Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

295results about How to "High impact energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

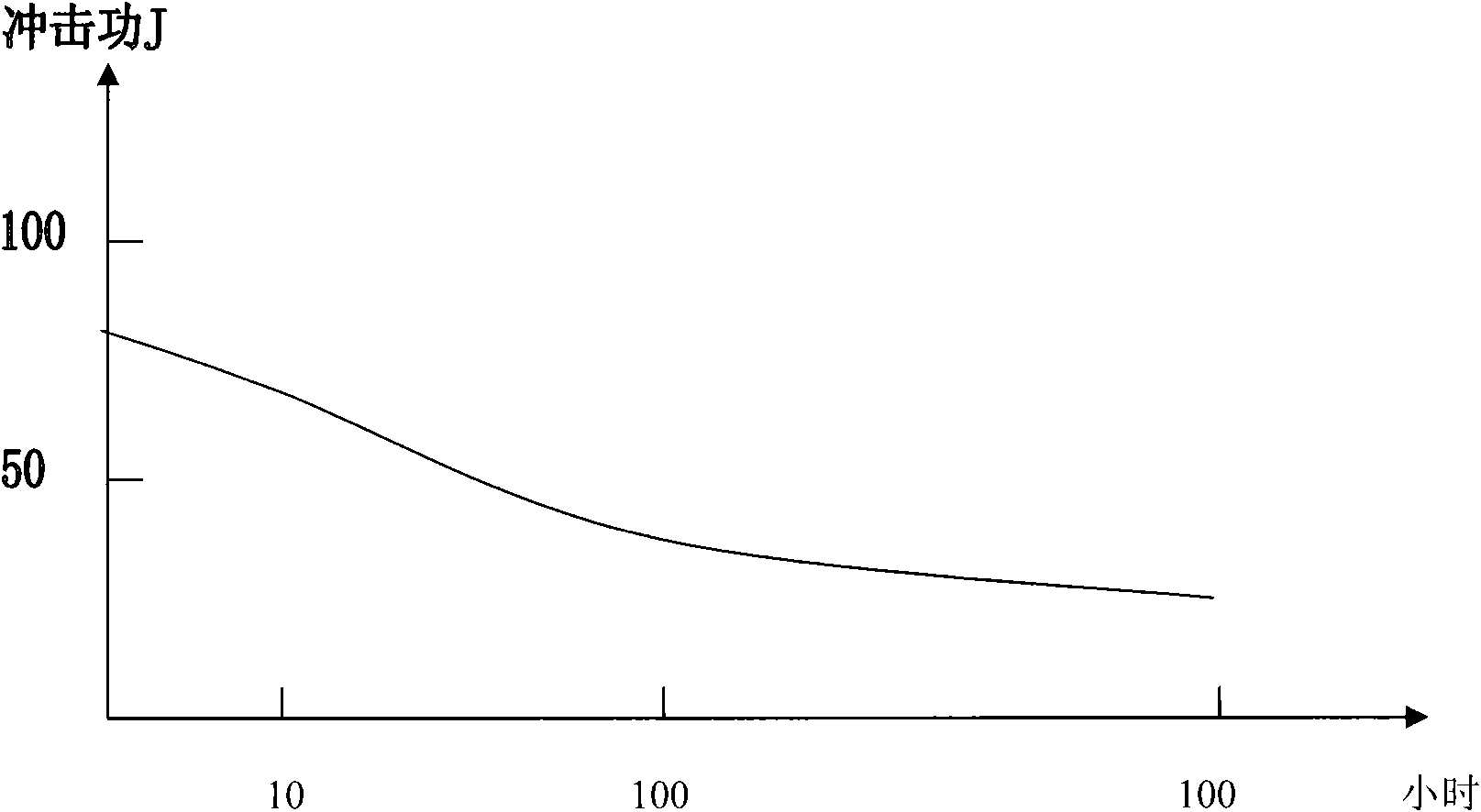

Method for producing wear-resisting steel plate

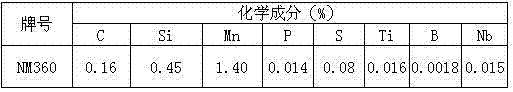

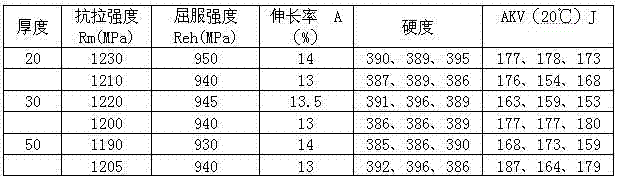

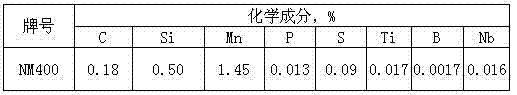

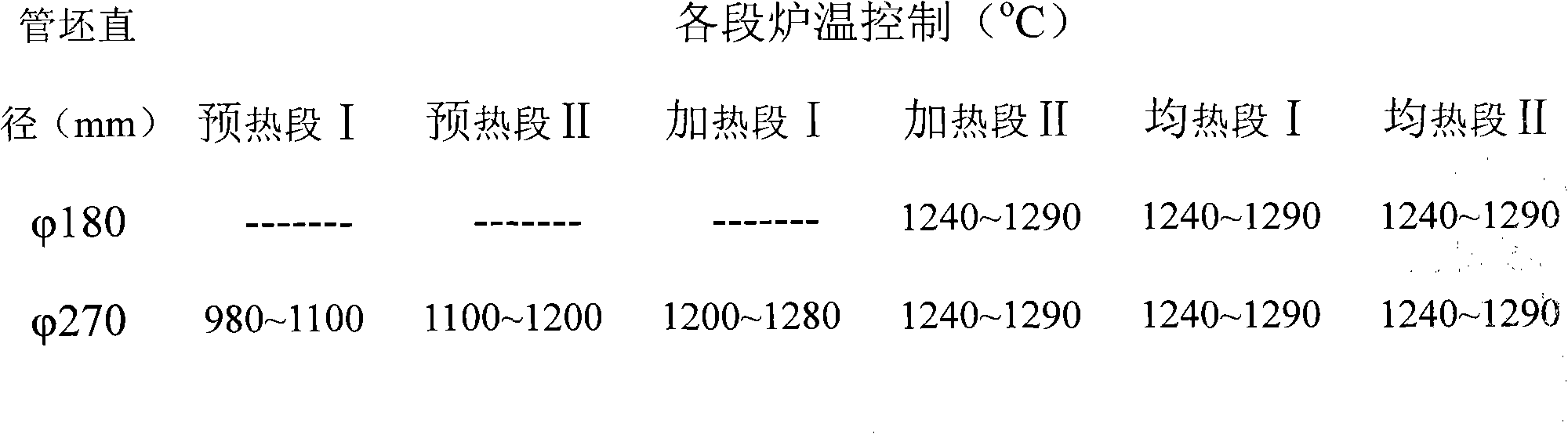

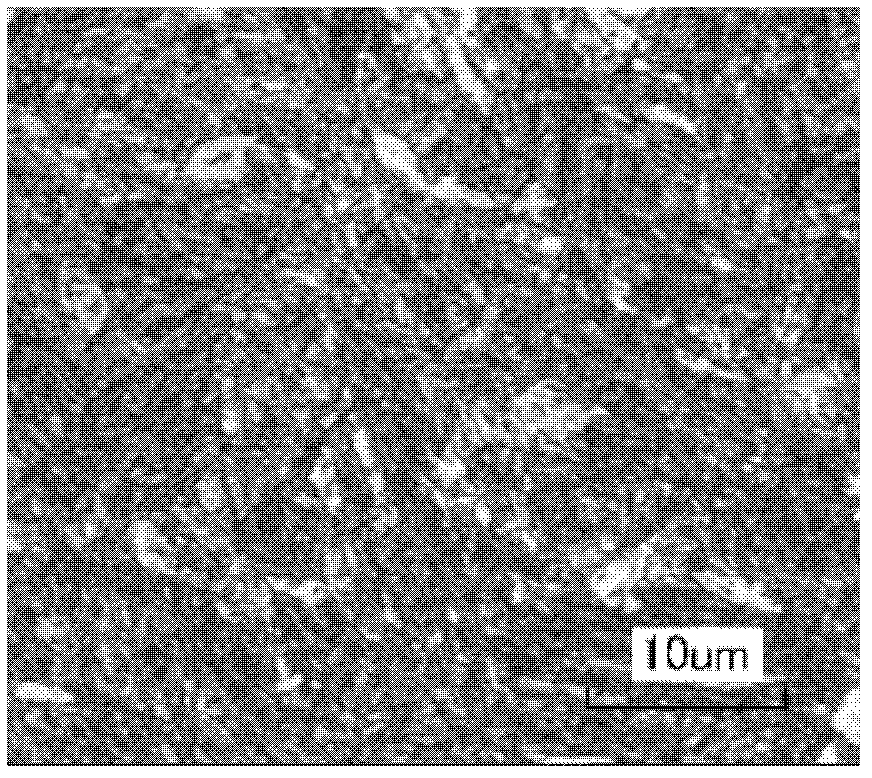

The invention relates to a method for producing a wear-resisting steel plate. Steel comprises the following chemical ingredients in percentage by mass: 0.15 to 0.20 percent of C, 0.4 to 0.7 percent of Si, 0.7 to 1.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.020 to 0.10 percent of Ti, 0.0005 to 0.0020 percent of B, 0.010 to 0.020 percent of Nb and the balance of Fe and inevitable impurities. A production process for the steel comprises the following steps of: desulfurizing by molten iron, smelting by a converter, refining, casting continuously, rolling and performing quenching-carbon partition (Q-P) treatment. In the ingredients of the wear-resisting steel, a C-Si-Mn-Nb-Ti ingredient system and the Nb and Ti micro alloy treatment are adopted, the hardenability of the steel is improved by adding B, an appropriate heat treatment process is adopted to ensure that the steel plate has high plasticity and toughness, and the impact energy of the steel plate is improved by over one time; and the heat treatment is performed by a Q-P process, lath martensite and lath retained austenite (between 5 and 10 percent) are formed and 50 to100 nanometers of carbide complex tissue is precipitated, so that the tissue is fine and uniform, and the tenacity of the steel plate is high.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

