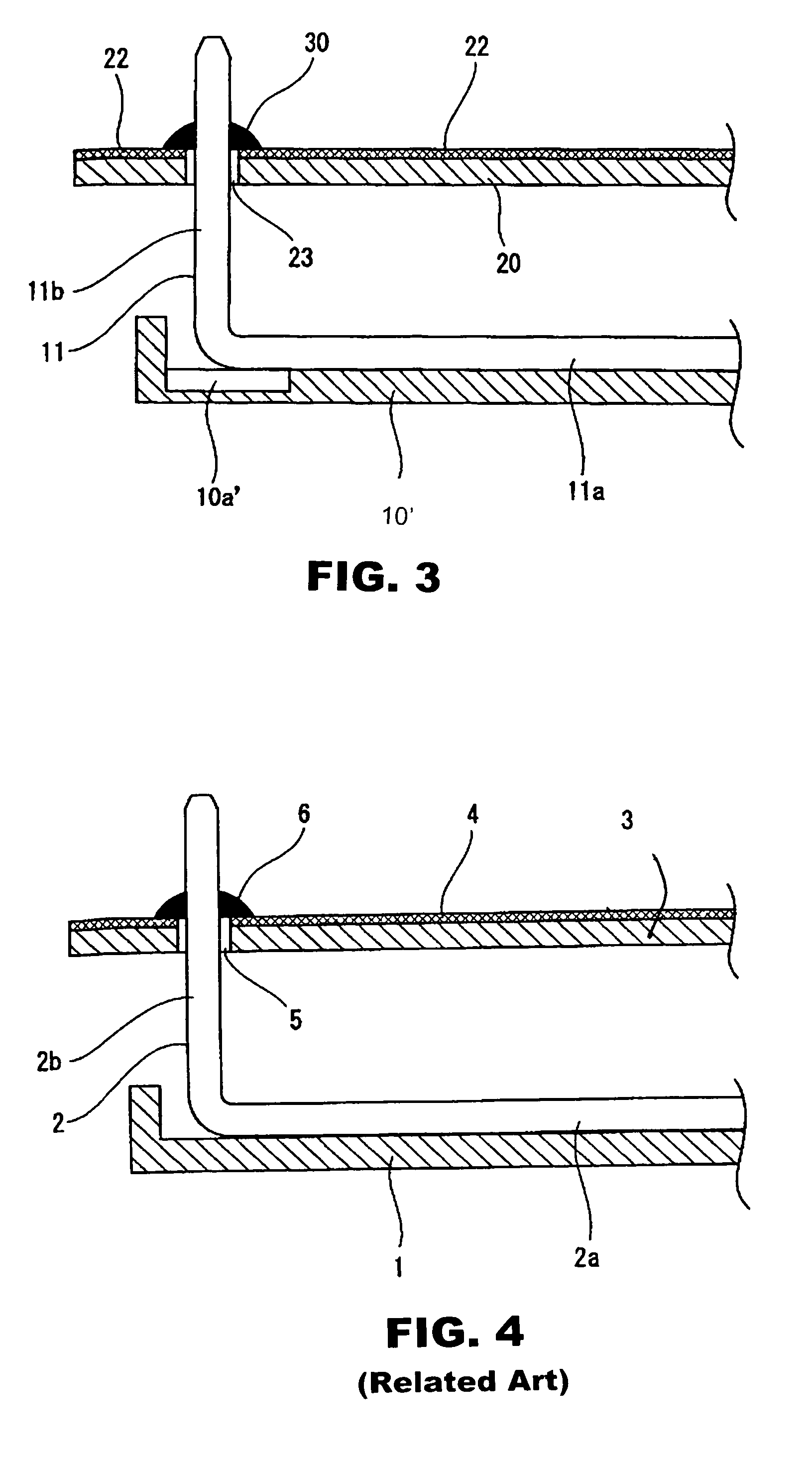

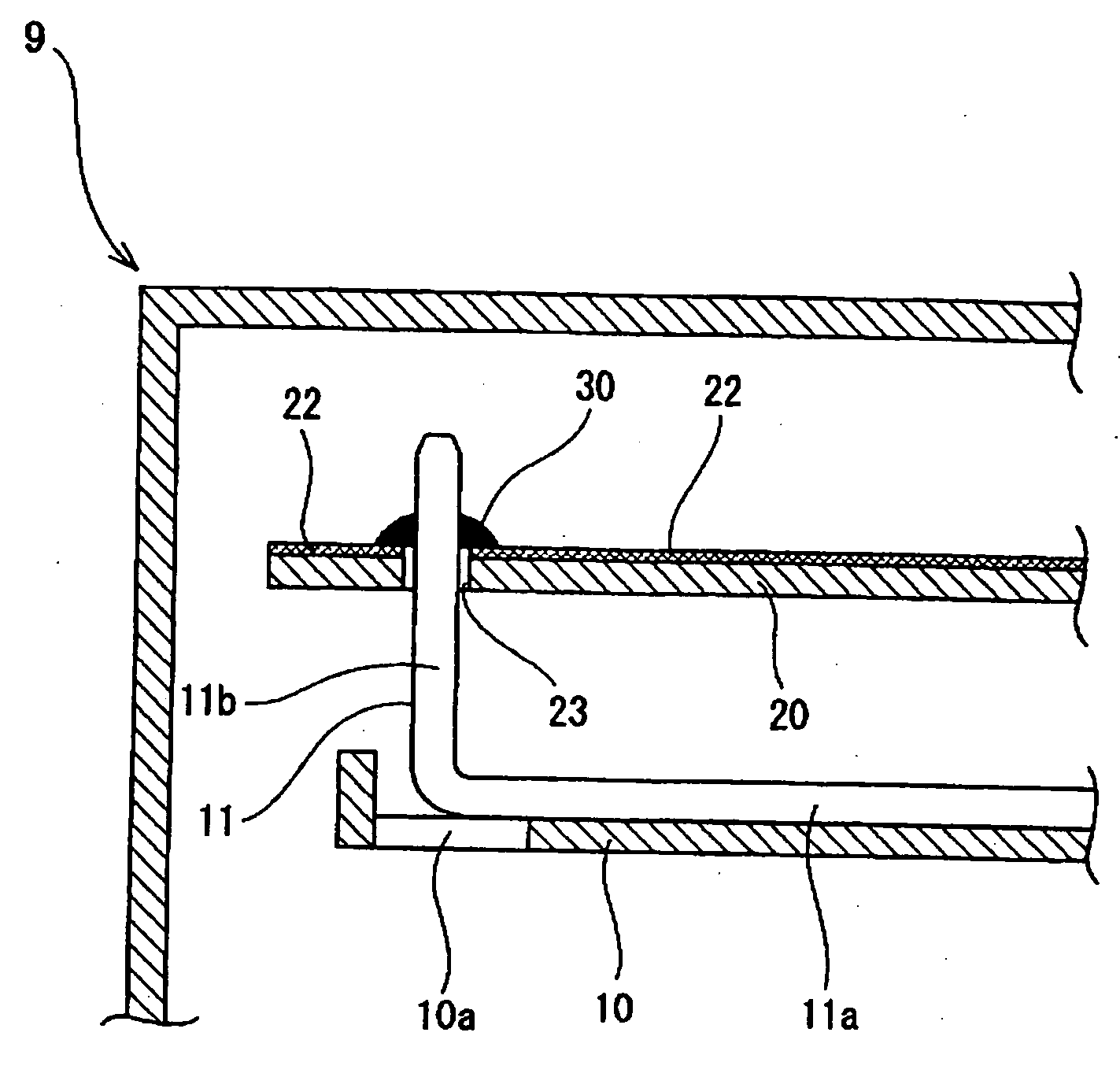

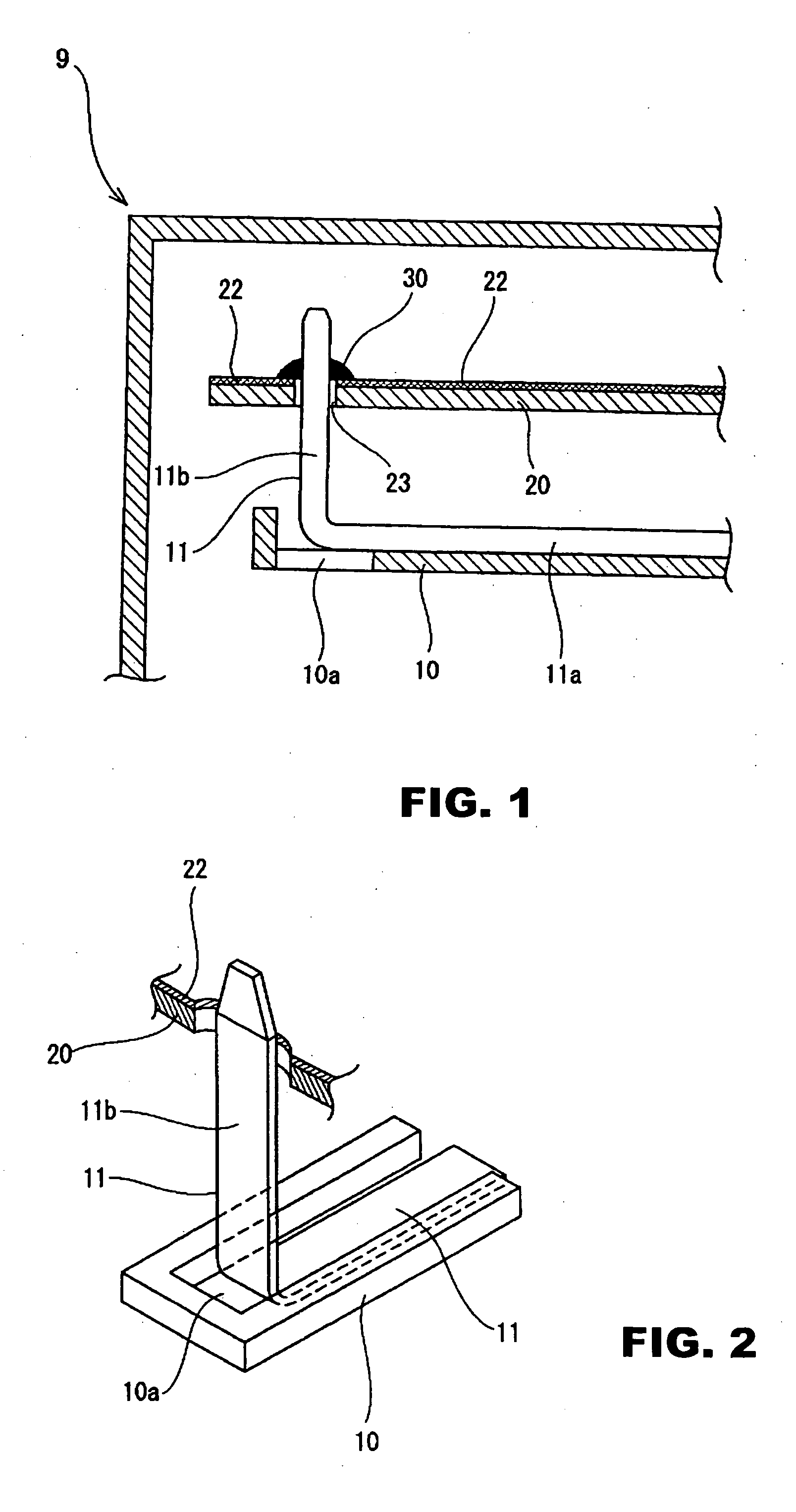

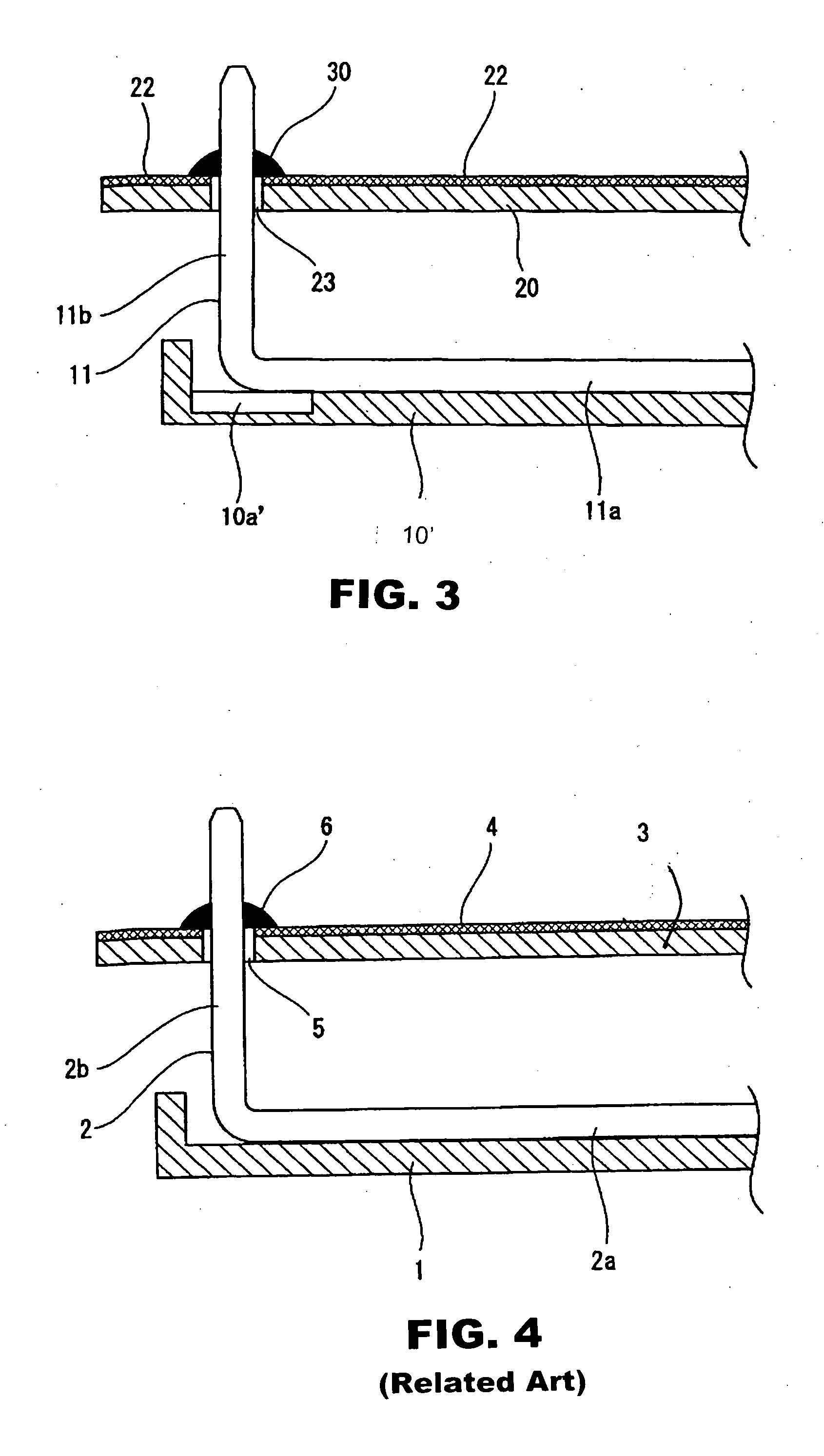

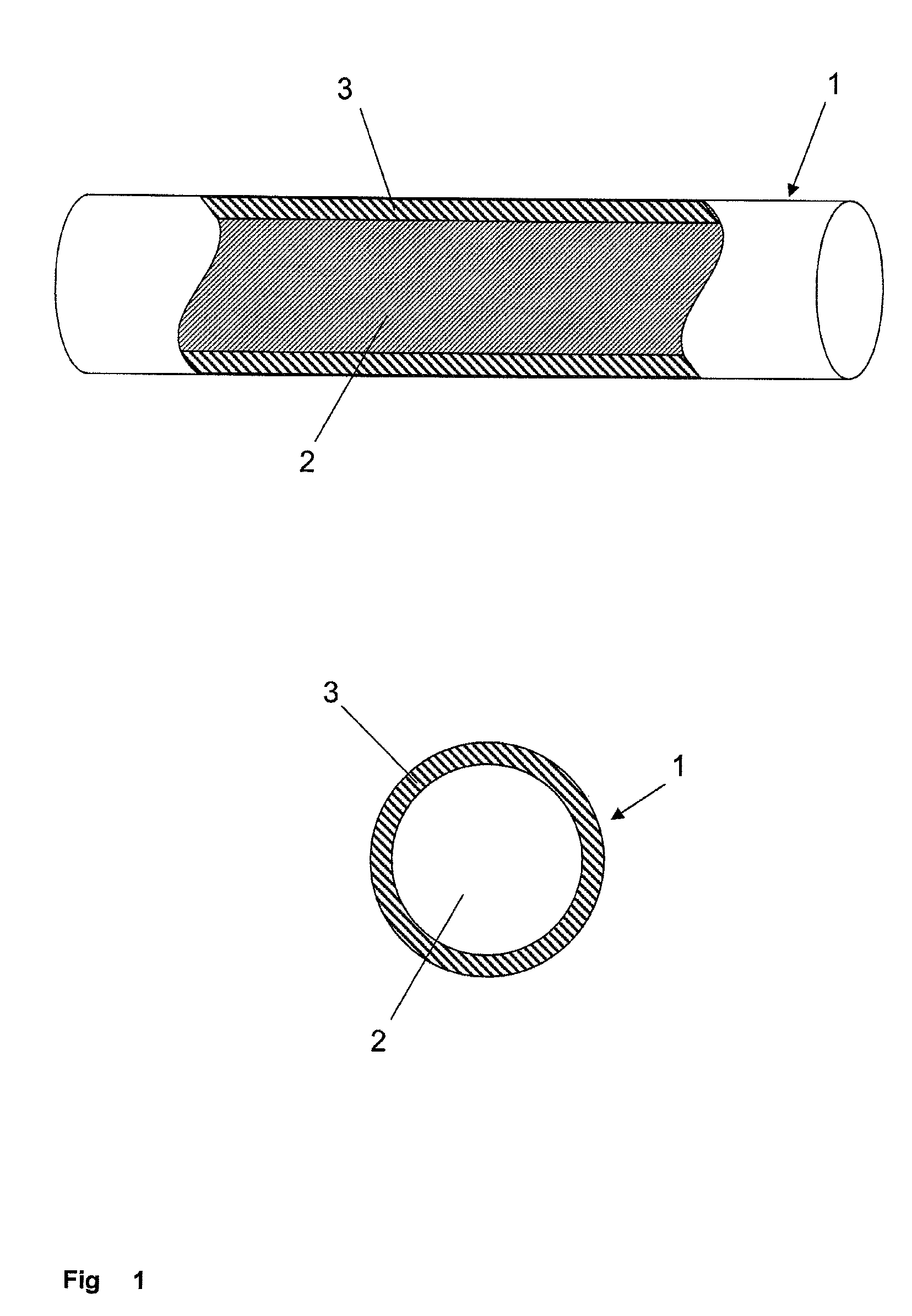

Soldering structure between a tab of a bus bar and a printed substrate

InactiveUS6997737B2Simplify the welding processLow costPrinted circuit assemblingLine/current collector detailsEngineeringConductive materials

A soldering structure between a tab of a bus bar and a printed substrate is disclosed to provide a soldering structure between a tab of a bus bar and a printed substrate that causes no crack. An electrical conductive material is formed on a printed substrate. A tab through-hole is provide to penetrate the electrical conductive material and printed substrate. A tab formed by bending a body of the bus bar enters the tab through-hole. A periphery of the tab and the electrical conductive material are interconnected by soldering. A stress-absorbing aperture or recess is provided in an insulation plate on which the body of the bus bar is mounted. The stress-absorbing aperture or recess can absorb an axial stress caused in the tab.

