Passive thermal management device

A technology of thermal management and heat dissipation device, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of no longer allowing thermal management, and achieve the effect of improving thermal conductivity and large usable volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

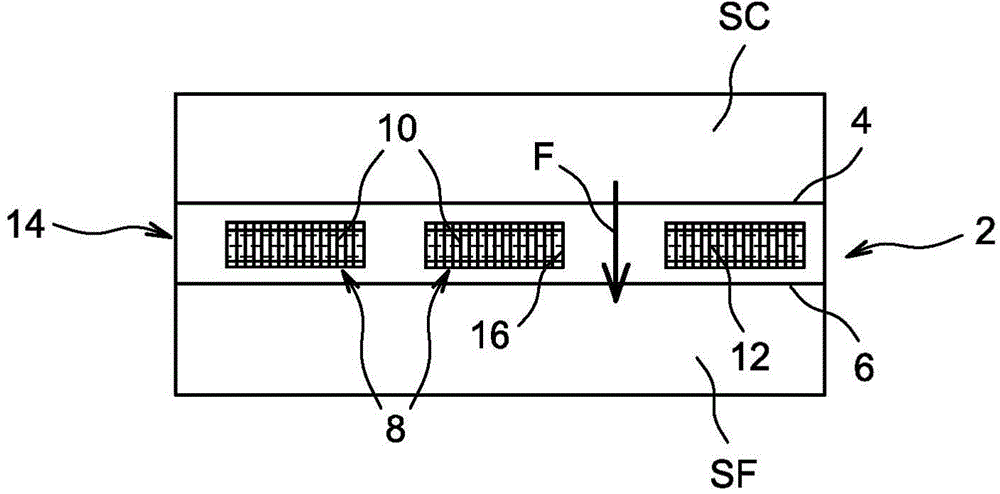

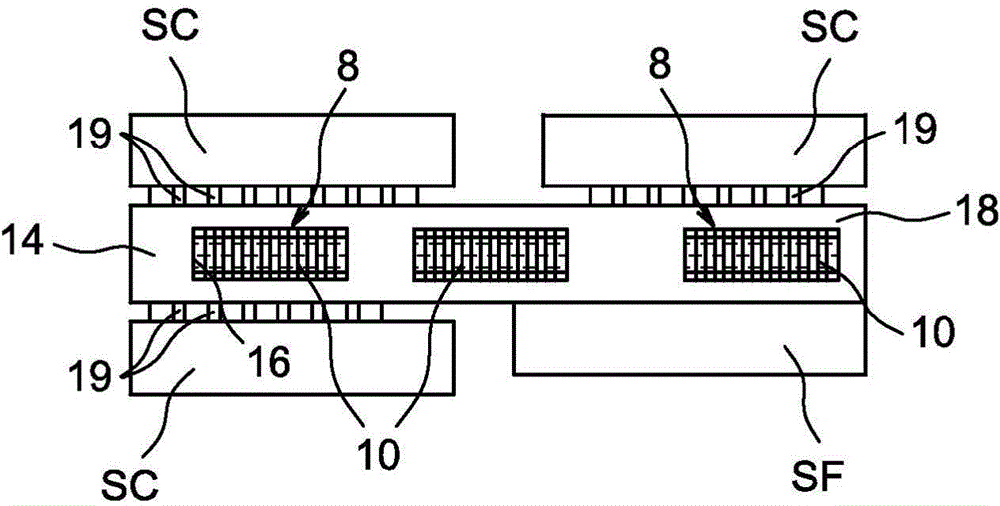

[0046] exist Figure 1A and Figure 1B , schematically shows an exemplary embodiment of a heat management device 2 in which a heat source SC and a heat sink SF are arranged.

[0047] For example, the heat source SC is an electronic system and the heat sink SF is a heat sink with cooling fins.

[0048] The substantially flat device comprises a first face 4 for contact with a heat source SC and a second face 6 opposite to the first face 4 for contact with a heat sink.

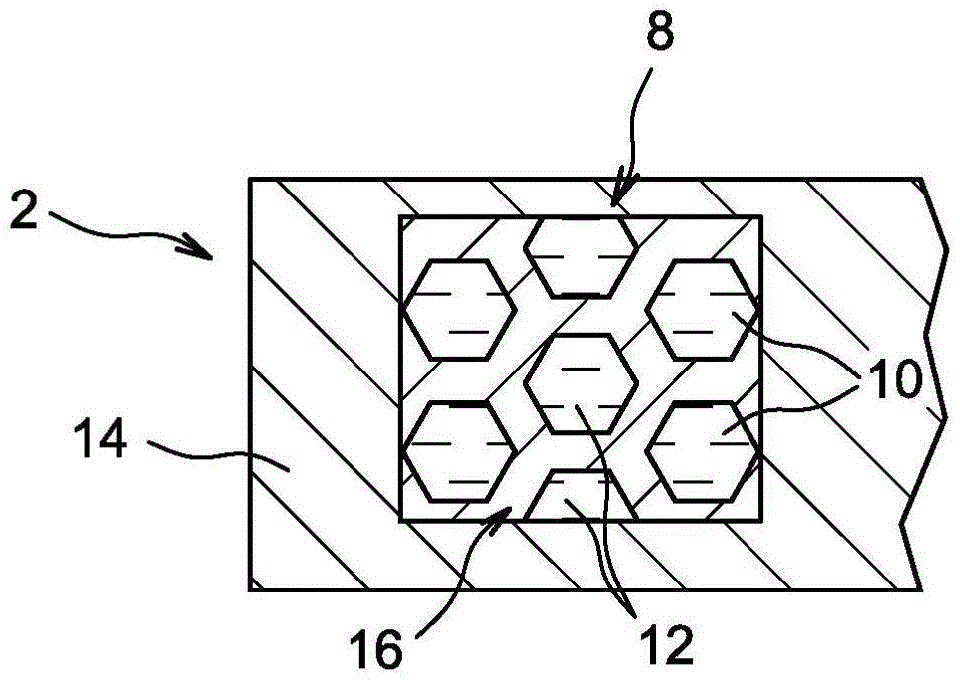

[0049]The device comprises a thermally conductive support 14 , for example made of monocrystalline silicon, in which a plurality of cavities 16 present in one face of the support 14 are produced. Each cavity 16 contains a network of cells 8 made of carbon nanotubes and a phase change material. Each cavity 16 is closed by a cover 18 . The first face 4 is formed by the cover 18 and the second face 6 is formed by the bottom of the support body 14 .

[0050] The device also comprises several unitary networks 8 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com