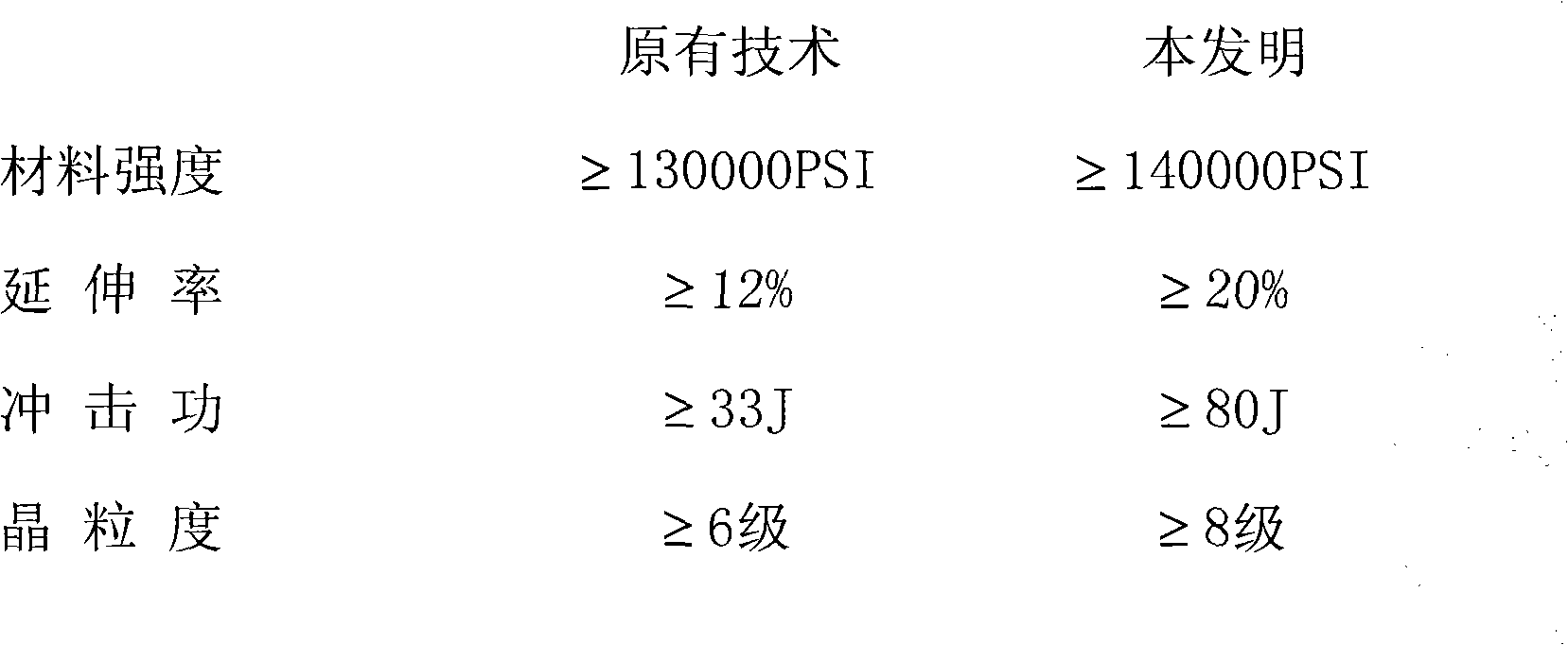

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

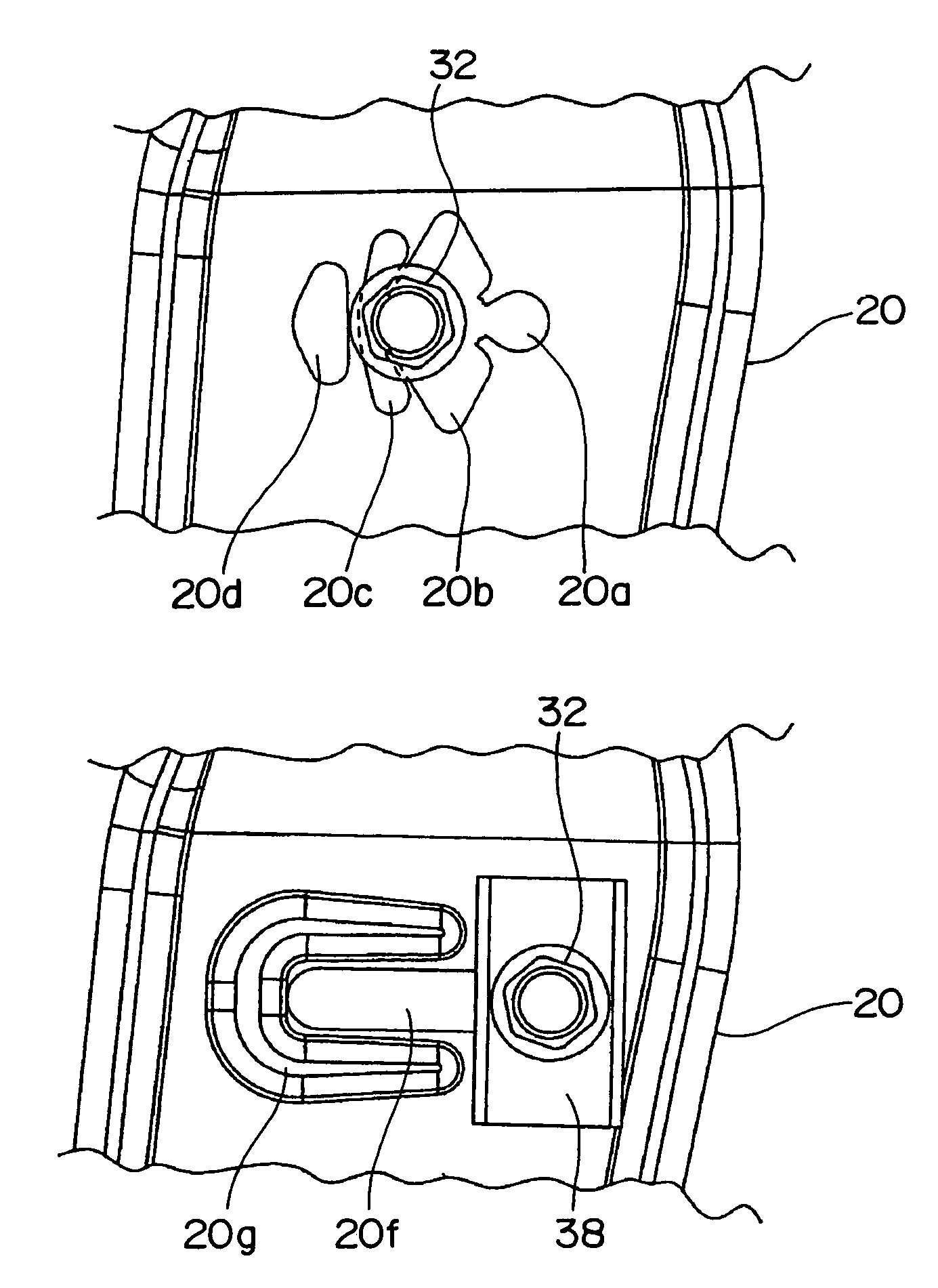

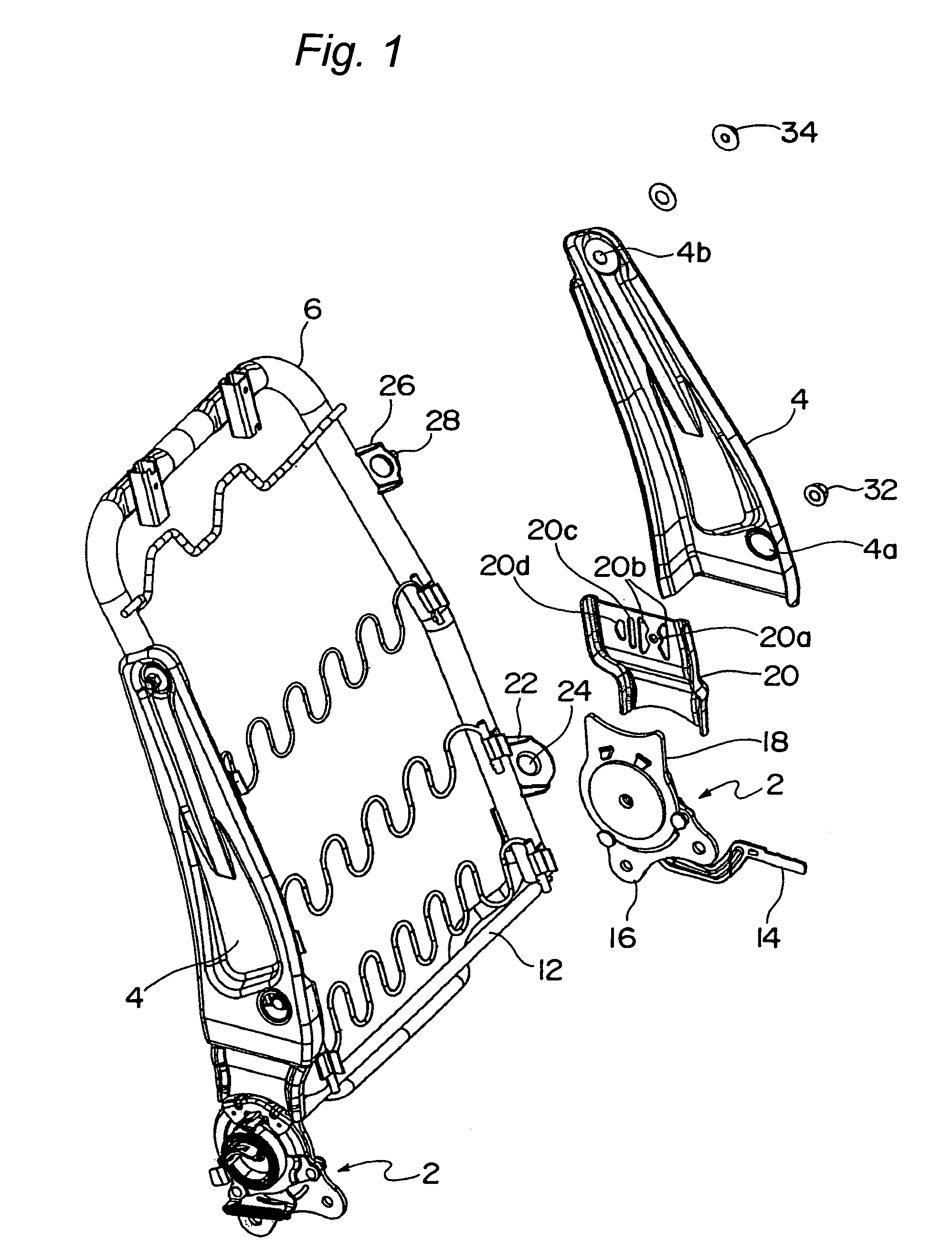

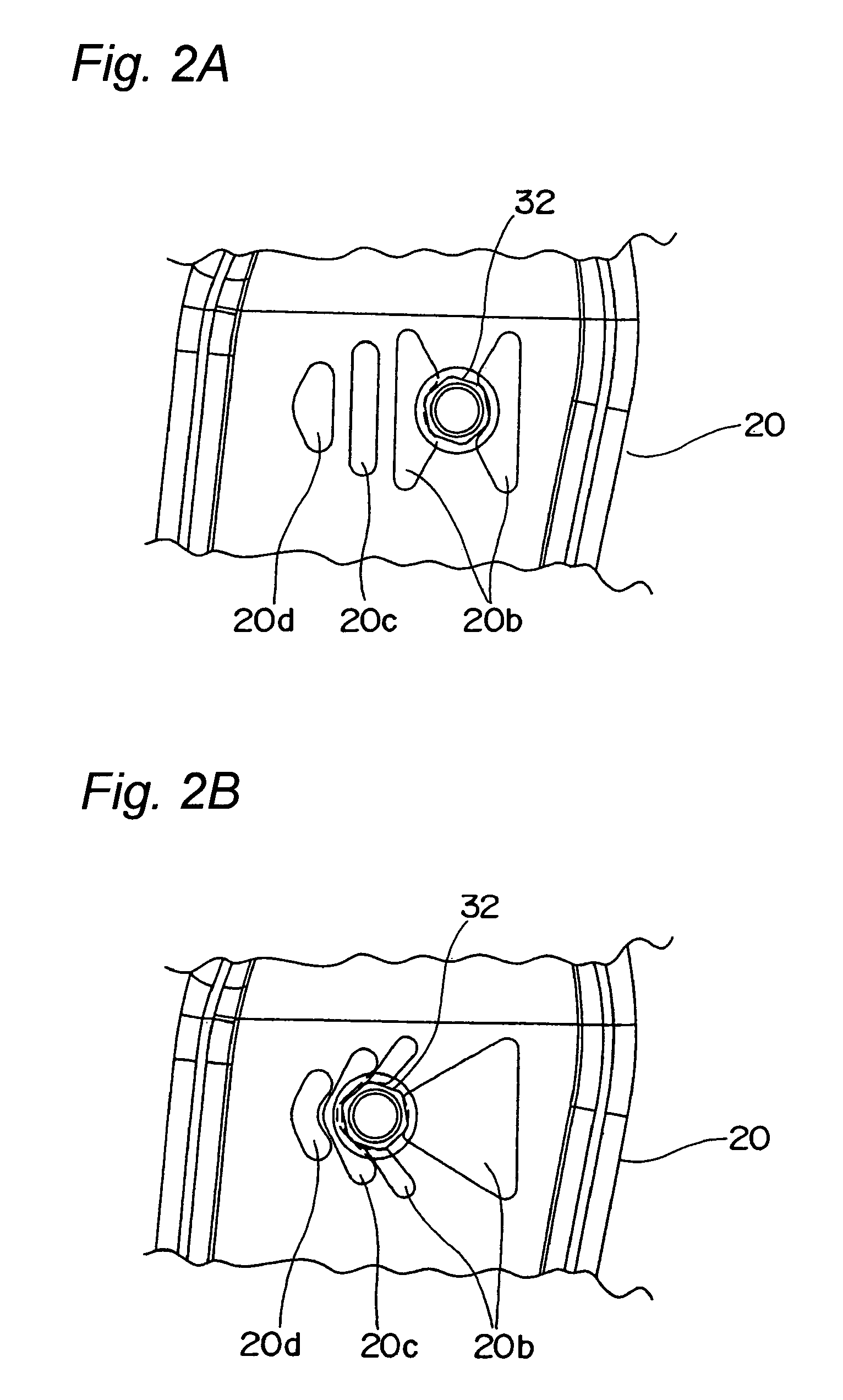

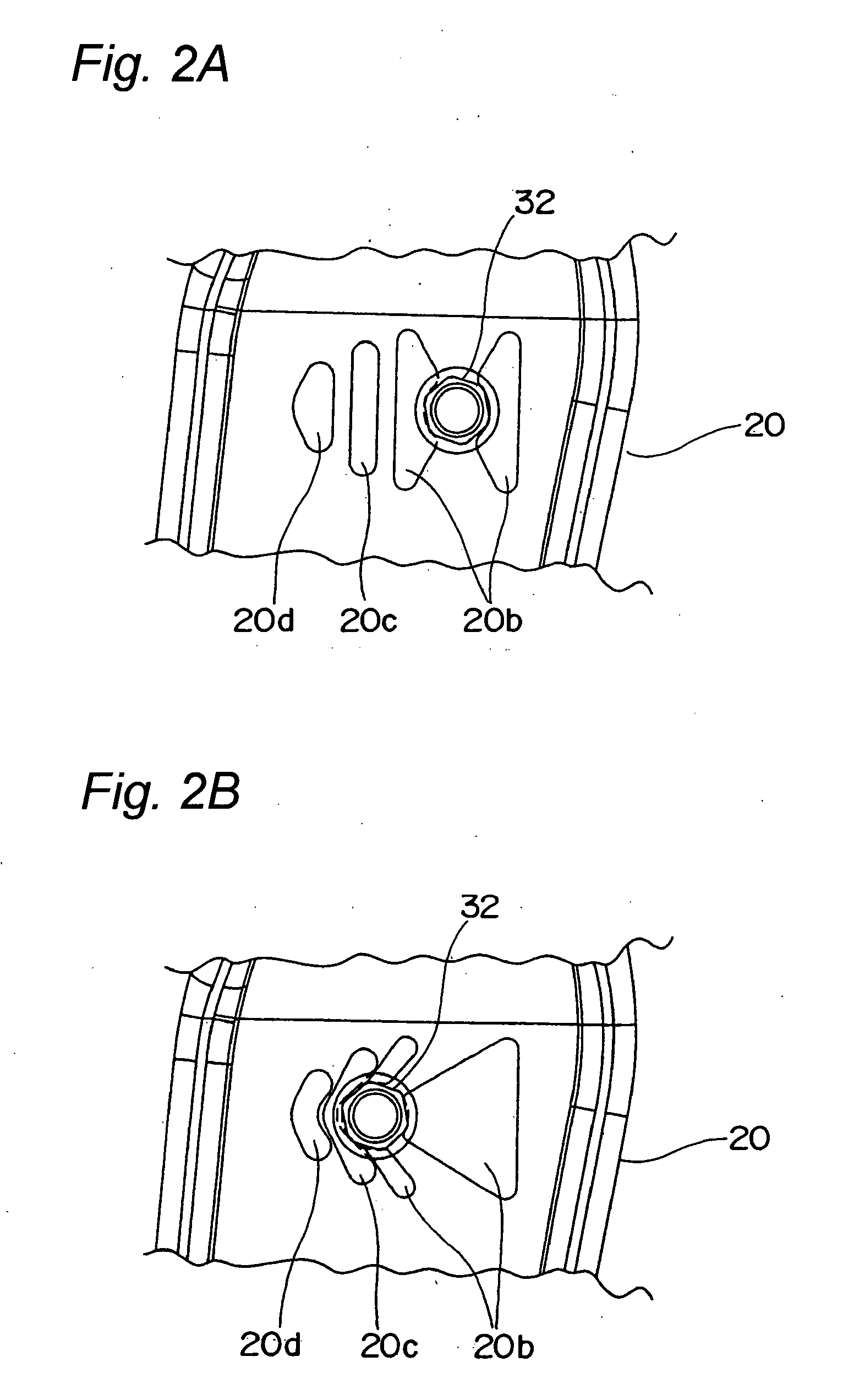

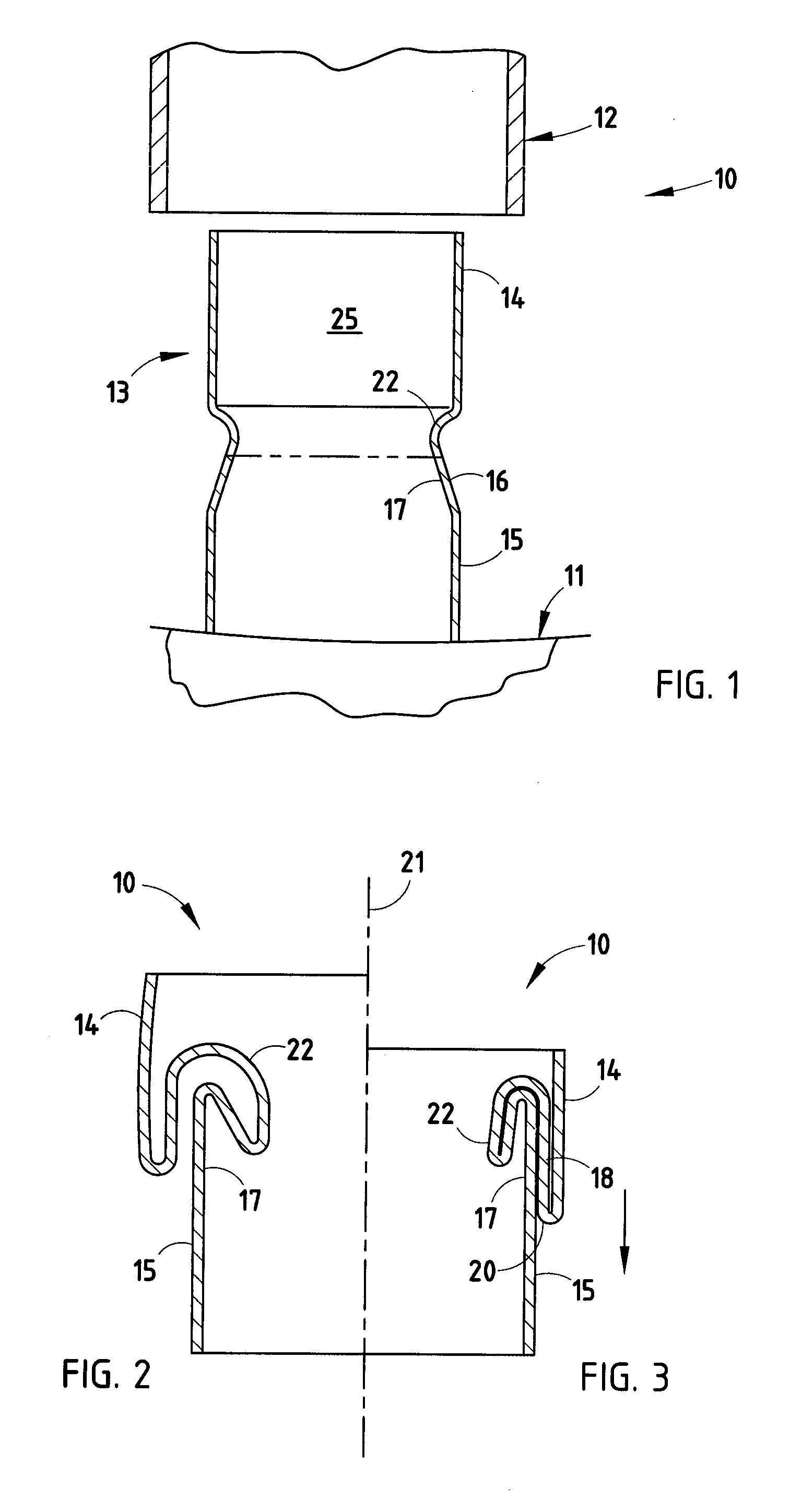

Automobile seat

InactiveUS7070236B2Easy constructionImprove securityVehicle seatsPedestrian/occupant safety arrangementEngineeringBack rests

An automobile seat includes a seat cushion and a seat back tiltably mounted on the seat cushion. The automobile seat also includes a seat cushion frame, a side frame mounted on the seat cushion frame, a seat back frame mounted on the side frame so as to be rotatable within a limited angle, and a fastening member mounted on the seat back frame. The side frame has an