Quantum dot film with long service life, preparation method of quantum dot film and application of quantum dot film in liquid crystal display

A technology with quantum dot film and long service life, which can be used in instruments, ion implantation plating, coating, etc., and can solve the problems of the influence of quantum dot film service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

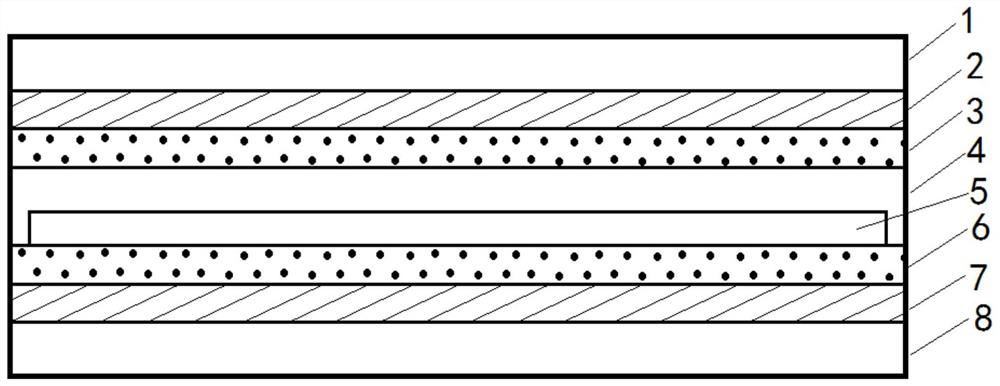

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing a quantum dot film with long service life as described above, comprising the following steps:

[0048] A) A ceramic layer B is formed on the surface of the second PET layer by magnetron sputtering, and a carbon functional layer B is formed by coating and solidifying the carbon material slurry B to obtain a second PET layer compounded with a second water-blocking layer. The ceramic Layer B and carbon functional layer B are formed in no particular order;

[0049] A ceramic layer A is formed on the surface of the first PET layer by magnetron sputtering, and a carbon functional layer A is formed by coating and solidifying a carbon material slurry A to obtain a first PET layer compounded with a first water blocking layer. The ceramic layer A The formation of the carbon functional layer A is in no particular order;

[0050] B) Coating quantum dot glue on the surface of the second water blocking layer to form a quantu...

Embodiment 1

[0086] Take a PET transparent film with a thickness of 38 μm, and form a SiO layer on its surface by magnetron sputtering. The target is a silicon target, and the gas is a mixture of argon and oxygen. The argon flow rate is 40 sccm, the oxygen flow rate is 40 sccm, and the sputtering power is 3 kW / m 2 , the roll-to-roll machine speed is 8m / min, and a SiO layer with a thickness of 130nm is obtained;

[0087] Mix graphene with polyurethane glue to obtain a graphene coating solution with a graphene content of 8%, then perform gravure coating on the surface of the SiO layer, and heat cure at 120°C to obtain a graphene layer with a thickness of 1.2 μm;

[0088] Take another 38 μm thick PET white film, form a 70nm thick SiO layer (roll-to-roll machine speed 15m / min) and a 1.2 μm thick graphene layer on its surface according to the above method;

[0089] On the graphene layer (PET white film) coating mass fraction is 5% CsPbBr 3 UV-curable acrylic pressure-sensitive adhesive with ...

