Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Difficult to concentrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

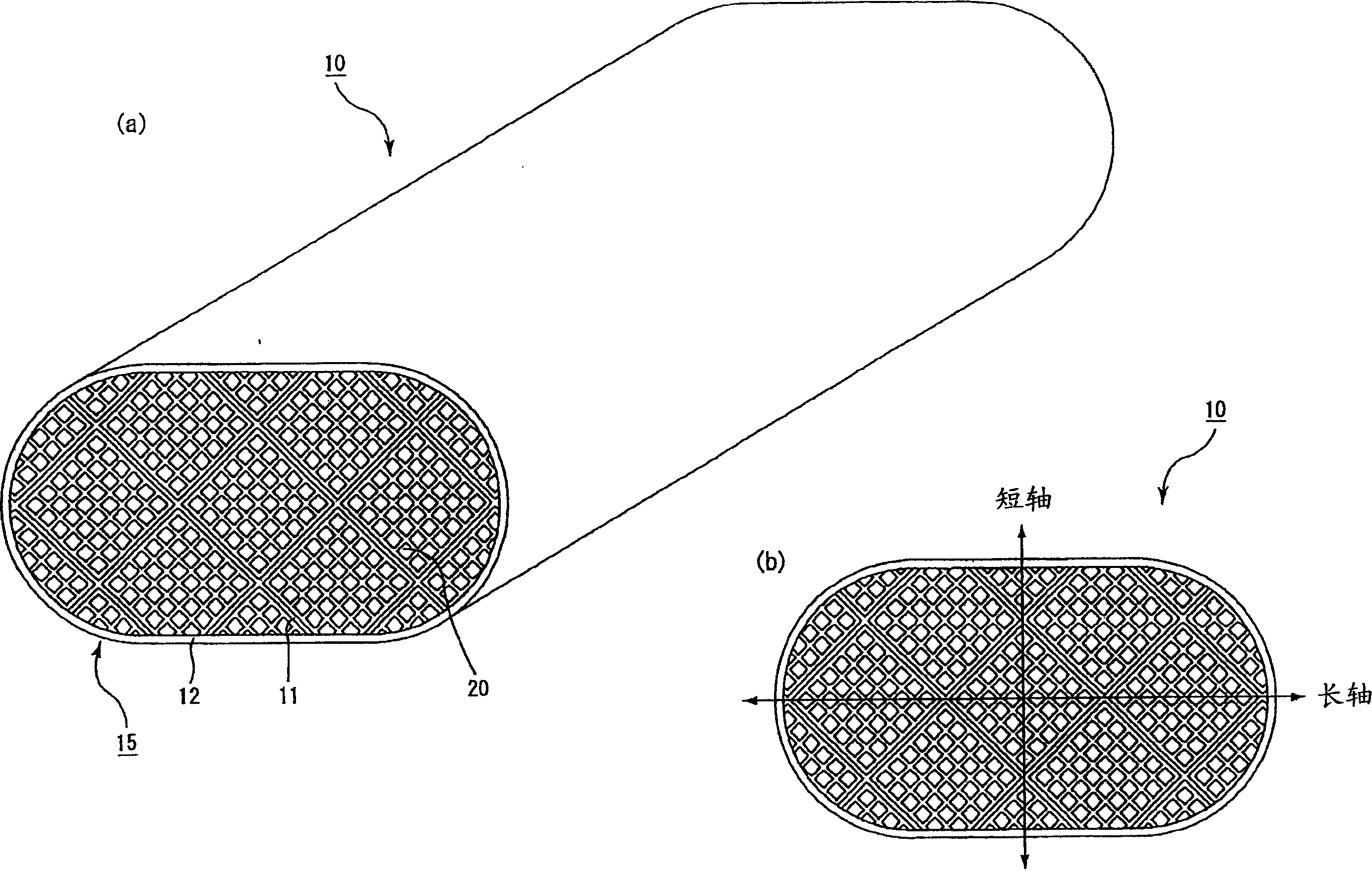

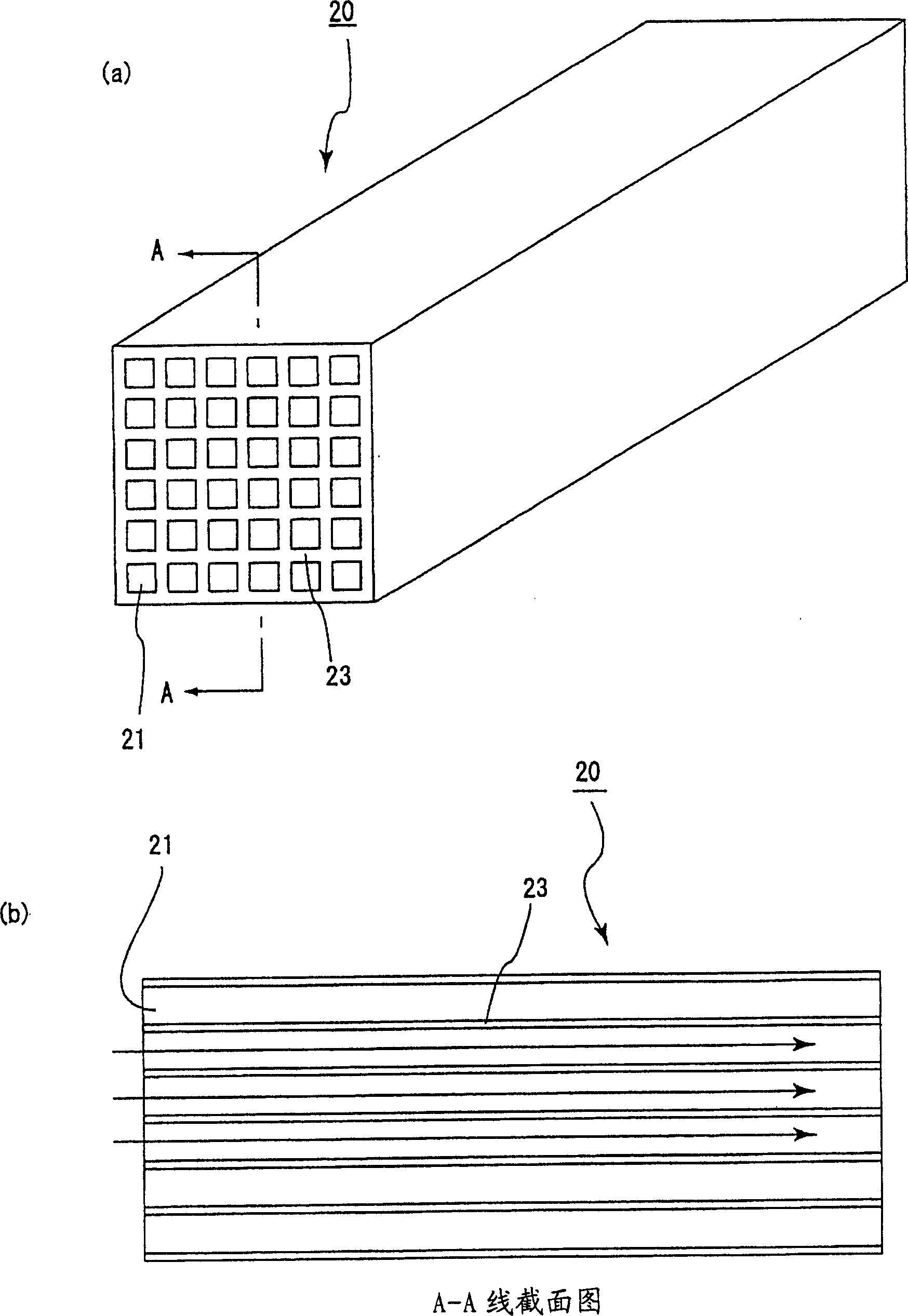

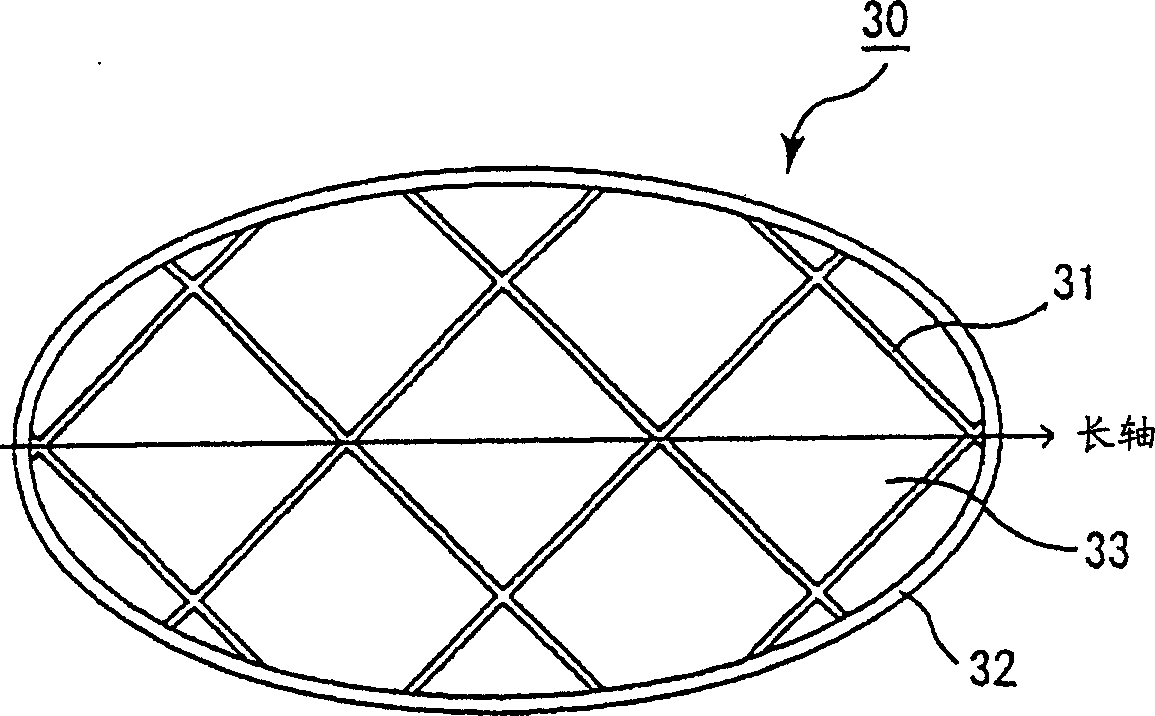

Honeycomb structure

InactiveCN1883791AImprove concentrationGuaranteed bonding strengthGas treatmentSolid waste managementFiberInorganic particle

An object of the present invention is to provide a flat-shaped honeycomb structured body in which sealing material layers are hardly damaged during use and in which adhesion strength can be maintained. The honeycomb structured body of the present invention is a honeycomb structured body including: a honeycomb block which has a flat-shaped cross section and has a structure in which plural honeycomb units are bonded to one another through sealing material layers, each unit including as amain component a porous ceramic and having in the longitudinal direction a number of cells placed in parallel with a cell wall therebetween; and a sealing material layer provided on an outer peripheral portion of the honeycomb block. Herein, each honeycomb unit contains inorganic fibers and / or whiskers in addition to inorganic particles, and the sealing material layer between the honeycomb units on the cross section perpendicular to the longitudinal direction is formed such that the direction thereof is diagonal to the major axis of a shape constituting the contour of the cross section.

Owner:IBIDEN CO LTD

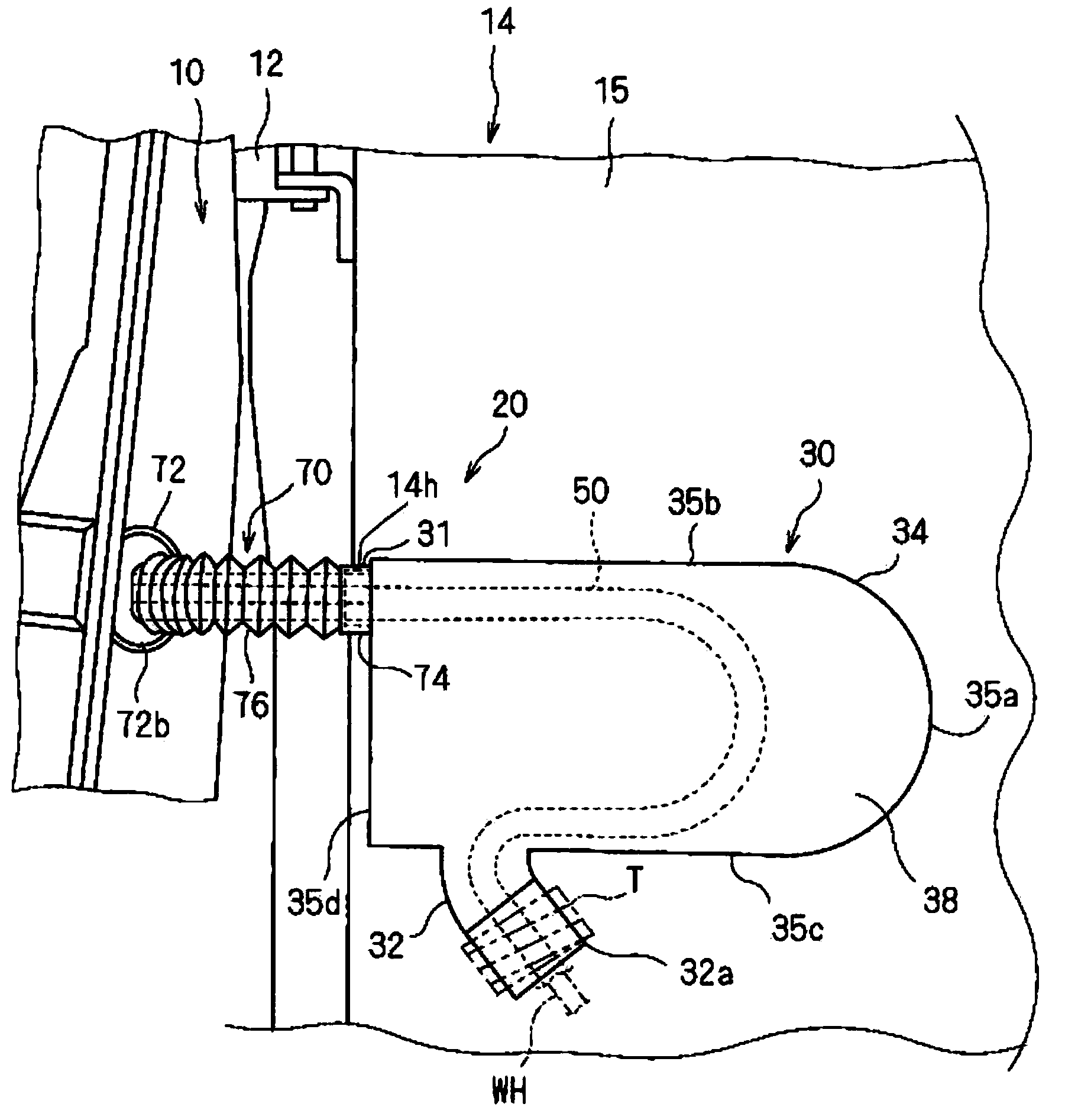

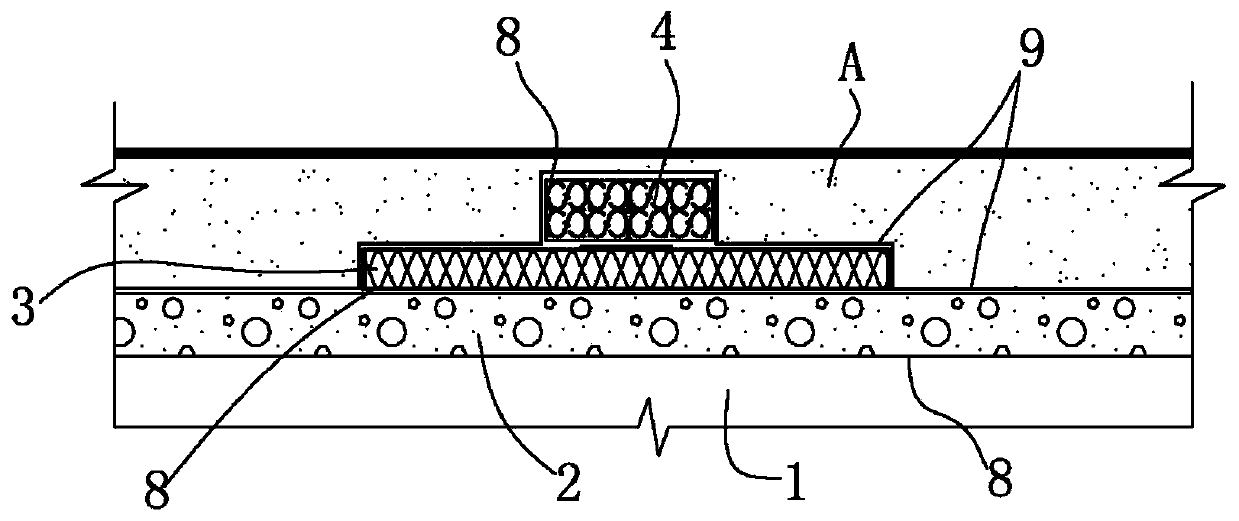

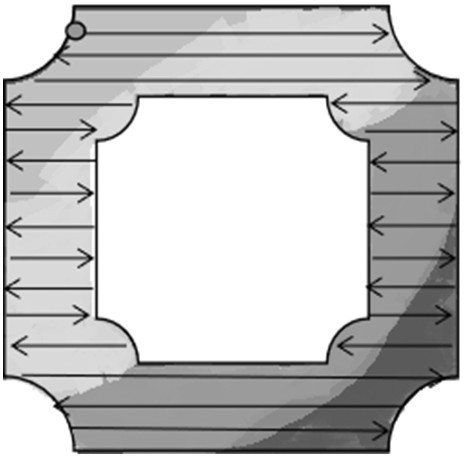

Wiring device for automotive door

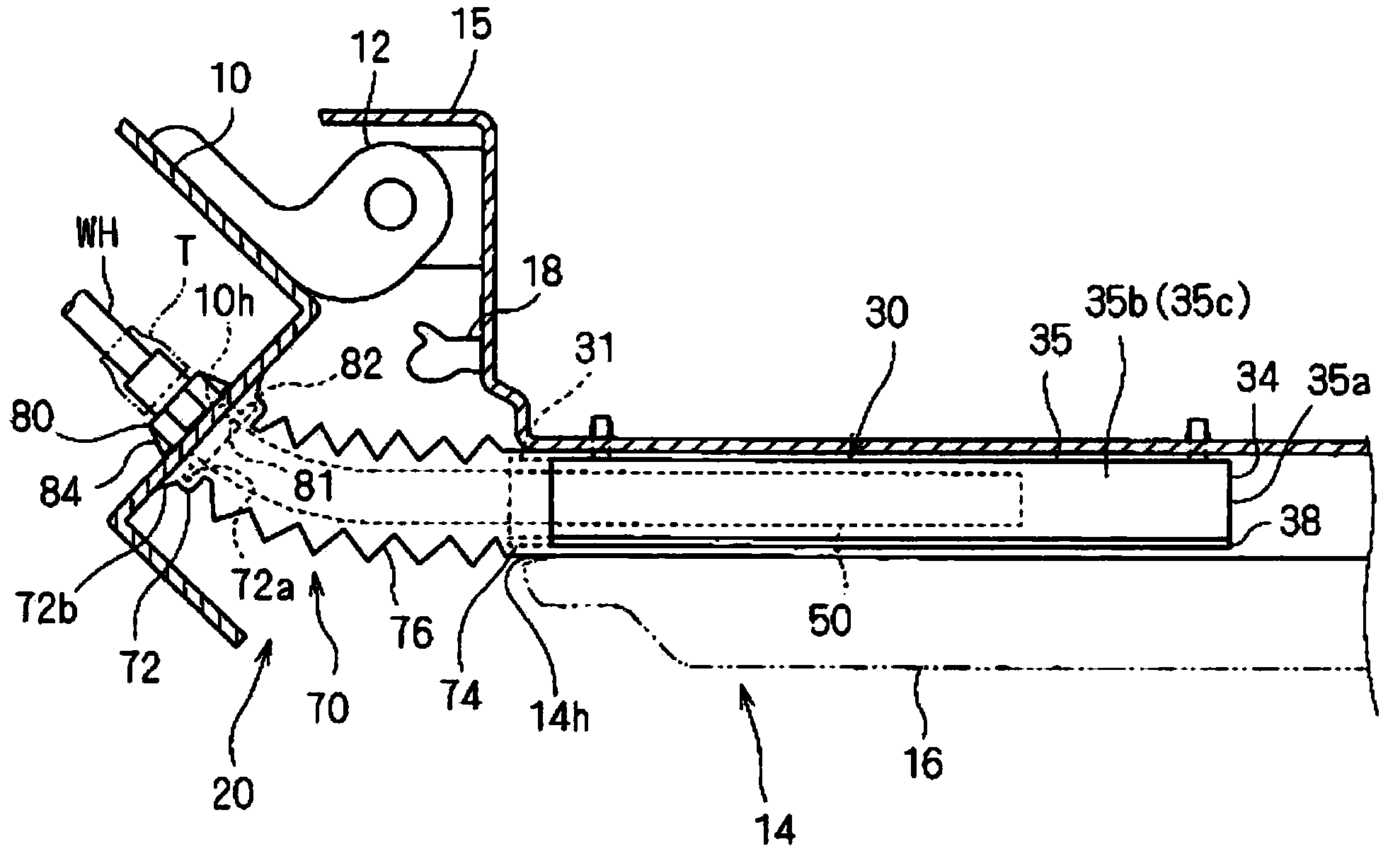

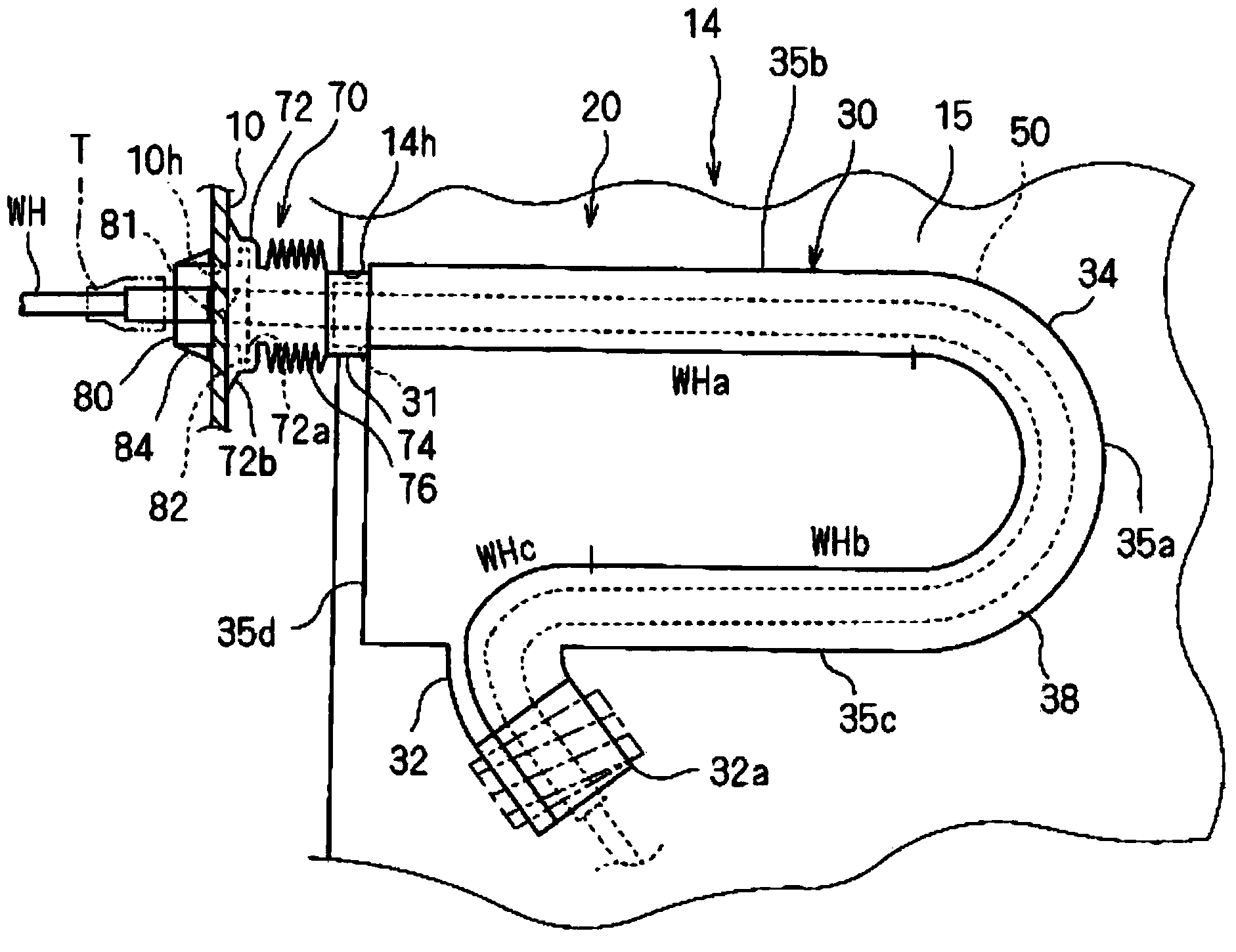

The invention provides a wiring device for an automotive door, which aims to stabilize bending action at a part between an automotive body and the automotive door and a part in the automotive door. The wiring device (20) for the automotive door comprises the components of: a wire harness (WH); a protector (30) which is configured in the automotive door (14) and is provided with an insertion opening (31) for making the wire harness be inserted from the side of the automotive body (10) side; a pulling-out opening (32) which pulls the wire harness out to the part in the automotive door, wherein the protector has a flat shape in the extending direction of the automotive door and furthermore is provided with an accommodating space that can absorb residual length of the wire harness between the insertion opening and the pulling-out opening; a first bending restricting component (52A) which is mounted at a part next to the automotive body side in the wire harness; and a second bending restricting component (52B) which is mounted at a part next to the protector side in the wire harness. The bending restricting directions of the first bending restricting component and the second bending restricting component are different.

