High-welding strength long glass fiber-reinforced polypropylene material and preparation method thereof

A technology of long glass fiber and polypropylene material, which is applied in the field of high welding strength long glass fiber reinforced polypropylene material and its preparation, can solve the problems of low VOC and low odor, and achieves improved bonding fastness, low production cost, Ease of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

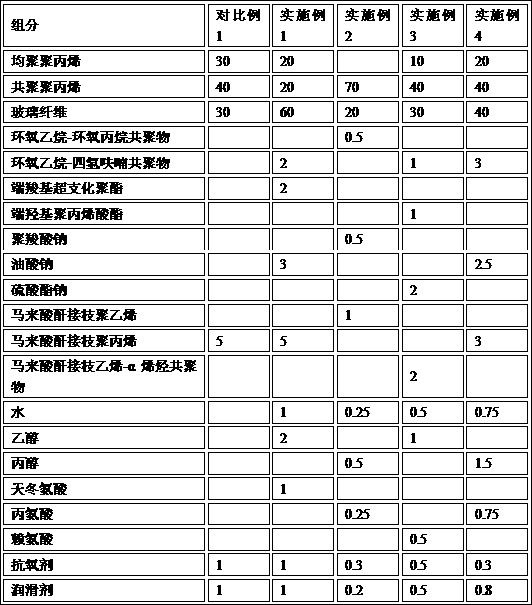

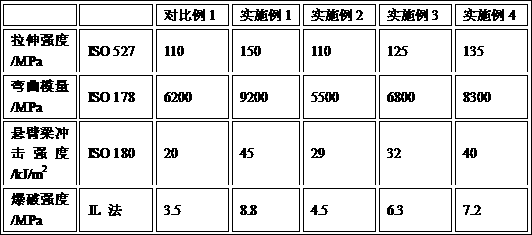

[0032] A preparation method of high welding strength long glass fiber reinforced polypropylene material includes the following steps:

[0033] Step 1: Mix 40-70 parts of polypropylene, 0.5-4 parts of hyperdispersant, 0.5-3 parts of dispersion synergist, 1-5 parts of compatibilizer, and 0.5-2 parts of other additives.

[0034] Step 2: Put the above mixture into a twin-screw extruder, pump 1-4 parts of deodorant into the screw extruder through the side feed port using a liquid pump, and draw it out through the vacuum port; mix the mixture obtained in the above steps The melt is extruded into the dipping die connected to the head of the twin-screw extruder, and then 20-60 parts of the long glass fiber is passed through the dipping die, so that the long glass fiber is fully impregnated by the melt, and finally cooled, drawn, and pelletized. A long glass fiber reinforced polypropylene material with high welding strength is obtained, and the fiber retention length in the particles is 6-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com