Owner:SUMITOMO WIRING SYST LTD

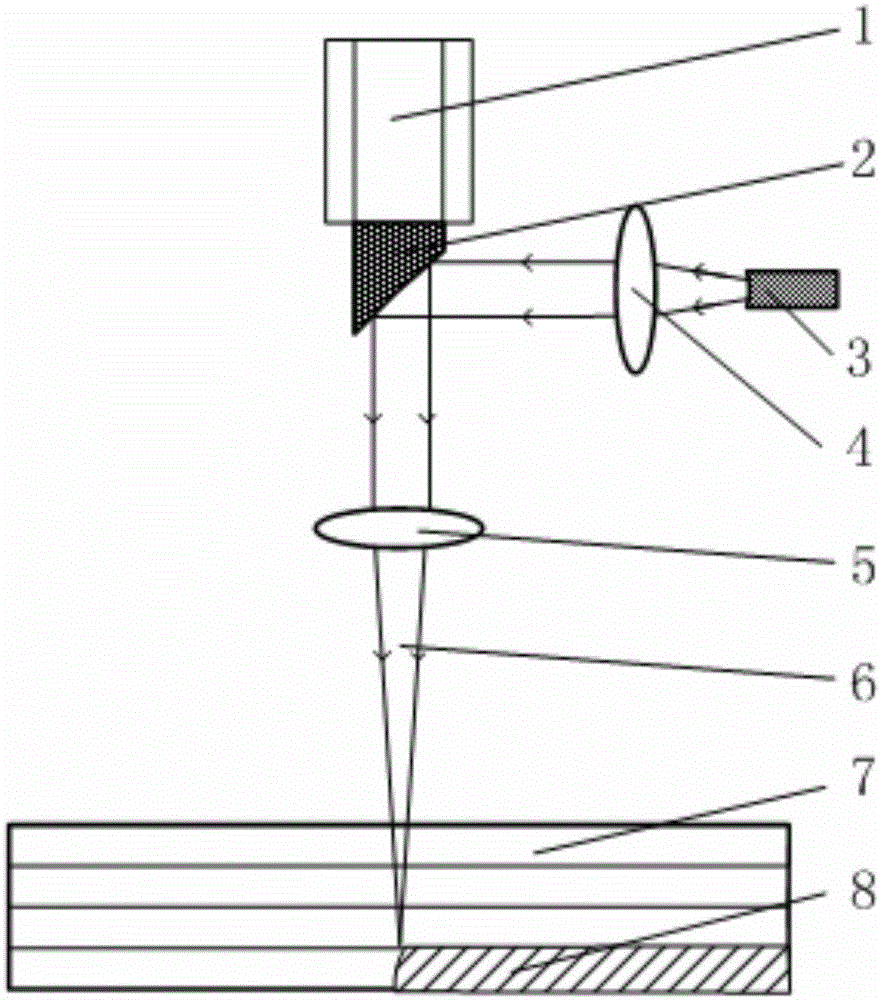

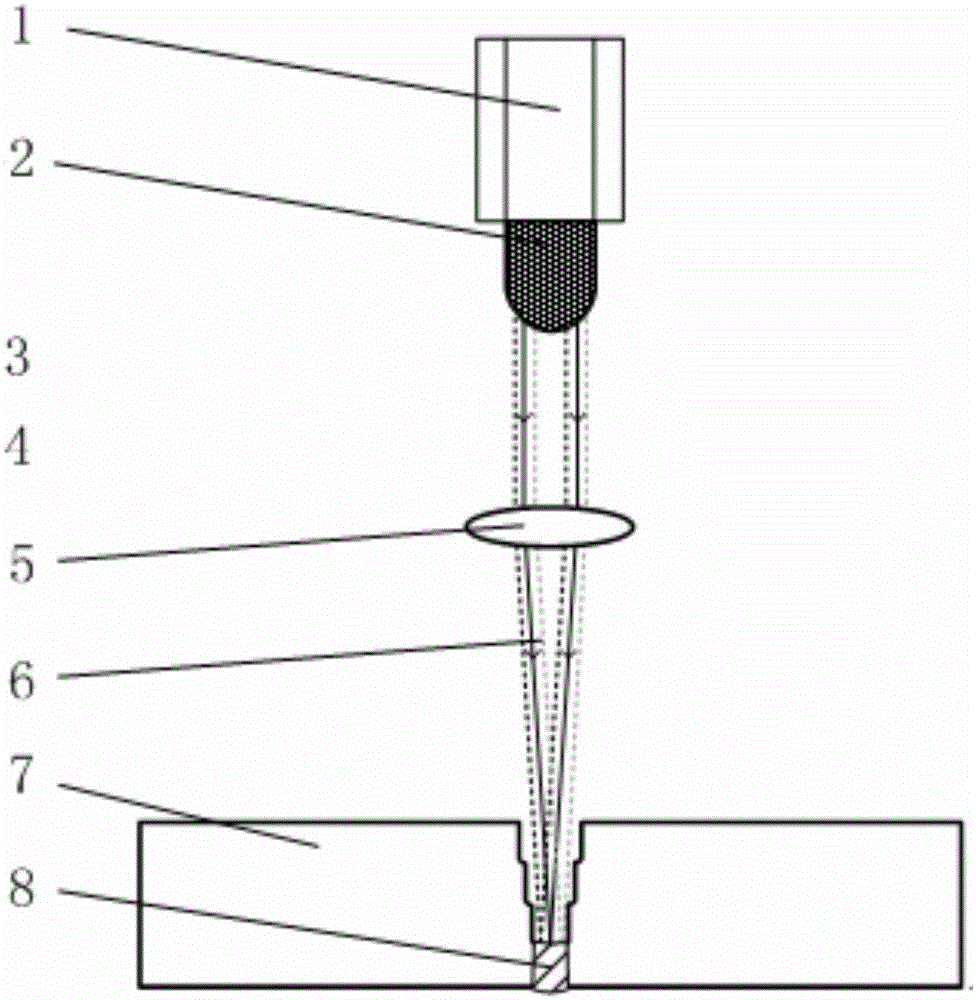

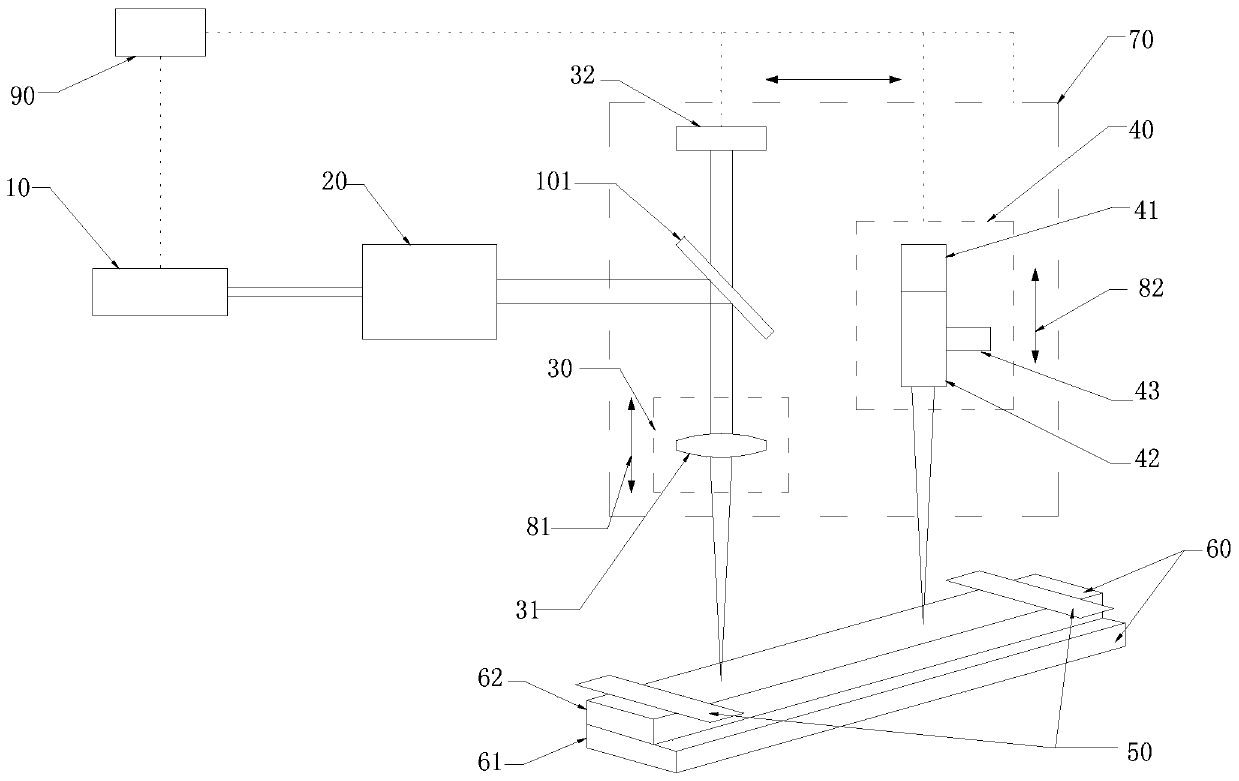

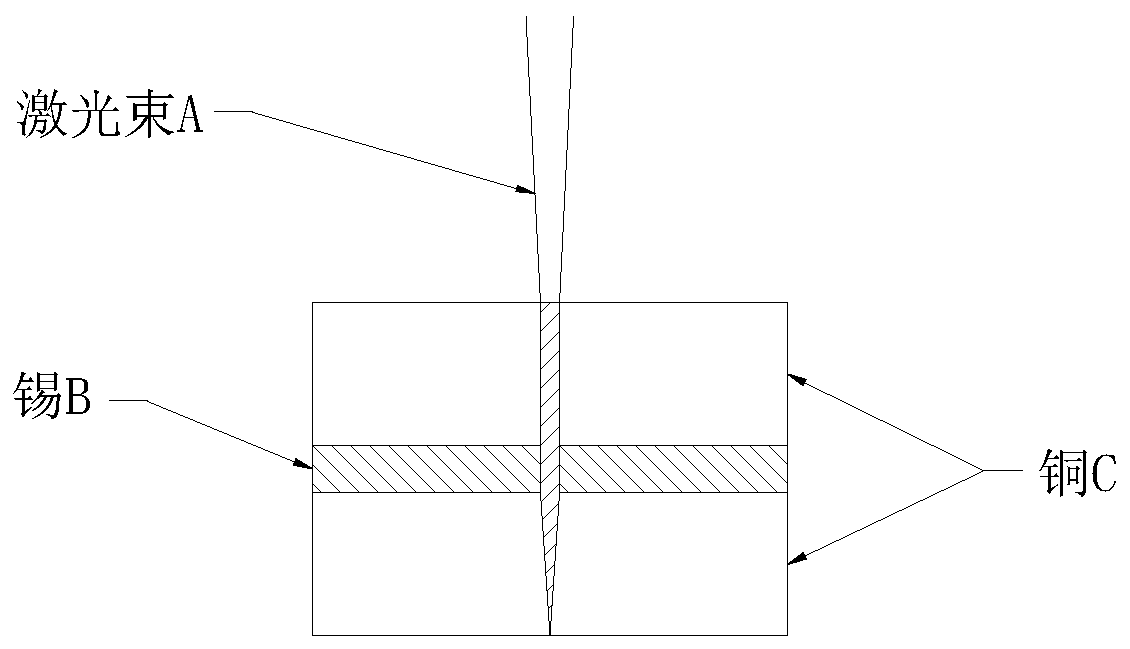

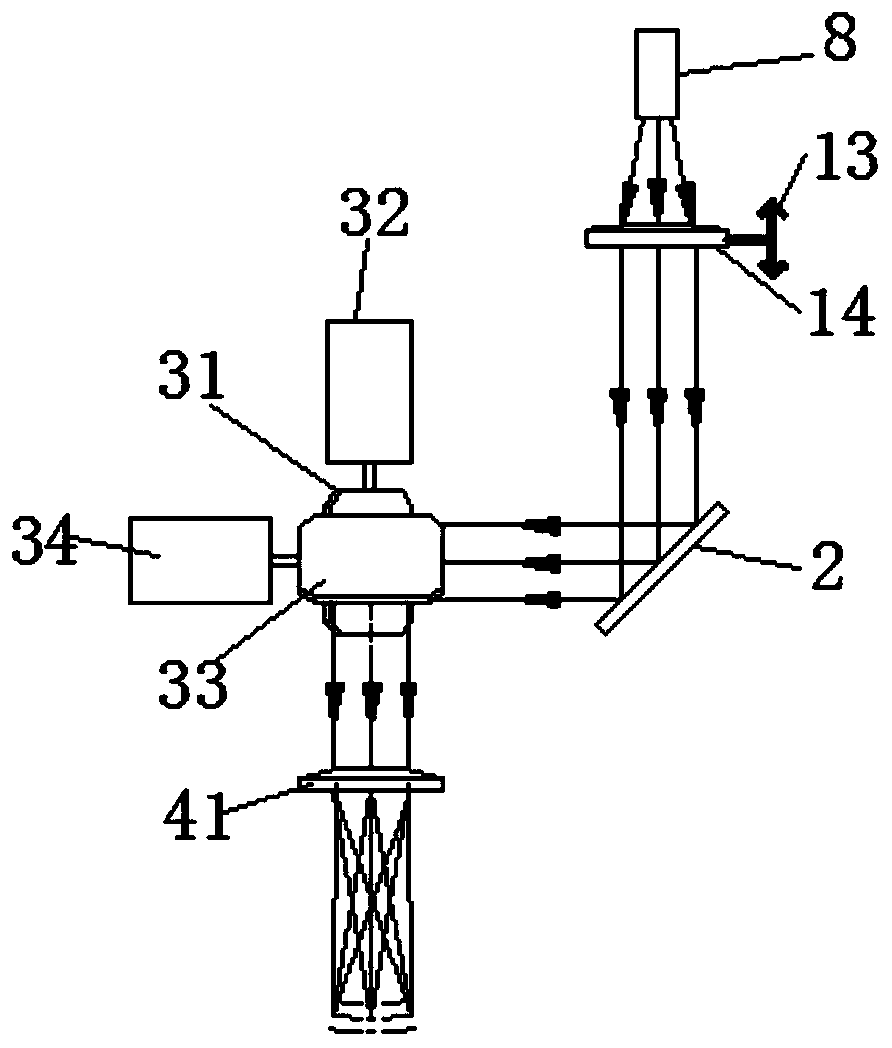

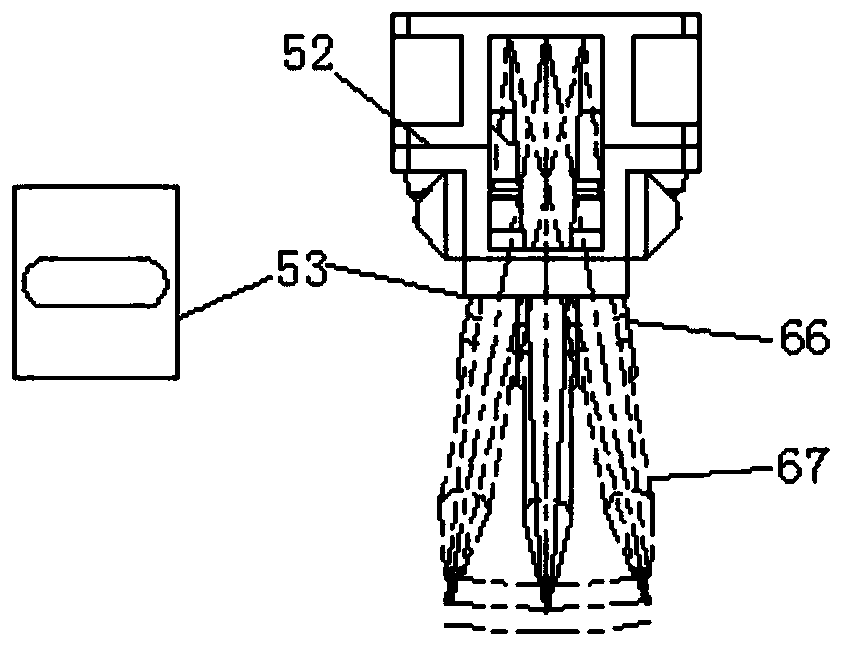

Penetrating type laser welding method of solar cell bus bars

PendingCN109986205AImprove heating efficiencySimplify the welding processLaser beam welding apparatusBeam expanderSurface layer

The invention relates to a penetrating type laser welding method of solar cell bus bars. The method comprises the following steps: outputting a laser beam through a pulse laser device, carrying out beam expansion control on diameter of the laser beam through a beam expander, focusing the laser beam subjected to beam expansion on a welding sample through a laser welding head, and enabling the laserwelding head to horizontally move up and down to adjust the size of a laser focal point and a laser welding spot; applying pre-pressure to a position near an area to be welded through a pre-pressingmechanism to enable two layers of welding strips to be in full contact with each other; receiving thermal radiation reflection laser in the welding process through a temperature feedback system, collecting a welding thermal radiation laser beam and converting the welding thermal radiation laser beam into temperature information, and calibrating the temperature of the welded area; enabling a visualimage system to move up and down to adjust a visual image focal point and identifying position information of the welding sample; focusing pulse laser on the welding strips, forming extremely high laser energy density in an action area, directly gasifying tin on the surface layers and copper on the inner sides of the welding strips, forming cavities in the materials and enabling the materials tobe tightly occluded with each other, and directly carrying out fusion welding of copper layers of the two layers of welding strips. The welding quality is high.

Owner:江阴德龙能源设备有限公司

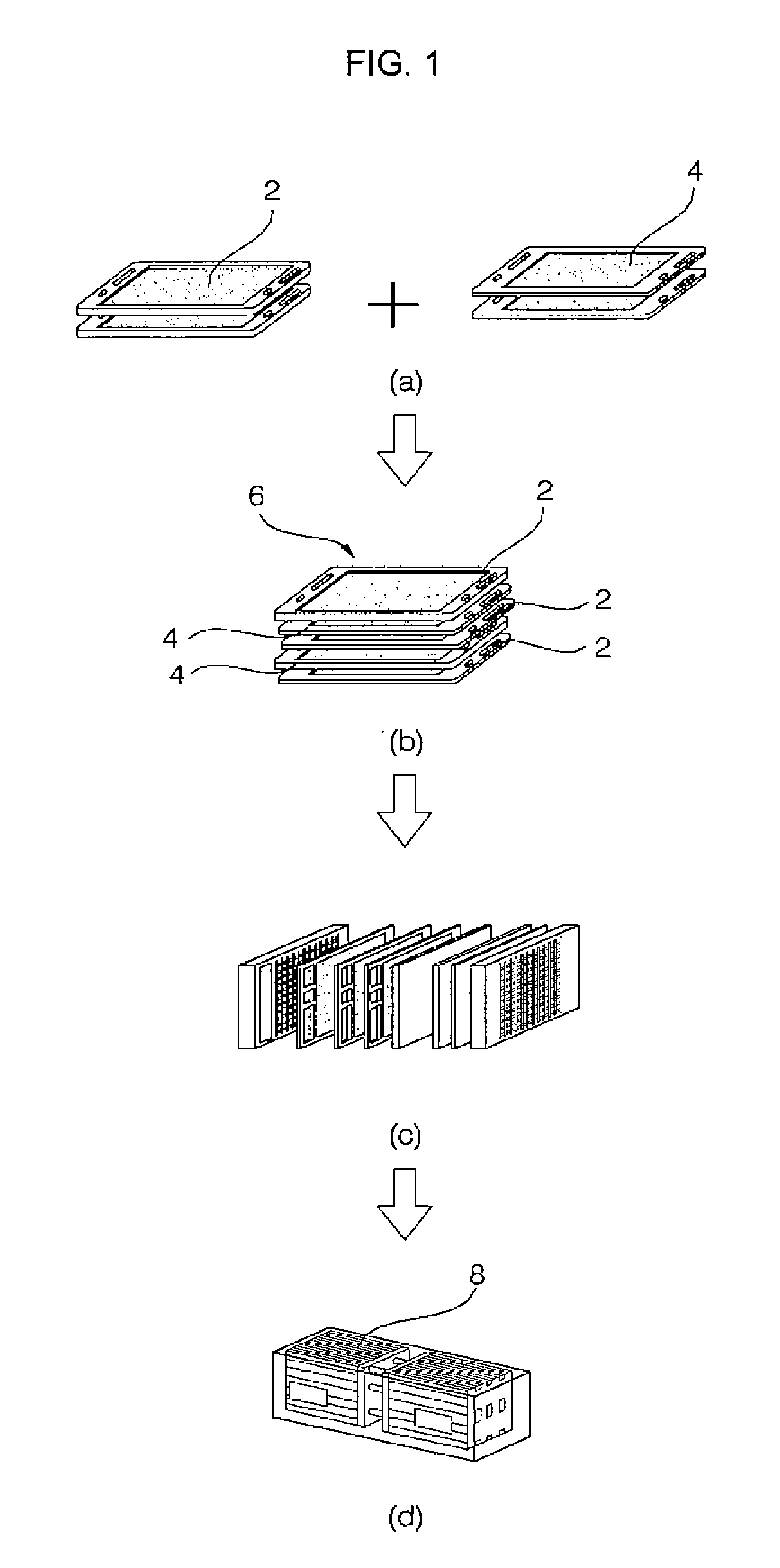

Preparing method of whole back electrode P type crystalline silicon heterojunction solar battery

ActiveCN104167471AImprove conversion efficiencyReduce manufacturing costFinal product manufacturePhotovoltaic energy generationHeterojunctionSlurry

The invention discloses a preparing method of a whole back electrode P type crystalline silicon heterojunction solar battery. The method comprises the steps that nanometer suede, a P+ type boron shallow diffusion crystalline silicon layer and an SiOx passivation / SiNx anti-reflection layer are prepared on the front surface of a P type silicon substrate; a P++ type boron heavy diffusion crystalline silicon layer is prepared on the back face of the P type silicon substrate, then printing