Owner:SUMITOMO WIRING SYST LTD

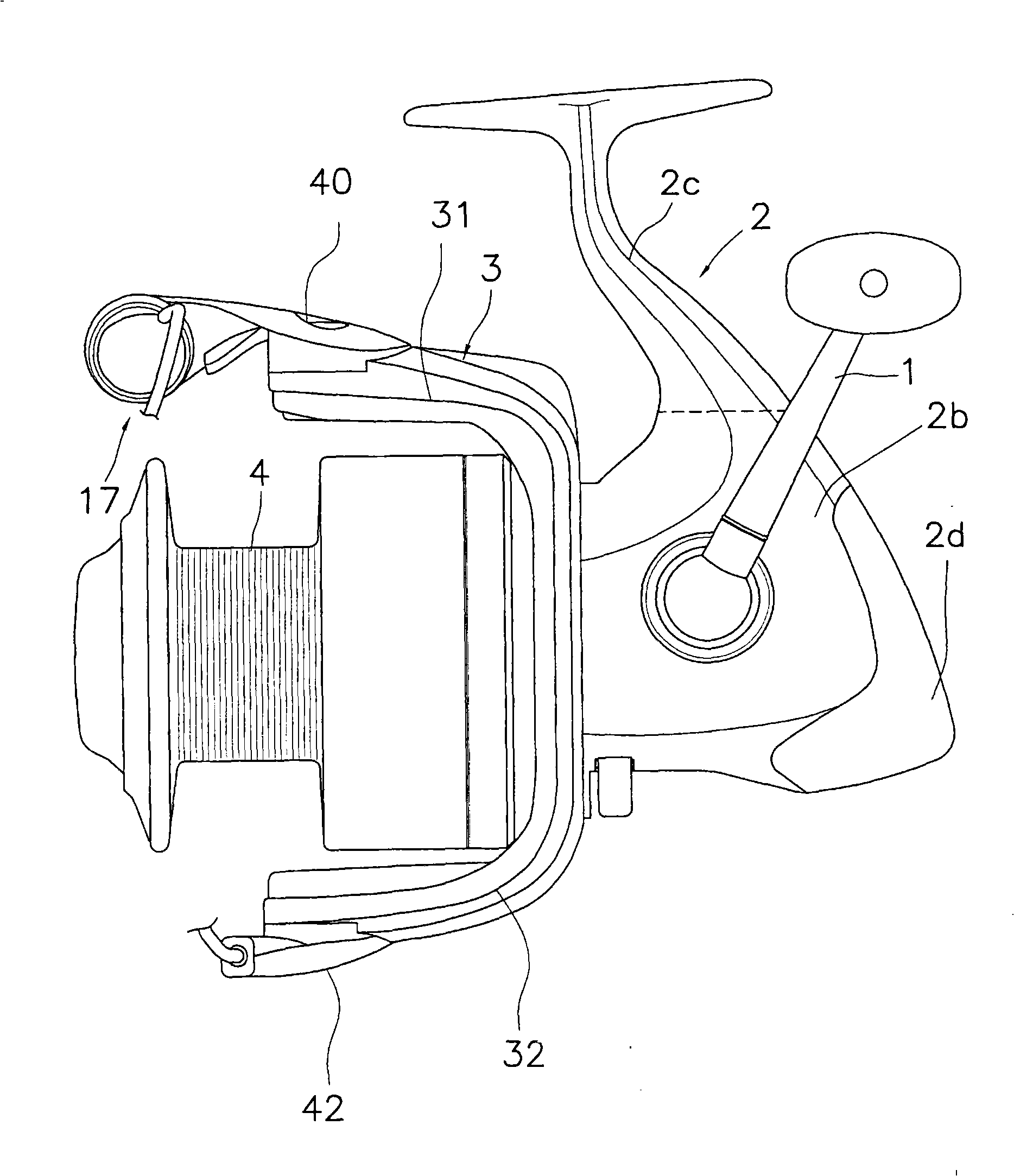

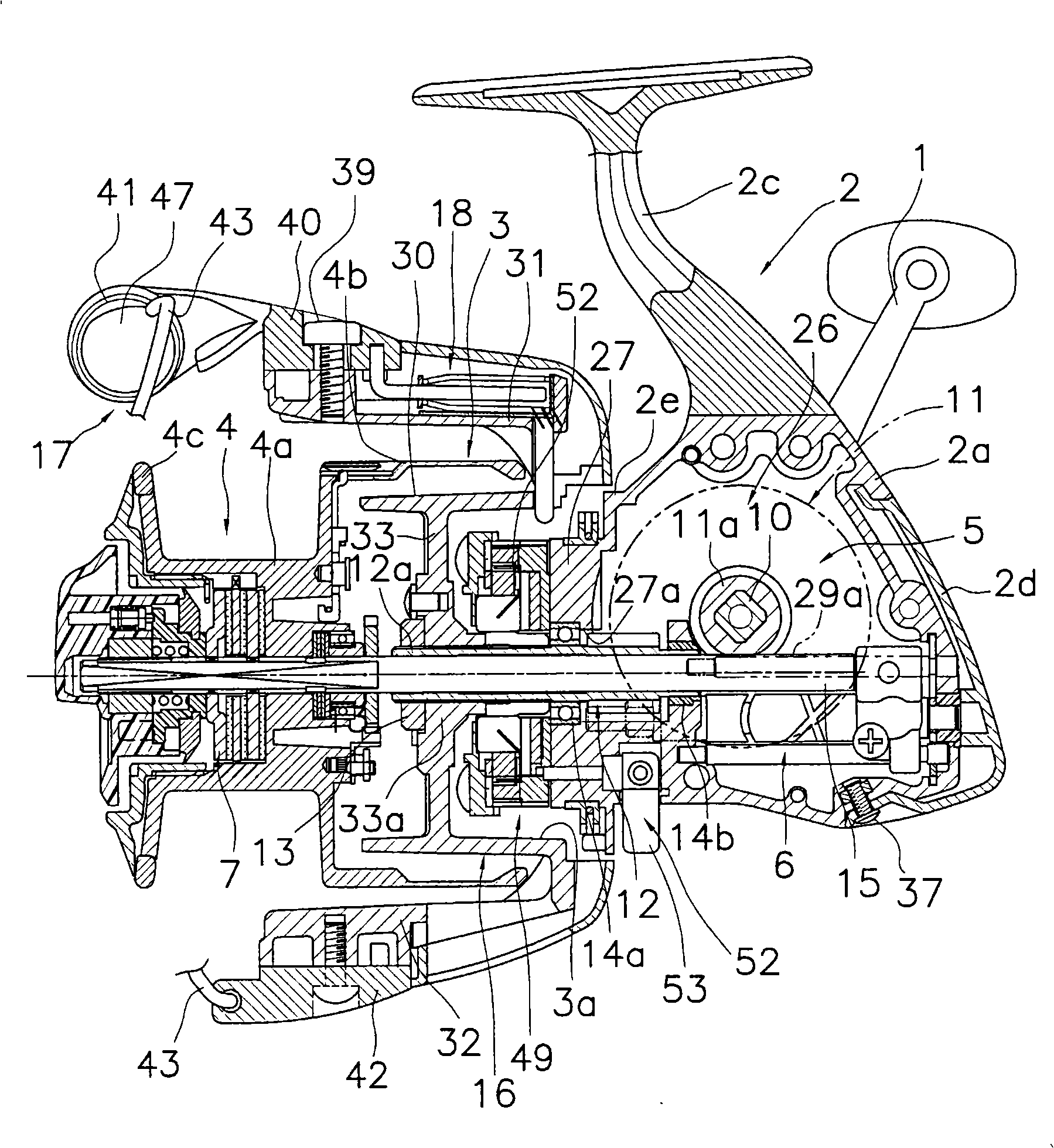

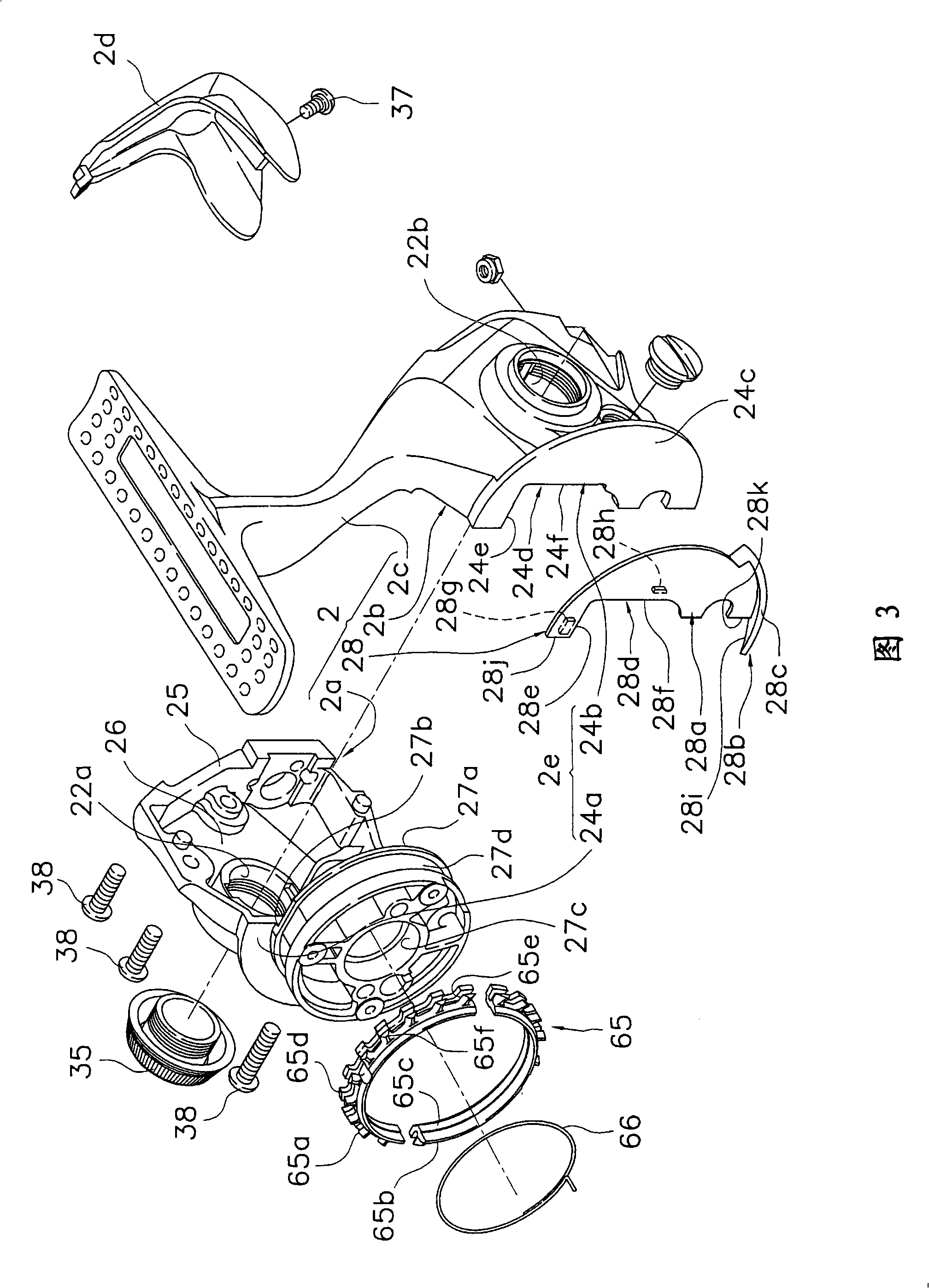

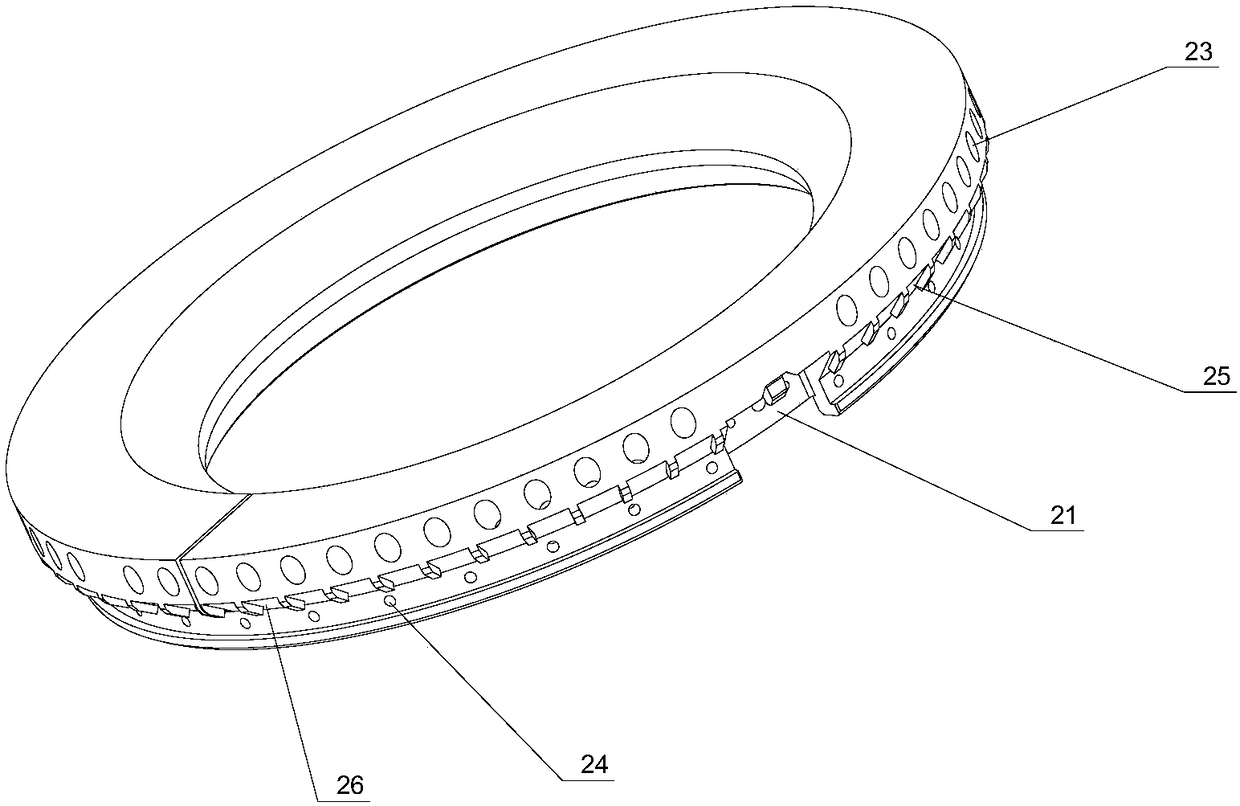

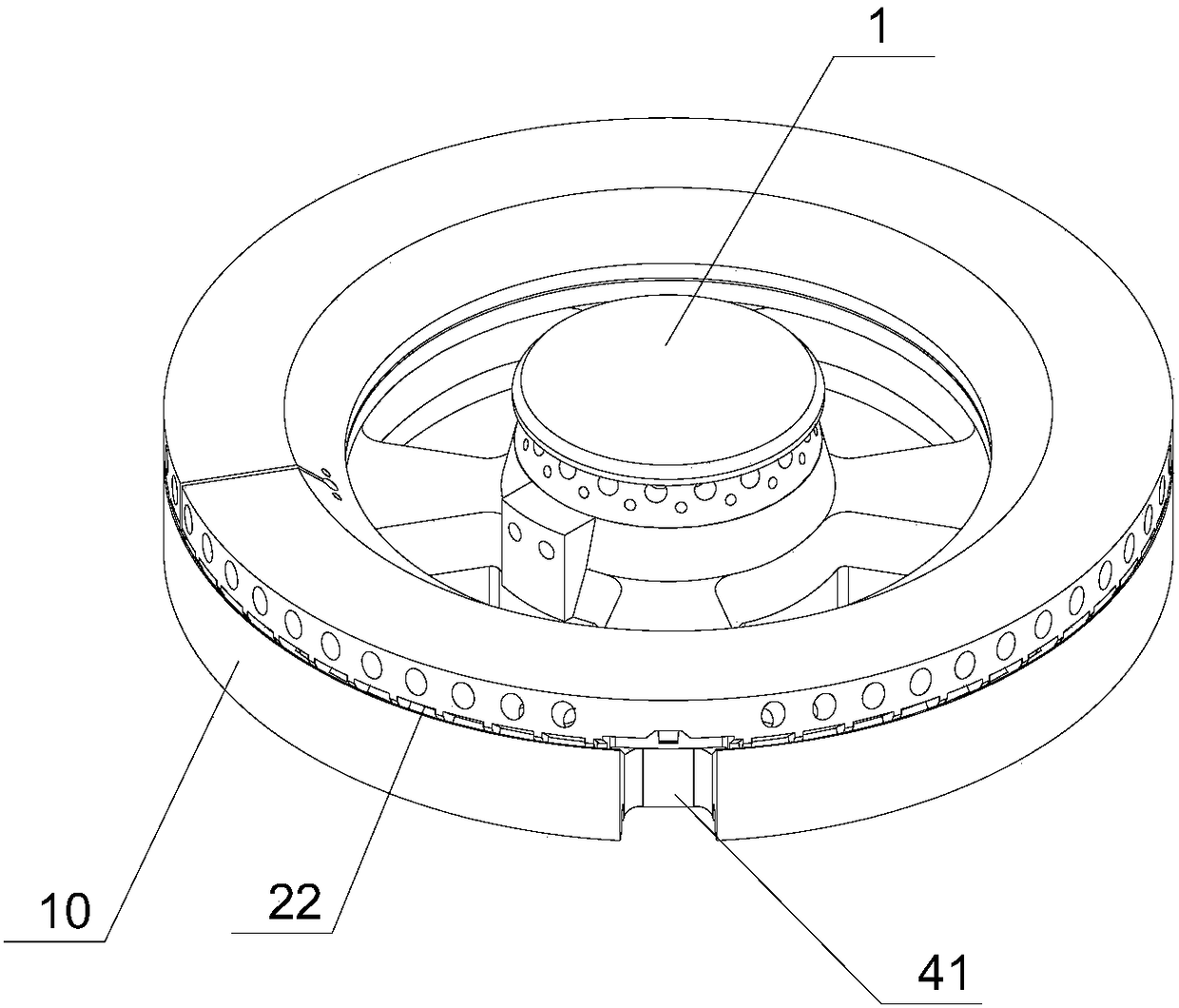

Reel unit for spinning reel

A reel unit for a spinning reel includes a housing unit, a lid portion, and a returning member. The housing unit includes a cylindrical portion and a somewhat semicircular first flange portion arranged behind the cylindrical portion. The lid portion has a somewhat semicircular second flange portion arranged behind and forming a gap with the rear surface of the cylindrical portion. The lid portion is detachably coupled to the housing unit. The returning member is detachably mounted in gap and includes a plate-like arranging portion disposed in gap and a protrusion gradually protruding from a front side of the arranging portion to face the first flange portion. The protrusion 28b has a first sloped surface contactable with a bail tripping mechanism.