insertion hole defined therein in which the fastening member is inserted and also has an impact absorbing structure. When a load greater than a predetermined value is inputted to the seat from behind, a lower portion of the seat back frame is pushed upon a rearward movement of a seat occupant to thereby cause the fastening member to move rearward while deforming the impact absorbing structure. As a result, the seat back frame rotates with respect to the side frame, and an impact is absorbed by deformation of the impact absorbing structure.

Owner:DELTA KOGYO CO LTD

Automobile seat

InactiveUS20050140190A1High impact energyEasy constructionVehicle seatsPedestrian/occupant safety arrangementEngineeringBack rests

An automobile seat includes a seat cushion and a seat back tiltably mounted on the seat cushion. The automobile seat also includes a seat cushion frame, a side frame mounted on the seat cushion frame, a seat back frame mounted on the side frame so as to be rotatable within a limited angle, and a fastening member mounted on the seat back frame. The side frame has an insertion hole defined therein in which the fastening member is inserted and also has an impact absorbing structure. Where a load greater than a predetermined value is inputted to the seat from behind, a lower portion of the seat back frame is pushed upon a rearward movement of a seat occupant to thereby cause the fastening member to move rearwards while deforming the impact absorbing structure. As a result, the seat back frame rotates with respect to the side frame, and an impact is absorbed by the deformation of the impact absorbing structure.