corrosion slurry is used for achieving local corrosion on the P++ type boron heavy diffusion crystalline silicon layer, an intrinsic amorphous silicon membrane layer and an n type amorphous silicon membrane layer are subjected to deposition in sequence, and intrinsic and n type amorphous silicon on the surface layer of a P++ type boron heavy diffusion crystalline silicon layer zone is removed; then a transparent conducting membrane layer is subjected to sputtering, a P zone and an N zone on the back face of the P type silicon substrate are separated through laser; and finally electrode printing is carried out, and low-temperature sintering is carried out. According to the method, all metal electrodes are moved to the back face of the battery, electrodes are not arranged on a light-borne face, component production cost is lowered, battery composite loss is lowered, accordingly, optical loss and resistance are obviously lowered, and efficiency is greatly improved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

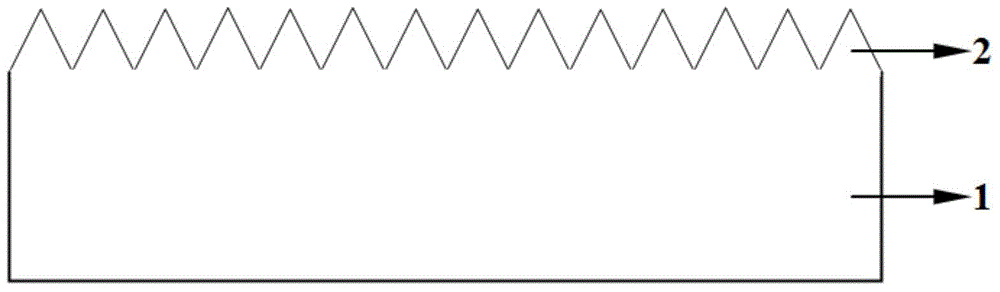

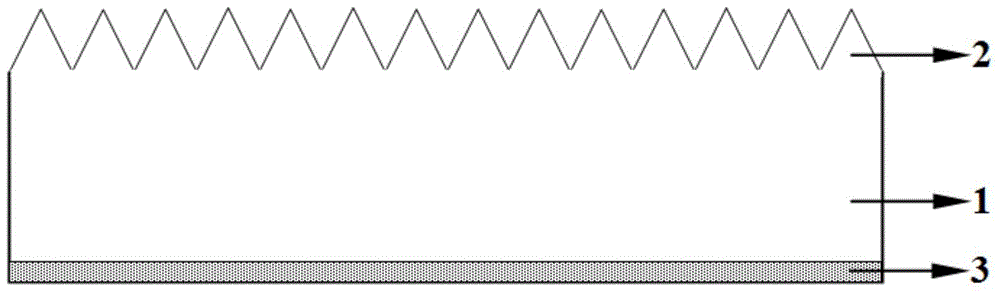

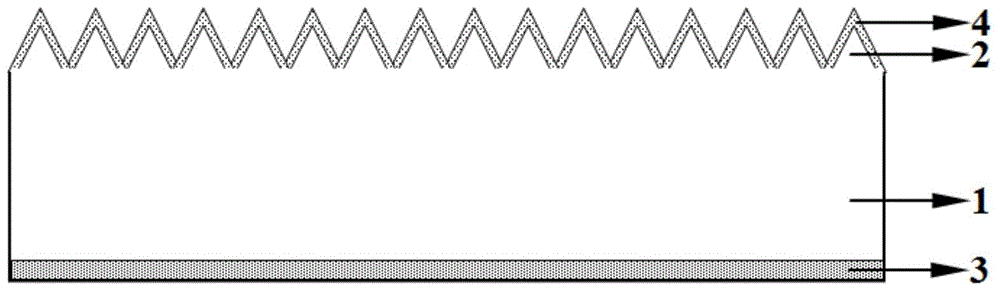

Laser welding method for high-reflection metal parts

ActiveCN104117776AReduce reflectivityImprove absorption rateCell component detailsWelding/soldering/cutting articlesLaser technologyOptoelectronics

The invention is applicable to the technical field of lasers and discloses a laser welding method for high-reflection metal parts. The laser welding method is used for welding a first connecting piece and a second connecting piece made of high-reflection metal materials. The laser welding method comprises the following steps of texturing processing, clamping, laser welding and withdrawing, wherein in the texturing processing step, the welding surface of the first connecting piece and / or the welding surface of the second connecting piece is subjected to texturing processing, and a texturing structure and an oxide film layer are formed on the welding surface of the first connecting piece and / or the welding surface of the second connecting piece; in the clamping step, a fixture is used for tightly clamping the first connecting piece and the second connecting piece; in the laser welding step, a laser welding device is used for illuminating the texturing structure and the oxide film layer with lasers, and the first connecting piece and the second connecting piece are connected to form a welding assembly; in the withdrawing step, the fixture is loosened, and the welding assembly is withdrawn. The laser welding method successfully solves the problems that in the prior art, when the laser welding technology is adopted to weld the high-reflection metal parts, the laser reflectivity is high, the welding energy is high, and the welding quality is poor.