Owner:SHIMANO INC

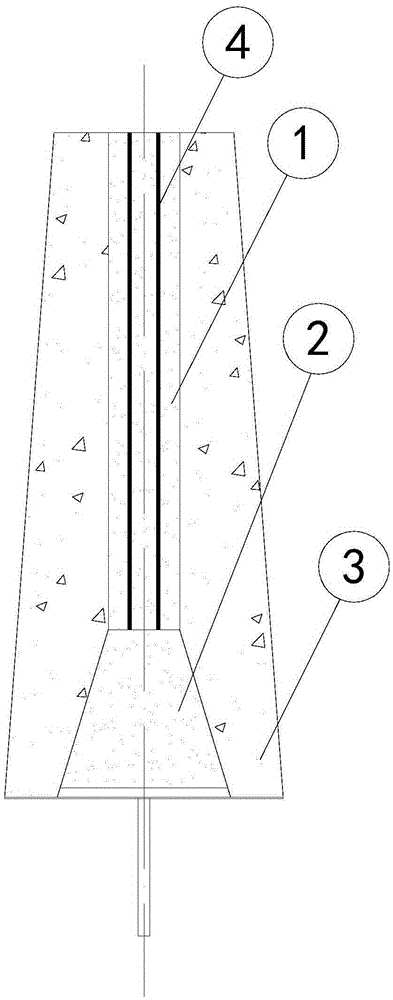

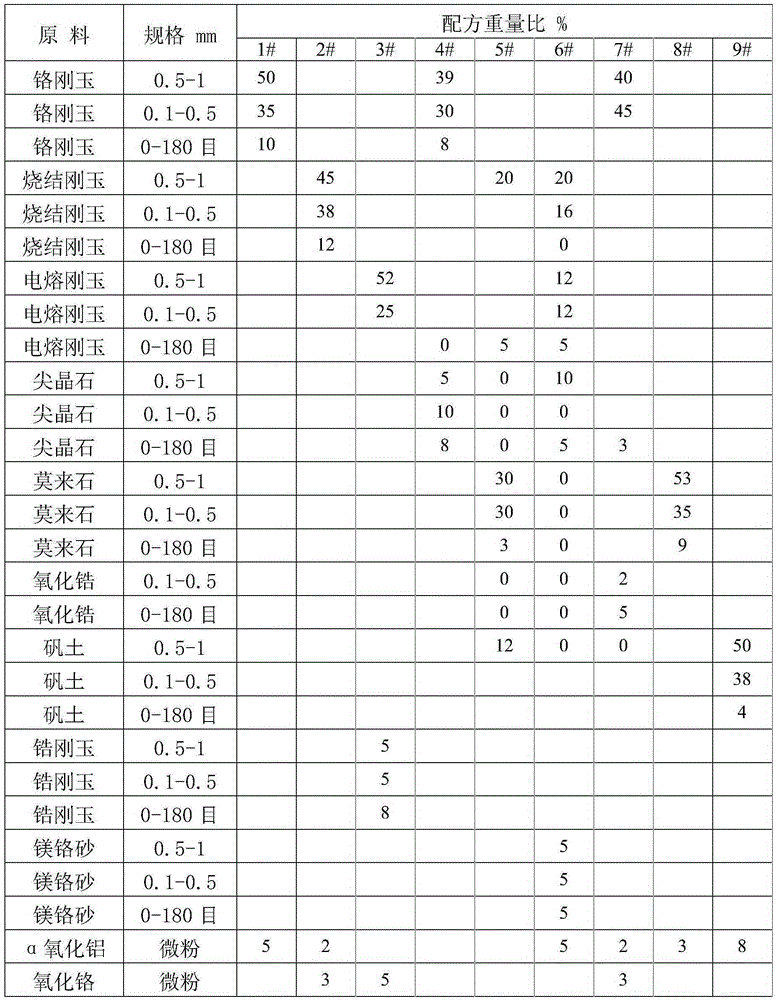

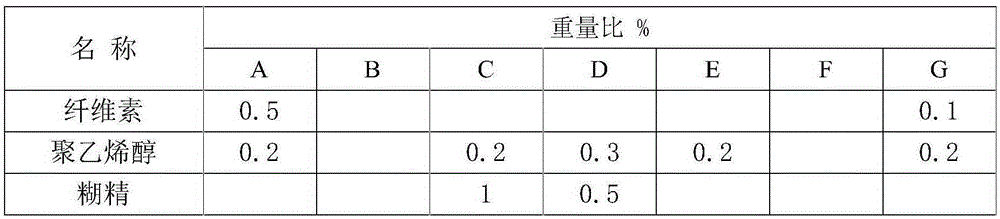

Cleaning-free air brick with uniform structure and manufacturing method thereof

The invention discloses a cleaning-free air brick with a uniform structure and a manufacturing method thereof. The air brick is technically characterized in that refractory raw materials such as chrome corundum, corundum and mullite are selected for one-time allowance-free net forming through an isostatic press, air bricks made from corresponding materials can be selected according to ladle working conditions and smelting requirements, the material of an air-permeable part is uniform in structure, penetration of molten steel is reduced in a using process, uniform and stable air permeability is achieved, the using and operating cost is reduced, and the production cycle of an air brick product is also shortened.

Owner:LUOYANG XUANSHI HIGH TEMPERATURE MATERIALS CO LTD

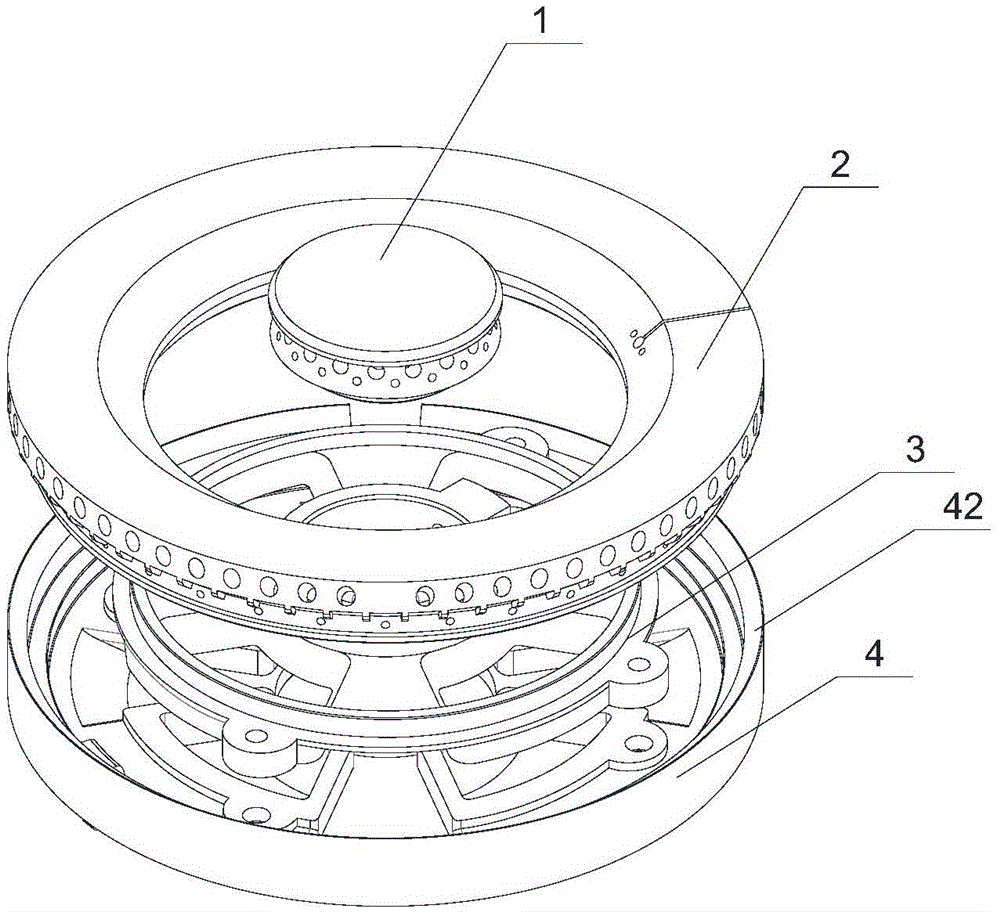

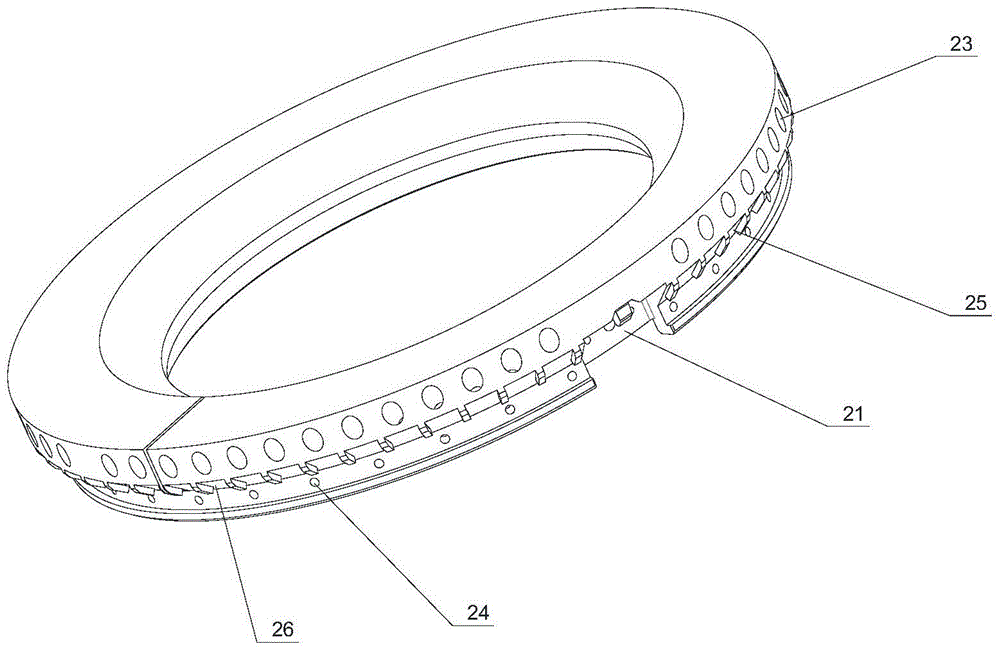

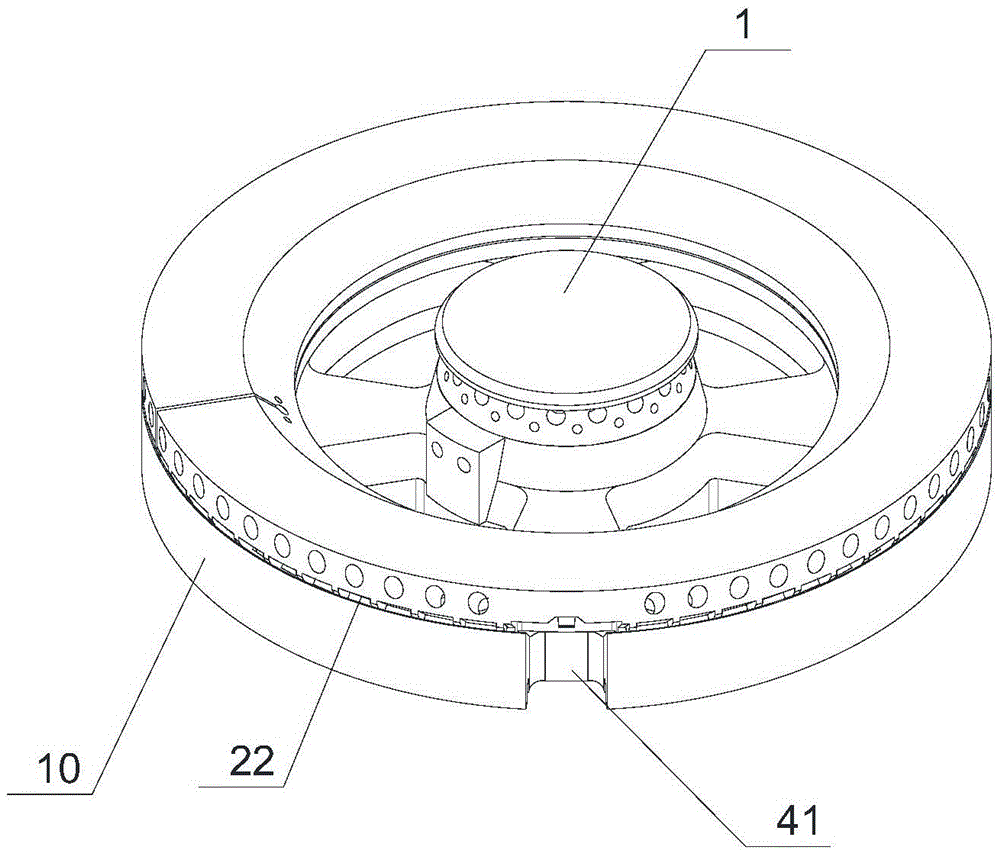

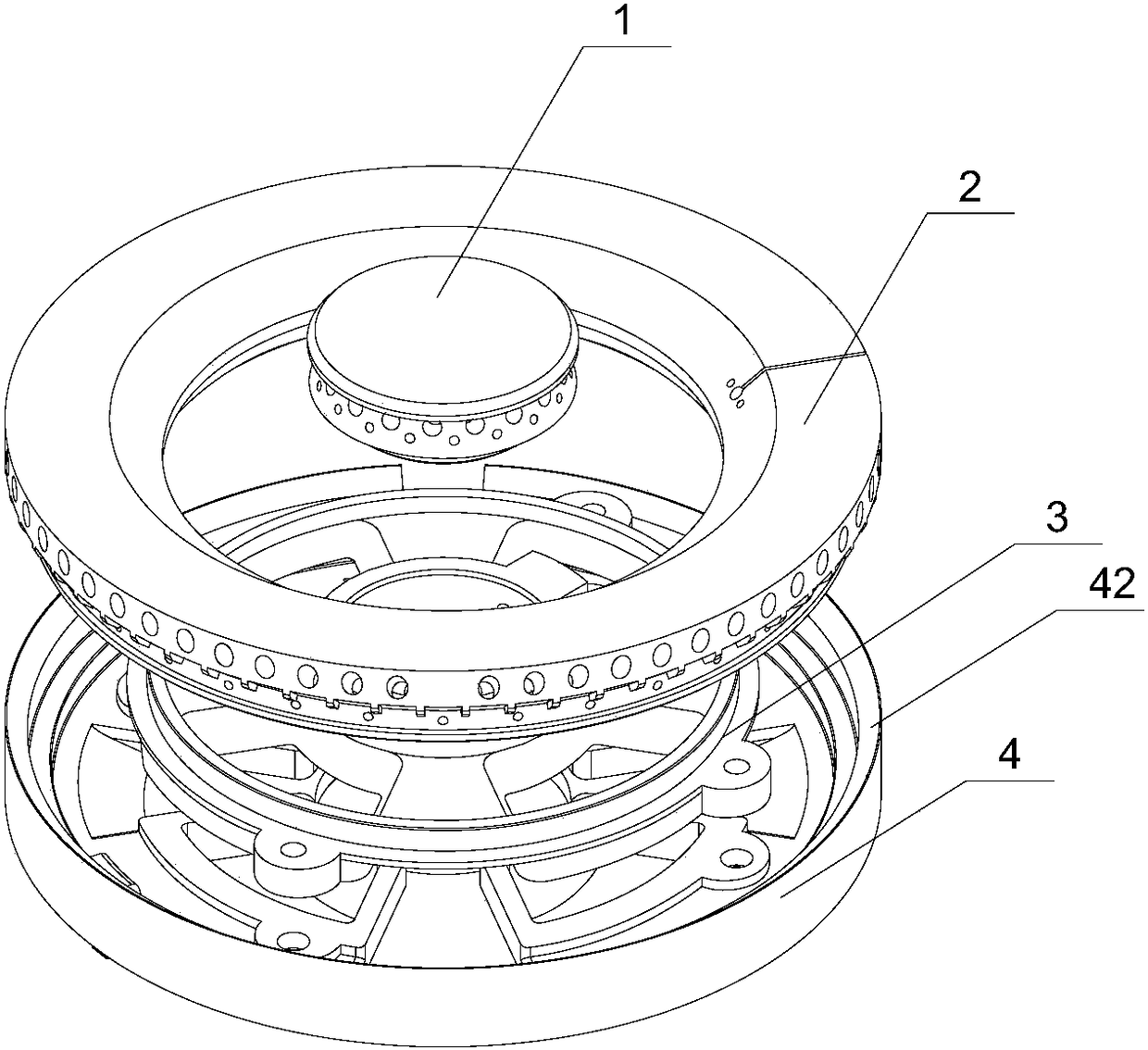

Burner with flame stabilizing structure

ActiveCN105650635ASmall diameterNot easy to leave the flameGaseous fuel burnerFlame propagationCombustor

The invention discloses a burner with a flame stabilizing structure. The burner comprises a burner cap and an air flow distributor, and the burner cap is provided with main flame holes. The burner is characterized in that flame stabilizing passages extending inwards and outwards are formed below the main flame holes, and the burner cap and the air flow distributor form a cavity which is communicated with the flame stabilizing passages. Due to difference between an air flow velocity and a flame propagation velocity, flames are prone to being instable, flames burning in the flame stabilizing passages can guarantee the temperature of roots of the main flame holes to realize stabilization of flames of the main flame holes, and excellent flame stabilizing effects can be achieved.

