Water discharge structure with anti-floating, seepage-proofing and filtering functions

A drainage structure and function technology, applied in the field of construction, can solve problems such as sand particles easily clogging rock layers, frequent changes in groundwater levels, and reducing the bearing capacity of foundation soil, so as to solve the problem of reverse seepage, save water and energy, and improve bearing capacity. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

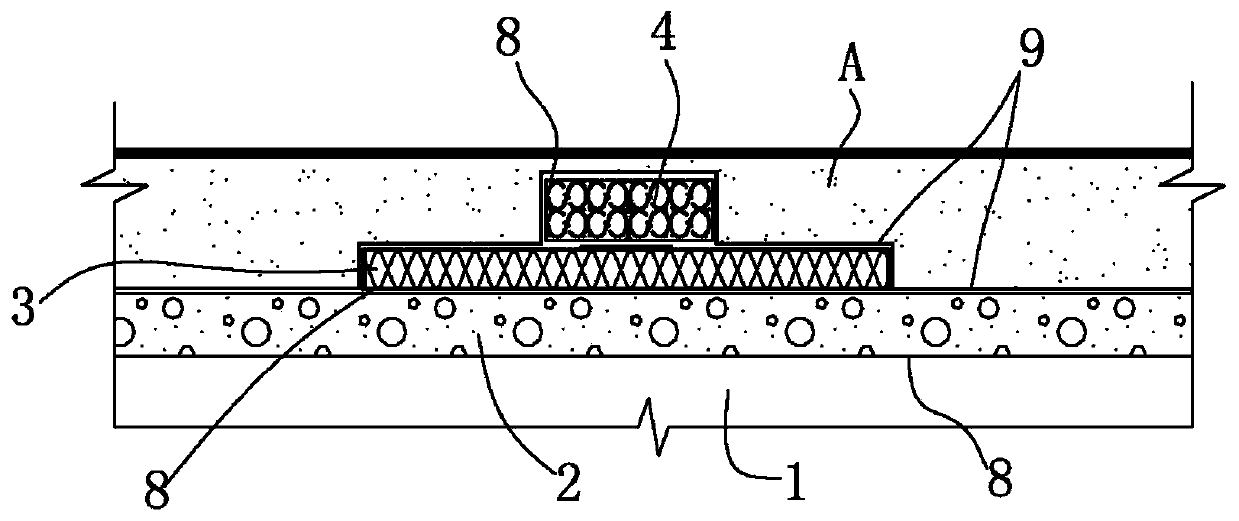

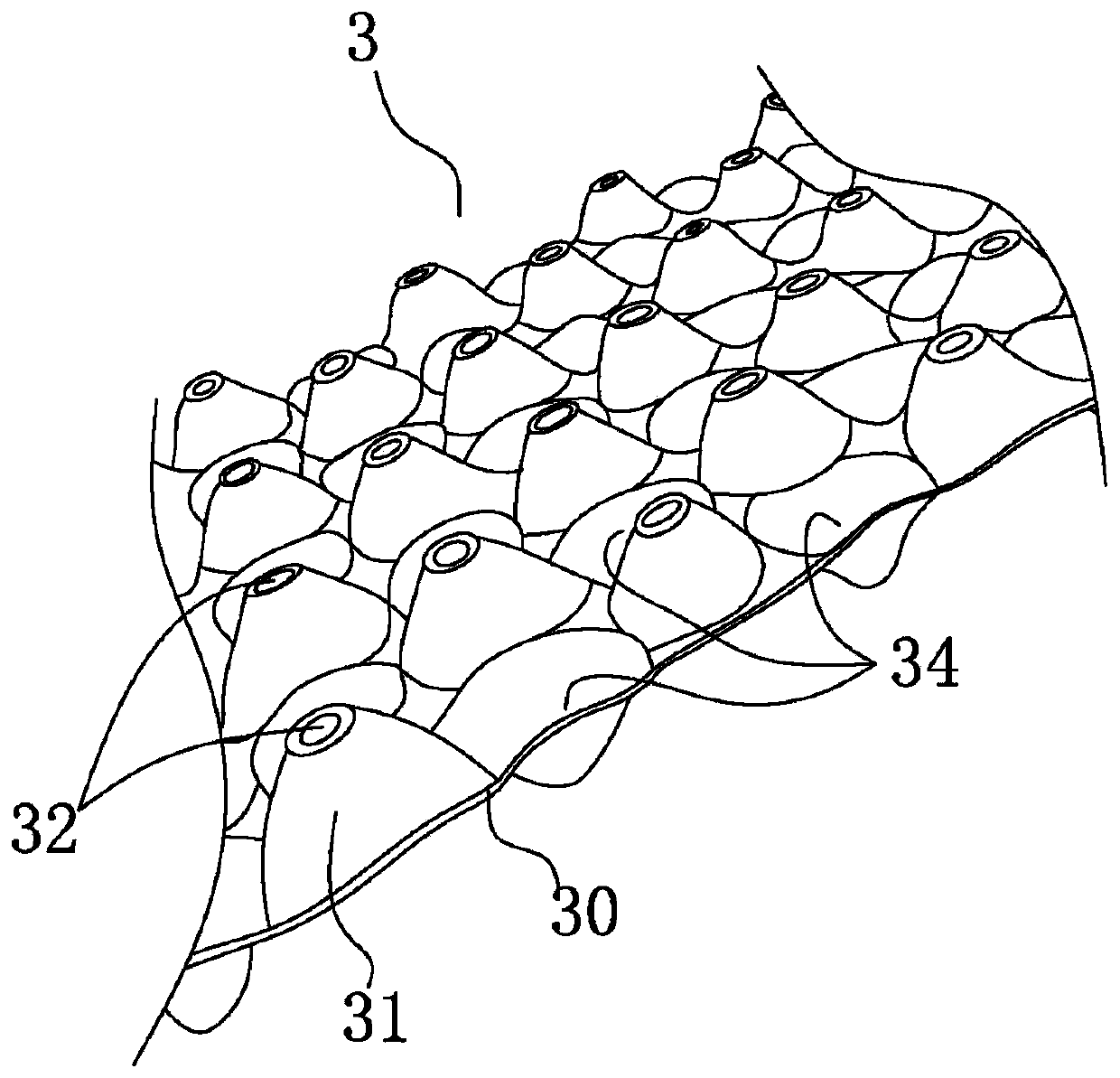

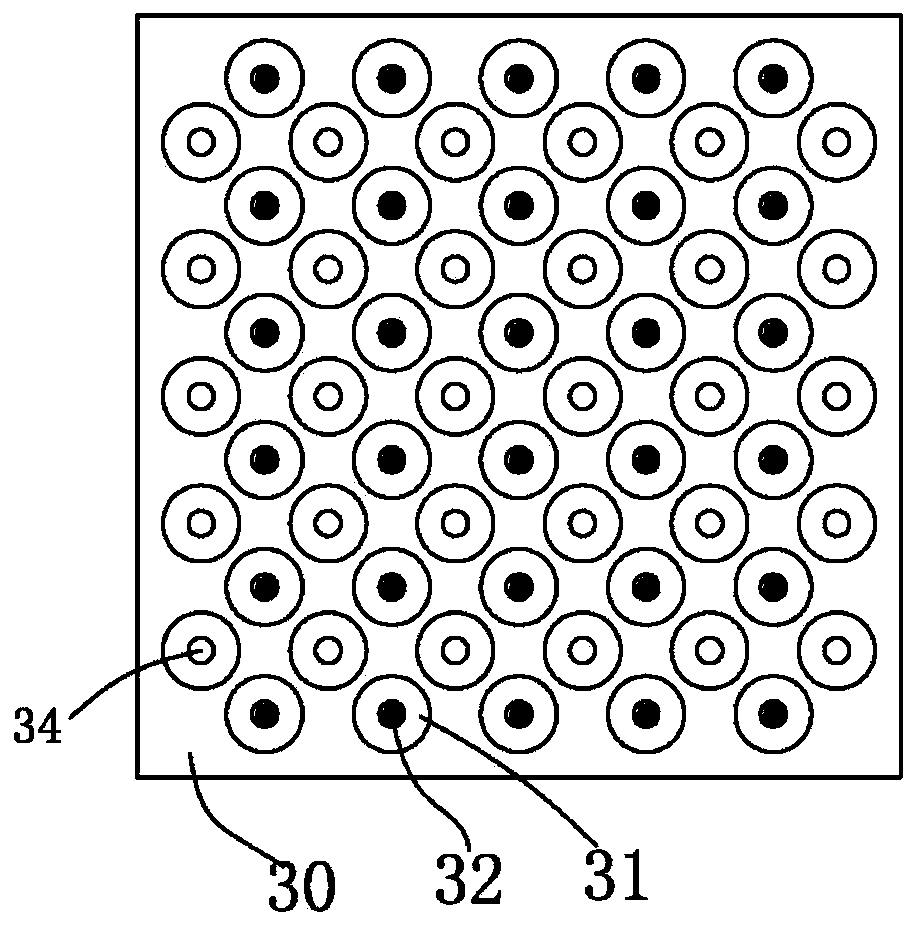

[0040] Specific implementation methods, such as Figure 1-6 As shown, a drainage structure with anti-floating, anti-seepage and filtering functions according to the present invention mainly includes the following parts: a water-passing layer 2 (gravel or sandstone layer), a water-filtering layer 3, and some water guide plates 40 , PVC casing joint (not shown in the figure), geotextile 8 and plastic film layer 9;

[0041] During actual construction, the construction sequence includes finishing the foundation soil 1 side, fully paving the first anti-silting geotextile 8, laying the water-permeable layer 2 (gravel or sand layer), construction of the water filtration layer 3, construction of the drainage layer 4, Lay plastic film layer 9 construction and drainage layer 4 sets to connect to catchment culverts, catchment wells, etc.;

[0042] 1. Finishing of the foundation soil surface: the anti-silting geotextile 8 is covered on the foundation soil surface; the first surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com