Production process for graphite cooling fin of battery cover

A technology of graphite heat sink and production process, which is applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., and can solve the problems of graphite debris scattering and affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

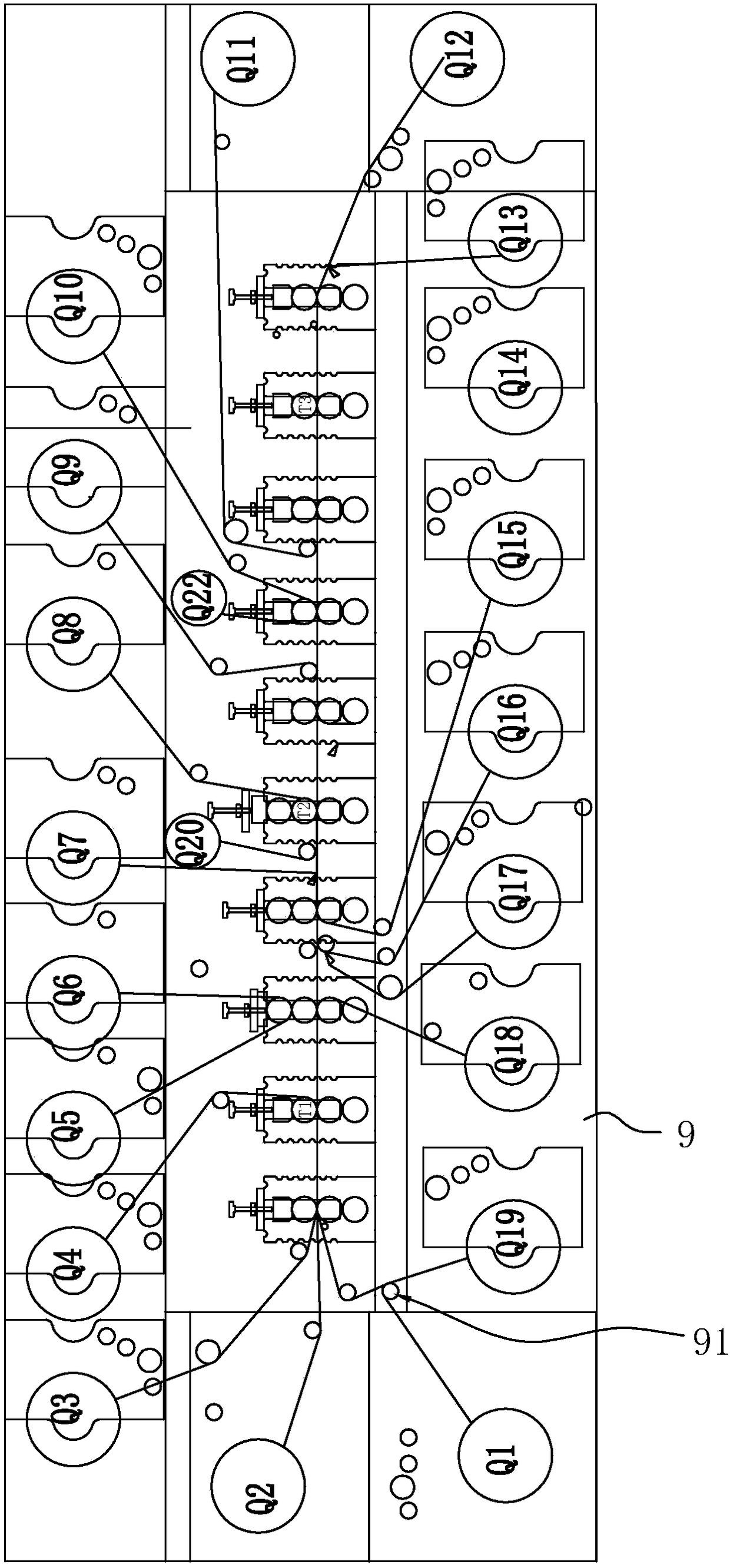

[0040] Embodiment: a kind of production process of battery cover graphite radiator, such as figure 1 As shown, this production process is the same as the existing process, and is all carried out on the rotary die-cutting machine 9. The rotary die cutting machine 9 includes a plurality of rotating rollers and a plurality of knife seats. There are two types of rotating rollers, one is the raw material roller, which is used to place various film raw materials; the other is the receiving roller, which rewinds various films and their waste materials during the rotation process. There is a roller shaft on the knife seat, and a cutter is installed on the roller shaft. During the rotation of the roller shaft, various films are pulled, so that various films are merged from different raw material rolls to the roller shaft for bonding, and are die-cut by the cutter. Form the outline of the battery cover and the reserved holes of various shapes (at the position of the mobile phone camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com