Owner:SHANGHAI RINNAI

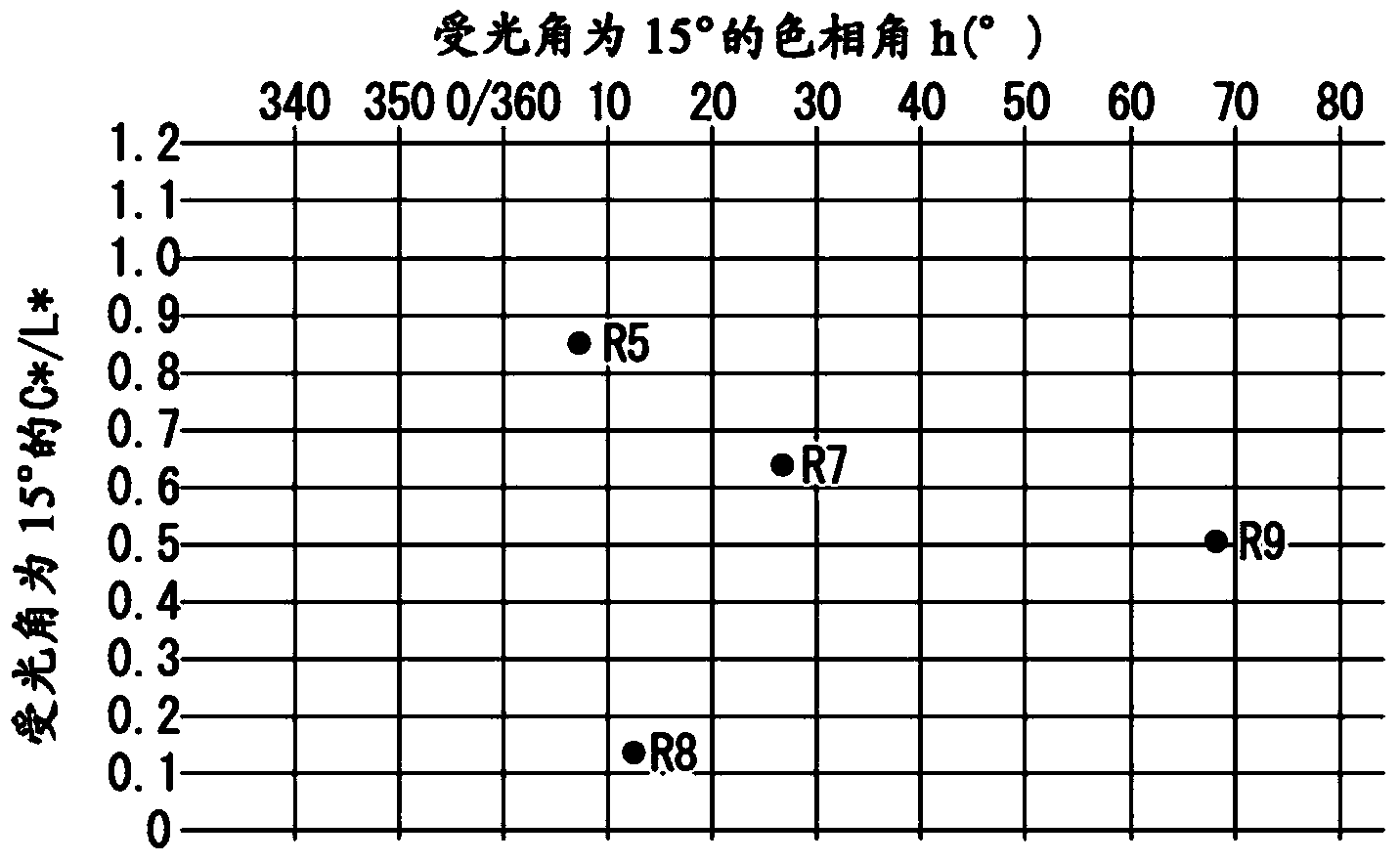

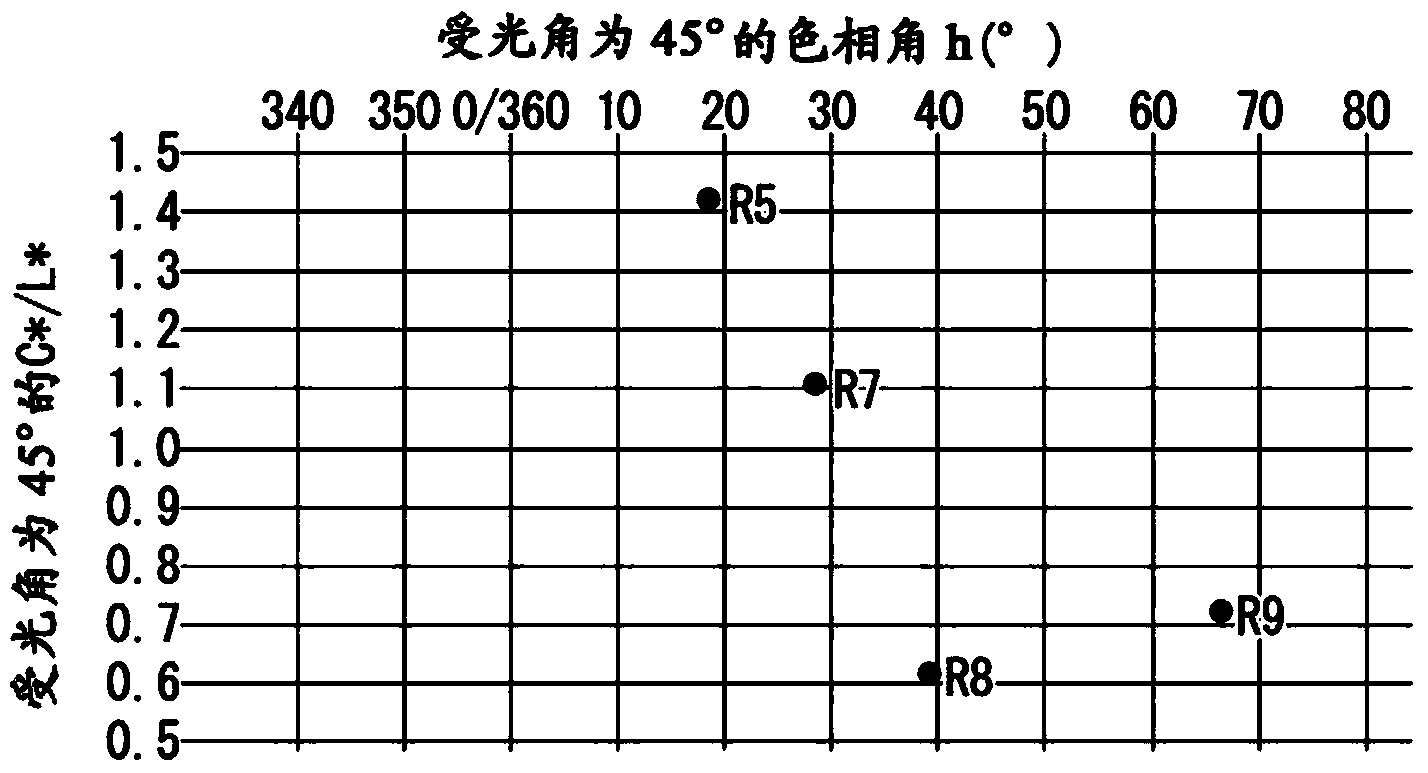

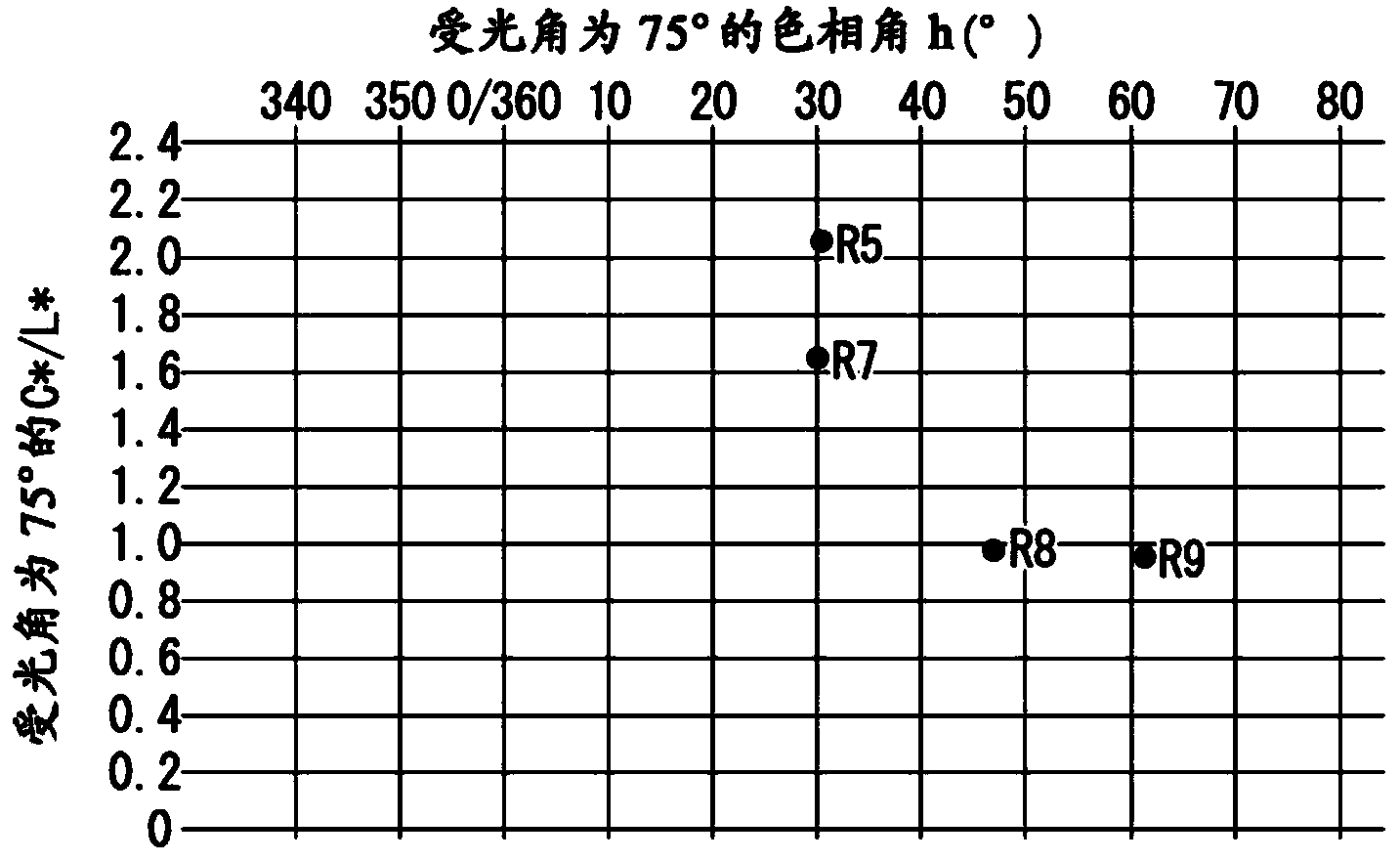

Coating color evaluation method

InactiveCN104204741AAids in color propertiesDifficult to concentrateColor measuring using colour chartsColor measuring using electric radiation detectorsPhotoluminescenceLightness

An evaluation method of a coating color is a method of evaluating a coating color of a coating material containing a color pigment and an effect pigment, the method including: measuring a spectral reflectance of a coating film of the coating material; and calculating C* / L*, which is a ratio of chroma C* to lightness L* in the L*C*h color space, from the spectral reflectance.

Owner:KANSAI PAINT CO LTD

Method for performing phase change memory cell integration by using electrochemical deposition

ActiveCN111081869ADifficult to concentratePrecise control of depositionElectrical apparatusElectrolytic agentPhase-change memory

The invention discloses a method for performing phase change memory cell integration by using electrochemical deposition. The method comprises the following steps of: S1, preparing a conductive substrate; S2, preparing an insulating layer; S3, preparing deep holes; S4, preparing a reaction solution mixed with two different electrolytes; S5, performing electrochemical deposition in the deep holes from bottom to top, and depositing an upper-layer material and a lower-layer material, namely a gating tube and a phase change unit, in each deep hole by adjusting deposition parameters; S6, preparingupper electrodes. The deep holes with nanoscale apertures are etched through a micro-nano machining technology, and then the deep holes are rapidly and effectively filled through the electrochemical deposition method; the nano phase change material can be grown from the bottom of each nano hole; the ultra-large depth-to-width ratio small holes can be filled with a sulfur phase-change material witha multi-layer complex structure; the growth of the materials can be accurately regulated and controlled by regulating and controlling the deposition parameters; graphical growth is realized by designing the shape of electrodes of which the bottom can apply potentials; and preparation of various materials with complex structures is carried out.

Owner:HUAZHONG UNIV OF SCI & TECH

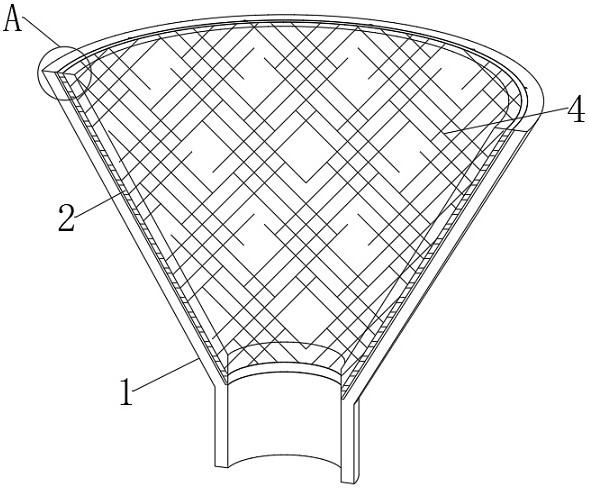

High-energy beam scanning path planning method and additive manufacturing method and device

ActiveCN113351885AGuaranteed forming qualityEvenly distributedAdditive manufacturing apparatusIncreasing energy efficiencyContinuous scanningScan line

The invention relates to a high-energy beam scanning path planning method and an additive manufacturing method and device, and relates to the technical field of additive manufacturing. The high-energy beam scanning path planning method comprises the following steps that a three-dimensional model of an additive manufacturing part is constructed; the three-dimensional model of the part is layered and sliced in the printing and manufacturing direction, and section contour data of each layer of slice are extracted; a contour line of each layer of slice is obtained according to the section contour data of each layer of slice, and at least one continuous scanning line is obtained after the contour lines are contracted inwards or expanded outwards; the scanning line is randomly divided into N sections, wherein the length of each scanning line section is smaller than or equal to a preset value; and each scanning line section is numbered, each scanning line section is scanned according to a preset numbering scanning sequence, and at least one scanning line segment is arranged between every two scanning line sections which are scanned in sequence. The uniformity of heat distribution during additive manufacturing of thin-wall parts is improved, the thermal stress is reduced, and deformation and cracking of the parts are prevented.

Owner:西安赛隆增材技术股份有限公司

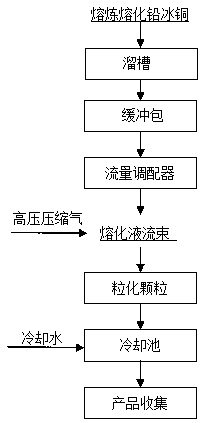

Air-quenching water-cooling granulation method of lead matte

InactiveCN109022761AAvoid ExplosionsImprove securityProcess efficiency improvementEngineeringHigh pressure

The invention discloses an air-quenching water-cooling granulation method of lead matte. The air-quenching water-cooling granulation method of the lead matte comprises the following steps that (1) a round hole allowing liquid to flow out and a sealing switch matched with the round hole are arranged on the lateral portion of a smelting furnace, the round hole is blocked through the sealing switch first, then the lead matte is placed in the smelting furnace, and afterwards, the sealing switch is opened to allow high-temperature molten lead matte to flow out of the smelting furnace via the roundhole, so that a melt flow is formed; (2) high-pressure compressed gas is sprayed out of a high-pressure gas container to tangentially impact the melt flow formed in step (1), the melt flow is shearedinto high-temperature tiny liquid particles by the high-pressure compressed gas, and then the high-temperature tiny liquid particles are sprayed into air in a parabolic shape; and (3) the high-temperature liquid particles sprayed out in step (2) are cooled and hardened when moving in air, the hardened particles fall into a cooling water pool arranged below the smelting furnace so as to be cooled and are finally deposited to the bottom of the cooling water pool so as to be collected, and thus, air-quenching water-cooling granulation of the lead matte is completed. By adoption of the air-quenching water-cooling granulation method, the lead matte is effectively refined into small particles, the process is simple, and the safety is high.

Owner:浙江科菲科技股份有限公司

Production process of niobium carbide hard alloy roller ring

InactiveCN110394453AImprove high temperature resistanceHigh hardnessTransportation and packagingMetal-working apparatusWaxCompression molding

The invention relates to the technical field of hard alloy production, in particular to a production process of a niobium carbide hard alloy roller ring. The production process of the niobium carbidehard alloy roller ring comprises the following process steps that A, burdening is conducted, and specifically, 65wt%-75wt% of WC powder, 6.5wt%-8.5wt% of Ni powder and 16.5wt%-28.5wt% of NbC powder, in percentage by mass, are mixed; B, wet grinding is conducted, and specifically, the mixed powder in the step A is added into a tilting ball mill, and alcohol is added according to the ratio of alloyballs of 5 to 1, the rotating speed is 32 r / min, and the ball milling time is not less than 30-36 hours; C, drying is conducted, and specifically, the pulped material produced by the ball milling in the step B is sequentially sieved, wax is added, and the pulped material is conveyed to a spray tower to prepare powder particles; D, compression molding is conducted, and specifically, the powder particles prepared in the step C are added into a mold cavity, and the mold cavity is matched according to the shape of the roller ring required to be produced so as to press the powder particles into a blank; and E, sintering is conducted, the blank is put into a sintering furnace to be sintered and formed. According to the process, the roll ring is prepared, so that the metallographic structure of the roll ring is more uniform, so that the wear resistance of the roll ring is improved.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

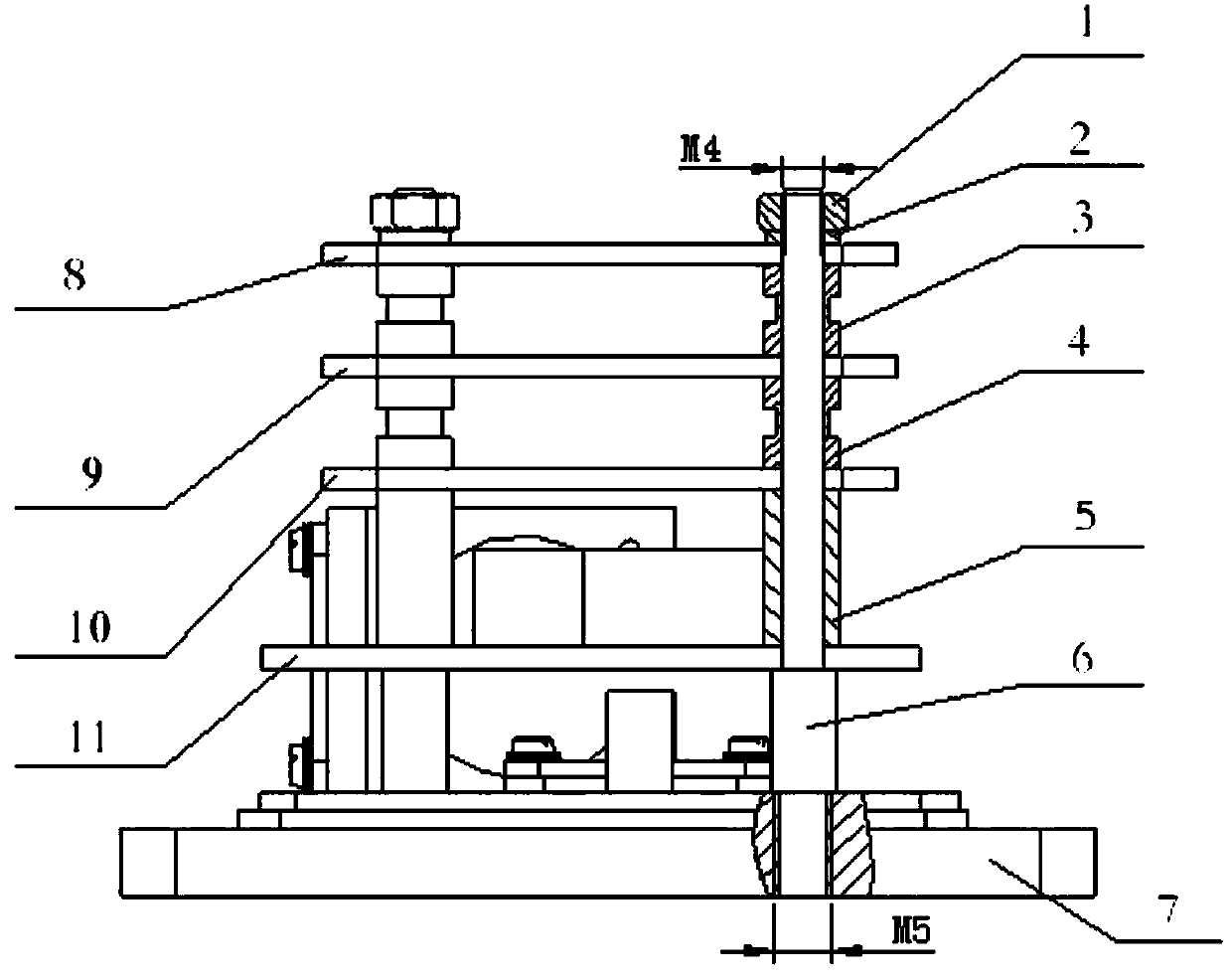

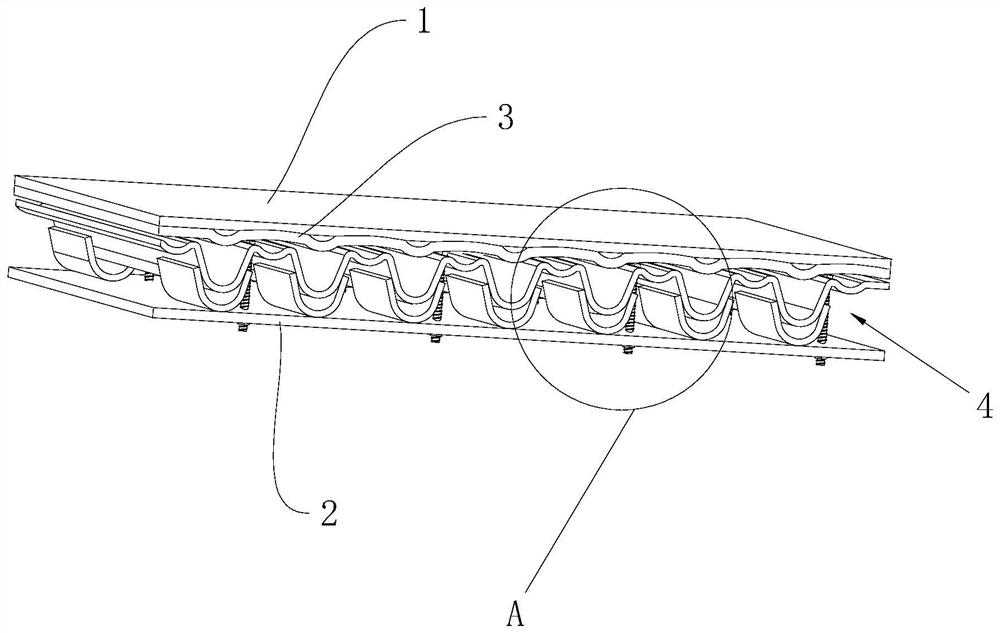

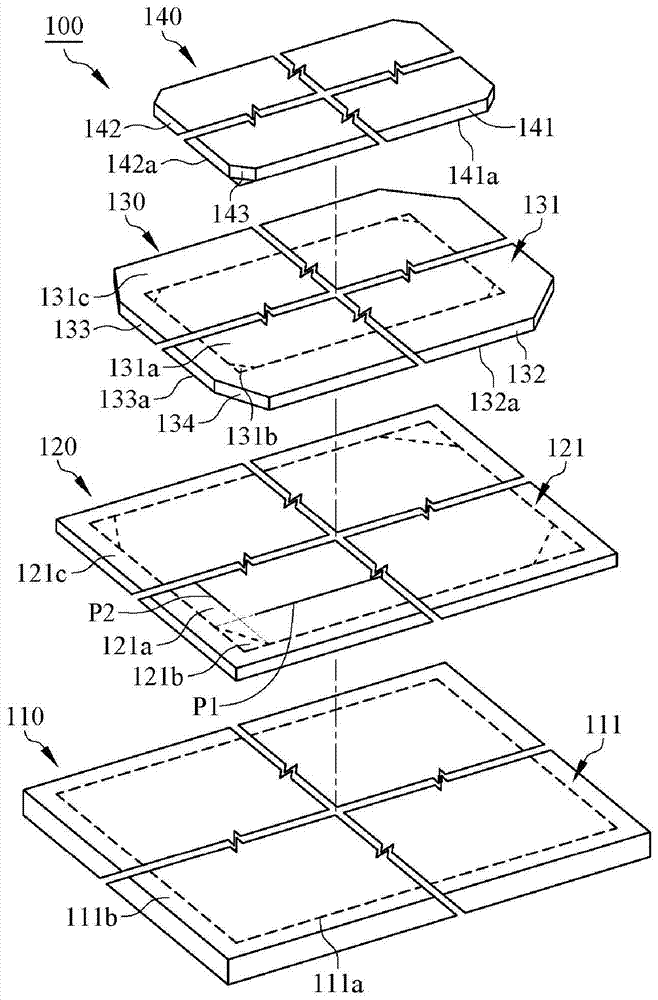

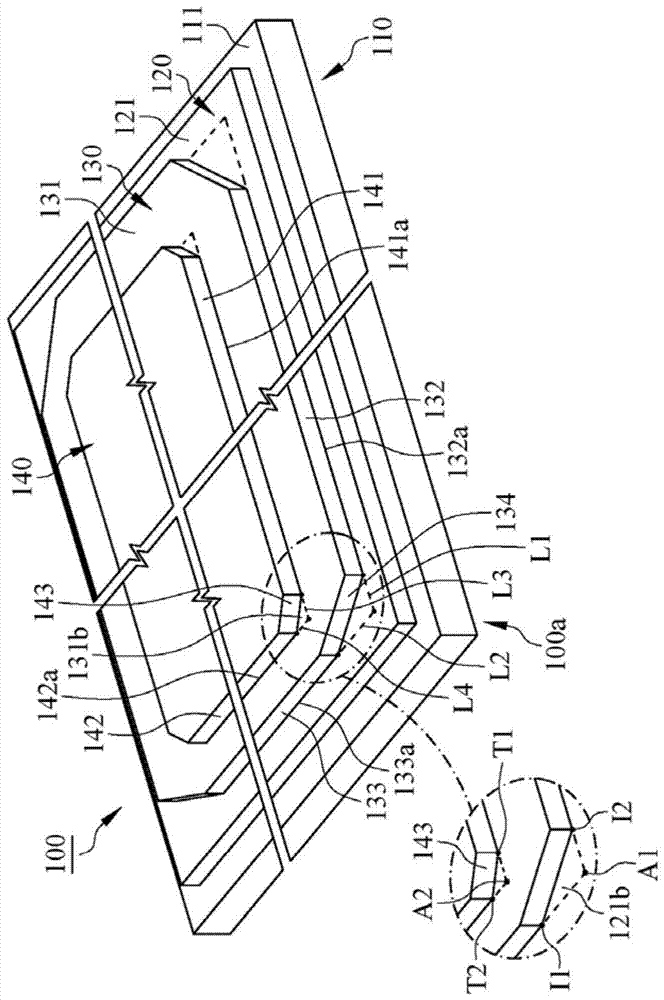

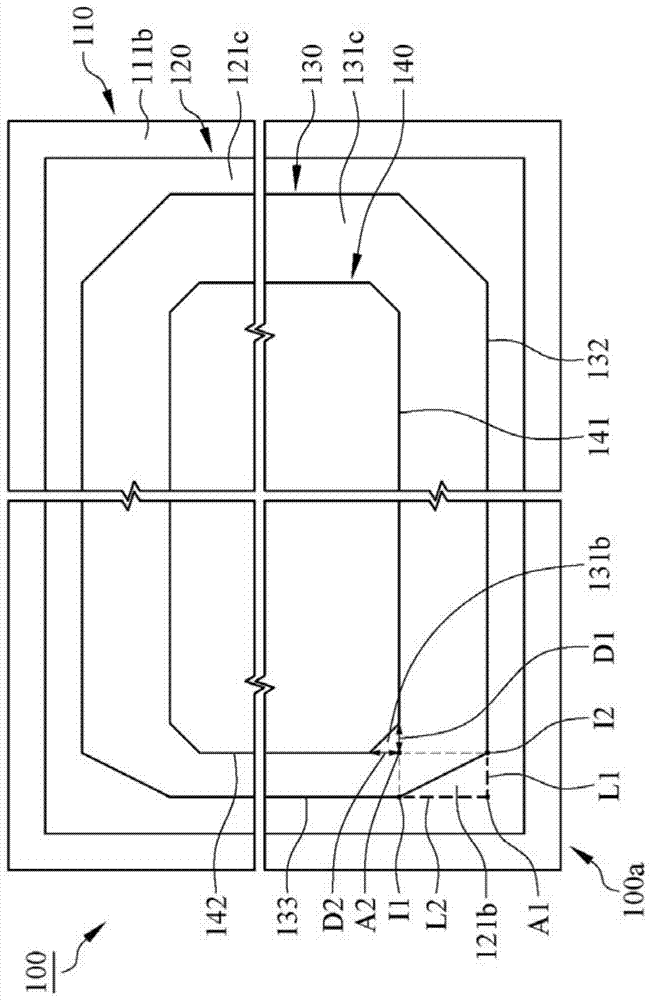

Multi-layer circuit board installing structure with vibration resistance

InactiveCN107864589ANot easy to collideVibration amplitude amplificationClamping/extracting meansEngineeringRandom vibration

The invention relates to the field of circuit installation and design, particularly to a multi-layer circuit board installing structure with vibration resistance. The multi-layer circuit board installing structure with vibration resistance can ensure resistance of circuit integral structures to random vibration. Due to the fact that environmental vibration conditions of accelerator sensors are improved from original sinusoidal vibration to random vibration, test level of random vibration is improved from low requirements of an aircraft cabin to high requirements of positions close to an engine. According to the multi-layer circuit board installing structure with vibration resistance, a base is provided with a support column, a first layer of circuit board is installed on the journal of thesupport column, a second layer of circuit board is separated from the first layer of circuit board as well as a plurality of upper layers of circuit boards through sleeves, and a top layer of circuitboard is fixed onto the support column through a nut and a spring washer. The multi-layer circuit board installing structure with vibration resistance prolongs the service life and improves reliability of the accelerator sensor.

