Planetary carrier

A planetary gear carrier and planetary gear technology, applied in the direction of belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problem of increasing the number of parts and the number of joining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

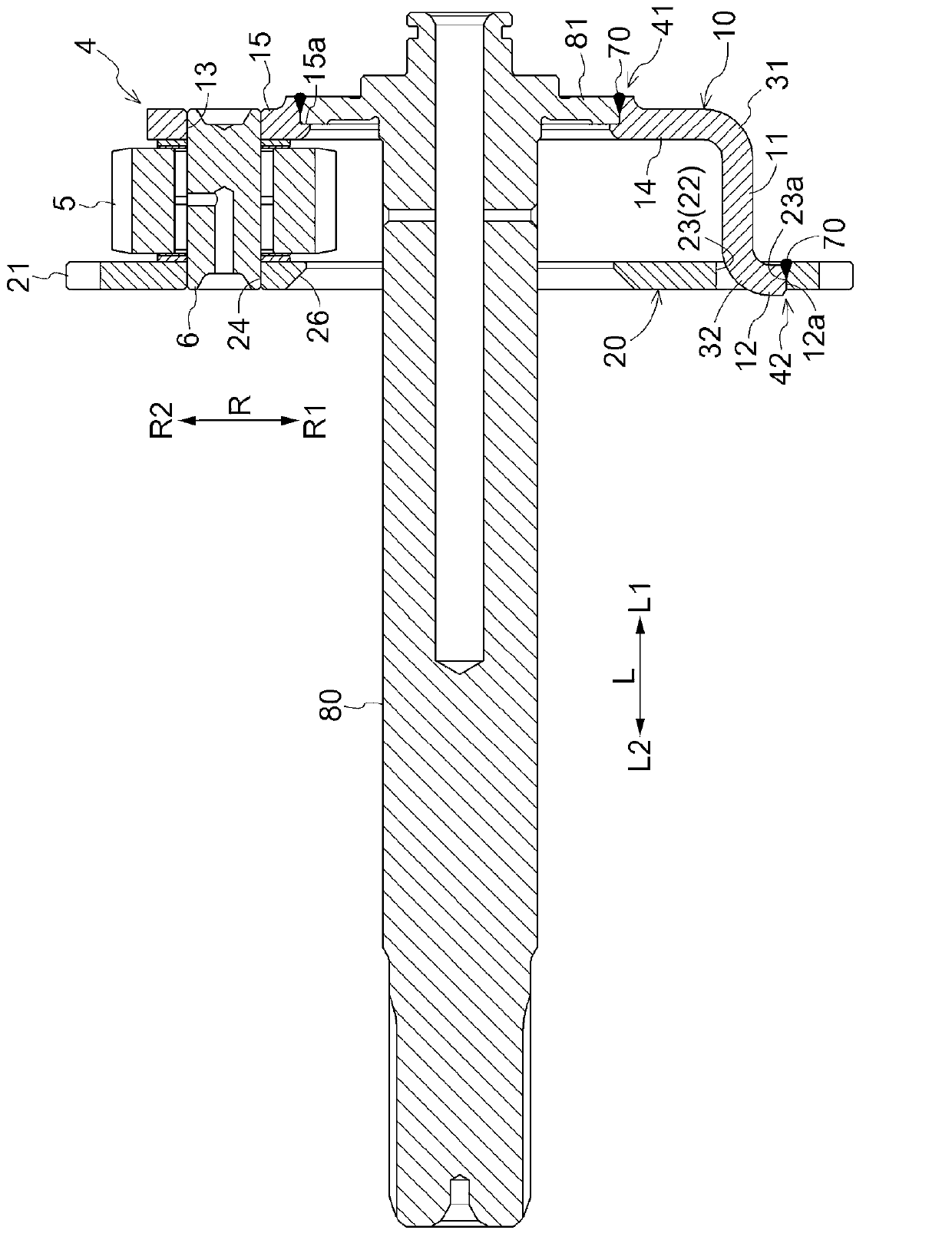

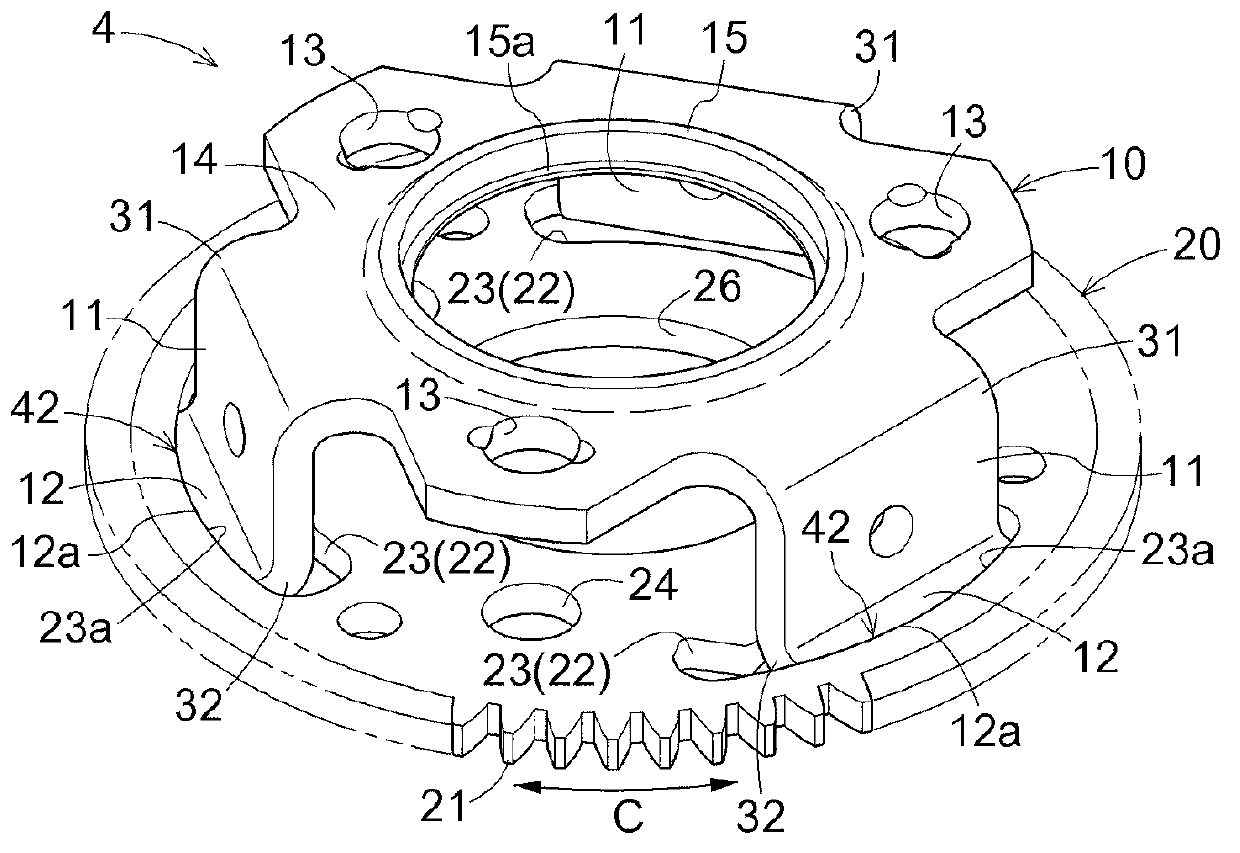

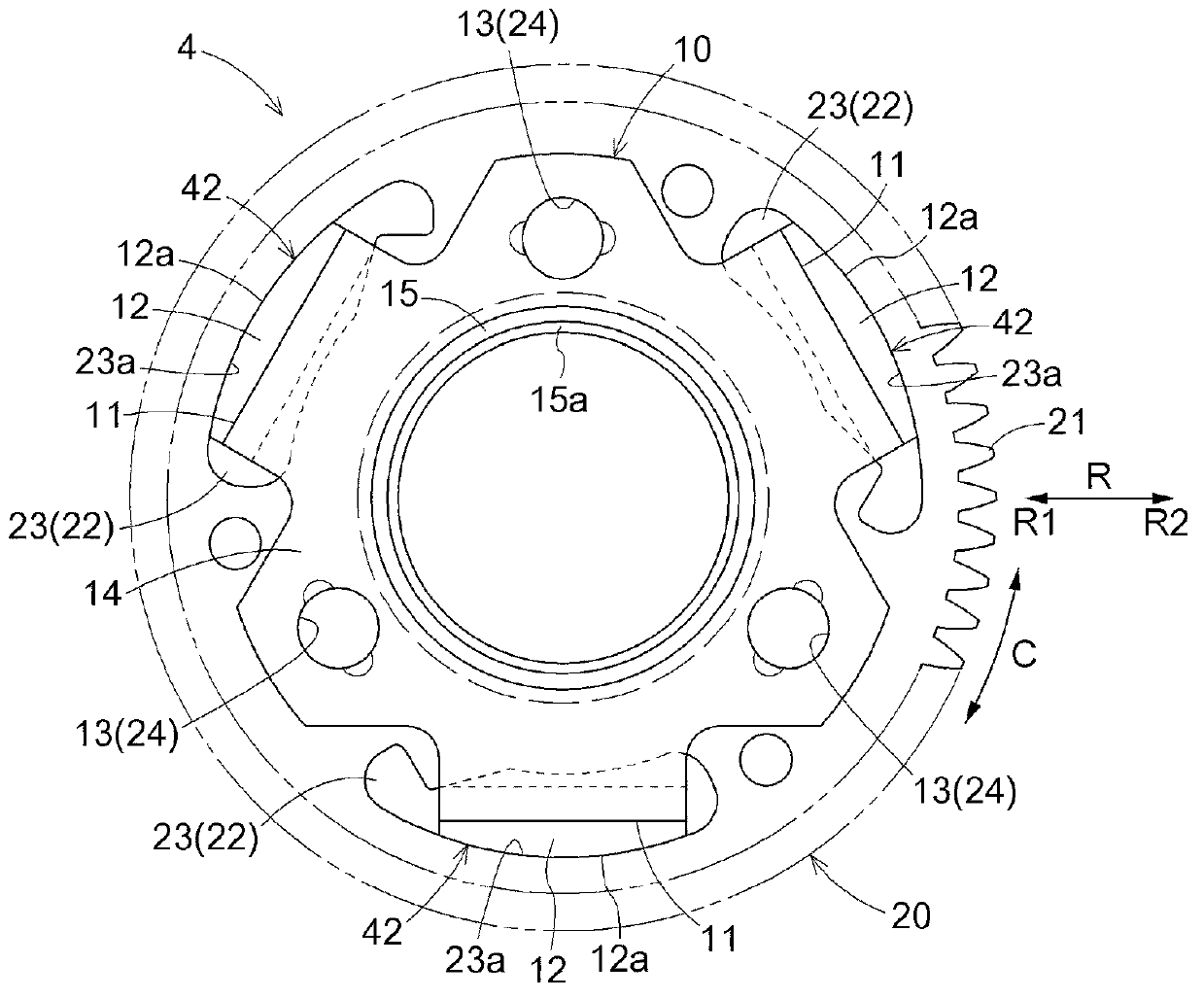

[0025] Embodiments according to the present invention will be described with reference to the drawings. Here, a case where the planetary carrier according to the present invention is applied to a single-pinion type planetary gear mechanism will be described. like Figure 1 to Figure 3 As shown, the planetary carrier 4 according to this embodiment is configured to include a pair of holding members 10, 20 that hold the pinion shaft 6 from both sides in the axial direction L, and the planetary carrier 4 Planetary gear mechanism 1 constituting a single pinion type (refer to Figure 4 ) of the rotation element. That is, the planetary carrier 4 is used for the planetary gear mechanism 1 . Furthermore, the planetary carrier 4 according to the present embodiment is configured such that the number of parts and the number of joining steps can be suppressed, and the outer peripheral gear 21 is provided. Hereinafter, the configuration of the carrier 4 according to the present embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com