Owner:HANS LASER TECH IND GRP CO LTD

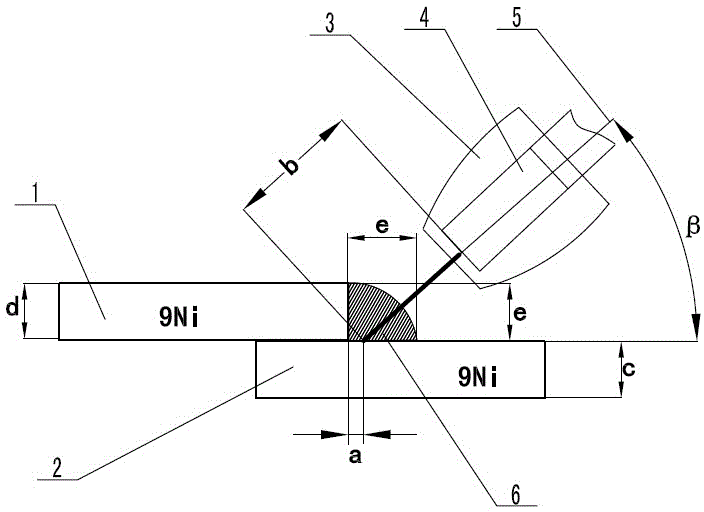

Welding technique for base plate of LNG low-temperature tank

InactiveCN104625359ASatisfy the pressure bearing capacity requirementsHigh hardnessArc welding apparatusDomestic vesselsFillet weldCurrent range

The invention discloses a welding technique for a base plate of an LNG low-temperature tank and belongs to the technical field of welding of LNG low-temperature tanks. According to the welding technique, two 9Ni steel plates with the thicknesses ranging from 6 mm to 9 mm are made to be in lap joint in the horizontal direction and overlap to form an overlap joint, the end face is cleaned, a preparation for welding is made, and then submerged-arc welding is conducted by means of alternating current, wherein the arc voltage ranges from 25 V to 29 V, the welding current ranges from 260 A to 290 A, the wire extension length ranges from 25 mm to 35 mm, the welding speed ranges from 22 in / min to 25 in / min, the welding wire angle ranges from 55 degrees to 65 degrees, and a full fillet weld with a welding foot with the length ranging from 6 mm to 9 mm is formed. By the adoption of the welding technique, submerged-arc welding of the base plate of the LNG low-temperature tank can be achieved, the problems that during submerged-arc welding, a lap fillet weld is poorly formed, hot cracks are formed during welding, and burning through occurs easily during welding are solved, the two 9Ni steel plates with the thicknesses ranging 6 mm to 9 mm can be welded in a single-pass mode at a time during actual operation, and welding efficiency is remarkably improved.

Owner:SINOPEC TENTH CONSTR

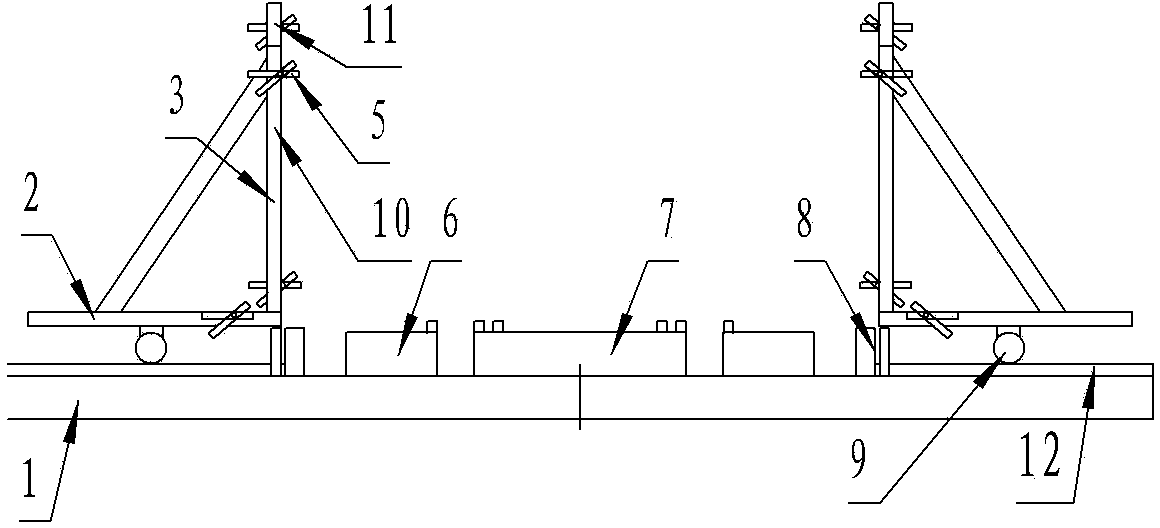

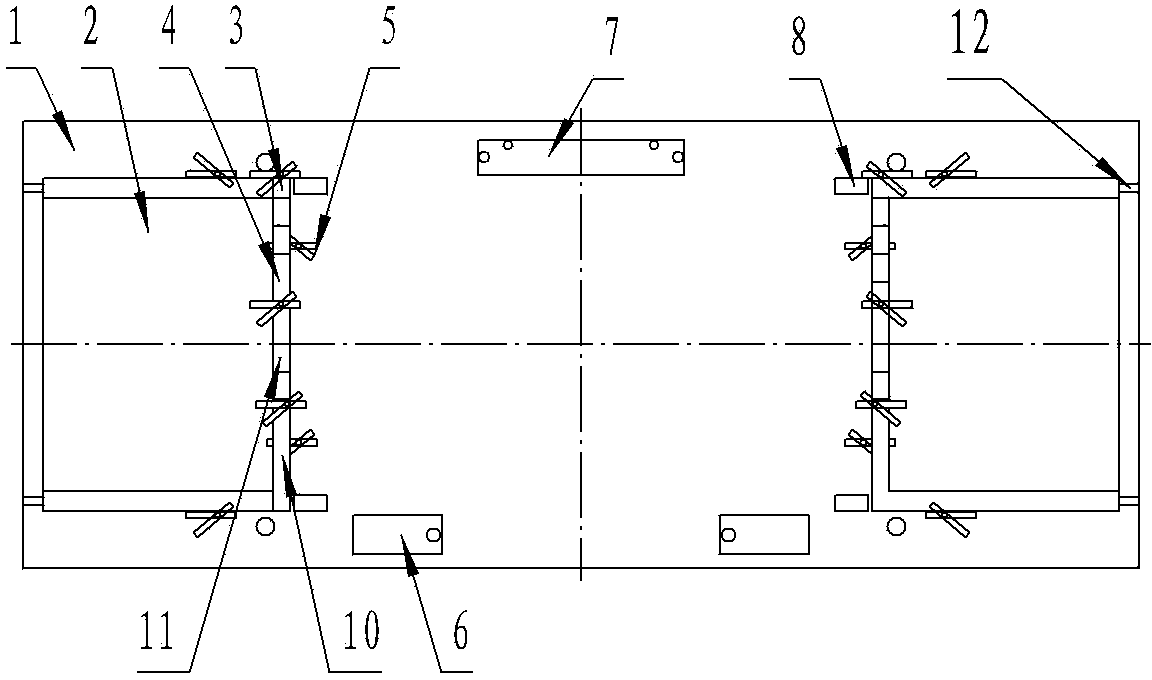

Agricultural vehicle cab welding method

InactiveCN104400282AGuaranteed positioning accuracyGuaranteed welding process requirementsWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringWelding

The invention discloses an agricultural vehicle cab welding method. An agricultural vehicle cab comprises a left side surrounding plate, a right side surrounding plate, a front plate, a back plate, a top plate and a baseplate; an agricultural vehicle cab welding tool is used for processing the agricultural vehicle cab, and comprises a base provided with a guide rail; and the base is symmetrically provided with a left positioning frame and a right positioning frame having walking wheels at the bottoms, positioning blocks between the two positioning frames, and multiple positioning clamps on the positioning frames. The method comprises the processing steps of: positioning and clamping the baseplate; positioning, clamping and welding the front plate, the back plate and the top plate; welding the two side surrounding plates; and loosening the positioning clamps, removing the positioning frames and unloading workpieces. The agricultural vehicle cab welding method can solve the problems of low welding quality and low efficiency of a traditional agricultural vehicle cab.

Owner:广西竞驰新能源汽车制造有限公司

Soldering structure between a tab of a bus bar and a printed substrate

InactiveUS20050048825A1Avoid applicationLow costPrinted circuit assemblingLine/current collector detailsEngineeringConductive materials

A soldering structure between a tab of a bus bar and a printed substrate is disclosed to provide a soldering structure between a tab of a bus bar and a printed substrate that causes no crack. An electrical conductive material is formed on a printed substrate. A tab through-hole is provide to penetrate the electrical conductive material and printed substrate. A tab formed by bending a body of the bus bar enters the tab through-hole. A periphery of the tab and the electrical conductive material are interconnected by soldering. A stress-absorbing aperture or recess is provided in an insulation plate on which the body of the bus bar is mounted. The stress-absorbing aperture or recess can absorb an axial stress caused in the tab.

Owner:SUMITOMO WIRING SYST LTD

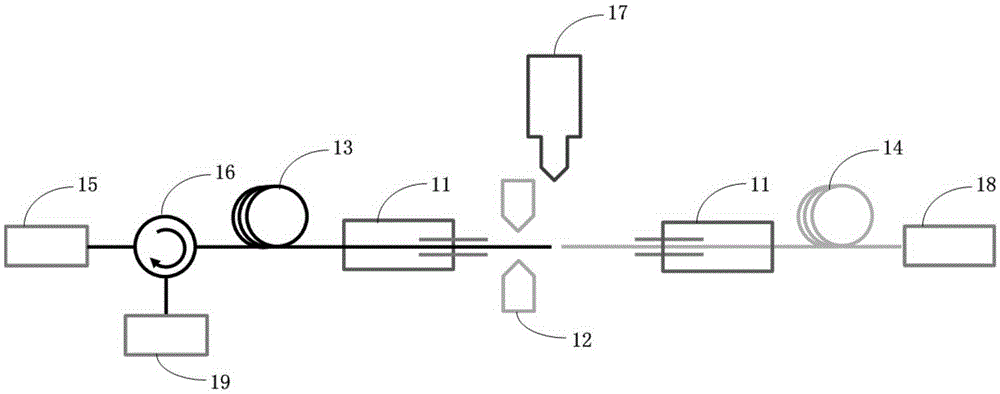

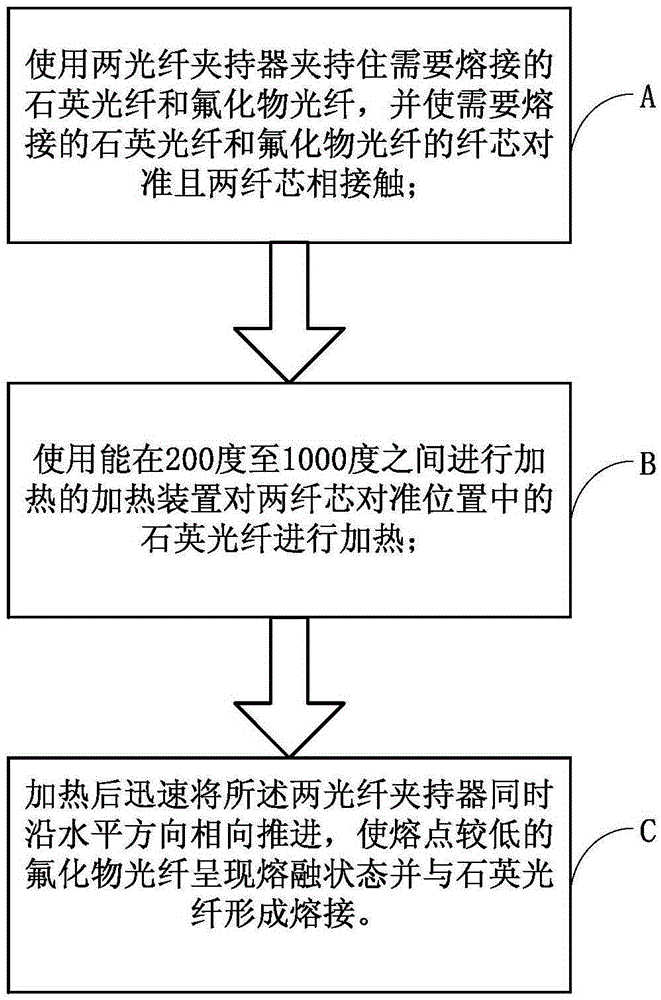

Fluoride fiber and quartz fiber fusing equipment and fusing method

The invention is applicable to the technical field of generation and applications of high-power mid-infrared fiber lasers and mid-infrared super-continuum spectrum source, and provides fluoride fiber and quartz fiber fusing equipment, which comprises two fiber holders and a heating device, wherein the heating device is arranged at the place where the quartz fiber and the fluoride fiber are in butt joint and close to the quartz fiber side for heating the quartz fiber, and the heating temperature is higher than a melting point of the fluoride fiber and lower than the melting point of the quartz fiber; and the two fiber holders hold the quartz fiber and the fluoride fiber respectively, adjustment is carried out in X, Y and Z directions to enable fiber cores of the quartz fiber and the fluoride fiber to be aligned and the two fiber cores are contacted, and after heating, the two fiber holders are pushed in a face to face mode along the horizontal direction to enable the fiber core of the quartz fiber and the fiber core of the fluoride fiber to be fused. The fusing equipment simplifies the fusing process, the fusing cost is low, and the fusing point after fusing has the advantages of low loss, high strength, high power resistance and the like.

