Surfactant for magnesium alloy TIG welding and its prepn process and usage

A surfactant and magnesium alloy technology, applied in welding equipment, welding equipment, arc welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

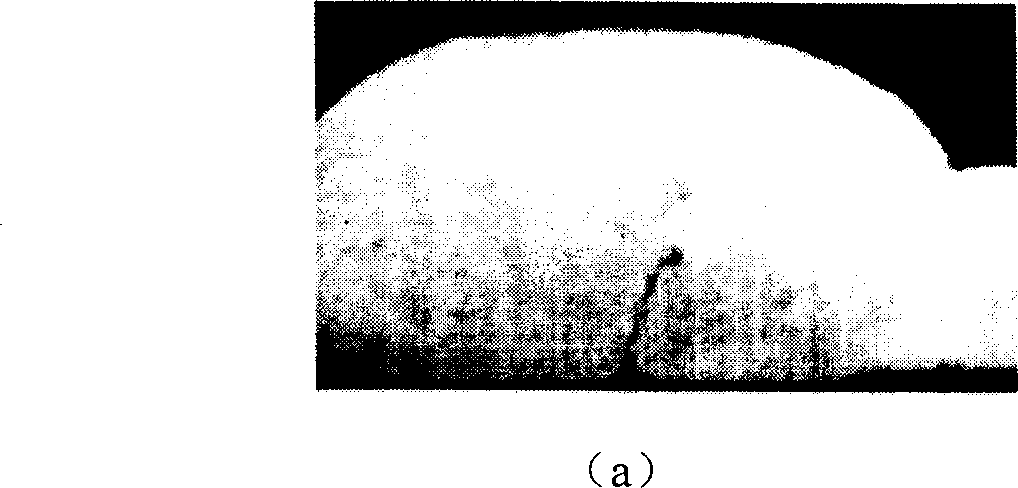

Image

Examples

example 1

[0019] Surfactant for magnesium alloy TIG welding (mass percentage): 40% CdCl 2 , 25%Cr 2 o 3 , 25%TiO 2 , 10% SiO 2 .

[0020] The surfactants configured according to the above ingredients were mixed and ball milled in a ball mill for 4 hours. The active agent after ball milling is mixed with acetone into a slurry that is easy to coat, and it is evenly coated on the surface of the weld bead of the magnesium alloy workpiece to be welded by spraying, and the coating amount is 2mg / cm 2 . The magnesium alloy workpiece is an AZ61 magnesium alloy extruded plate of 90mm×50mm×4mm, the joint form is a non-groove butt joint, the filler wire is AZ31 magnesium alloy, and the diameter of the welding wire is 2.5mm. NSA-400 AC argon arc welding machine is used on CZ-2 type welding trolley with pure Ar gas protection for welding (industrial argon welding is prone to porosity). The welding process parameters are welding current 100A, welding speed 270mm / min, The flow rate of argon gas ...

example 2

[0022] Surfactant for magnesium alloy TIG welding (mass percentage): 20% CdCl 2 , 35% ZnCl 2 , 15%Cr 2 o 3 , 20%TiO 2 , 10% SiO 2 .

[0023] The surfactants configured according to the above ingredients were mixed and ball milled in a ball mill for 4 hours. The active agent after ball milling is prepared with acetone into a slurry that is easy to apply, and is evenly applied to the surface of the weld bead of the magnesium alloy workpiece to be welded by brushing, and the coating amount is 4mg / cm 2 . The magnesium alloy workpiece is an AZ31 magnesium alloy extruded plate of 90mm×50mm×4mm, the joint form is a non-groove butt joint, the filler wire is AZ31 magnesium alloy, and the diameter of the welding wire is 2.5mm. NSA-400 AC argon arc welding machine is used on CZ-2 type welding trolley with pure Ar gas protection for welding (industrial argon welding is prone to porosity). The welding process parameters are welding current 100A, welding speed 270mm / min, The flow ra...

example 3

[0025] Surfactant for magnesium alloy TIG welding (mass percentage): 60% ZnCl 2 , 15%Cr 2 o 3 , 15%TiO 2 , 10% SiO 2 .

[0026] The surfactants configured according to the above ingredients were mixed and ball milled in a ball mill for 4 hours. The active agent after ball milling is mixed with acetone into a slurry that is easy to apply, and is evenly applied to the surface of the weld bead of the magnesium alloy workpiece to be welded by brushing, and the coating amount is 3mg / cm 2 . The magnesium alloy workpiece is a 90mm×50mm×10mm AZ31 magnesium alloy extruded plate, the joint form is non-groove butt joint, the filler wire is AZ31 magnesium alloy, and the diameter of the welding wire is 2.5mm. NSA-400 AC argon arc welding machine is used on the CZ-2 type welding trolley to use pure Ar gas protection for welding (industrial argon welding seams are prone to porosity). The welding process parameters are welding current 250A, welding speed 270mm / min, The flow rate of arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com