Owner:WUHAN AVIATION INSTR

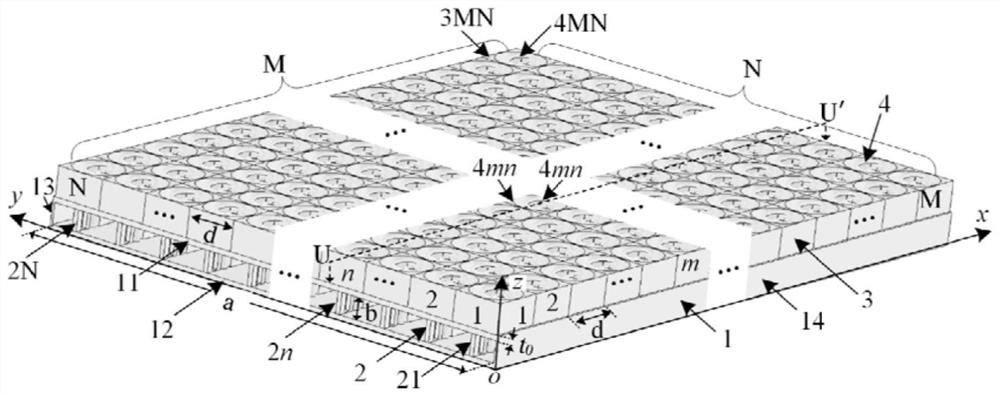

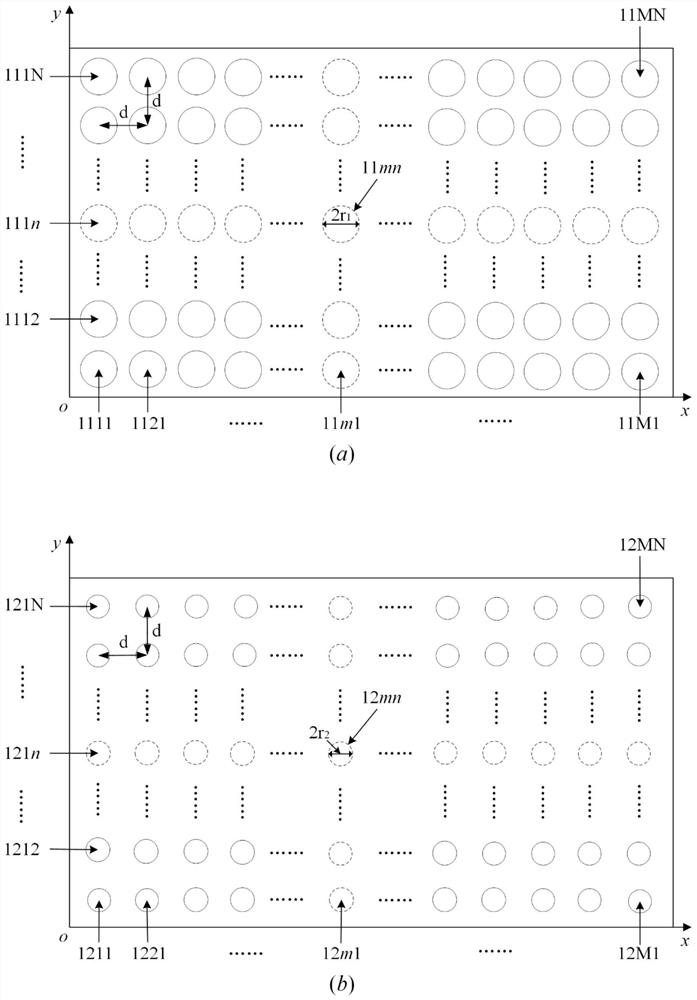

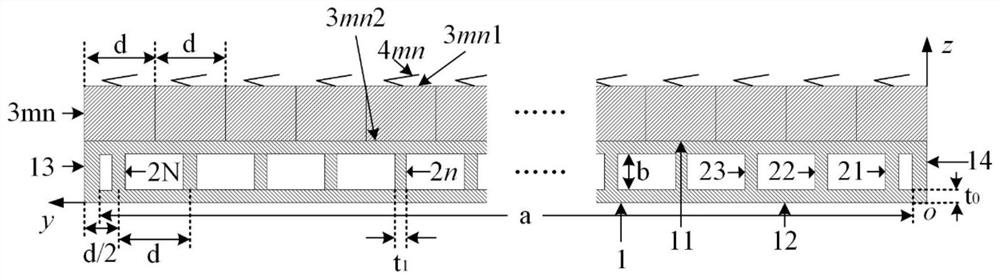

Flat waveguide feed two-dimensional beam scanning antenna

ActiveCN112615156AReduce section heightReduce connection structureParticular array feeding systemsIndividually energised antenna arraysEngineeringBeam scanning

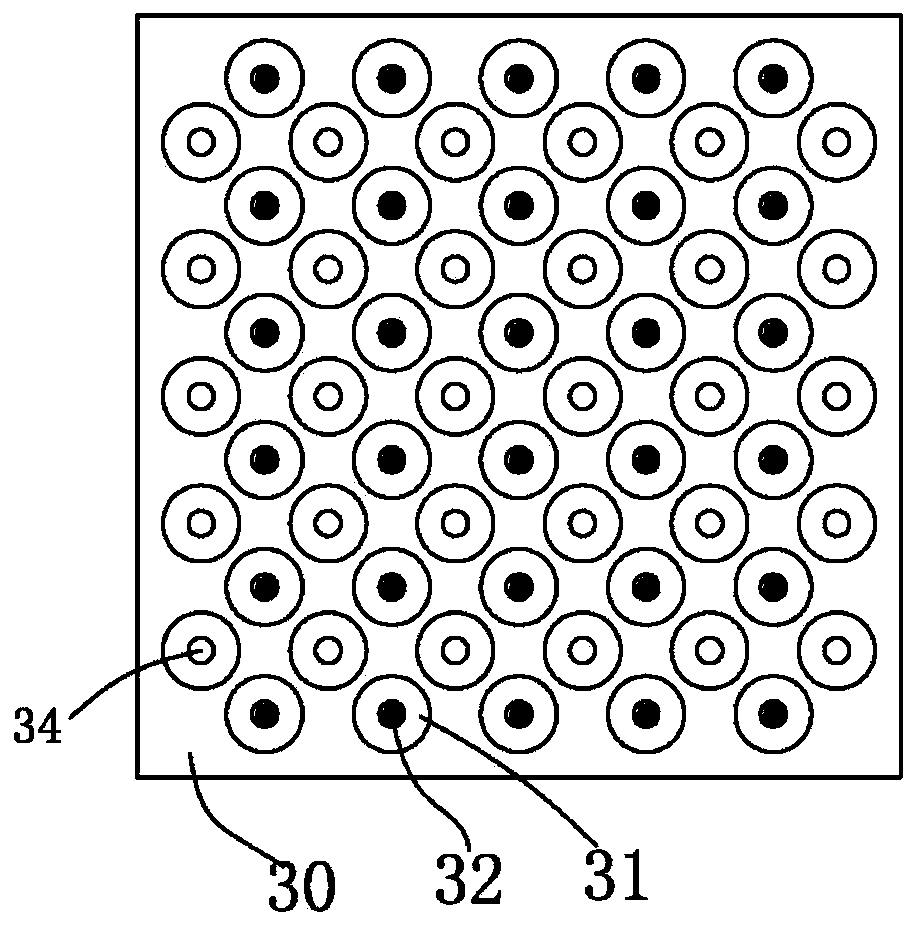

The invention discloses a flat waveguide feed two-dimensional beam scanning antenna; the antenna is composed of a flat waveguide, N baffles, M*N outer cavities and M*N short spiral antennas; the baffle is a long rectangular plate; the outer cavity is a cuboid of which the center is provided with a radius-variable circular channel; the N baffles are inserted into the flat waveguide in the direction parallel to the x axis, so N+1 rectangular channels are formed in the flat waveguide, and the width of the N-1 rectangular channels in the middle is d; the M*N outer cavities are tightly arranged in a manner that square grids with the side length of d are parallel to the xoy plane, and the lower surfaces of the outer cavities are attached to the upper surface of the flat waveguide; and the M*N short helical antennas respectively pass through the M*N outer cavity circular channels and sequentially pass through the upper waveguide wall of the flat waveguide, the baffle plate and the lower waveguide wall of the flat waveguide. According to the method, defects of high profile, narrow working bandwidth, low power capacity and non-uniform microwave transmission of the existing spiral array antenna are overcome, the spiral antenna can be controlled to rotate in rows and columns, and two-dimensional scanning of wave beams is realized.

Owner:NAT UNIV OF DEFENSE TECH

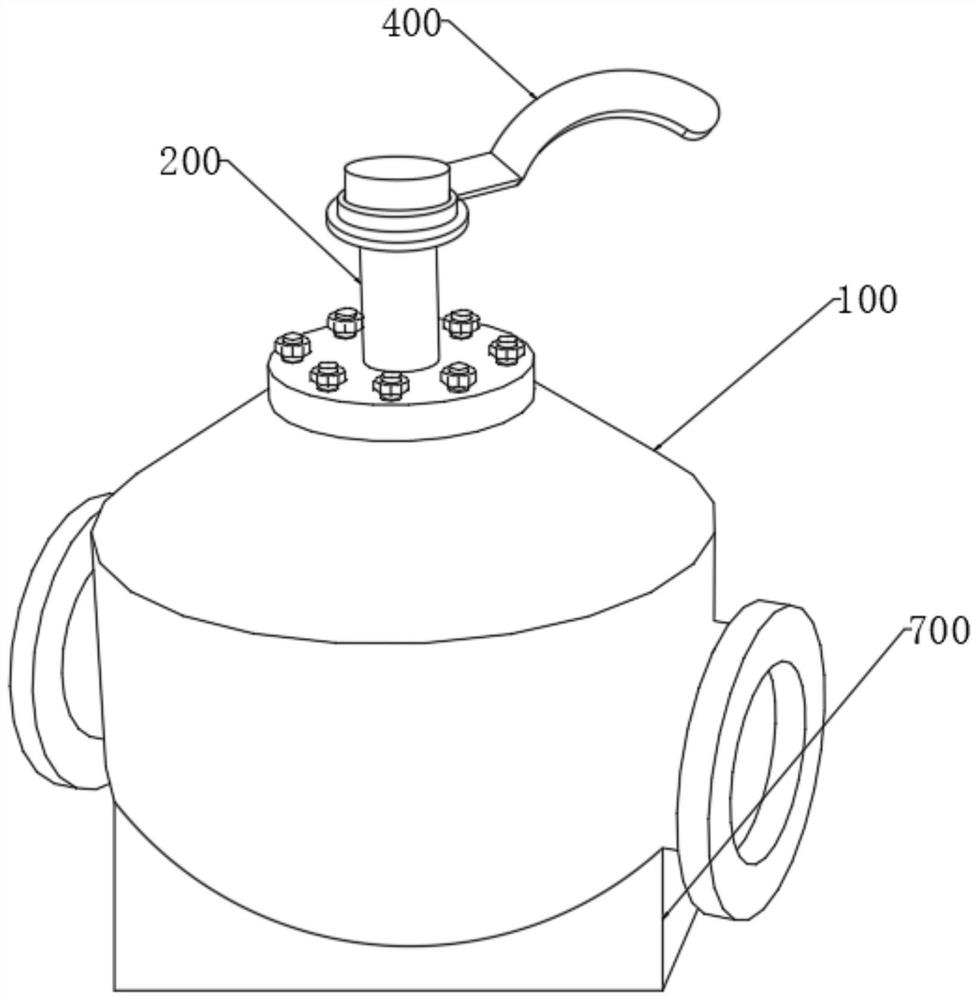

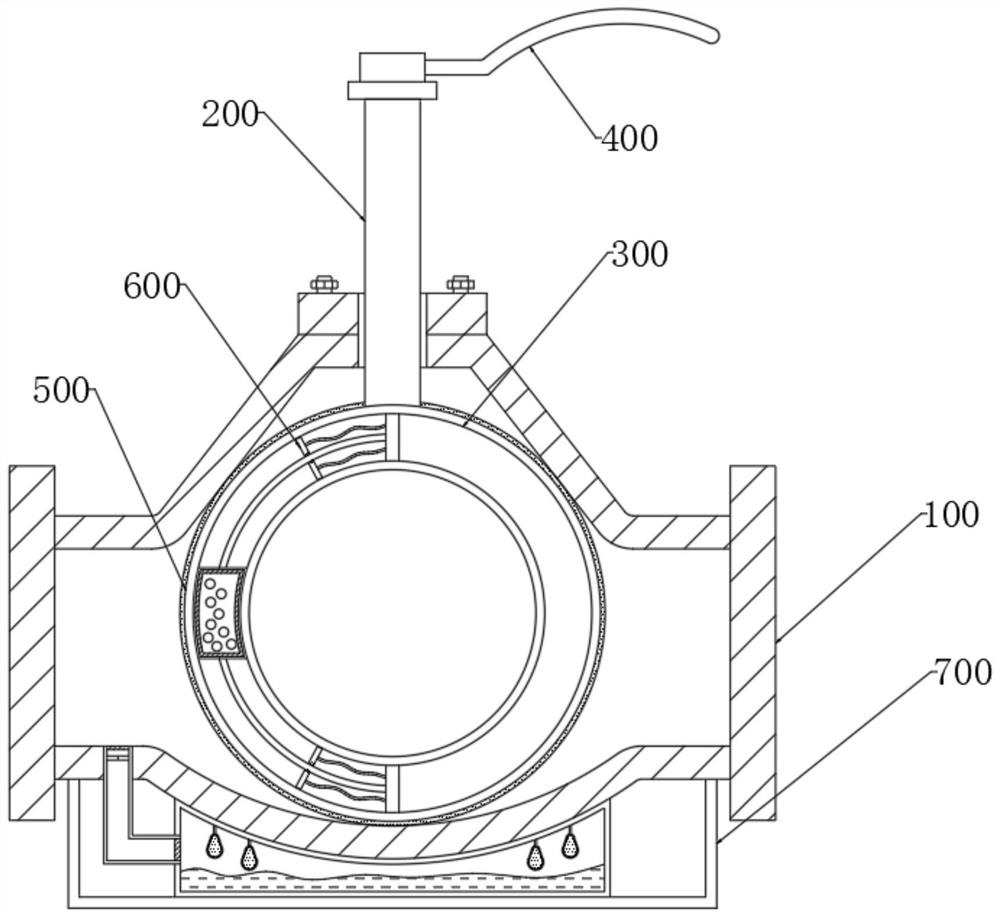

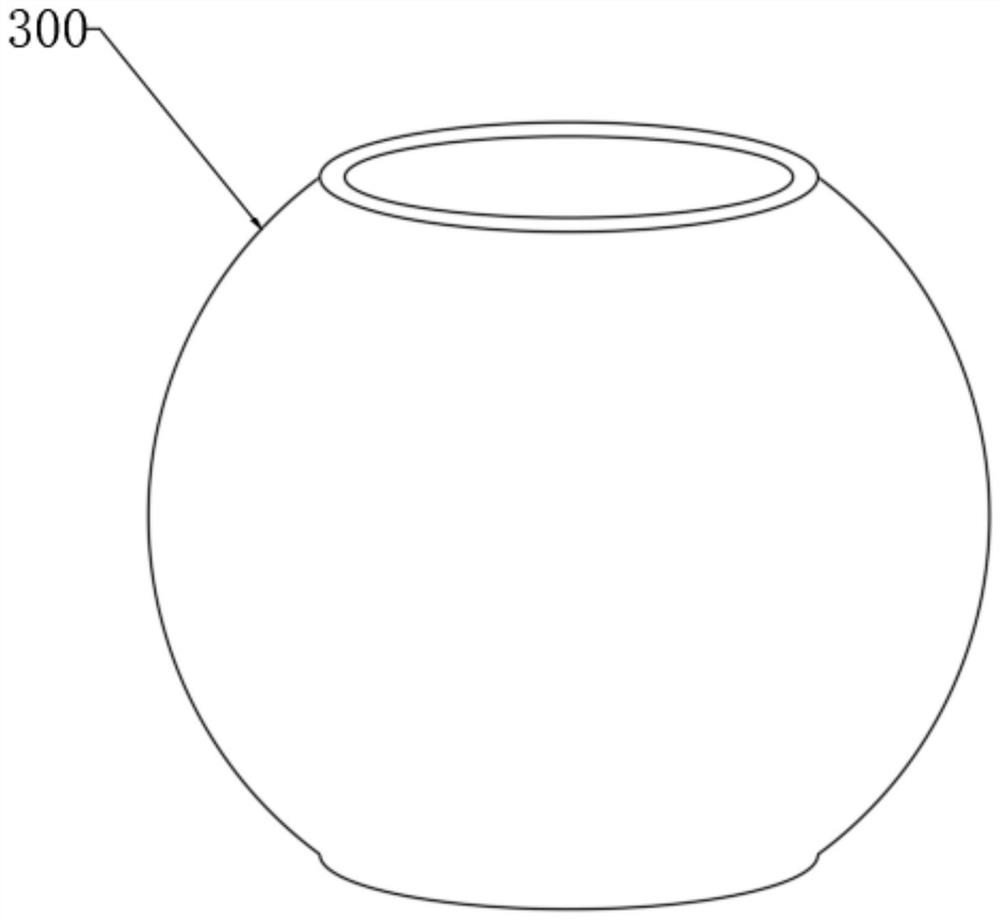

Ball valve capable of reducing impact effect

PendingCN114484002AReduce dispersionNot easy to damagePlug valvesNon-rotating vibration suppressionMechanicsImpact

The invention discloses a ball valve capable of reducing the impact effect, and belongs to the field of ball valves. According to the scheme, when fluid impacts on a valve ball body, the impact force borne by the valve ball body is dispersed and absorbed through a buffering and dispersing mechanism, the impact force transmitted to the valve ball body is relieved, and the impact effect is reduced; meanwhile, the impact force transmitted to the valve ball body drives the opposite abutting mechanisms to extrude air in the valve ball body to be sprayed out, reaction blowing is carried out on subsequent fluid impact, the blowing force and the fluid impact force are counteracted, the subsequent impact effect is effectively reduced, the valve ball body is not prone to damage, and the service life of the valve ball body is prolonged. And the pneumatic dispersing mechanism releases a large amount of carbon dioxide gas and sprays the carbon dioxide gas upwards under the impact effect, upward force is applied to follow-up flowing fluid, the follow-up flowing fluid is dispersed and is not prone to being concentrated together, and therefore impact force is relieved and dispersed, the valve ball body is not prone to being damaged under the continuous impact effect, and the protection effect is enhanced.