Owner:SHENZHEN UNIV

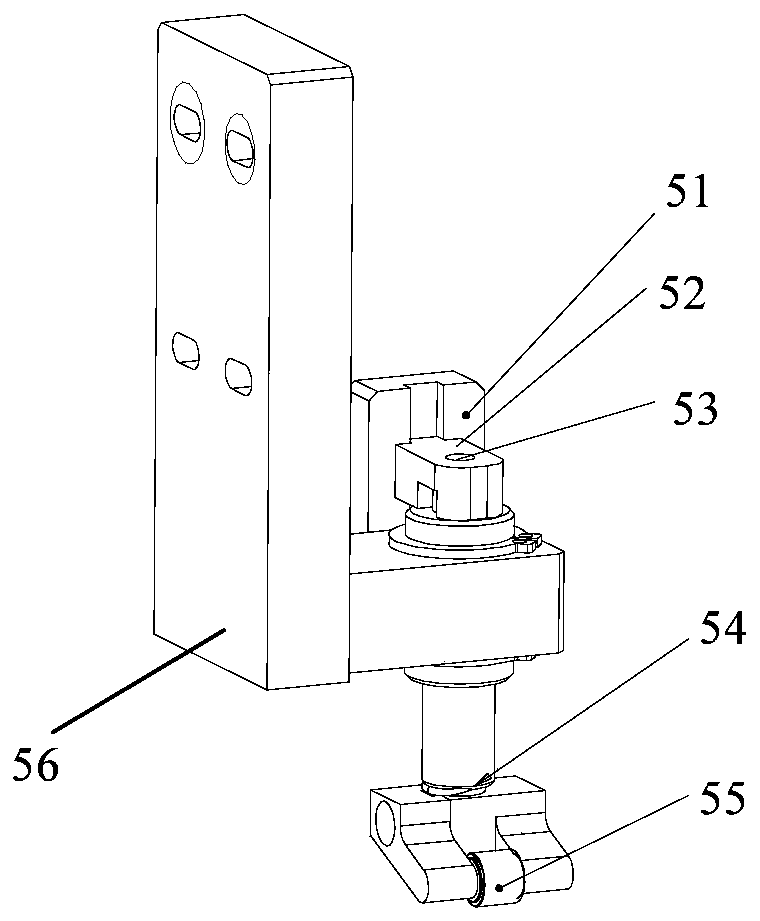

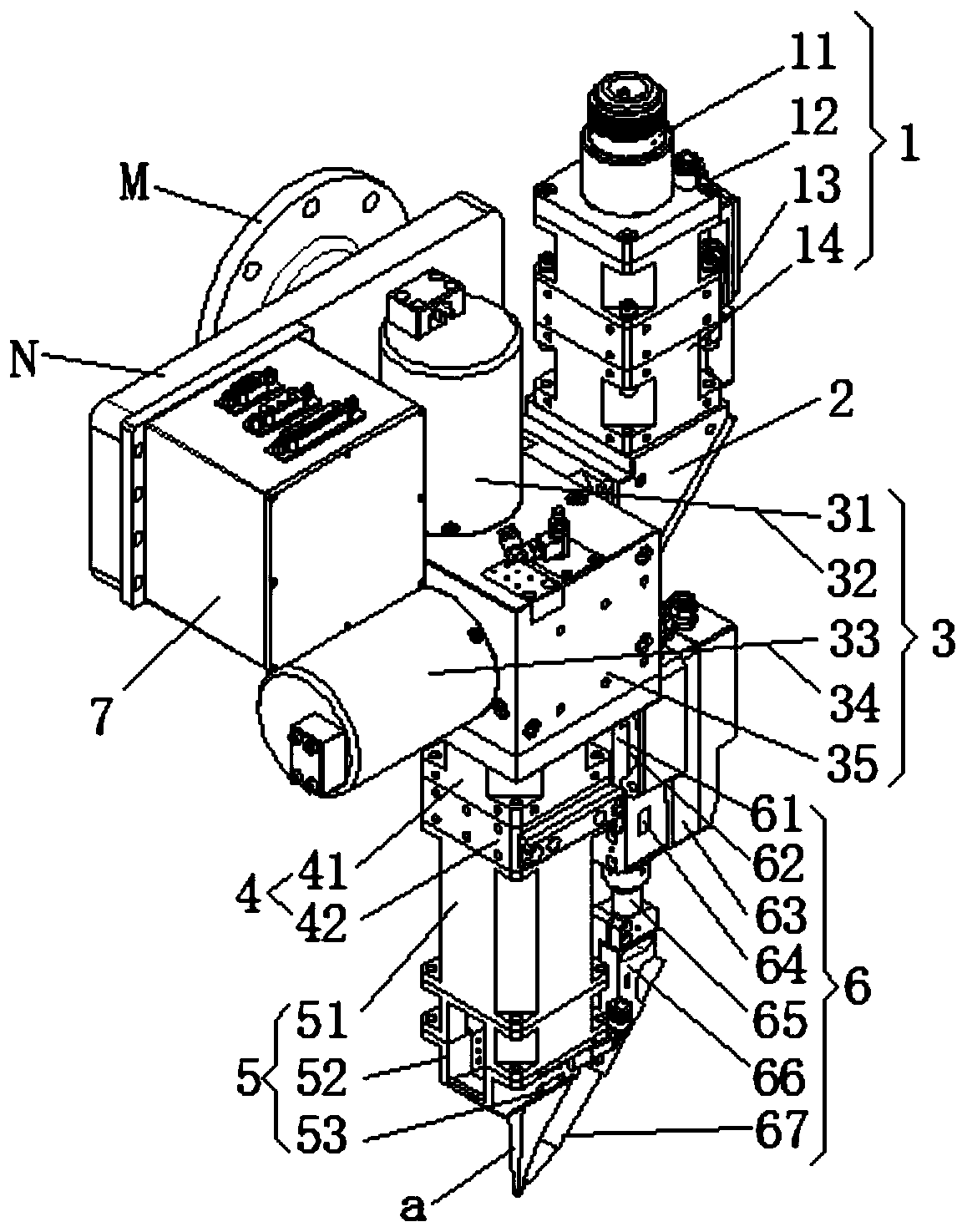

Laser stirring welding device with tactile tracking

ActiveCN111331248AImprove efficiencySimple structureLaser beam welding apparatusNumerical controlElectric machinery

The invention discloses a laser stirring welding device with tactile tracking. The laser stirring welding device with tactile tracking comprises a shell, a collimating assembly, a mirror group, a numerical control mirror assembly, a focusing assembly and a tactile tracking assembly. The collimating assembly comprises an optical fiber interface and a collimating mirror; the mirror group comprises afixed mirror installed in the shell; the numerical control mirror assembly comprises a numerical control mirror and a numerical control mirror driving mechanism. A focusing mirror group comprises a focusing mirror installed in the shell; the tactile tracking assembly comprises a swinging seat, a motor, a guide pin and an encoder, and the guide pin is installed on the swinging seat; and the encoder is connected with a motor shaft of the motor. A control box assembly drives the numerical control mirror to rotate through the driving mechanism, so that spot formed by the concentrated laser on a workpiece is moved to the specified position, and the workpiece is welded by different laser stirring trajectory patterns according the requirements. Irregular welding seams can be compensated and tracked in real time, stability and reliability are achieved, the efficiency is relatively high, energy can be evenly distributed in wide welding seams, and relatively large depth of fusion is achieved.

Owner:武汉新耐视智能科技有限责任公司

Method for welding cast iron by use of carbon dioxide gas

The invention relates to a method for welding cast iron by use of carbon dioxide gas. The method is characterized by comprising the following steps: 1) eliminating cracks on a repair welding part and drilling crack-stopping holes on the cracks at the ends of the cracks; 2) providing the repair welding part with a groove; 3) choosing welding wires 0.6 to 1.0 mm in diameter; and 4) using a CO2 gas method for welding. The method is suitable for welding large cast iron workpieces, and has the advantages of low production cost and good machining properties.

Owner:CHONGQING JIANSHE MOTORCYCLE CO LTD

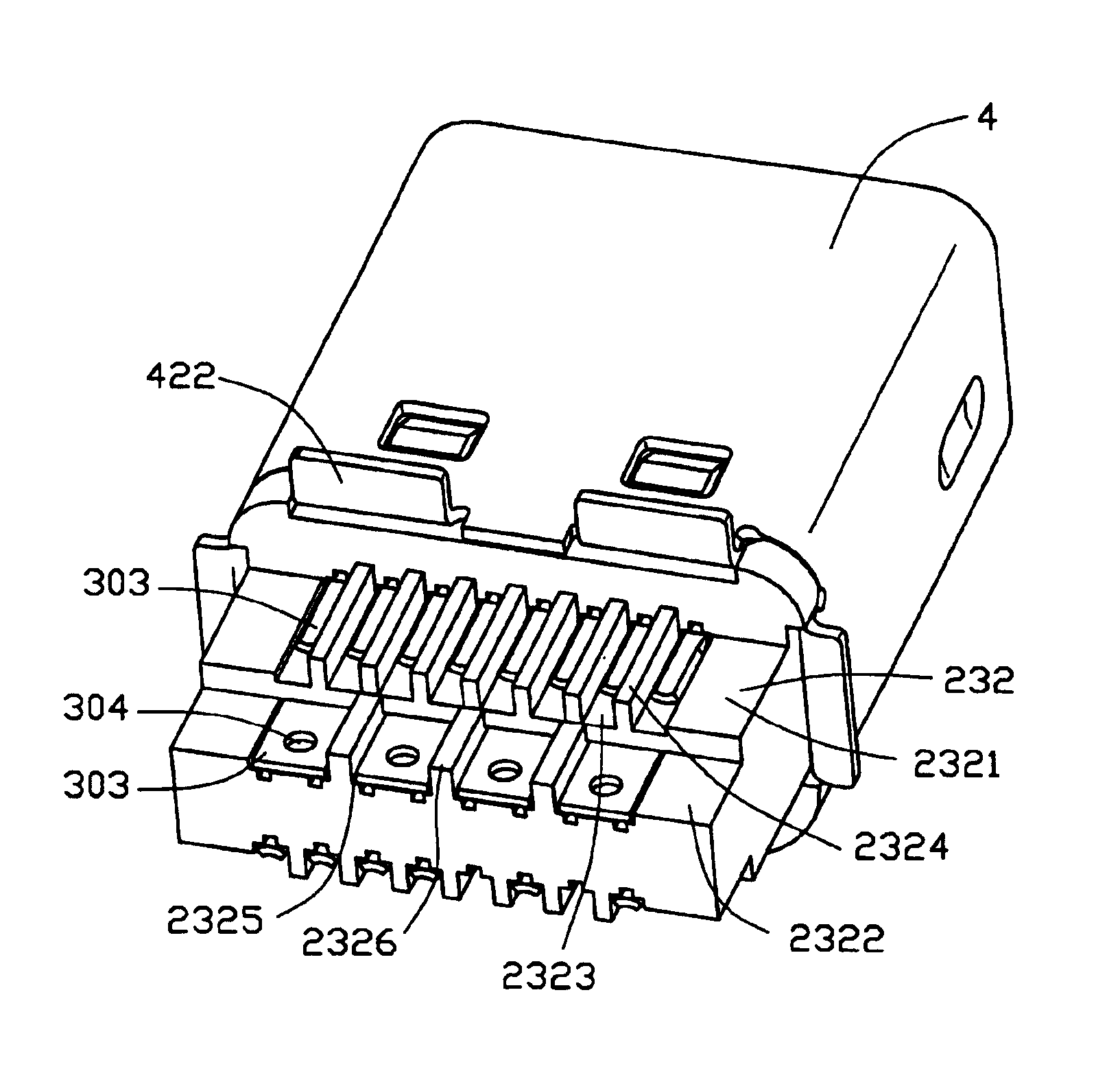

Electrical connector

InactiveUS20120052726A1Simple processImprove assembly accuracyCoupling protective earth/shielding arrangementsElectrical connectorSoldering process

An electrical connector has an insulating housing. The insulating housing has a base. At least one positioning block is protruded from a front of the base and separates the base into several equal parts. A plurality of terminals is mounted into the insulating housing. A connecting element is fixed on the positioning block. A shielding shell wraps the insulating housing. The positioning block cooperates with the shielding shell to form receiving spaces for receiving plug connectors. So, the electrical connector is capable of receiving multiple plug connectors. Meanwhile, the electrical connector simplifies the soldering process while assembling multiple connectors, and also, improves the assembly accuracy.