Owner:DELTA KOGYO CO LTD

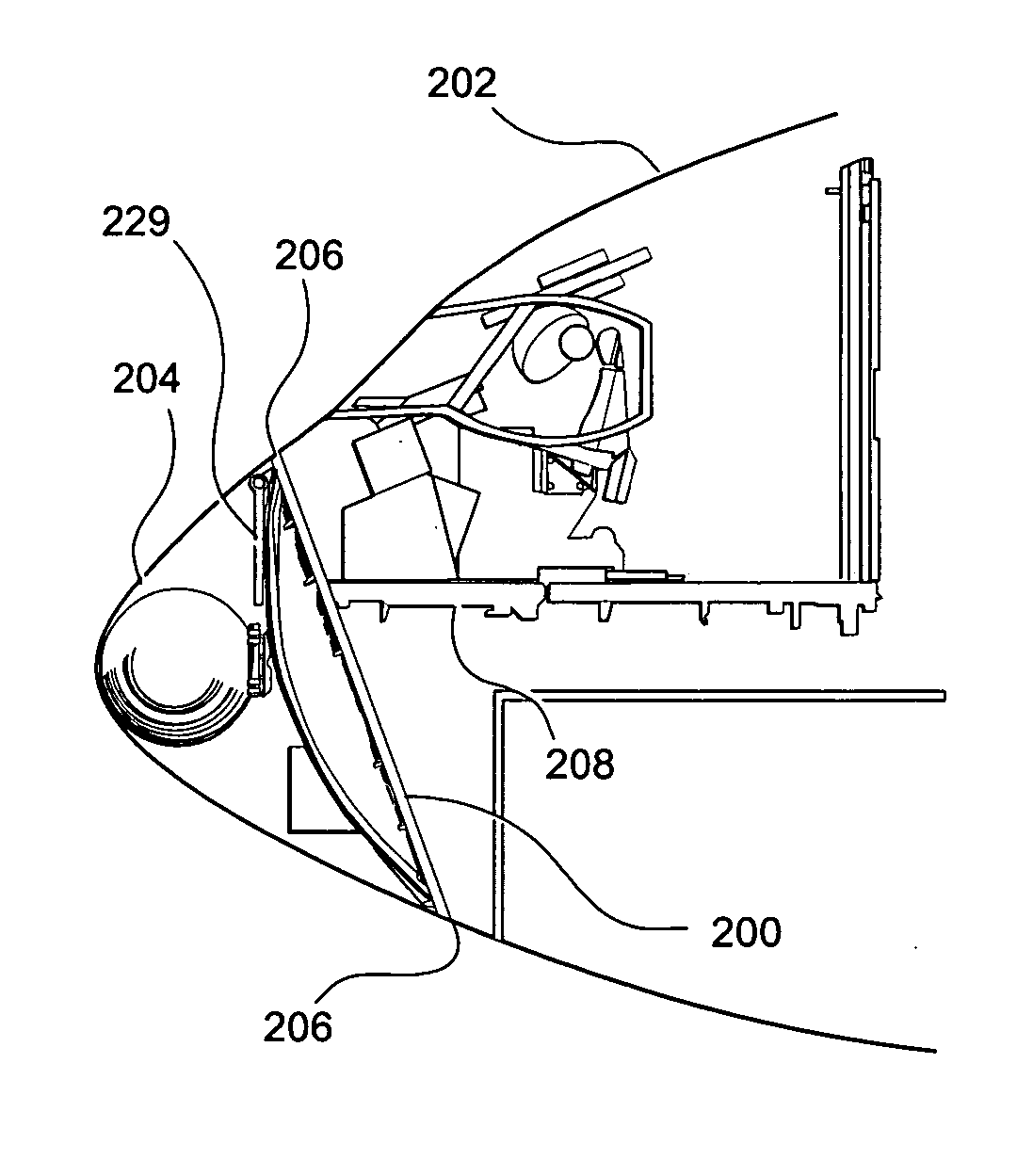

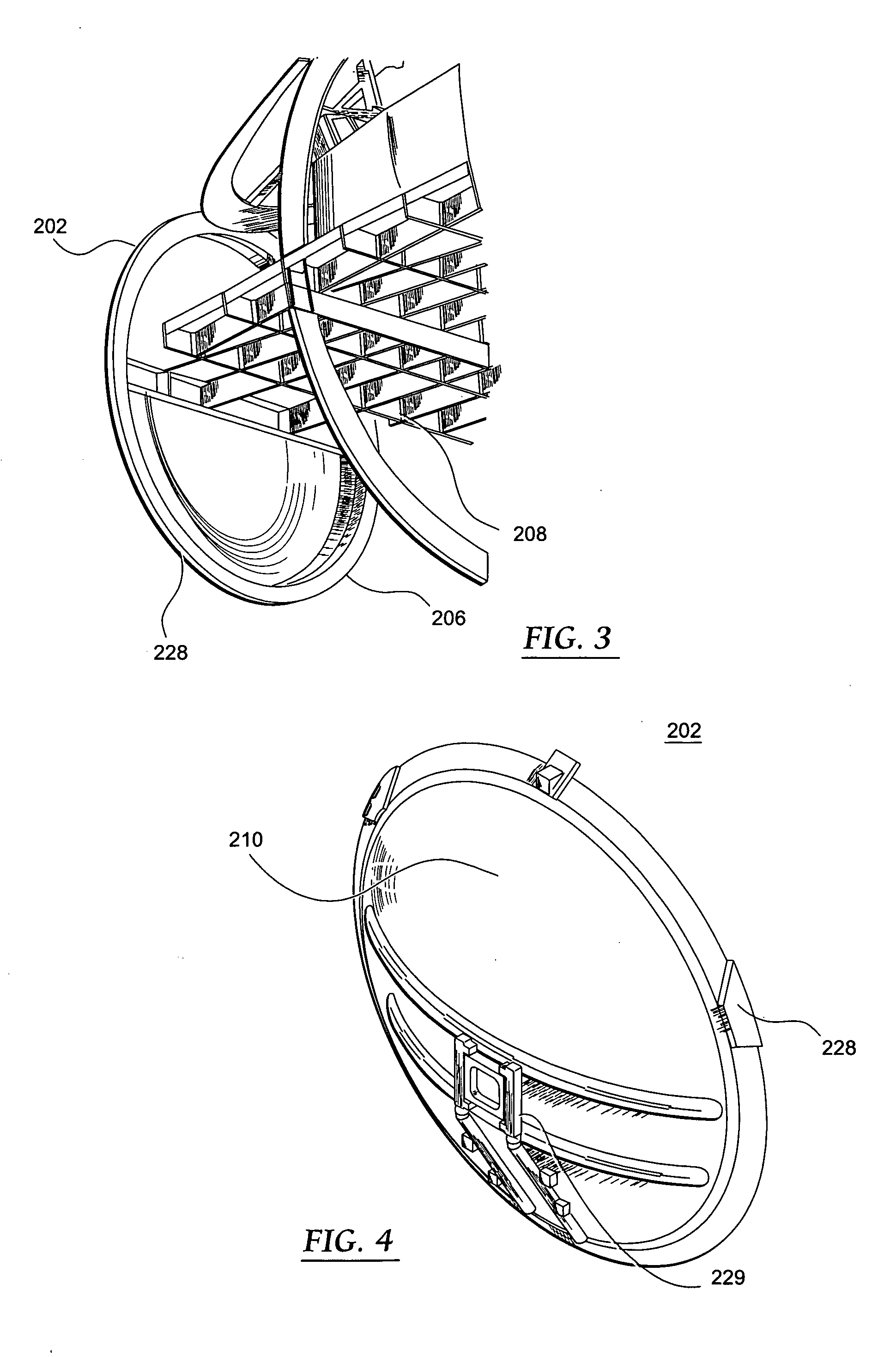

Deformable forward pressure bulkhead for an aircraft

ActiveUS20070164152A1Little strengthReduce weightMilitary adjustmentFuselage bulkheadsForeign matterForeign object

An aircraft forward pressure bulkhead as described herein includes a malleable and deformable dome that is configured to “catch” foreign objects, such as birds. The dome is intentionally designed to deform in response to a foreign object strike that imparts at least a threshold amount of impact energy to the bulkhead. The dome is free of rigid stiffeners and non-deformable reinforcement members that would otherwise hinder the flexible characteristic of the dome. Practical embodiments of the bulkhead utilize fewer parts, are less heavy, and are less expensive than traditional bulkheads that utilize rigid stiffeners.