Owner:浩工阀门有限公司

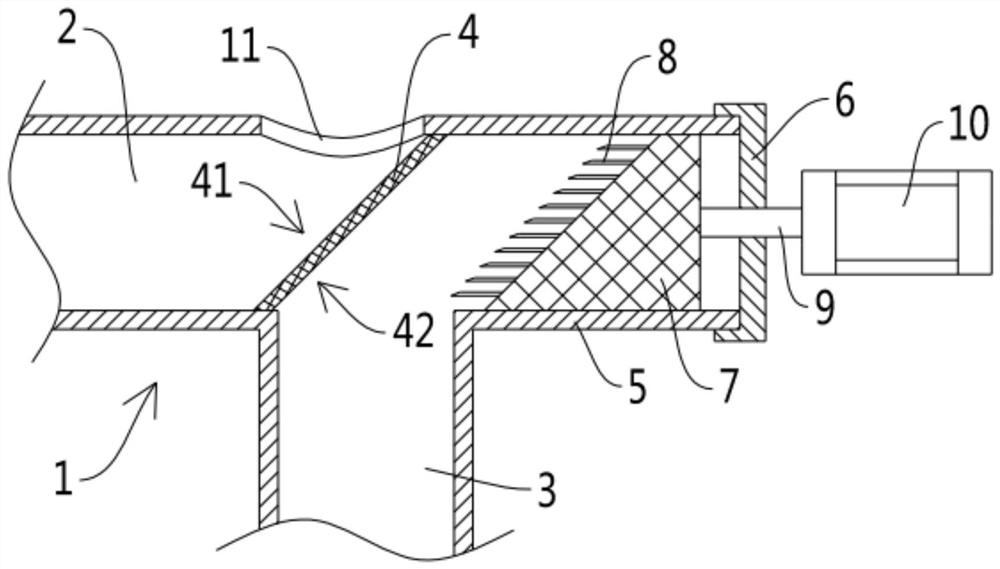

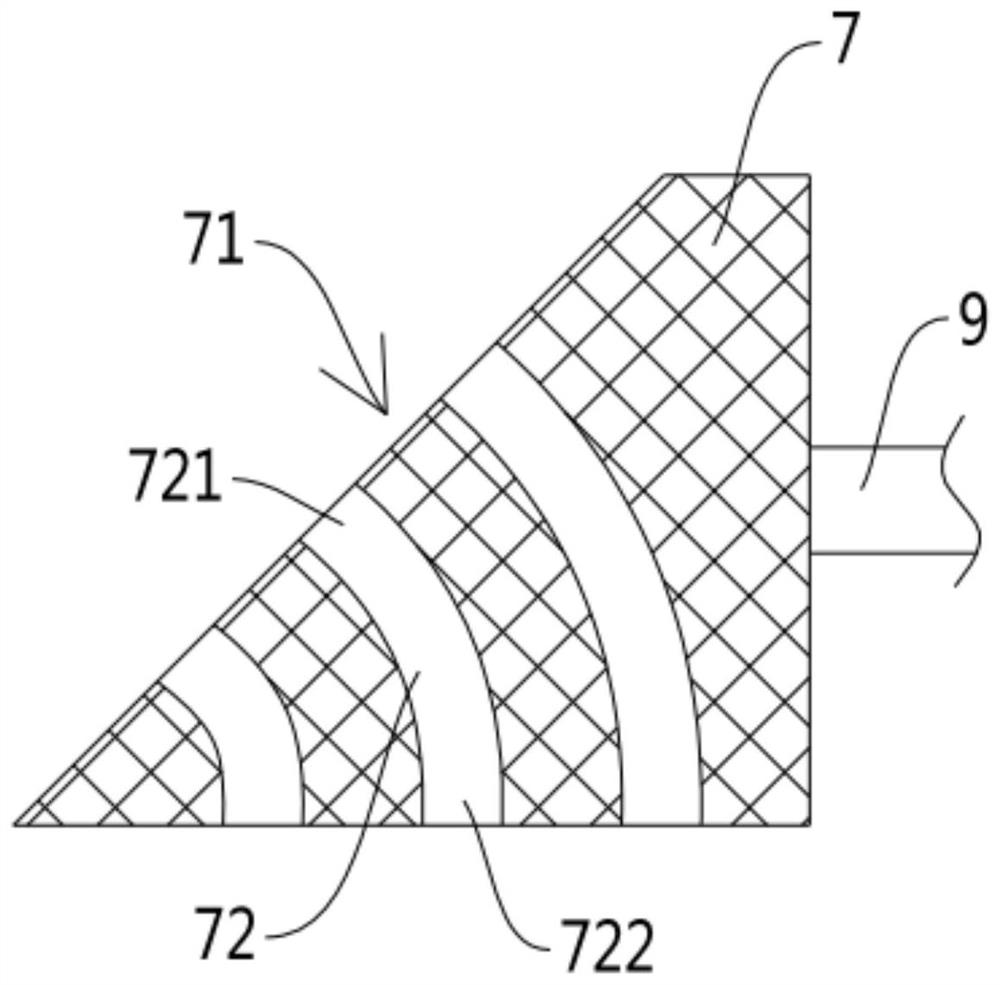

Anti-blocking filtering pipeline

InactiveCN112807783AEasy to recycleDifficult to concentrateStationary filtering element filtersPipe units with cleaning aperturesCleaning needleReciprocating motion

The invention disclsoes an anti-blocking filtering pipeline that comprises an L-shaped bent pipe body composed of a transverse pipe body horizontally and laterally extending and a vertical pipe body vertically extending up and down, wherein a filtering net plate for blocking the interior of the bent pipe body is arranged in the bent pipe body, and the filtering net plate is arranged at the corner of the transverse pipe body and the vertical pipe body; the filter screen plate is provided with an upstream face and a downstream face, a discharge port located over the upstream face is formed in the transverse pipe body, and the vertical pipe body is located under the downstream face; branch pipes located on the same straight line extend on the transverse pipe body, the branch pipes are arranged on one side of the downstream face of the filter screen plate, sealing plates are arranged on the branch pipes, movable plugs are slidably connected into the branch pipes, cleaning needles inserted into the filter screen plate are distributed on the movable plugs, and guide rods are slidably connected to the sealing plates; one end of each guide rod is connected with the movable plug, and the other end of same is provided with a linear reciprocating mechanism. The pipeline has the advantages of being good in filtering effect, not prone to blockage, complete in overall function and high in practicability.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

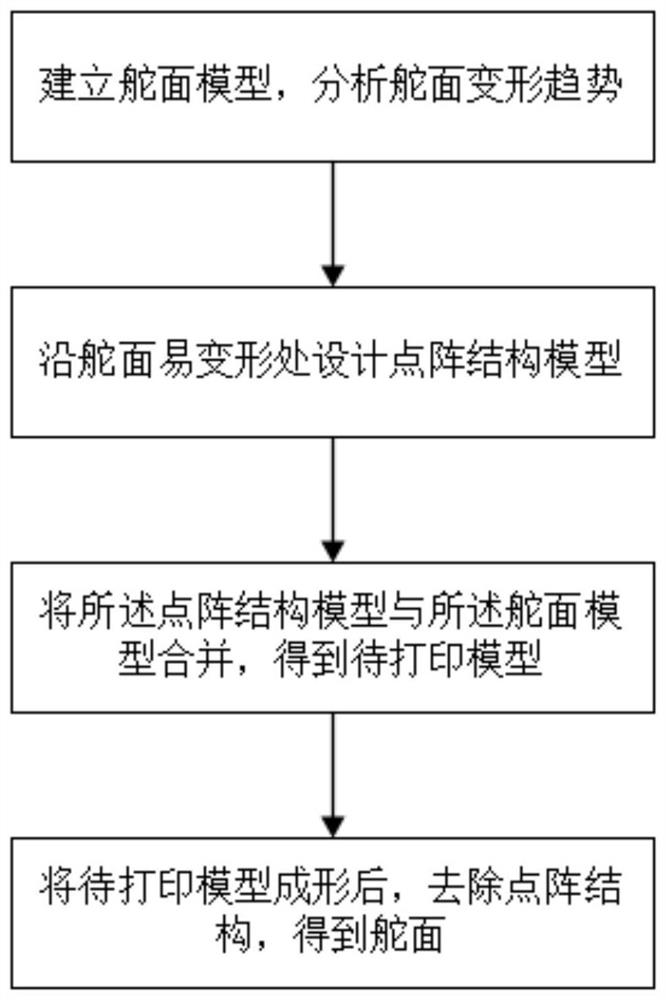

Method for preventing deformation of titanium alloy control surface formed by selective laser melting and control surface thereof

PendingCN114192796AControl deformationSolve the bulgeAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingTitanium alloy

The invention discloses a selective laser melting forming titanium alloy control surface anti-deformation method and a control surface thereof, and relates to the field of titanium alloy additive manufacturing. The method comprises the steps that S1, a control surface model is established, and the control surface deformation trend is analyzed; s2, designing a lattice structure model along the easy-to-deform part of the control surface; s3, the lattice structure model and the control surface model are combined, and a to-be-printed model is obtained; and S4, after the to-be-printed model is formed, the lattice structure is removed, and the control surface is obtained. According to the anti-deformation method for the titanium alloy control surface formed through selective laser melting and the control surface thereof, the anti-deformation design of the control surface skin is achieved by constructing a reasonable lattice structure support, rapid forming of the control surface skin framework is achieved through the selective laser melting method, the deformation problems of skin bulging or sinking and the like are solved, and the stability of the control surface is improved. And the profile precision and the product qualification rate are improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

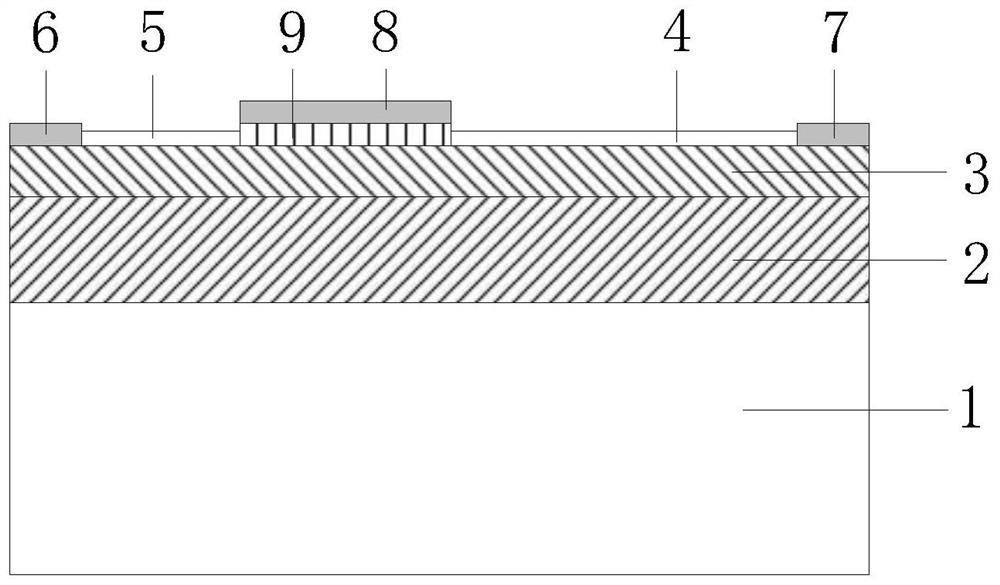

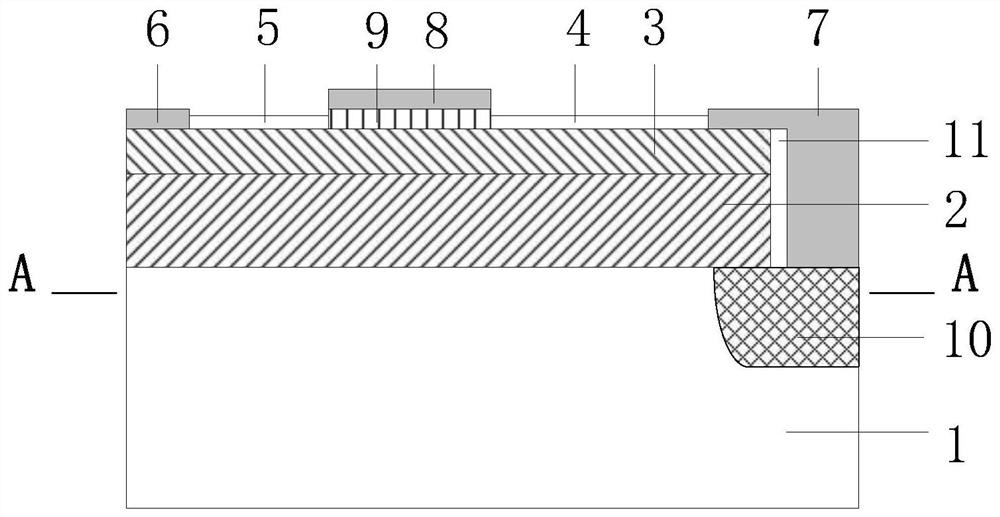

Gallium nitride power device with high avalanche capability and production process thereof

InactiveCN113594244AThe disadvantage of poor ability to avoid avalanchesStrong avalanche abilityThyristorSemiconductor/solid-state device manufacturingEngineeringGallium nitride

The invention discloses a gallium nitride power device with a high avalanche capability and a production process thereof. The device is characterized in that a gallium nitride buffer layer is arranged on a P-type silicon substrate, an aluminum-gallium-nitrogen barrier layer is arranged on the gallium nitride buffer layer, and then a metal source electrode, a metal drain electrode, a P-type gallium nitride layer and a metal grid electrode are arranged on the gallium nitride buffer layer; and an N-type region is arranged in the P-type silicon substrate, the metal drain electrode extends to penetrate through the aluminum-gallium-nitrogen barrier layer and the gallium nitride buffer layer and is connected to the N-type region, and a nitride passivation layer is arranged between the metal drain electrode and the gallium nitride buffer layer and is used for isolating the metal drain electrode from the gallium nitride buffer layer. The production process comprises the following steps of 1, forming an N-type region in a P-type silicon substrate; 2, growing the gallium nitride buffer layer on the P-type silicon substrate; 3, growing the aluminum-gallium-nitrogen barrier layer on the gallium nitride buffer layer; 4, forming a P-type gallium nitride layer on the aluminum gallium nitride barrier layer; 5, forming a nitride passivation layer; and 6, respectively depositing metal to form a metal source electrode, a metal drain electrode and a metal grid electrode.

Owner:SOUTHEAST UNIV

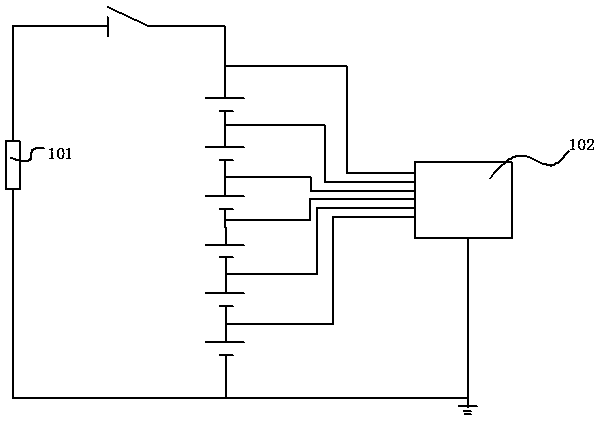

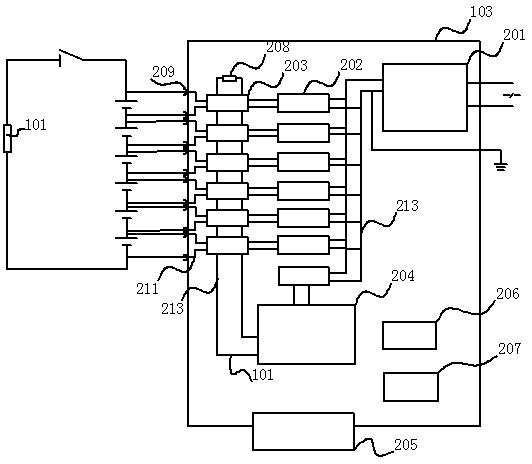

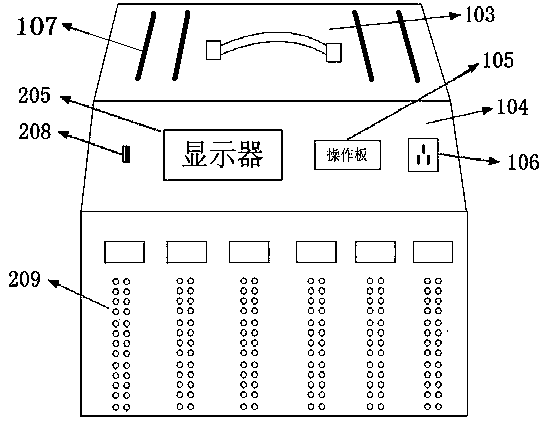

Portable storage battery pack voltage acquisition instrument

InactiveCN109507607ASolve communication transmission problemsImprove cooling effectElectrical testingTransformerDifferential transmission

The invention discloses a portable storage battery pack voltage acquisition instrument, relates to a battery pack detection device which is convenient to hold and move, in particular to a voltage measurement device for testing capacity of a battery pack. The voltage measurement device comprises a voltage stabilizing circuit, an isolation module, voltage acquisition modules and a central processingunit which are arranged in a box body, wherein a signal input end of each voltage acquisition module is separately connected with an anode and a cathode of a corresponding storage battery; an outputend of the voltage stabilizing circuit is respectively connected with a power supply end of the voltage acquisition module or the central processing unit by virtue of the isolation module; and a communication end of the voltage acquisition module is connected with a communication end of the central processing unit by virtue of a differential transmission bus. The invention provides a test instrument for acquiring the voltage of the transformer station storage battery pack, which is convenient to carry and high in practicability.

Owner:STATE GRID CORP OF CHINA +2

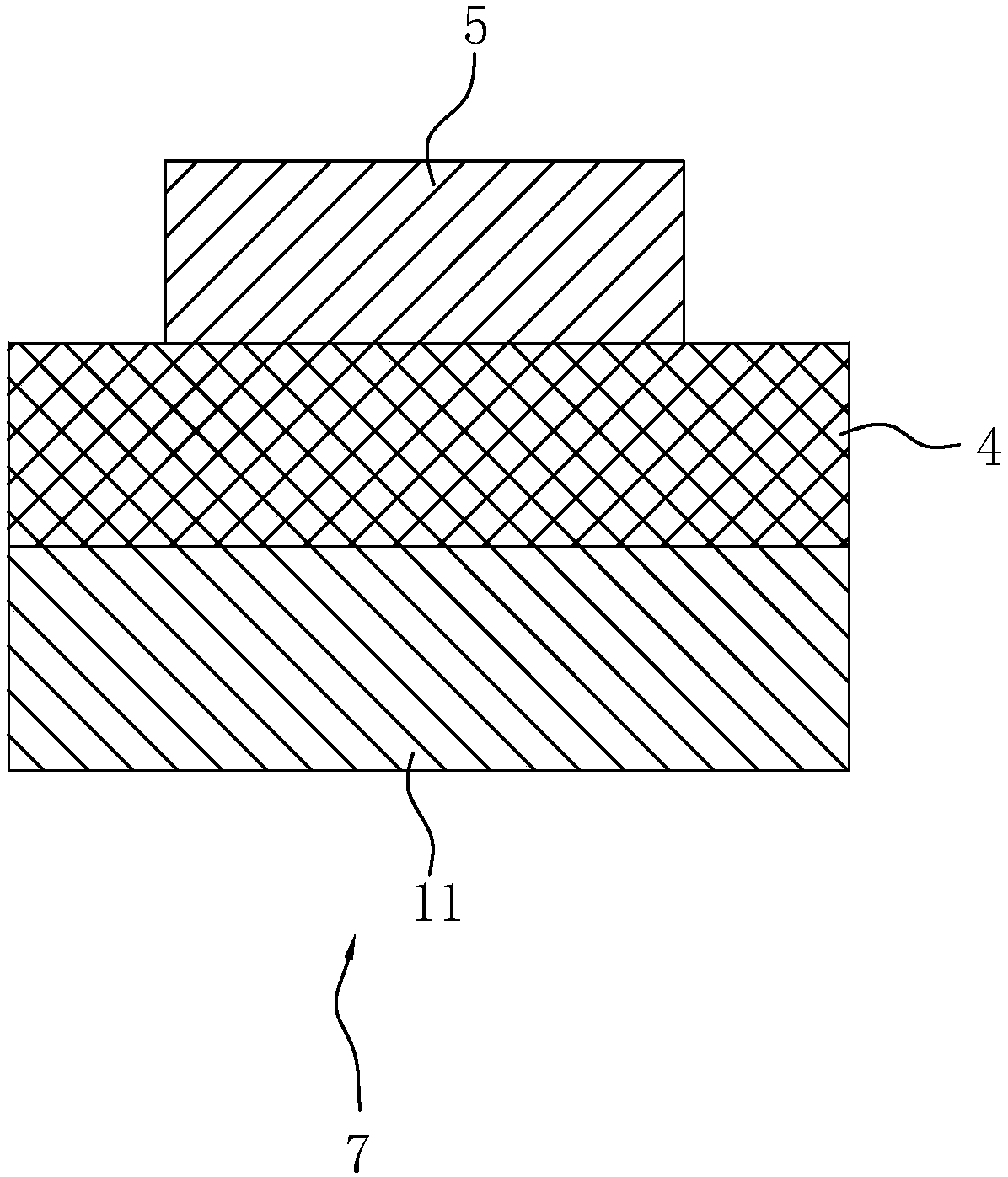

Production process for graphite cooling fin of battery cover

ActiveCN108068438ANot easy to scatterEasy to chopLamination ancillary operationsLaminationComposite filmPolyethylene terephthalate glycol

The invention discloses a production process for a graphite cooling fin of a battery cover. The key point of the technical scheme is as follows: the production process comprises the following steps: using a graphite film, a weak rubber film and a PET (Polyethylene Terephthalate) film to form a first composite film; conveying the first composite film into a second knife holder, conducting die cutting to form an outer contour; adhering a double faced adhesive tape to the first composite film, rolling and recycling the weak rubber film and the PET film to form a second composite film; adhering ablue film and a black film to the lower part of the second composite film; locating the blue film on the lowest layer; adhering the PET film to the lower part of the blue film to form a third composite film, recycling the PET film on the surface of the double faced adhesive tape on the uppermost layer, and adhering a soft film to the upper surface of the double faced adhesive tape. A preformed hole and the contour of the cooling fin formed through die cutting are only cut to the upper surface of the PET film on the lowest layer; the soft film left after cutting is recycled to form a fourth composite film; and a piece of release paper is adhered to the upper surface of the double faced adhesive tape layer and a breaking point is cut to form a product. The production process has the advantage that the possibility of producing chippings in the die cutting process of the graphite film is reduced.

Owner:路德通电子设备(北京)有限公司

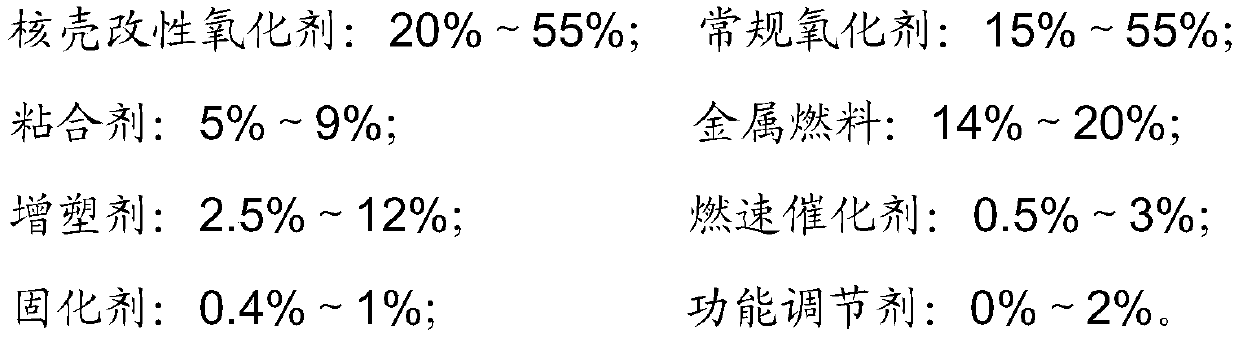

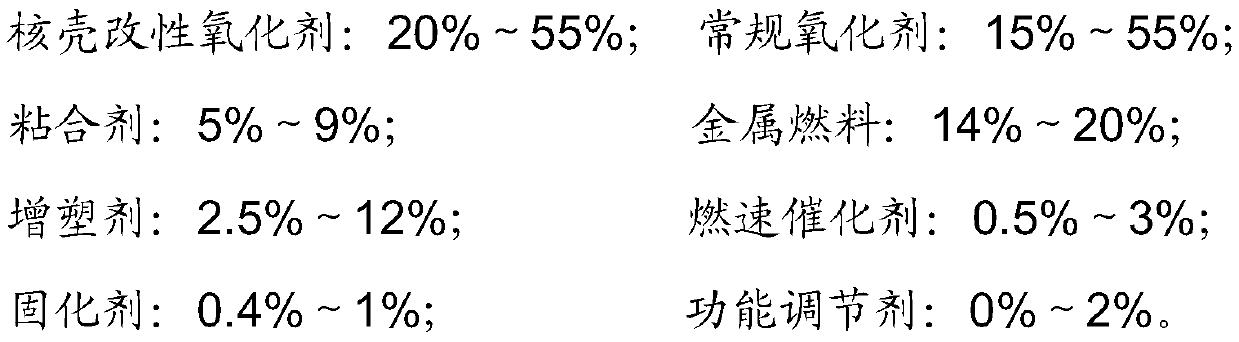

Solid propellant containing core-shell modified oxidant and preparation method of solid propellant

ActiveCN110981670AImprove securityImprove ductilityExplosive working-up apparatusPressure gas generationPtru catalystPlasticizer

The invention belongs to the field of solid propellants, and particularly relates to a solid propellant containing a core-shell modified oxidant and a preparation method of the solid propellant. The solid propellant comprises the following components in parts by weight: 20-55% of the core-shell modified oxidant, 15%-55% of a conventional oxidant, 5%-9% of an adhesive, 14%-20% of a metal fuel, 2.5%-12% of a plasticizer, 0.5%-3% of a combustion rate catalyst, 0.4%-1% of a curing agent, and 0%-2% of a function regulator. Compared with a propellant prepared from ammonium perchlorate under the samecondition, the propellant prepared by the invention has higher propellant combustion rate and volume heat value and better safety performance, and is particularly suitable for advanced tactical and strategic weapon type charging with higher requirements on the combustion rate, energy and safety performance of the propellant.

