Method for preparing large-size silicon pore array

A large-size, silicon-hole technology, applied in the field of preparing large-size silicon-hole arrays, can solve the problems of high manufacturing cost and difficulty of large-size silicon-hole arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

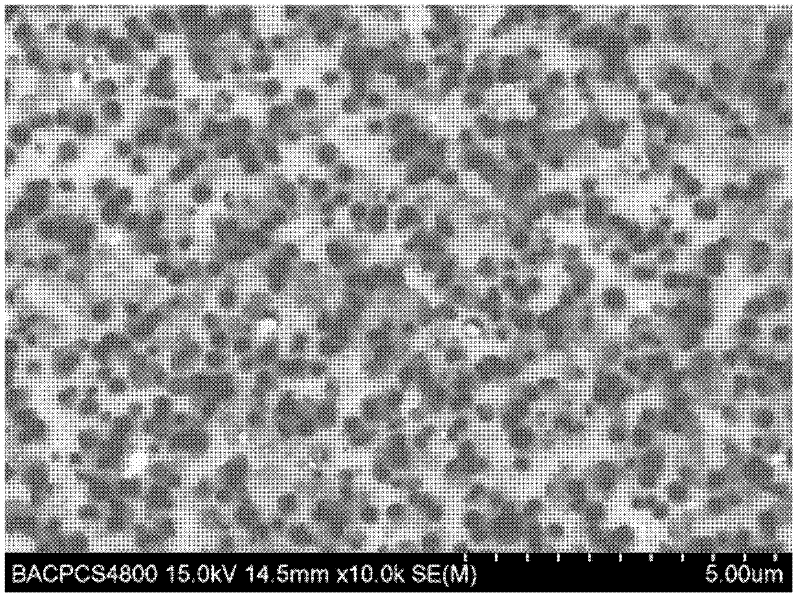

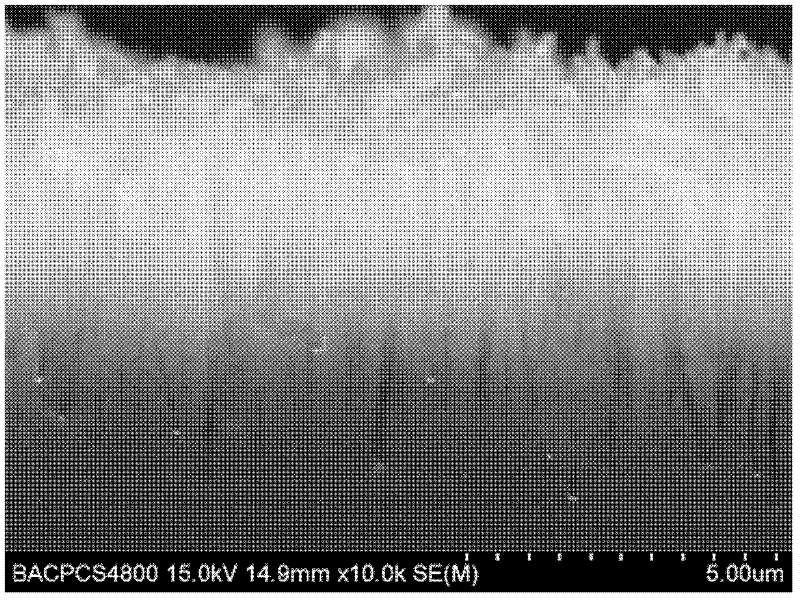

[0019] First, immerse a p-type silicon substrate with a resistivity of about 0.5Ω·cm into HF: AgNO 3 In the mixed aqueous solution, silver nanoparticles are deposited on the surface of the p-type silicon substrate. The HF: AgNO 3 In the mixed solution, the concentration of HF is 0.07M, AgNO 3 The concentration is 1×10 -3 M, the immersion time of the silicon substrate is 1 minute. Then the silicon substrate deposited with silver nanoparticles was immersed in HF:H 2 O 2 : H 2 Anodizing in O mixed solution, the HF:H 2 O 2 : H 2 The ratio of O mixture is 45:150:360 by volume, and the current density for anodizing is 0.06A / cm 2 , The corrosion time is 30 minutes. figure 1 with figure 2 The scanning electron microscope (SEM) photographs of the surface and cross-section of the silicon hole array prepared according to this embodiment are given. It can be seen that the diameter of the silicon hole array is about 200 nanometers and the depth is about 4 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com