Owner:THE BOEING CO

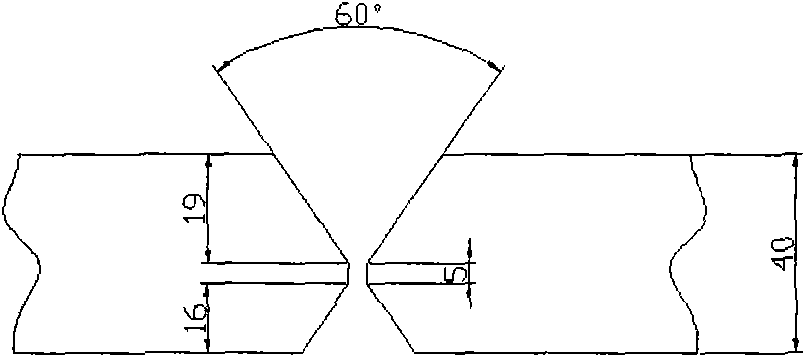

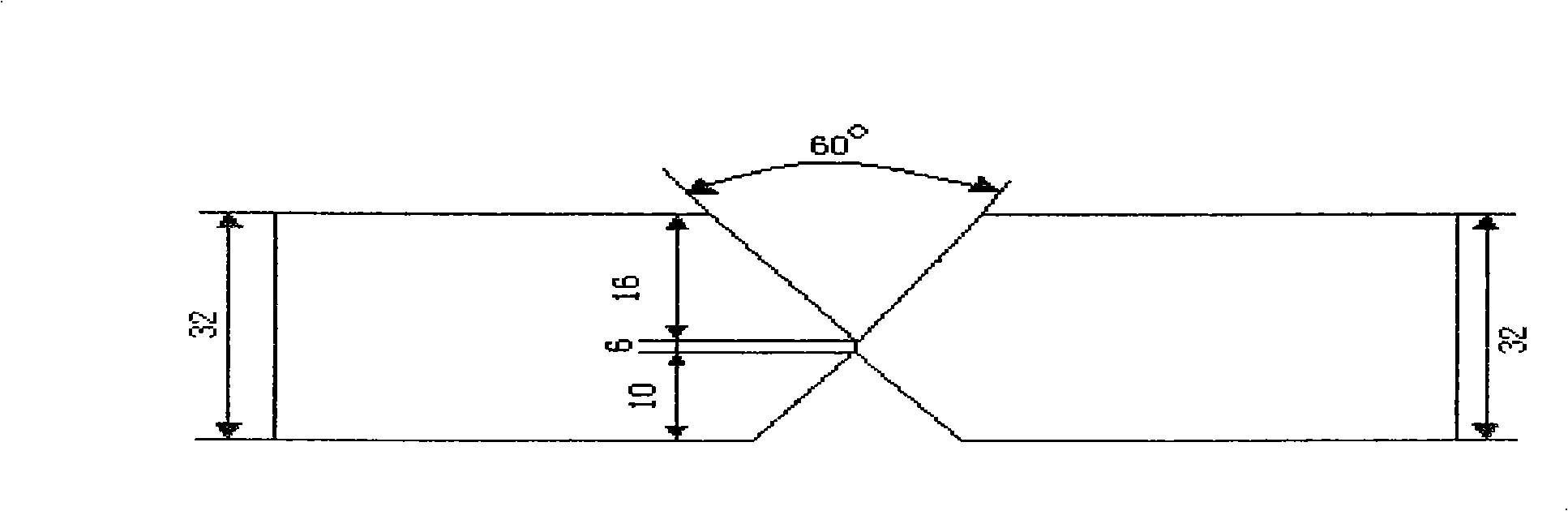

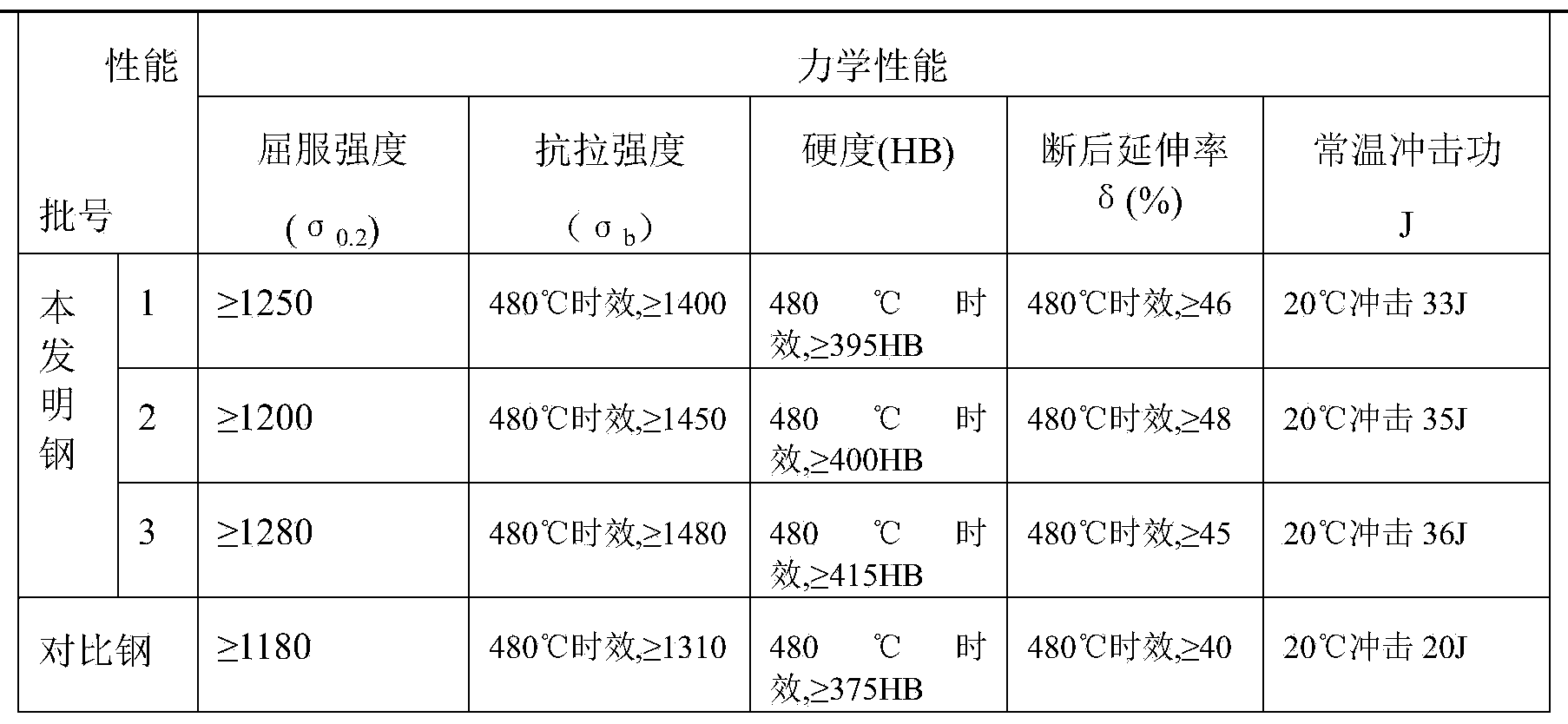

Butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade

InactiveCN101658970AHigh tensile strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsButt jointWeld seam

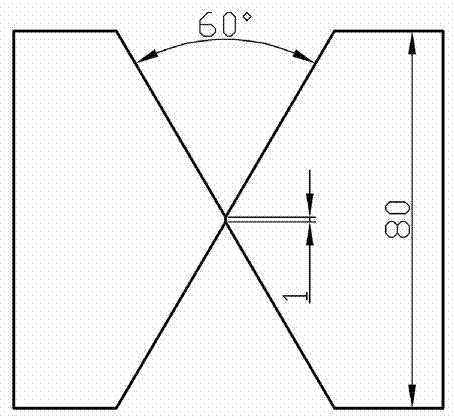

The invention relates to a butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade, overcoming the defects that at the present, bridge steel and other engineering structural steel which are in 690Mpa strength grade needs preheating before welding and heat treatment after welding and has severe welding environment and the like during manual and gas protective welding. The butt joint submerged-arc welding method comprises the following steps: adopting steel with tensile strength Rm of between 690Mpa and 745Mpa, the yield strength ReL of between 550 and 690Mpa, the extension rate A of between 19 percent and 21 percent, KV2 ballistic work of between 165J and 180J at 40 DEG C below zero and the thickness of 40mmm, and adopting same-thickness butting;adopting matched welding wires with the tensile strength more than 690Mpa and diameter phi of 4.0mm, and using CHF105 as a welding flux; adopting a double-sided X-type asymmetrical submerged-arc welding groove with the angle of 60 degrees and the truncated edge of 5mm; continuously welding until welding seams are full, and under the conditions that the welding current is 570A, the voltage is 31V,the speed is 35cm / min and the linear energy is 30kj / cm; baking the welding flux for 1 hour at 350DEG C and keeping the temperature of welding layers between 100 DEG C and 150DEG C.