Owner:SHANGHAI AEROSPACE CHEM ENG INST

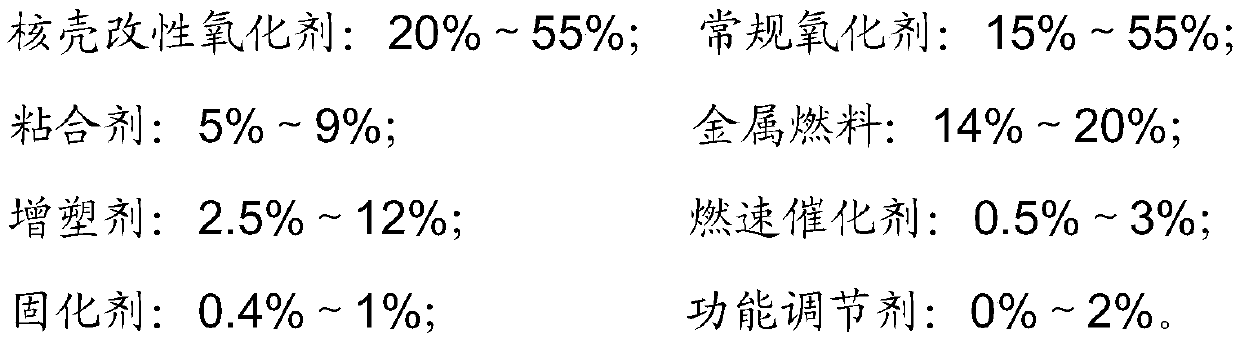

Water discharge structure with anti-floating, seepage-proofing and filtering functions

PendingCN110397022AAnti-floating and anti-seepageWith filter functionProtective foundationSoil preservationWater dischargeWater filter

The invention discloses a water discharge structure with anti-floating, seepage-proofing and filtering functions. The water discharge structure is laid on foundation soil, is used for discharging andguiding reverse seepage water flowing from the underground to the ground and comprises a water passing layer, a water filtering layer and a water discharging layer which are arranged from bottom to top in sequence, wherein the water passing layer is laid on the foundation soil and is used for dredging underground seepage water; the water filtering layer is used for depositing the underground seepage water of the water passing layer and guiding the underground seepage water to the water discharging layer and comprises a plurality of protrusion portions and a base layer, all the protrusion portions are alternately arranged on the base layer in a matrix form and are further provided with water passing passages correspondingly, and the positions, on the base layer, between all the protrusion portions form sunken portions used for depositing and filtering the underground seepage water correspondingly; and the water discharging layer is laid facing the water filtering layer and is used for guiding and discharging out the underground seepage water of the water filtering layer. By means of the water discharge structure with the anti-floating, seepage-proofing and filtering functions, the water discharge structure with the anti-floating, seepage-proofing and filtering functions is provided, the water discharge structure is simple in structure, reasonable in design and easy to realize, rapid water discharging is achieved, and meanwhile, the water discharge structure further has the effect of filtering the underground water.

Owner:黄逸飞 +1

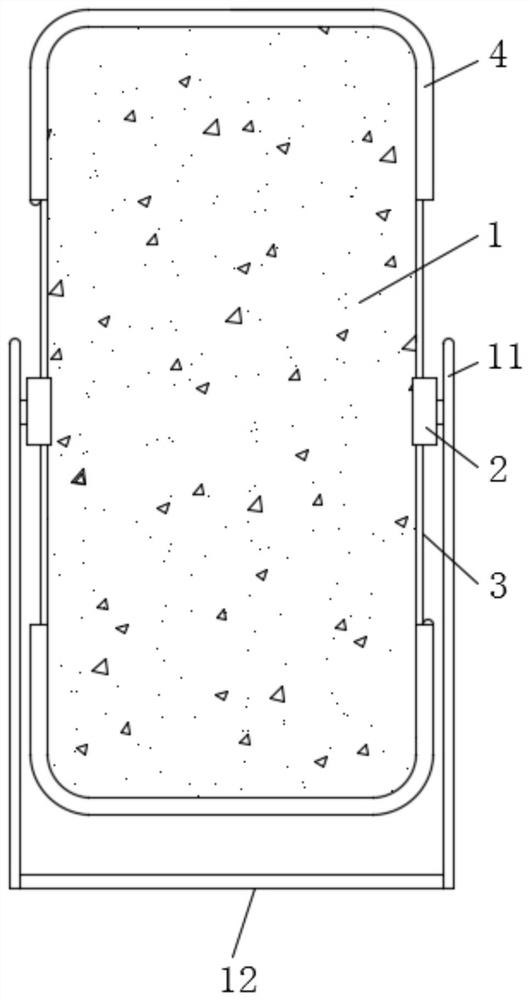

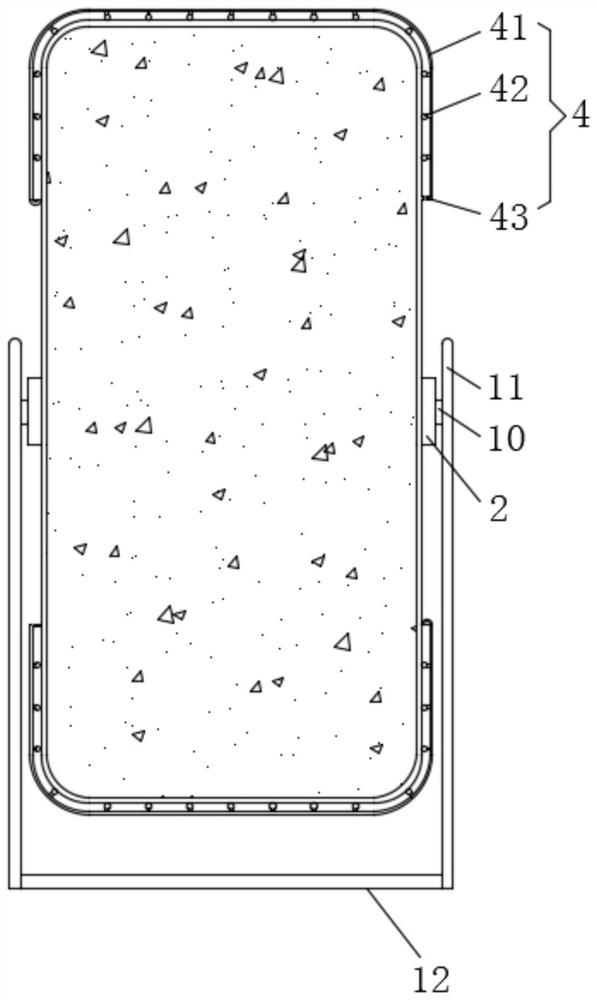

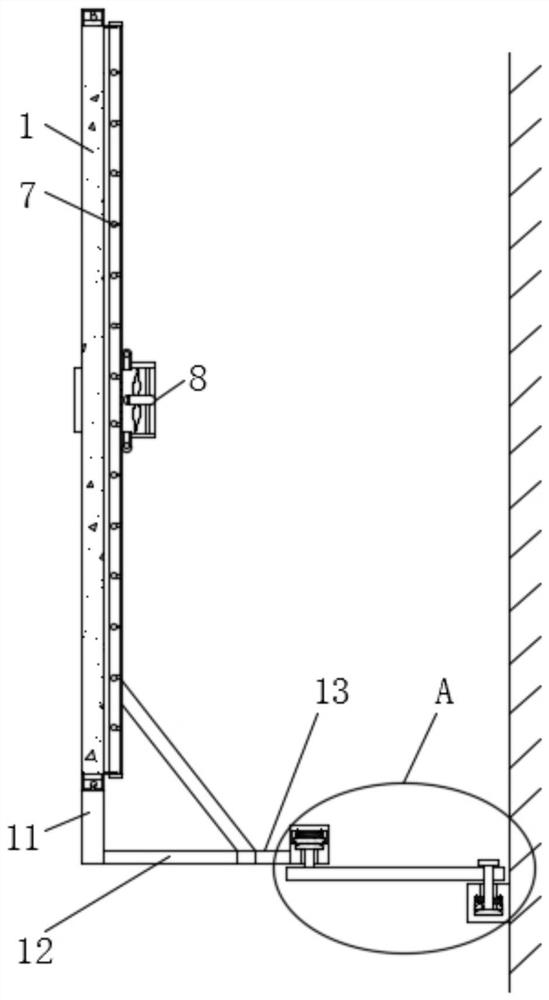

Mirror with good light scattering effect and light guide and modified light guide structure

ActiveCN113040509AEasy to importEvenly dispersedMechanical apparatusLighting heating/cooling arrangementsLight guideBlurred vision

The invention discloses a mirror with a good light scattering effect and a light guide and modified light guide structure, and relates to the technical field of mirrors, the mirror specifically comprises a mirror body and clamping blocks, the side face of the mirror body is provided with a light guide strip used for conducting light, and the top and the bottom of the mirror body are both provided with LED lamp strip structures used for supplementing light. The LED lamp strip structures are fixedly connected to the positions, located at the top and the bottom of the mirror body, of the light guide strip, and the clamping blocks are fixedly connected to the middle positions of the two sides of the mirror body. The LED lamp strip structures, the light guide strip, a light guide plate and an LED lamp structure are arranged, so that the effects of supplementing light and preventing blurred vision are achieved, the heat dissipation effect of the LED lamp strip structures and the LED lamp structure is enhanced by arranging a heat dissipation structure, a guide pipe, an air inlet hole, an air inlet and an air outlet, the LED lamp strip structure, and the mirror body can be far away from or close to a wall by arranging a connecting frame, a rotating structure A and a rotating structure B. The mirror body can rotate at any angle at will, and the practicability is high.

Owner:深圳市建源达镜业科技有限公司

Lightweight Metal Composite Decorative Panel

ActiveCN111270825BReduce impactNot easy to transferCovering/liningsFlooringEngineeringMechanical engineering

The invention relates to a lightweight metal composite decorative board, which includes an exterior panel, a bottom lining board, and a structural layer between the exterior decoration panel and the bottom lining board; the structural layer includes an absorption board and a buffer structure that interferes with the absorption board , the end of the buffer structure facing away from the absorbing plate is connected to the bottom liner. The invention has the advantages that when the exterior decorative panel is hit, the absorbing plate shares part of the impact force, and the remaining part of the impact force is buffered by the buffer mechanism in contact with it, so that the impact force received by the bottom lining plate is reduced, and the impact force is not easily absorbed by the bottom lining plate. Transferred to the buildings connected to it, the effect of impact resistance is better.

Owner:广州市柏舍装饰设计有限公司

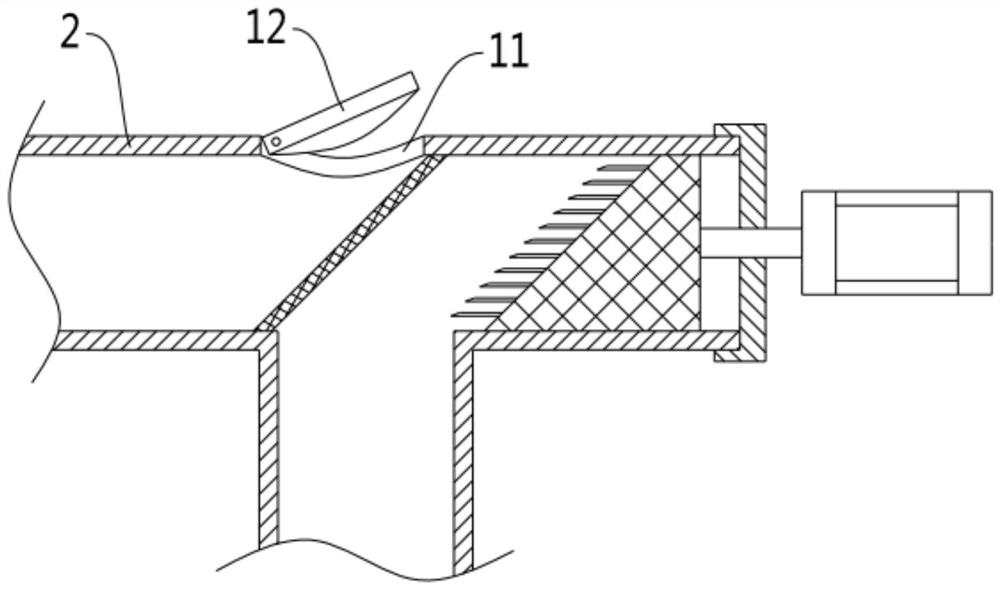

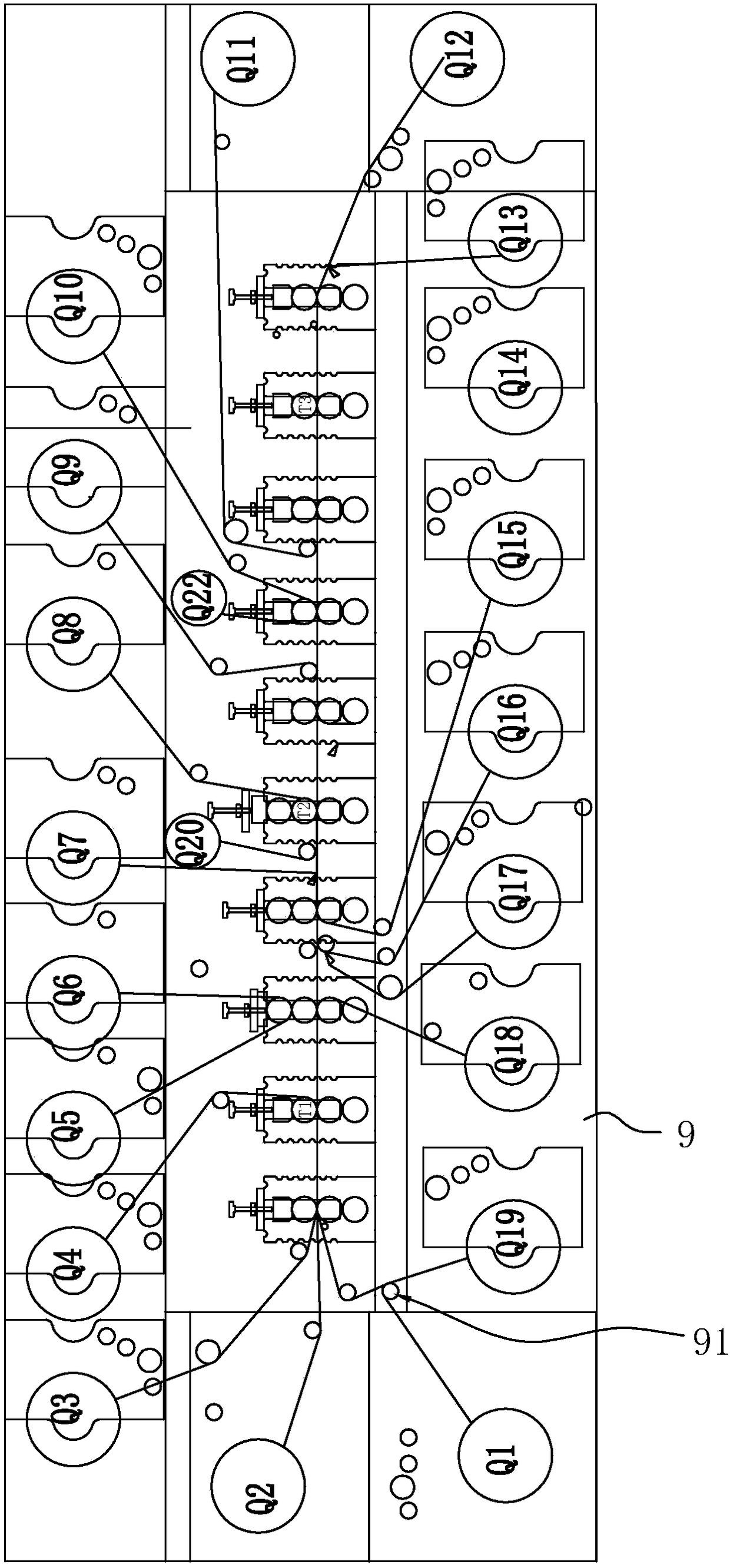

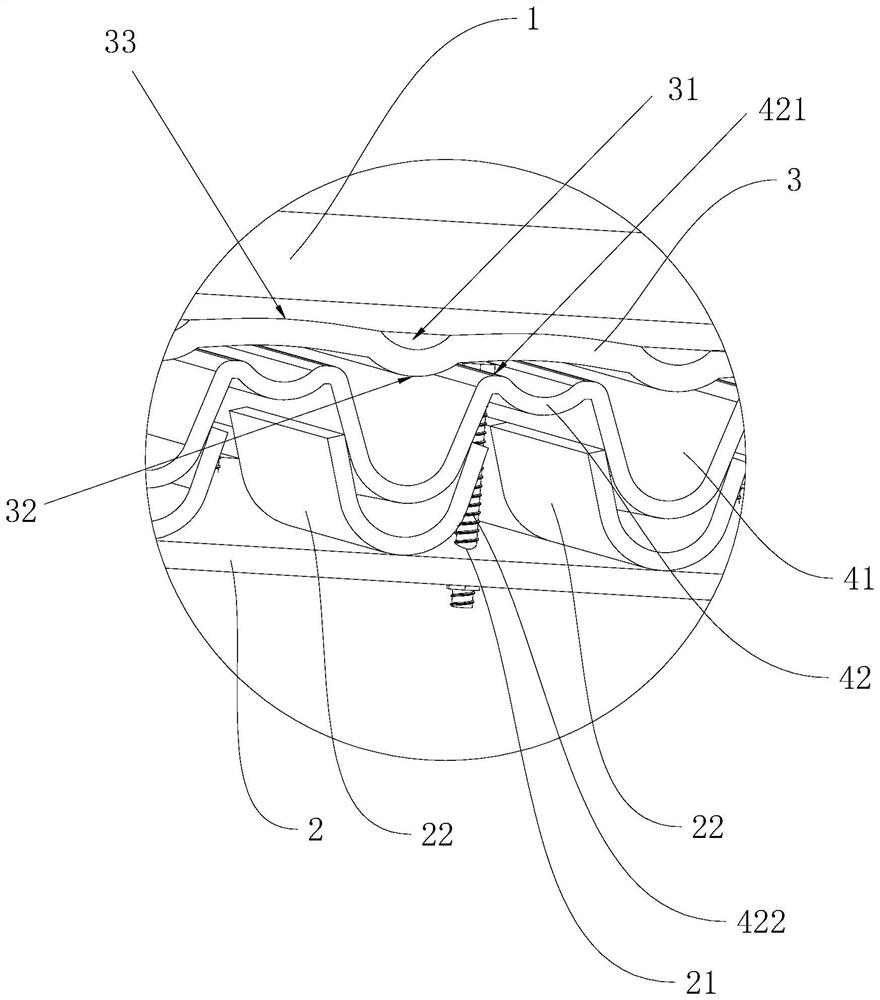

A quantitative packaging scale for functional color masterbatch packaging

The invention discloses a quantitative packaging scale for functional color masterbatch packaging, which belongs to the field of color masterbatch packaging scales. It is a quantitative packaging scale for functional color masterbatch packaging. The quantitative packaging scale of this solution is in normal use. In the process, the functional color masterbatch will be added along the inner wall of the feeding funnel, and the feeding funnel will rotate at a low speed synchronously during the adding process, so that the functional color masterbatch will be more uniform in the process of falling along the inner wall of the feeding funnel, and it will not be easy to concentrate on a certain part of the feeding funnel. On one side, the distribution of functional masterbatches is relatively uniform, and the function of the three-dimensional helical elastic screw end makes it difficult for functional masterbatches to collide with the feeding funnel, reducing the occurrence of functional masterbatches in the feeding process due to collisions. The phenomenon of cracking or peeling of pigment blocks attached to the surface can be achieved. During the process of packaging color masterbatch with quantitative packaging scales, it is not easy to cause the pigment on the surface of the color masterbatch to fall off, and it is not easy to affect the normal processing of the color masterbatch.