Owner:CHENG UEI PRECISION IND CO LTD

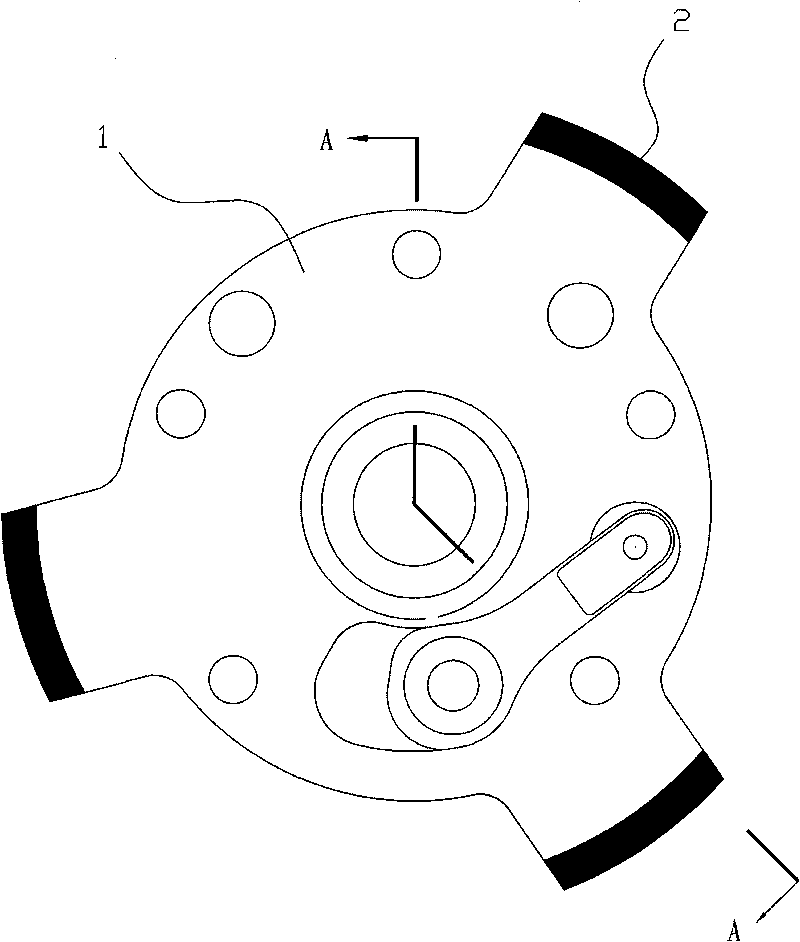

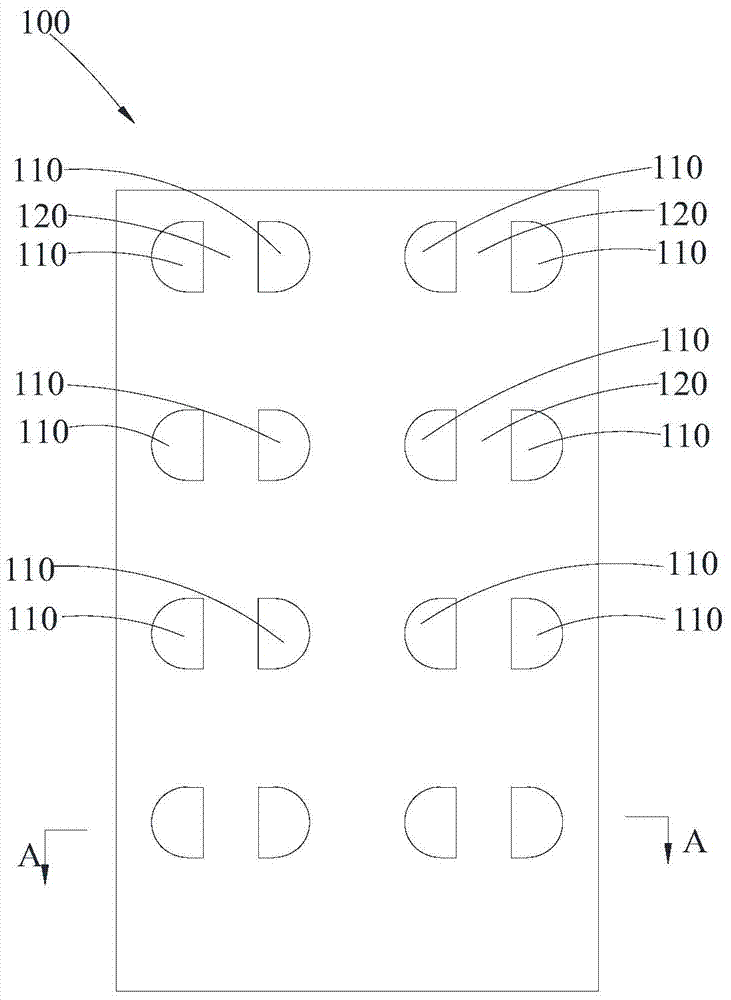

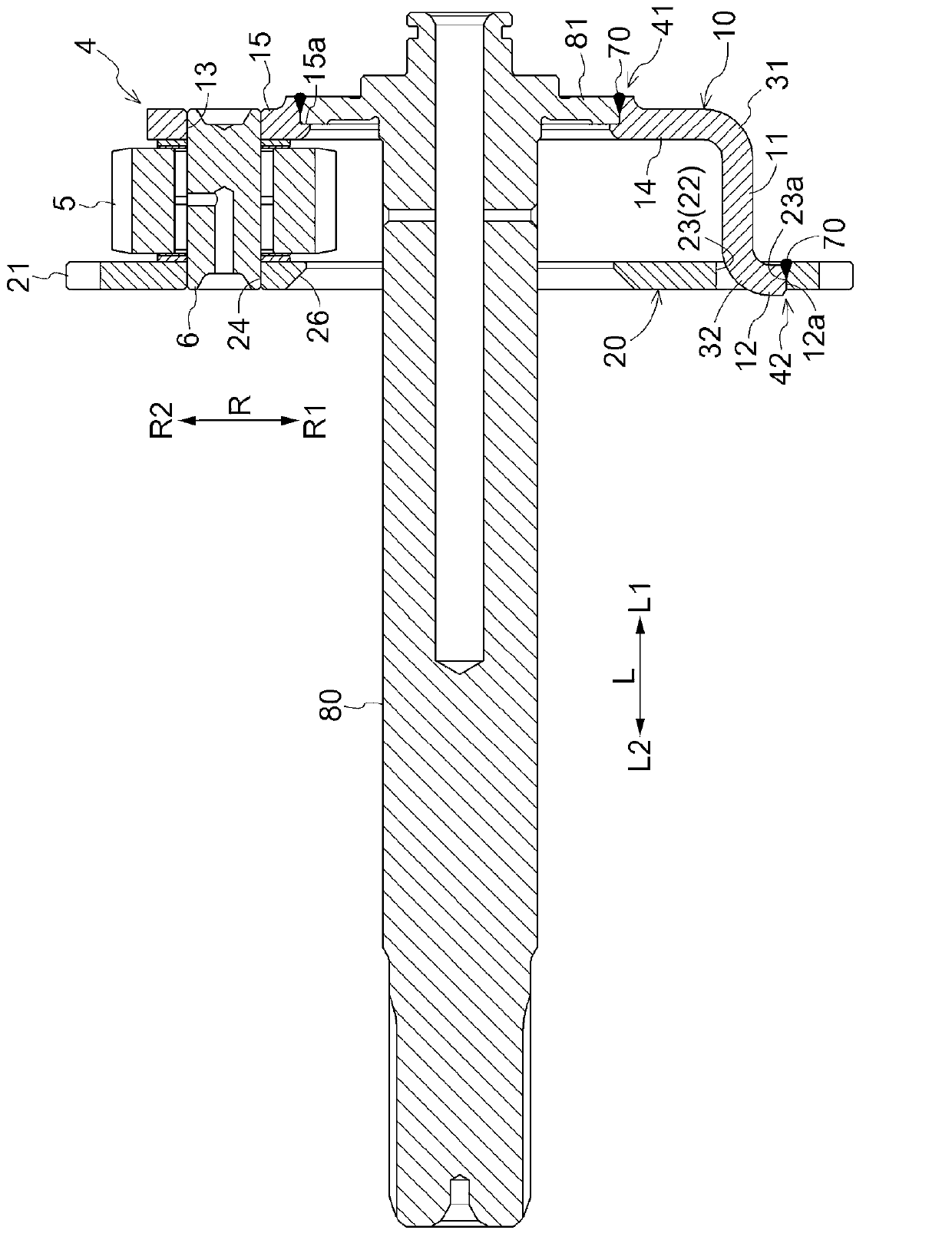

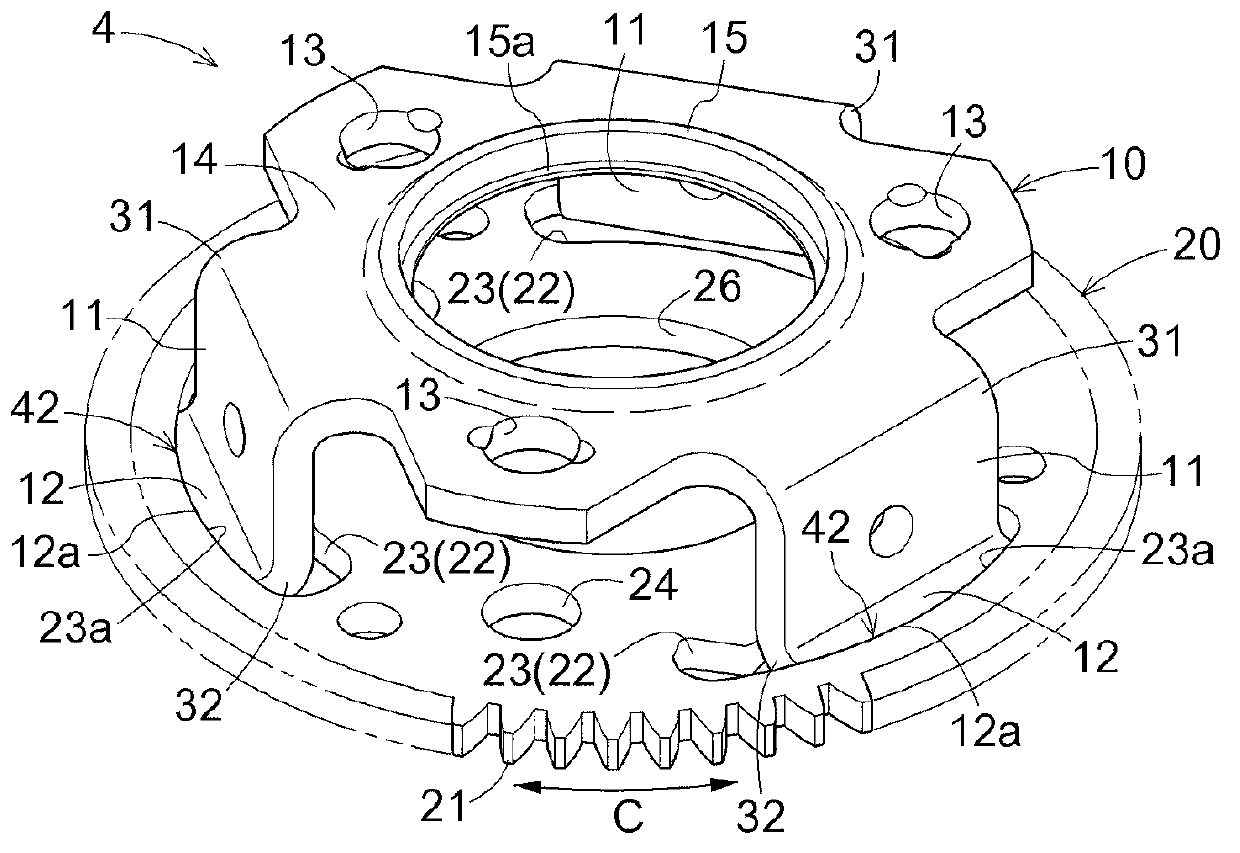

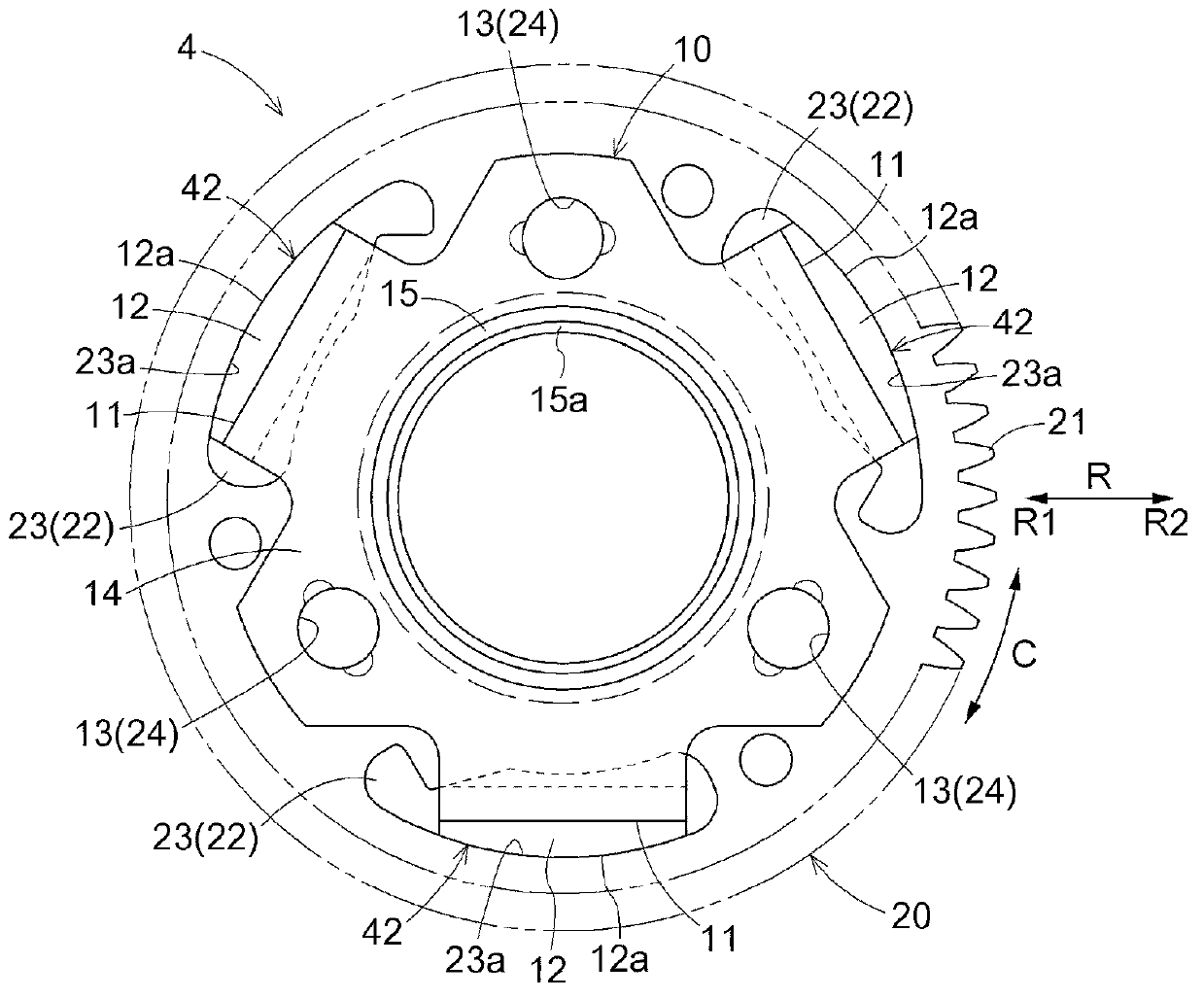

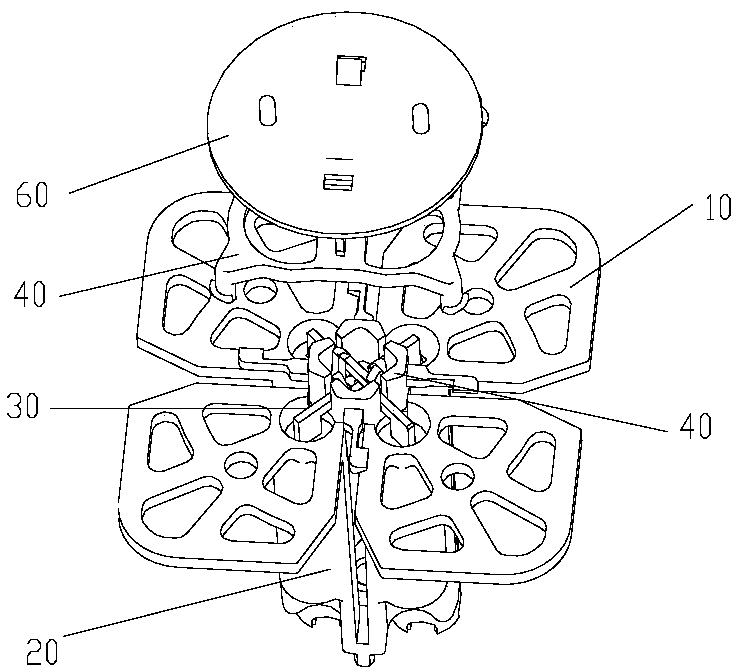

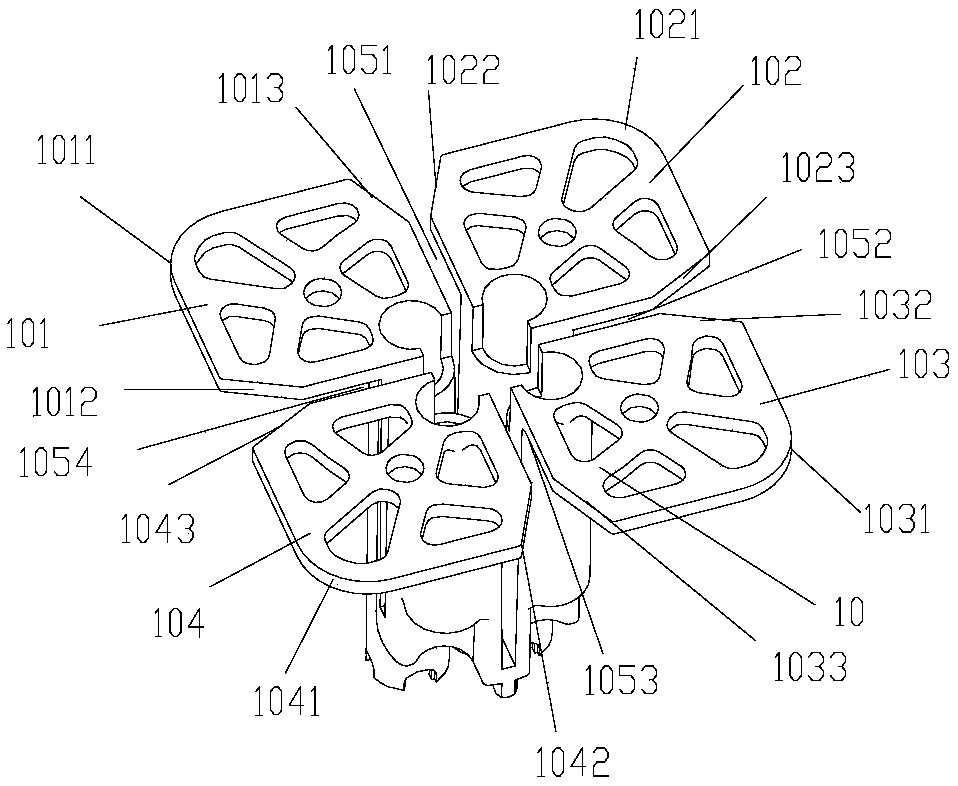

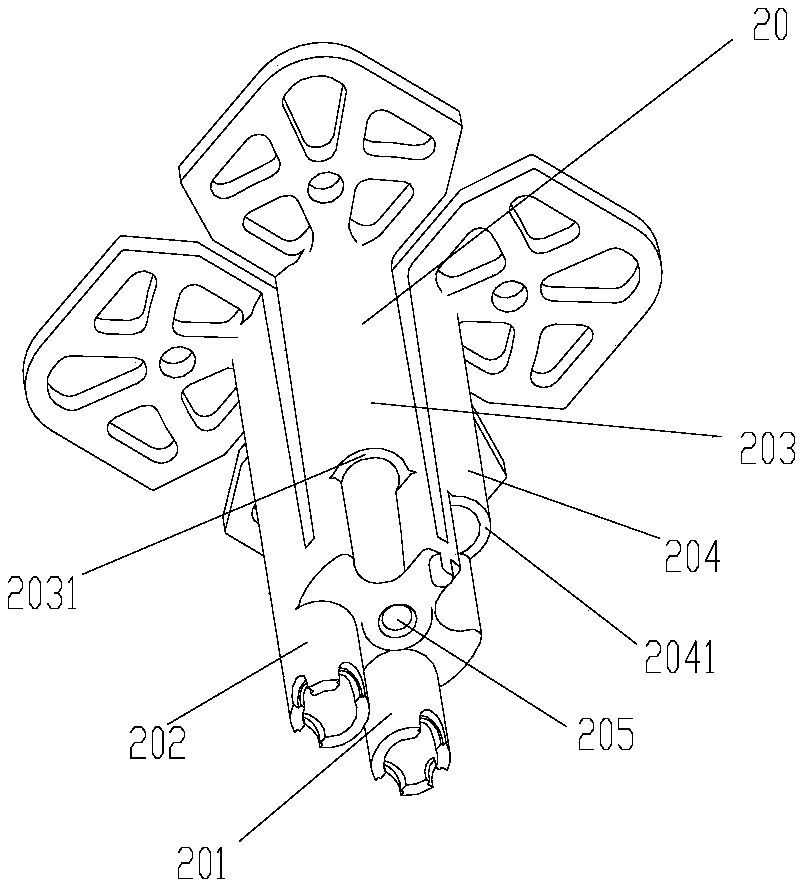

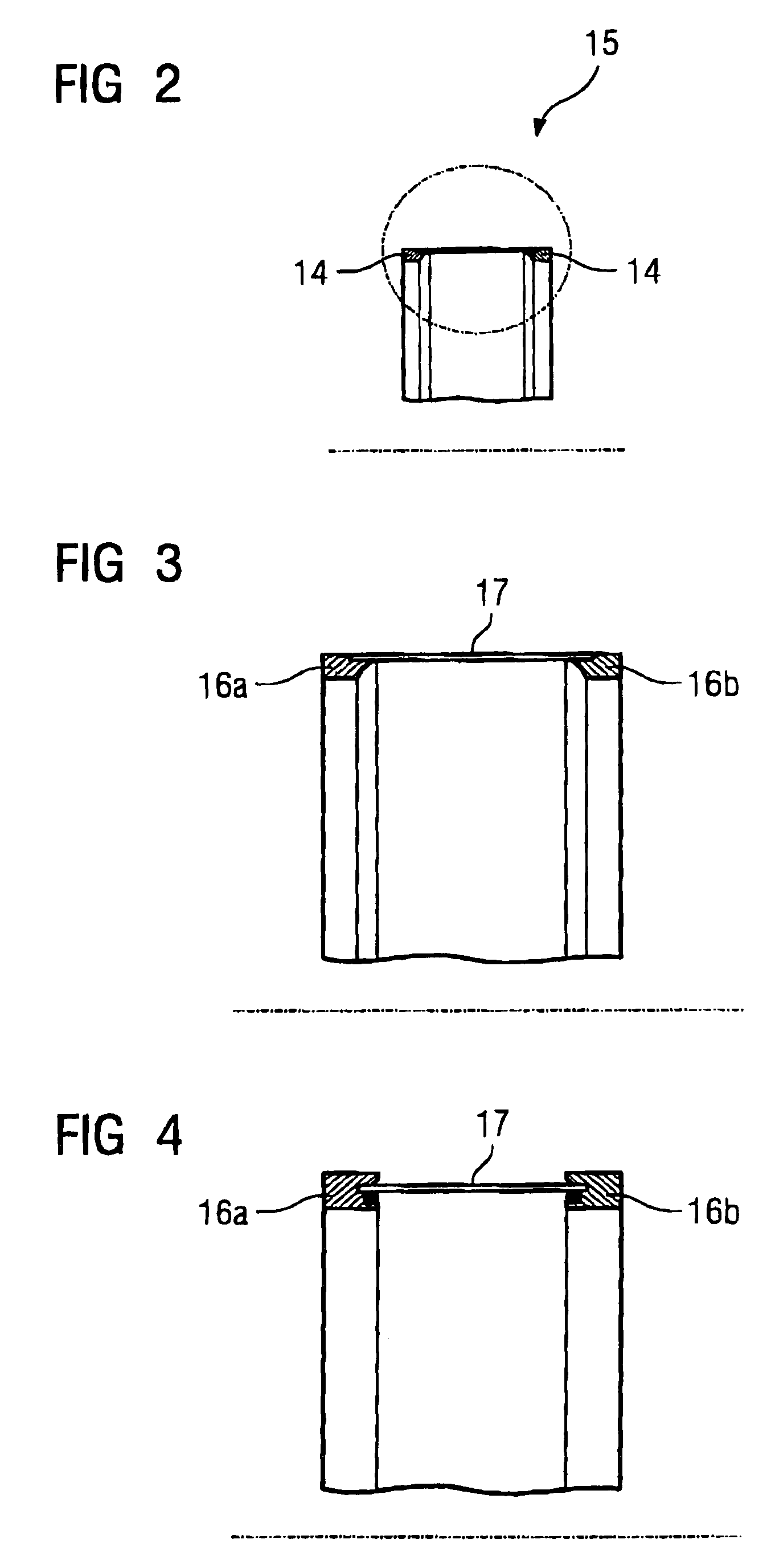

Planetary carrier

ActiveCN103328864ASimplify the welding processSuppress manufacturing costGearing detailsEngineeringPinion

A planetary carrier having a reduced number of parts and a reduced number of joining steps is provided. The planetary carrier is provided with a pair of holding members for holding a pinion shaft (6), which supports a pinion gear (5), from both sides in the axial direction (L). A first holding member (10), which is one of the pair of holding members, is provided with connection sections (11) extending in the axial direction (L) toward a second holding member (20), which is the other of the pair of holding members. The second holding member (20) is a circular plate-shaped member and has an externally toothed outer peripheral gear (21) formed integrally with the outer periphery of the second holding member (20). The connection sections (11) and connection joint sections (22) provided in the second holding member (20) at positions on the inner side (R1) of the outer peripheral gear (21) in the radial direction are joined together.

Owner:AISIN AW CO LTD +1

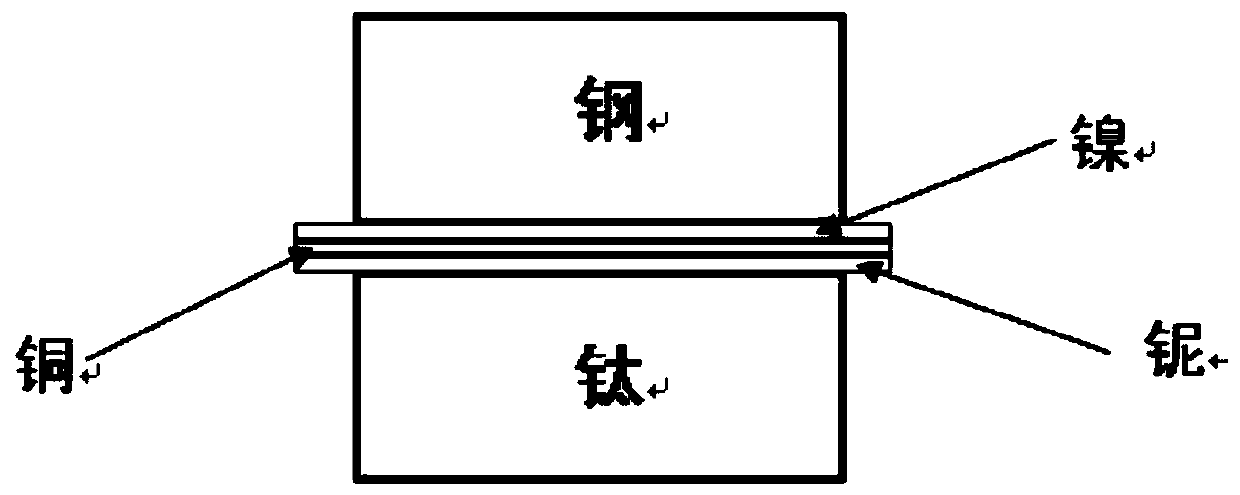

High-strength diffusion connection method for titanium-steel alloy

ActiveCN110238504AHigh strengthReduce distortionWelding/soldering/cutting articlesNon-electric welding apparatusCompound aNiobium

The invention relates to a high-strength diffusion connection method for a titanium-steel alloy, and belongs to the technical field of welding. The method comprises the following steps that a composite intermediate layer is increased between the welding surface of a titanium alloy welding part and the welding surface of a steel alloy welding part, and then placed in a vacuum diffusion furnace for diffusion connection, so that the titanium alloy welding part and the steel alloy welding part are connected into an integrated structure through the composite intermediate layer, wherein the composite intermediate layer is formed by compounding a nickel foil, a copper foil and a niobium foil. Nickel, copper and niobium are adopted as the composite intermediate layer, and the composite intermediate layer is in diffusion connection with the titanium alloy and the steel alloy, so that the connection strength of the titanium alloy and the steel alloy is improved, and the method can meet the manufacturing technical requirements in the field of high-end equipment such as aviation and spaceflight.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Electrical connector

InactiveUS6953367B2Simplify the welding processElectric discharge tubesCouplings bases/casesElectrical connectorElectrical and Electronics engineering

An electrical connector (1) includes a housing (2), a number of contacts (3) received in the housing, and a shell (4) retained to the housing. The housing includes a main body (21), a first and a second tongues (22, 24) extending forwardly from the main body, and a mounting portion (23) extending rearwardly form the main body. The first and the second tongues define a number of passageways extending rearwardly throughout the main body. The mounting portion has a first and a second faces (2311,2312) on a first side (231), a third and a fourth faces (2321, 2322) on a second side (232), and a number of channels on the first, the second, the third and the fourth faces and communicating with the passageways. The second and the fourth faces are behind and offset from the first face and the third faces respectively.