Owner:武钢集团有限公司

Steel for heavy loading gear

ActiveCN1861830AHigh tensile strengthHigh impact energyPortable liftingGearing elementsQuenchingChemical Ingredients

This invention belongs to the alloy, it especially relates to the steel of gear which is strictly demanded on carburize quenching deformation and can bear on the heavy load. The specific chemical ingredient of the steel is as follows: C 0.17-0.25%, Si 0.05-0.15%, Mn 0.2-0.5%, P<=0.015%, S 0.002%-0.01%, Cr 1.4-2.5%, Ni 1.5-4.0%, Mo 0.1-0.8%, Nb 0.03-0.15%, RE 0.001-0.05%, Al 0.015-0.06%, [N] 0.005-003%, [O]<=0.0015%, the other is Fe and inevitable impurity, it also contains V which is less than 0.2%. This invention is high strength of extension, high ballistic work, low carburize quenching deformation and easy to prepare, contrasting to the existing technology.

Owner:CENT IRON & STEEL RES INST

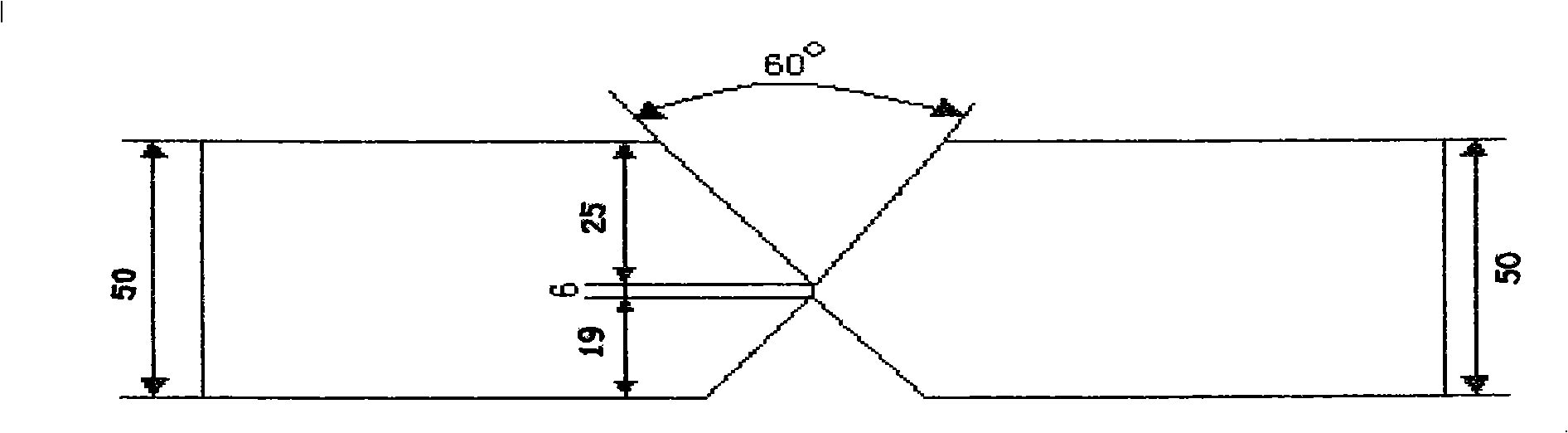

Submerged arc welding method of bridge steel of different intensity scale

InactiveCN101337301AImprove toughnessImprove securityArc welding apparatusWelding/cutting media/materialsSheet steelIntensity scaling

The invention discloses a hidden arc welding method for bridge steel at different levels of strength, which adopts two steel types with different tensile strengths, namely 510-550MPa and 570-650MPa as the subject of hidden arc welding; an X-type asymmetric divided edge is adopted as the divided edge of hidden arc welding; the adopted steel types are 14MnNbq steel and WNQ5709 steel; the yield strength ReL of the 14MnNb steel is 370-415MPa, the tensile strength Rm thereof is 510-550MPa, the unit extension A thereof is 20-35%, and the -40 DEG C AKV impact energy thereof is 120-290J; the yield strength Rel of the WNQ570 steel is 420-560MPa, the tensile strength Rm thereof is 570-650MPa, the unit extension A thereof is 18-27%, and the -40 DEG C AKV impact energy thereof is 120-270J; the thickness of steel plates is 32-60mm; the angle of the divided edge is 60 DEG; and the length of the truncated edge is 6mm. The hidden arc welding method meet the requirements for using the key hidden arc welding technique to manufacture dissimilar steel joints with a novel bridge structure of large-span, heavy-duty, high-speed, high-strength and high-tenacity. The joints made through hidden arc welding have good tensile strength and cold-bending performance; the impact energy of the three areas of the joint reaches a high level; and the joints have relatively high impact tenacity reserve and safety margin.

Owner:武钢集团有限公司

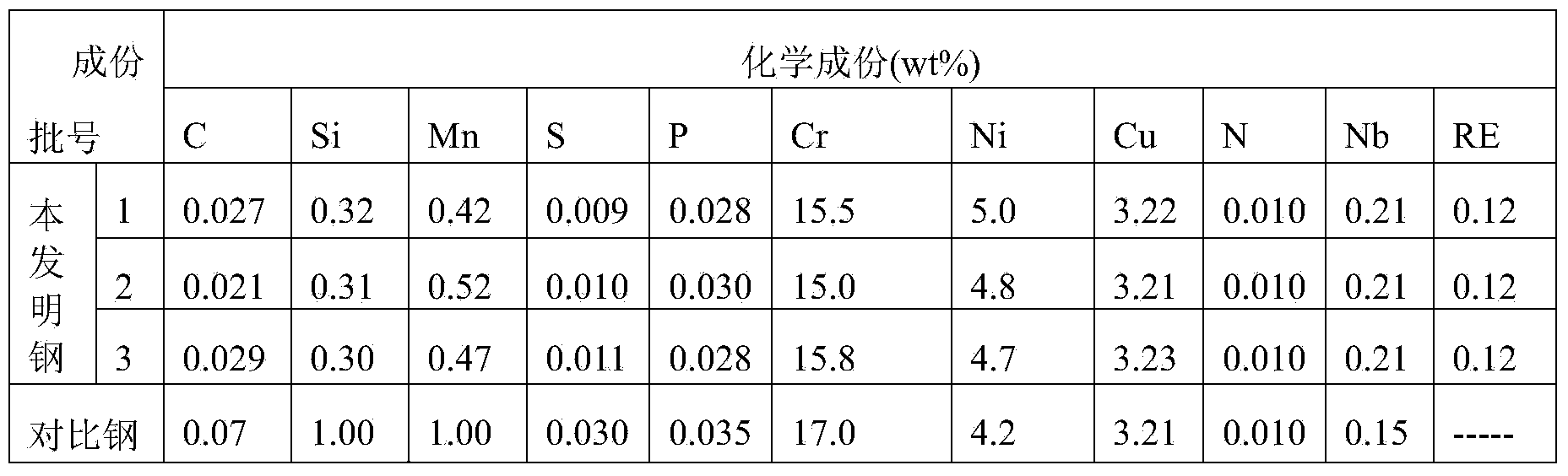

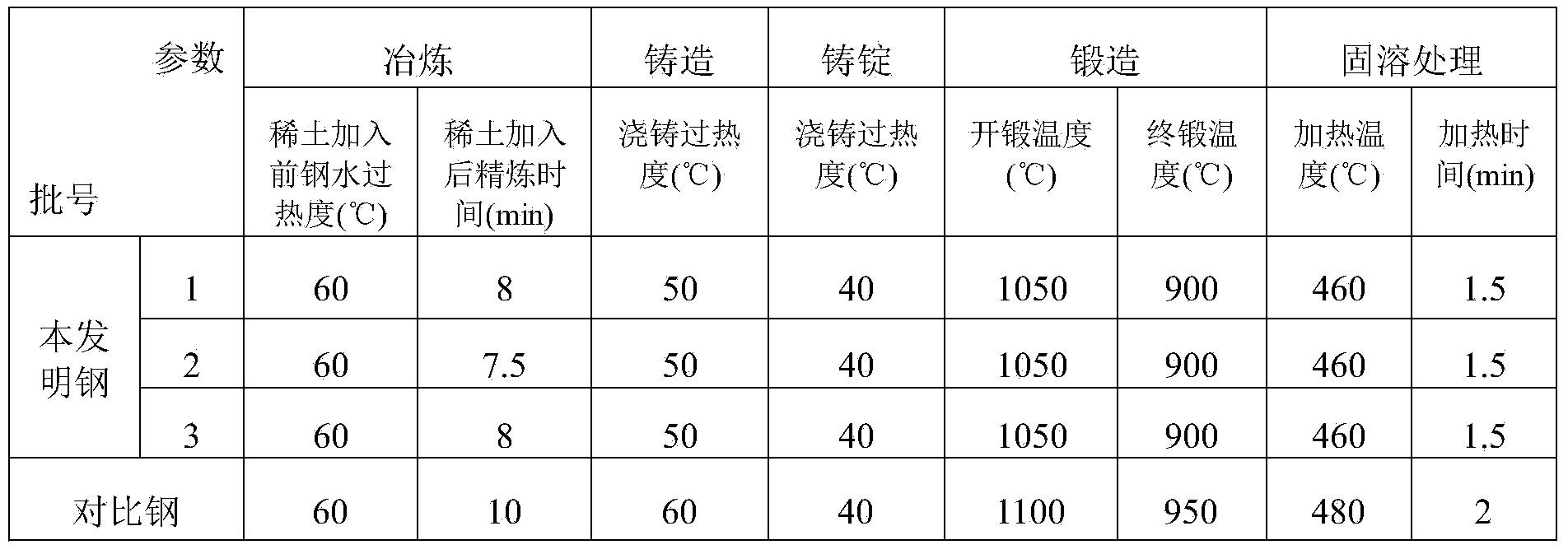

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

High intensity bridge steel manual welding technique method

InactiveCN101332528AImprove toughnessImprove securityArc welding apparatusWelding/soldering/cutting articlesCrack resistancePower flow