Owner:湖南省升阳新材料有限公司

A burner with flame-stabilizing structure

ActiveCN105650635BSmall diameterNot easy to leave the flameGaseous fuel burnerFlame propagationEngineering

Owner:SHANGHAI RINNAI

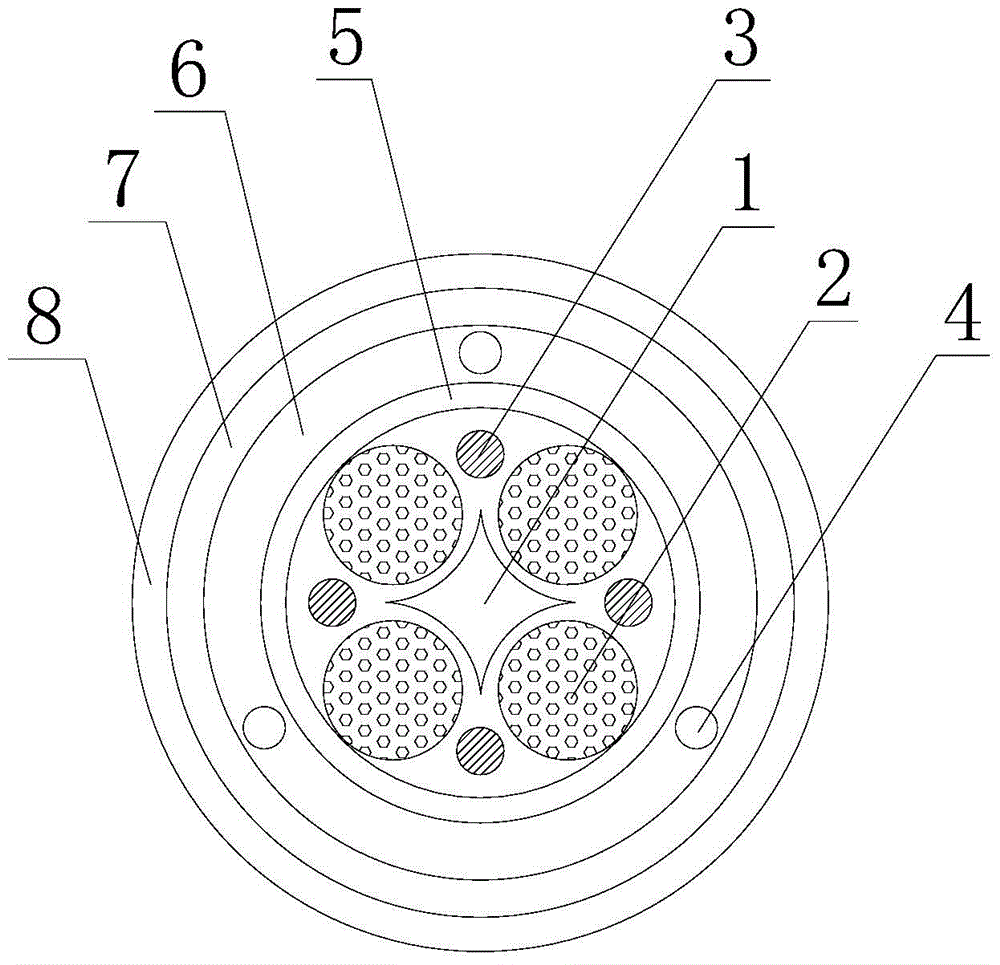

An anti-extrusion composite cable

ActiveCN103903785BNot easy to damageImprove protectionInsulated cablesPower cablesEngineeringElectric power

The invention discloses an extrusion-resistant composite cable. The extrusion-resistant composite cable comprises a buffering space located in the center of the cable, wherein on any one section, the buffering space is defined by four curves, the four curves are sequentially connected and bent in the direction far away from the center of the cable, the corresponding position of each curve is provided with a communication conductive wire, a reinforcing rope is arranged in a hole space formed by every two adjacent communication conductive wires, the buffering space, the communication conductive wires and the reinforcing ropes are integrated because space among the buffering space, the communication conductive wires and the reinforcing ropes is filled with flexible materials, the peripheries of the flexible materials are sequentially provided with a shielding layer, an insulating layer, a water-proof layer and a protecting sheath, and three electric lines serving as a live line, a zero line and a ground line are arranged inside the insulating layer; the communication conductive wires are symmetrically distributed with respect to the central axis of the cable, and the included angle between the connection line of one communication conductive wire and the geometric center of the cable and the connection line of another adjacent communication conductive wire and the geometric center of the cable is 90 degrees on any cross section of the cable. The extrusion-resistant composite cable is compact in structure and high in extrusion-resistant ability.

Owner:扬中市新坝科创服务有限公司

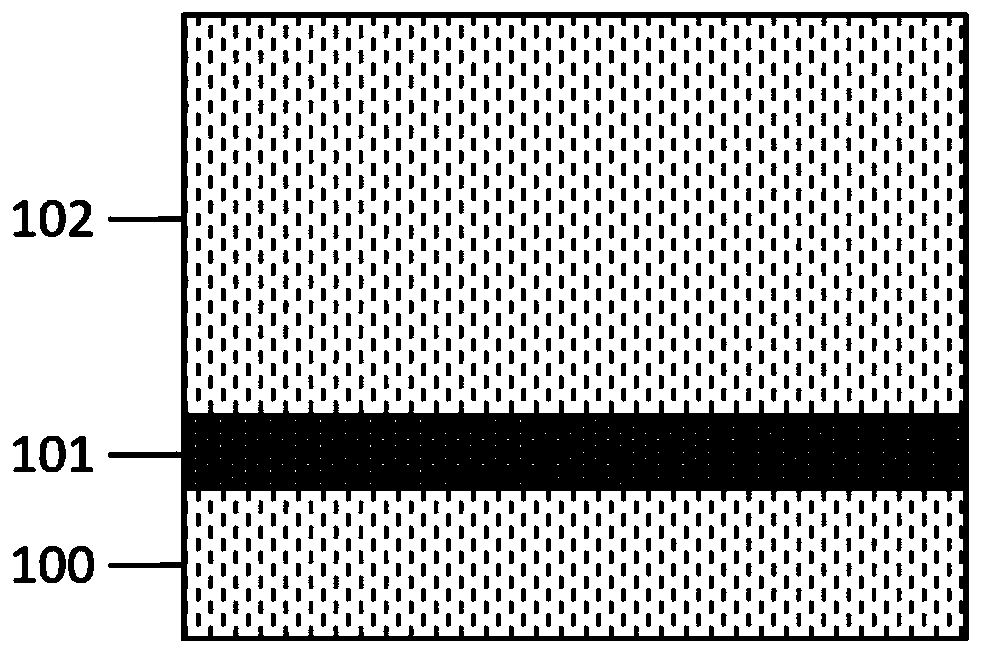

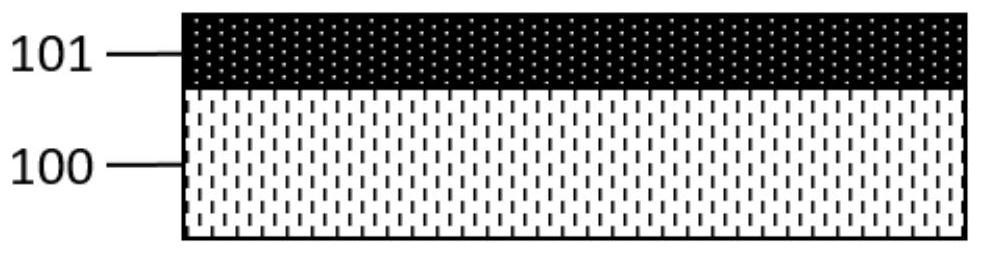

semiconductor structure

ActiveCN104425564BWidely used valueDifficult to concentrateSemiconductor/solid-state device detailsSolid-state devicesAnti stressSemiconductor structure

The present invention relates to a semiconductor structure, comprising a carrier, a first protection layer, a second protection layer and a third protection layer, the first surface of the first protection layer has a first anti-stress region, the second protection layer The first anti-stress region is exposed, the second protective layer has a first side and a second side, a first extension line extending from the first bottom of the first side and a second bottom of the second side The extended second extension lines intersect to form a first base point, the third protective layer has a third side and a fourth side, the third side forms a first projection line on the first surface, and the first projection line The extension line intersects with the second base to form a first intersection point, the fourth side surface forms a second projection line on the first surface, and the extension line of the second projection line intersects with the first base to form a second intersection point. The area formed by the intersection point, the first base point, the first intersection point and the second intersection point is the first anti-stress area.

Owner:CHIPBOND TECH

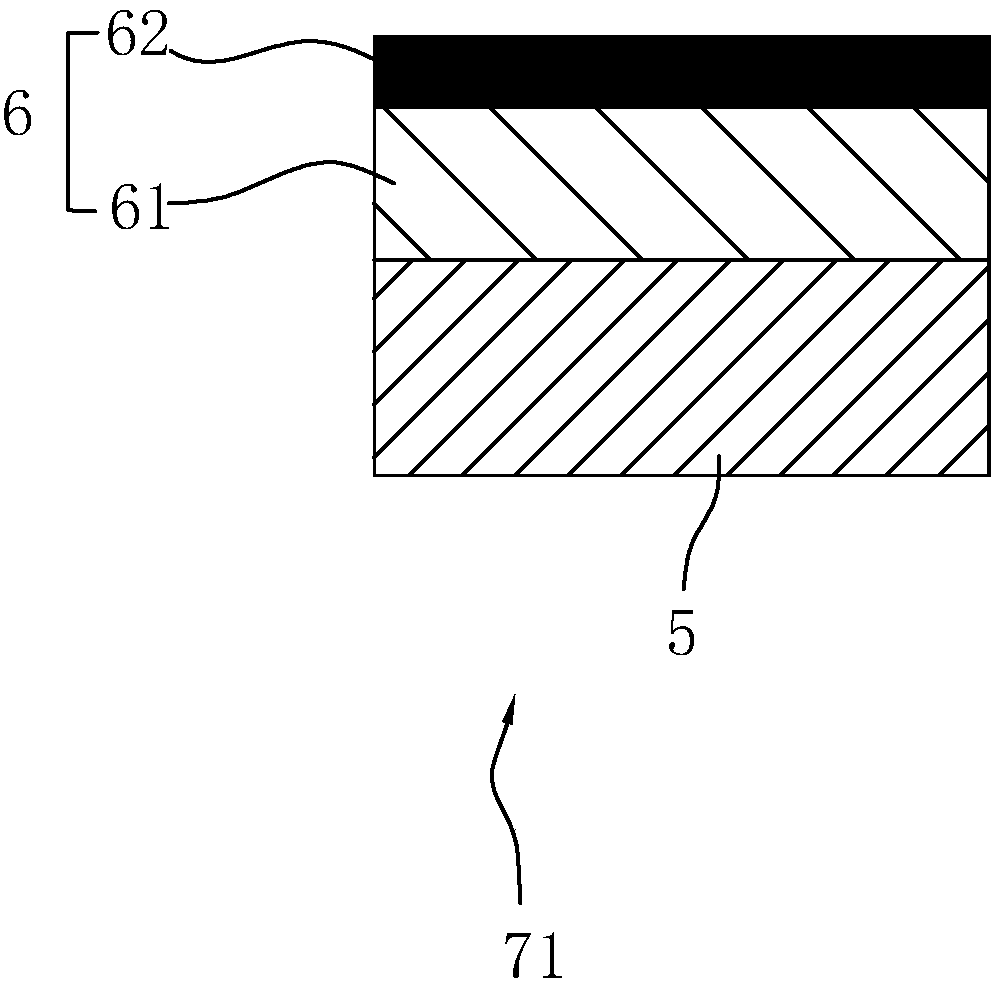

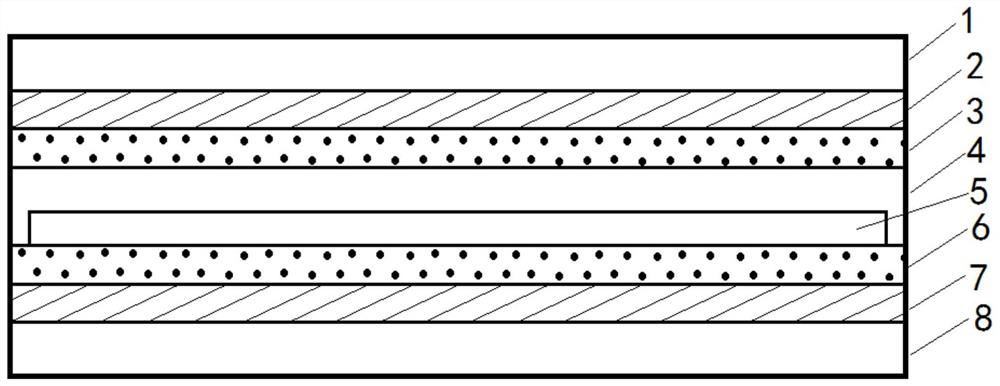

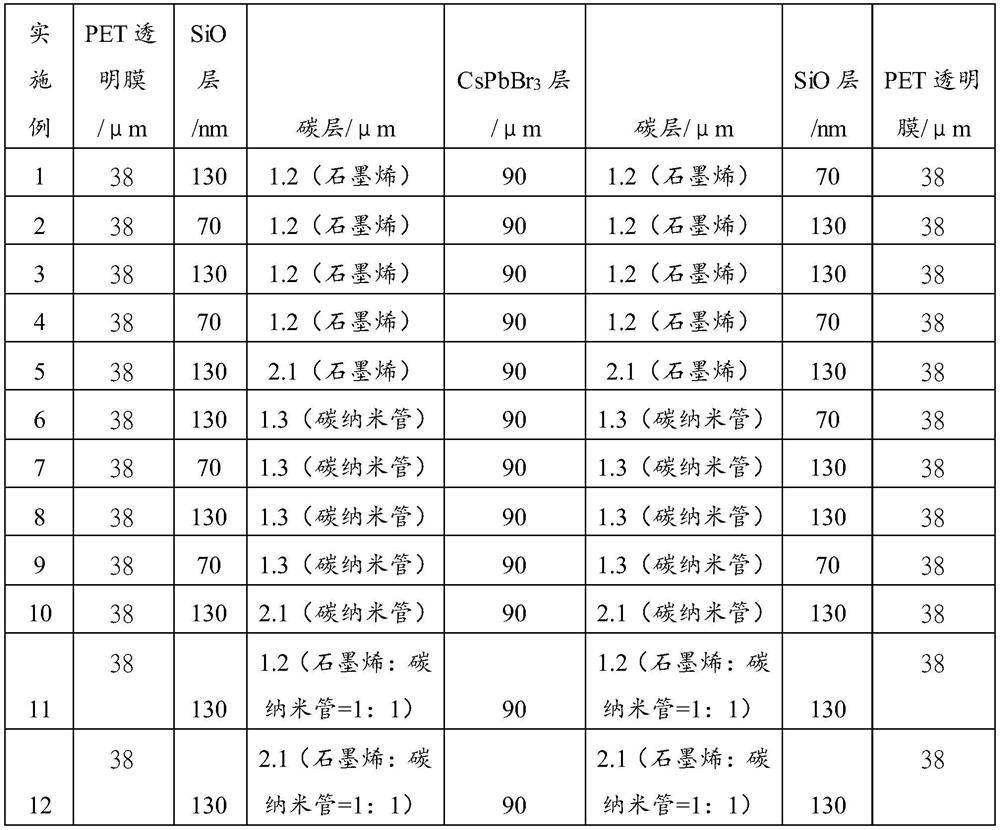

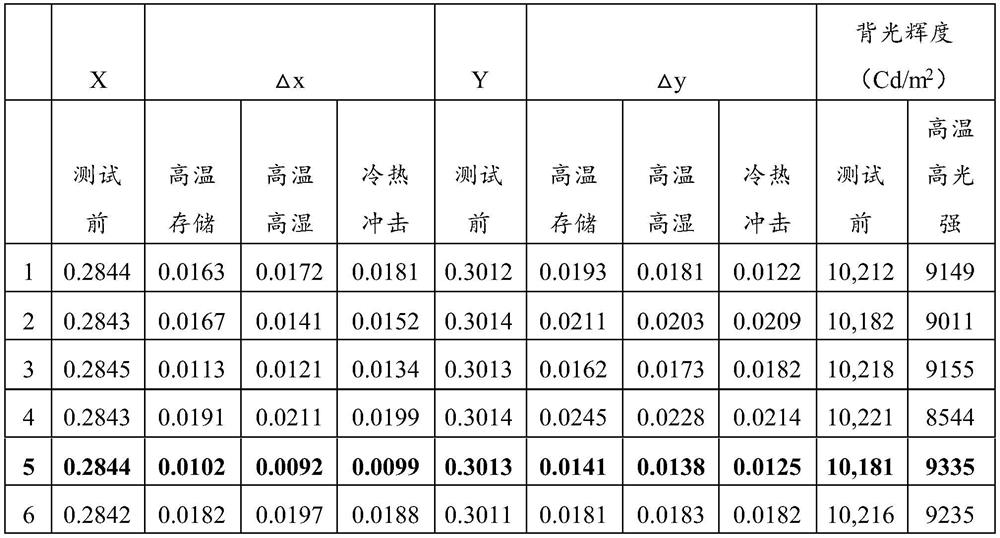

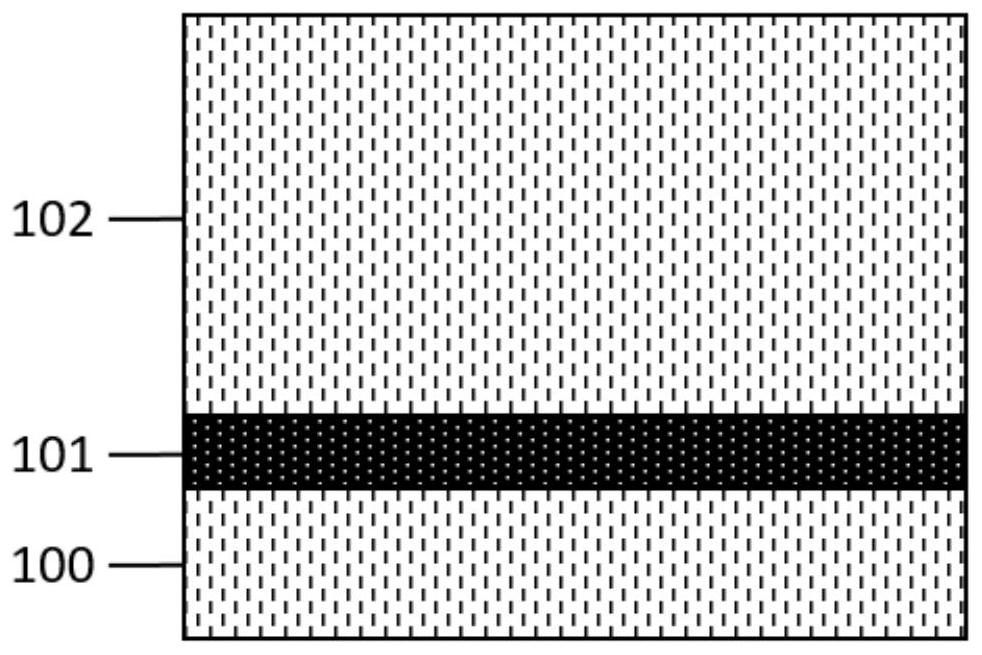

Quantum dot film with long service life, preparation method of quantum dot film and application of quantum dot film in liquid crystal display

PendingCN112698530AExtend your lifeNot easily oxidizedVacuum evaporation coatingSputtering coatingLiquid-crystal displayCarbon nanotube

The invention provides a quantum dot film with long service life. The quantum dot film comprises a first PET layer, a first waterproof layer, a quantum dot layer, a second waterproof layer and a second PET layer which are in contact in sequence, the first waterproof layer comprises a ceramic layer A and a carbon functional layer A; the second waterproof layer comprises a ceramic layer B and a carbon functional layer B; the ceramic layer A and the ceramic layer B are respectively and independently selected from silicon oxide and / or silicon nitride; and the carbon functional layer A and the carbon functional layer B respectively and independently comprise graphene and / or carbon nanotubes. By utilizing the loose and defective structures of the carbon nanotubes and graphene, water vapor can be stored, the water vapor can be stored after entering the PET water-blocking and gas-blocking film, the service life of the quantum dot film can be prolonged, and the film form can disperse heat and is not easy to concentrate in a local area. The invention provides a preparation method and application of a quantum dot film with long service life.

Owner:DONGGUAN GUANGZHI PHOTOELECTRIC CO LTD

Deep hole superlattice filling method based on electrochemical deposition

ActiveCN110911555BDifficult to concentratePrecise control of depositionElectrical apparatusNanotechnologyElectrolytic agentMaterial growth

The invention discloses a deep hole superlattice filling method based on electrochemical deposition, comprising the following steps: S1: preparing a conductive substrate; S2: preparing an insulating layer; S3: preparing a deep hole; S4: configuring a reaction solution, wherein two different electrolytes; S5: electrochemical deposition is carried out from the bottom to the top in the deep hole, wherein, by adjusting the deposition parameters, the first phase change material layer and the second phase change material layer are alternately deposited in the deep hole respectively, forming a super Lattice structure; S6: Preparation of upper electrode. The invention uses micro-nano processing technology to etch deep holes with nano-scale apertures and then uses electrochemical deposition to quickly and effectively fill the deep holes. The nano-phase change material can be grown from the bottom of the nano-hole, and the ultra-high depth can be realized. The wide-ratio pores are filled with chalcogenide phase change materials, and the precise control of material growth can be achieved by adjusting the deposition parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for phase change memory cell integration using electrochemical deposition

ActiveCN111081869BDifficult to concentratePrecise control of depositionElectrical apparatusElectrolytic agentPhase-change memory

The invention discloses a method for integrating phase-change storage units by using electrochemical deposition, comprising the steps of: S1: preparing a conductive substrate; S2: preparing an insulating layer; S3: preparing deep holes; S4: configuring a reaction solution, which is mixed with Two different electrolytes; S5: Electrochemical deposition is carried out from the bottom up in the deep hole. By adjusting the deposition parameters, the upper and lower layers of materials are deposited in the deep hole, namely the gating tube and the phase change unit; S6: Prepare the upper electrode . The deep hole with nanoscale aperture is etched by micro-nano processing technology, and then the electrochemical deposition method is used to quickly and effectively fill the deep hole. The nano phase change material can be grown from the bottom of the nanopore, which can achieve a super large aspect ratio. The small holes are filled with chalcogenide phase change materials with multi-layer complex structures. The precise control of material growth can be realized by adjusting the deposition parameters. The patterned growth can be realized by designing the electrode shape with potential applied at the bottom, and various complex structures can be realized. Preparation of materials.

Owner:HUAZHONG UNIV OF SCI & TECH

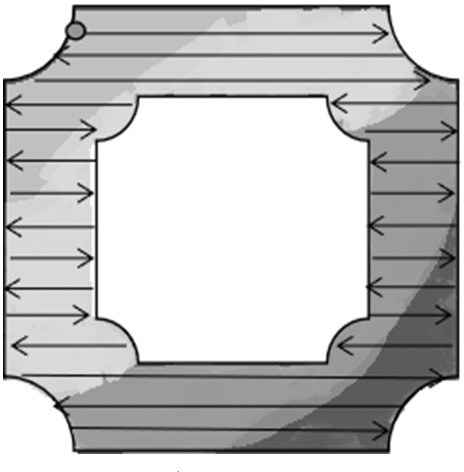

High energy beam scanning path planning method, additive manufacturing method and device

ActiveCN113351885BGuaranteed forming qualityEvenly distributedAdditive manufacturing apparatusIncreasing energy efficiencyScan lineBeam scanning

The invention relates to a high-energy beam scanning path planning method, an additive manufacturing method and a device, and relates to the technical field of additive manufacturing. The high-energy beam scanning path planning method includes: constructing a three-dimensional model of an additively manufactured part; slicing the three-dimensional model of the part in layers along the direction of printing and manufacturing, and extracting section profile data of each layer slice; according to the section profile data of each layer slice Obtain the contour line of each slice, and after the contour line is contracted inward or expanded outward, at least one continuous scan line is obtained; the scan line is randomly divided into N segments, and the length of each scan line segment is less than or equal to a preset value; Each scan line is numbered, and each scan line segment is scanned according to a preset numbered scanning sequence, wherein at least one scan line segment is spaced between two scan line segments scanned in succession. The invention improves the uniformity of heat distribution during additive manufacturing of thin-walled parts, reduces thermal stress, and prevents deformation and cracking of parts.

Owner:西安赛隆增材技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com