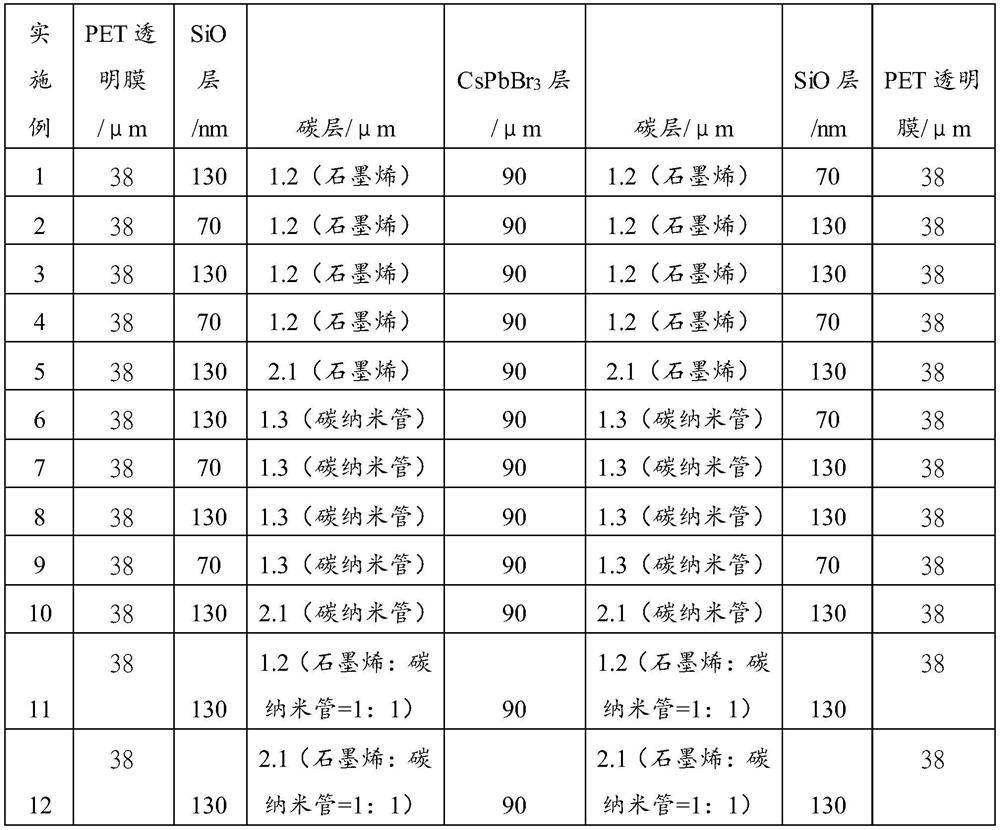

Embodiment 2~12

[0092] Prepare the quantum dot film according to the method in Example 1, the difference is that it is prepared according to the structural parameters in Table 1:

[0093] The film layer thickness of table 1 embodiment 1~12 (all are transparent PET films up and down)

[0094]

[0095] Among them, in the preparation of the SiO layer with a thickness of 130nm, the roll-to-roll machine speed is 8m / min, and in the preparation of the SiO layer with a thickness of 70nm, the roll-to-roll machine speed is 15m / min.

[0096] In the preparation of the carbon functional layer with a thickness of 1.2 μm and 1.3 μm, the content of the carbon material in the carbon material slurry is 8%, and in the preparation of the carbon functional layer with a thickness of 2.1 μm, the content of the carbon material in the carbon material slurry is 15% .

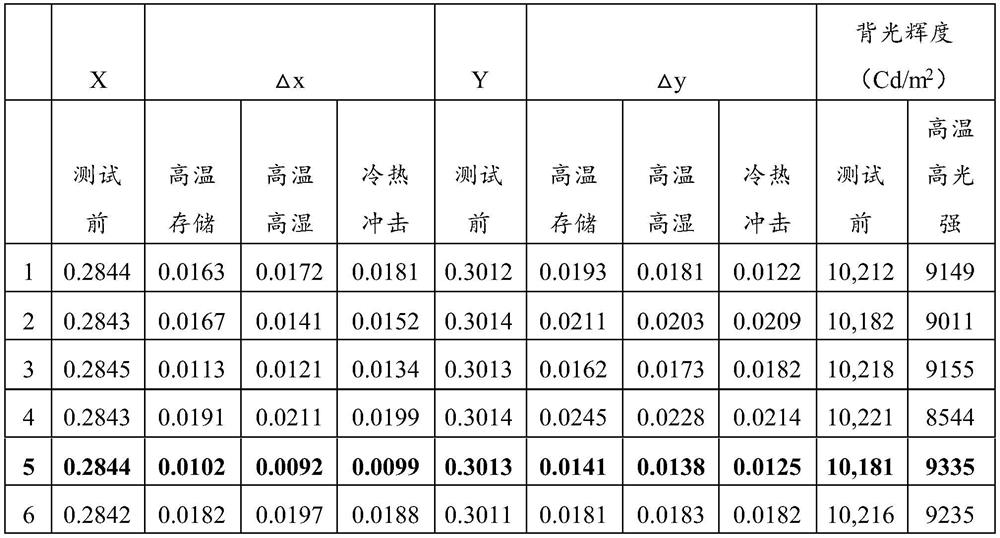

[0097] The quantum dot films prepared in Examples 1-12 are tested as follows, the light source is a blue-violet lamp (LED backlight) x=0.2931y=0.15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com