Owner:HON HAI PRECISION IND CO LTD

Broadband dual-polarization radiation unit and antenna

ActiveCN109286067AAvoid performance degradationSimplify the assembly processAntenna supports/mountingsRadiating elements structural formsNested arraysBroadband

The invention discloses a broadband dual-polarization radiation unit and an antenna. The broadband dual-polarization radiation unit comprises a radiation arm group, a balance-imbalance converter, a feed sheet group, a coupling plastic member, a supporting plastic member and a parasitic sheet, wherein the radiation arm group includes two pairs of sub-radiation arm groups which are placed at +45 degrees and -45 degrees and are in 90-degree rotational symmetry relative to the center of the radiation unit, and each pair of the sub-radiation arm groups is composed of two sub-radiation arms which are diagonally arranged; the balance-imbalance converter is connected with and supports the radiation arm group to form a main body part of the radiation unit, and the overall height is about 1 / 4 of thespatial wavelength of the broadband dual-polarization radiation unit at a low frequency; the feed sheet group includes an upper feed sheet and a lower feed sheet and is fixed by the coupling plasticmember so as to realize non-direct connection between the feed sheet group and the sub-radiation arms; and the supporting plastic member and the parasitic sheet are arranged on the radiation arm group, and the supporting plastic member is fixed on the radiation arm group. The broadband dual-polarization radiation unit solves performance deterioration of the radiation unit after nested array arrangement in the prior art, and the assembly process is simplified at the same time.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Tab limiting plate, battery module, battery pack and automobile

ActiveCN112542656AIncrease productivityShorten welding timeCell component detailsPower batteryEngineering

The invention discloses a tab limiting plate, a battery module, a battery pack and an automobile. A tab limiting plate main body comprises a base; the base is provided with more than two tab through holes and tab guide surfaces; the number of the tab guide surfaces is the same as that of the tab through holes; the positions of the tab guide surfaces are in one-to-one correspondence with the positions of the tab through holes; and at least one tab guide surface comprises a guide inclined surface, and the guide inclined surface inclines towards the same design position, so that a protruding partis formed on one surface of the base, and a limiting mechanism is arranged at the tip end of the protruding part and used for clamping the end part of a tab. According to the tab limiting plate provided by the invention, tabs of a plurality of flexibly-packaged battery cells in the same flexibly-packaged battery cell assembly can be intensively connected together in parallel in a designed postureto form a tab row; and when the flexibly-packaged battery cell assemblies are connected, the tabs of two adjacent flexibly-packaged battery cell assemblies can be intensively welded at one time; a plurality of flexibly-packaged battery cell tabs do not need to be welded respectively; and therefore, the welding time is shortened, the welding process is simple, and the production efficiency of thepower battery is improved.

Owner:DONGFENG MOTOR CORP HUBEI

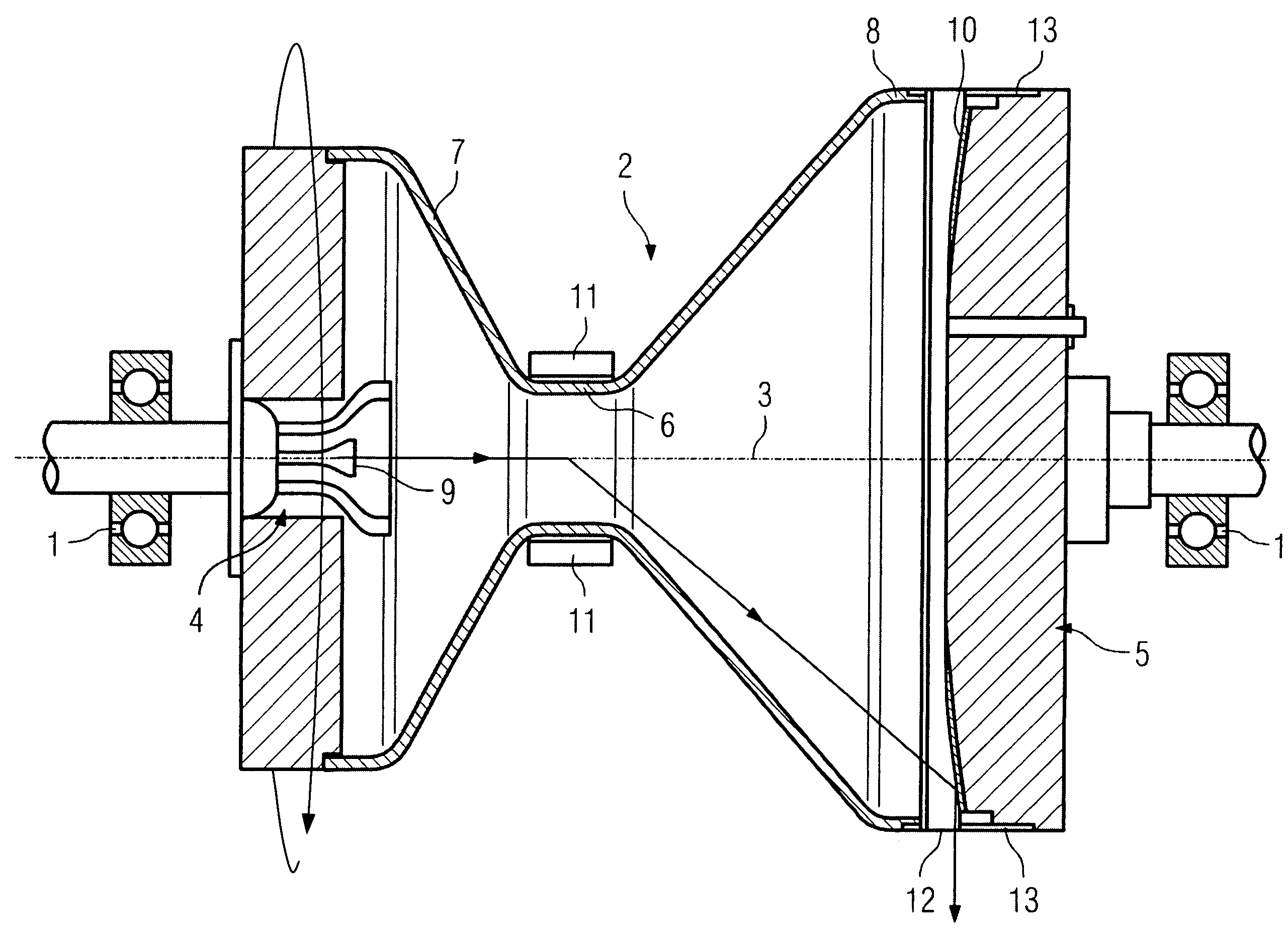

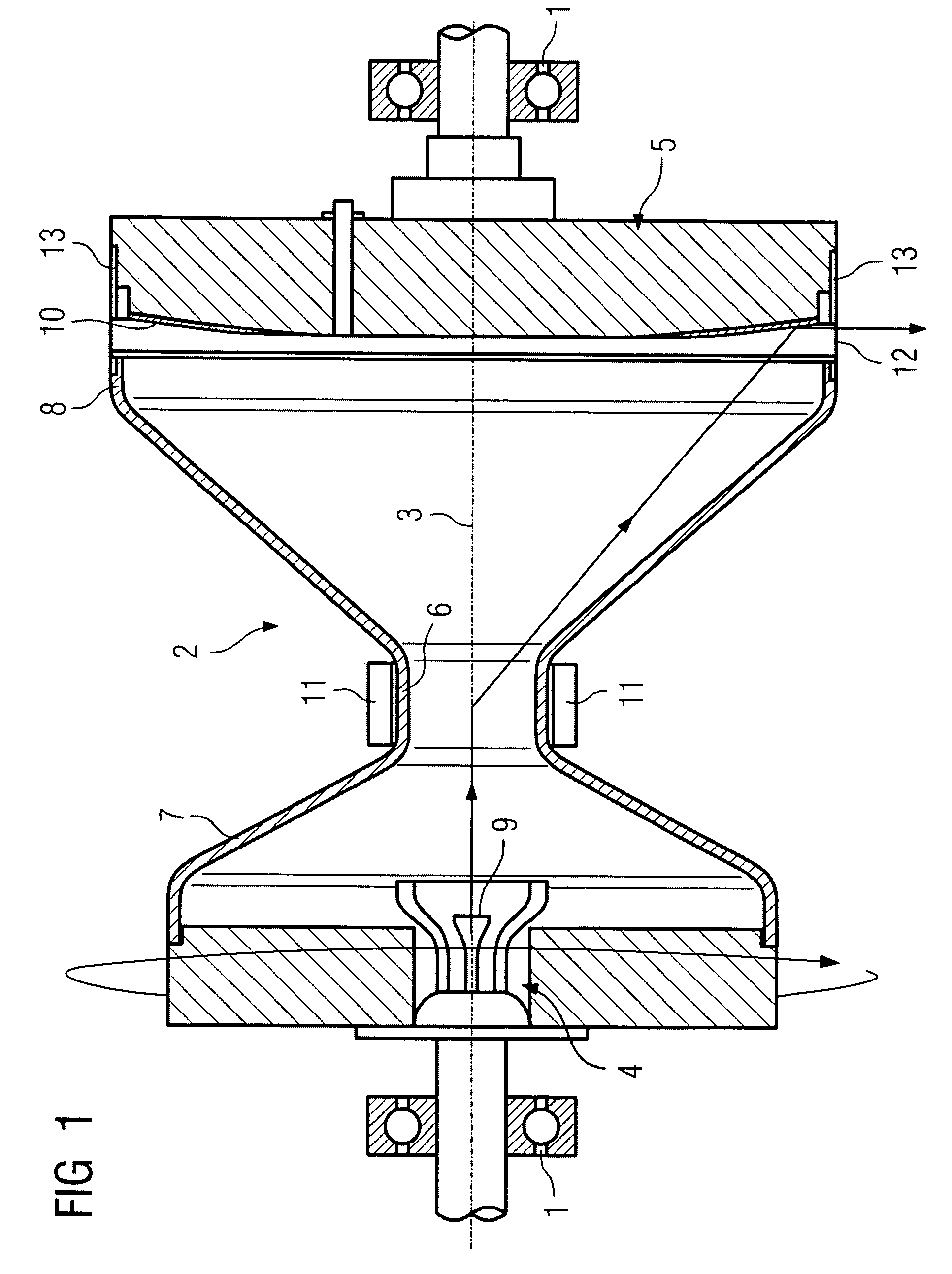

Rotary piston tube for an X-ray radiator

ActiveUS7103146B2Rigid enoughSimplify the welding processRadiation/particle handlingX-ray tube electrodesX-rayTitanium

A rotary piston tube for an x-ray radiator is provided in which the vacuum housing, accommodating an anode and a cathode and displaceable in rotation, comprises a 360° all-around ray exit window. For optimization of the ray exit window, this is produced according to one of the subsequently stated material specifications: a) a high-temperature steel or a high-temperature chromium and / or nickel alloy, listed in the standard EN 10273 and EN 10302, at a wall thickness between 0.1 to 0.4 mm; b) a titanium material at a wall thickness between 0.2 and 2 mm; and c) a ceramic material at a wall thickness between 1 mm and 5 mm.

Owner:SIEMENS HEALTHCARE GMBH

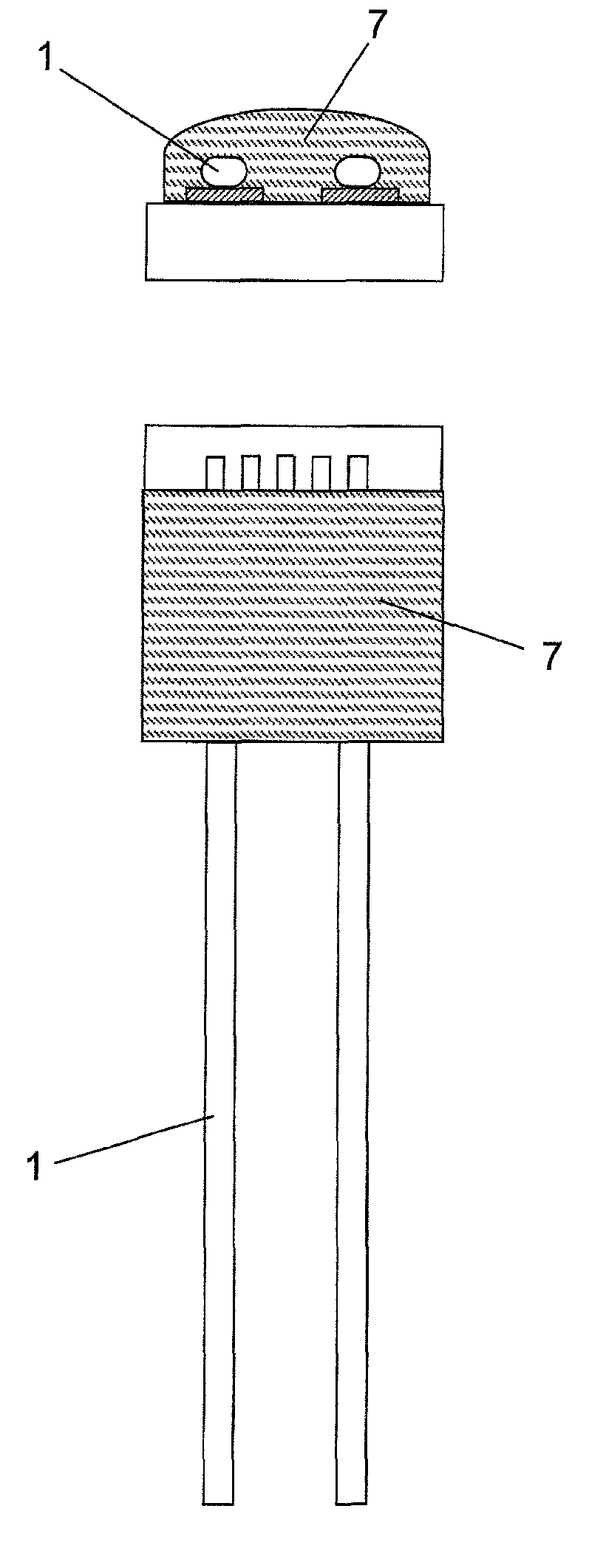

Coated wire and film resistor

ActiveUS8138881B2Simplify connecting linesSimple methodCurrent responsive resistorsThermometers using electric/magnetic elementsThin metalElectrical conductor

A coated wire is solderable with soft solder while maintaining separate phases of the core and the coating. A 100 μm to 400 μm thick nickel wire may be coated galvanically with silver. For a film resistor with coated wires as connection wires, including a platinum measurement resistor on an electrically insulating substrate and connection wires connected to the measurement resistor, the connection wires have a coated nickel core. The coating may be made of silver or glass or ceramic or a mixture of these materials, or on its outside may be made of glass or ceramic or a mixture of these materials. For producing film resistors a thin metal or glass component is deposited on a connection wire connected to a track conductor arranged on an electrically insulating substrate, and a thick glass paste is deposited and fired on this metal or glass component. For mass production of film, several film resistors encased together in glass may be partitioned by fracturing.

Owner:HERAEUS NEXENSOS GMBH

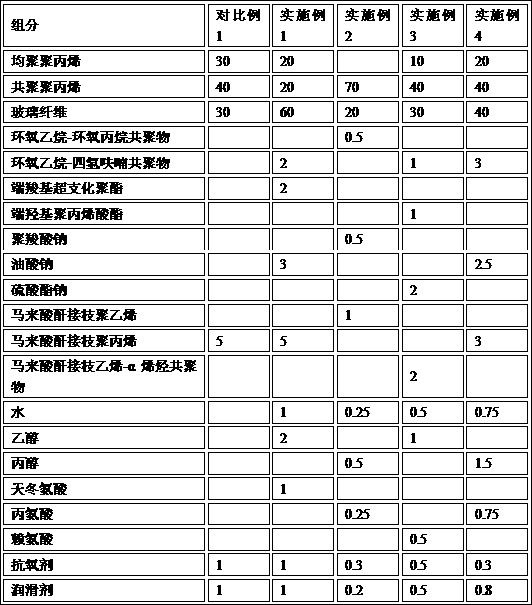

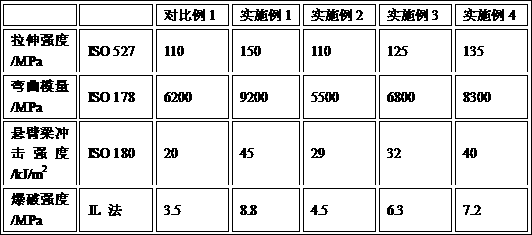

High-welding strength long glass fiber-reinforced polypropylene material and preparation method thereof

The invention relates to a long glass fiber-reinforced polypropylene material and a preparation method thereof, in particular to a high-welding strength long glass fiber-reinforced polypropylene material and a preparation method thereof. The material comprises the following components: in parts by weight, 40-70 parts of polypropylene, 20-60 parts of glass fiber, 0.5-4 parts of a hyperdispersant, 0.5-3 parts of a dispersion synergist, 1-5 parts of a compatilizer, 1-4 parts of a deodorant and 0.5-2 parts of other additives. It is ensured that the glass fiber in the long glass fiber-reinforced polypropylene has sufficient length, and meanwhile the dispersion efficiency of the glass fiber is higher, so that the problems of fiber emergence on surface of products and stacking of the long glass fiber are achieved; high welding strength can be achieved in the forming process of parts, excellent air tightness is achieved, and meanwhile the advantages of low odor and low VOC are achieved, so that requirements of environmental protection and emission of a host machine plant are met; and in addition, the long glass fiber-reinforced polypropylene material has high cost performance and easy industrialization.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com