The invention provides a manual welding process method of high strength bridge steel. The manual welding process method comprises the steps as follows: (1) the bridge steel with the tensile strength of 570-650MPa and the thickness of 32-60mm is taken as a base material for welding; the matching welding materials are as follows: the tensile strength of a manual electrode is 590-650MPa and the diameter Phi of the electrode is 4.0mm; (2) a groove is an X-shaped symmetrical groove and the groove angle is 60 degrees, the root face is 2mm; (3) the welding process parameters are as follows: the welding current is 165-170A, the welding voltage is 26-25V, the welding speed is 17-15cm / min, the weld line energy is 15-17kJ / cm and the baking system of the electrode is 350 DEG C multiplied by 1h; (4) the manual welding adopts continuous multilayer and multipass welding, the interlayer temperature is controlled within 100-150 DEG C. The manual welding process method of the invention is characterized by good welding process performance, simple operation, convenient use, high efficiency and energy conservation, and adaptation to the welding of steel for wide-span and high-strengthen bridge structure. The manual welding process method has excellent welding seam crack resistance, and three joint areas have relatively high impact toughness reserve and safety margin.

Owner:武钢集团有限公司

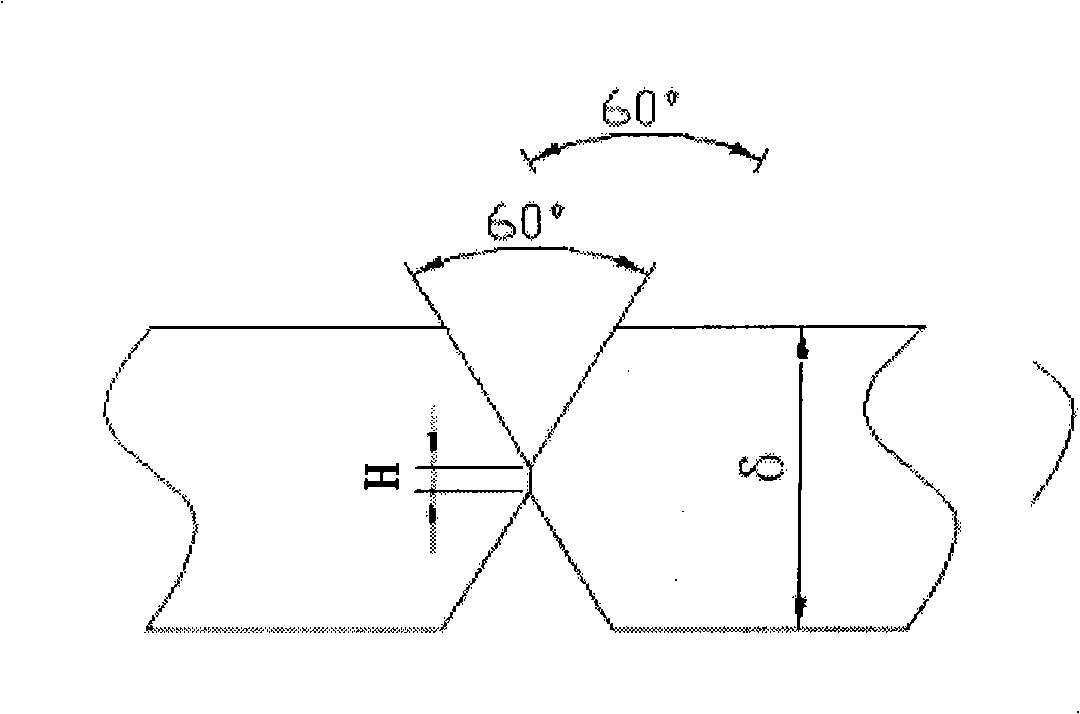

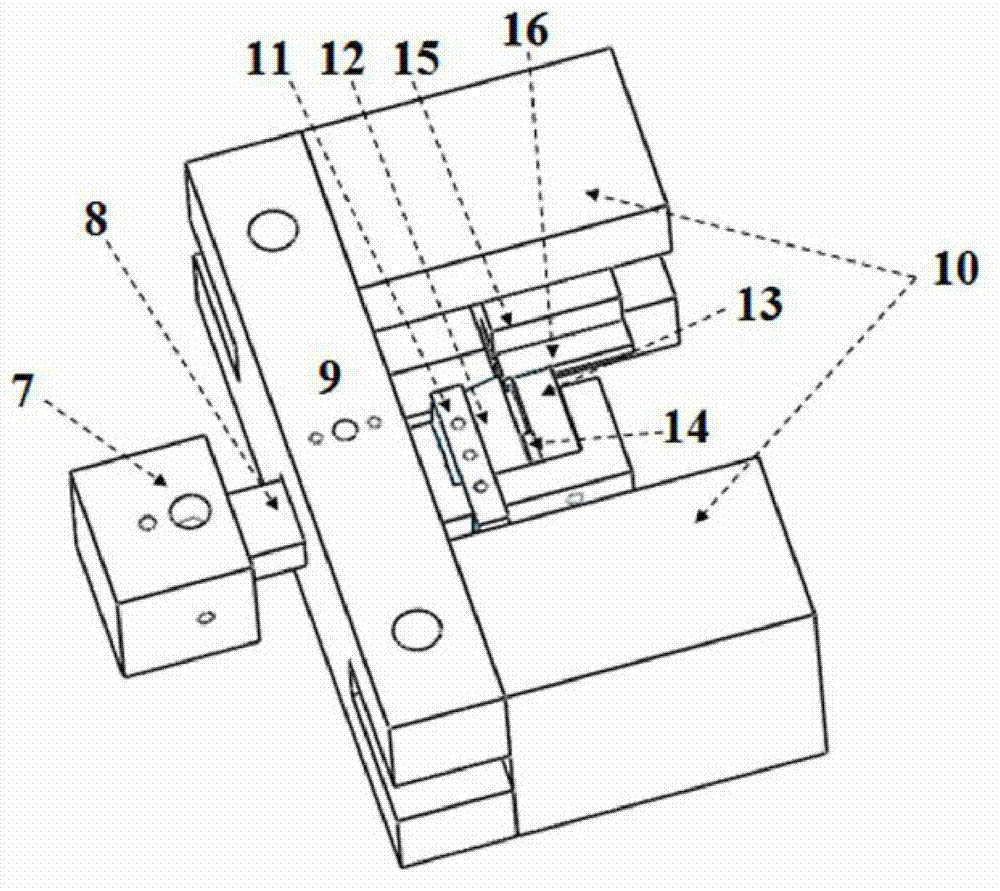

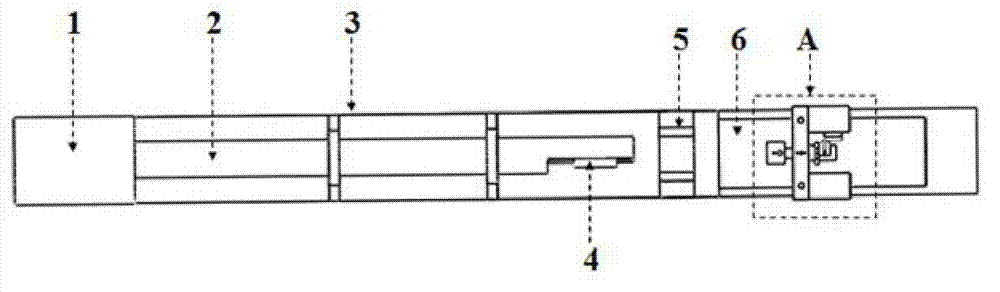

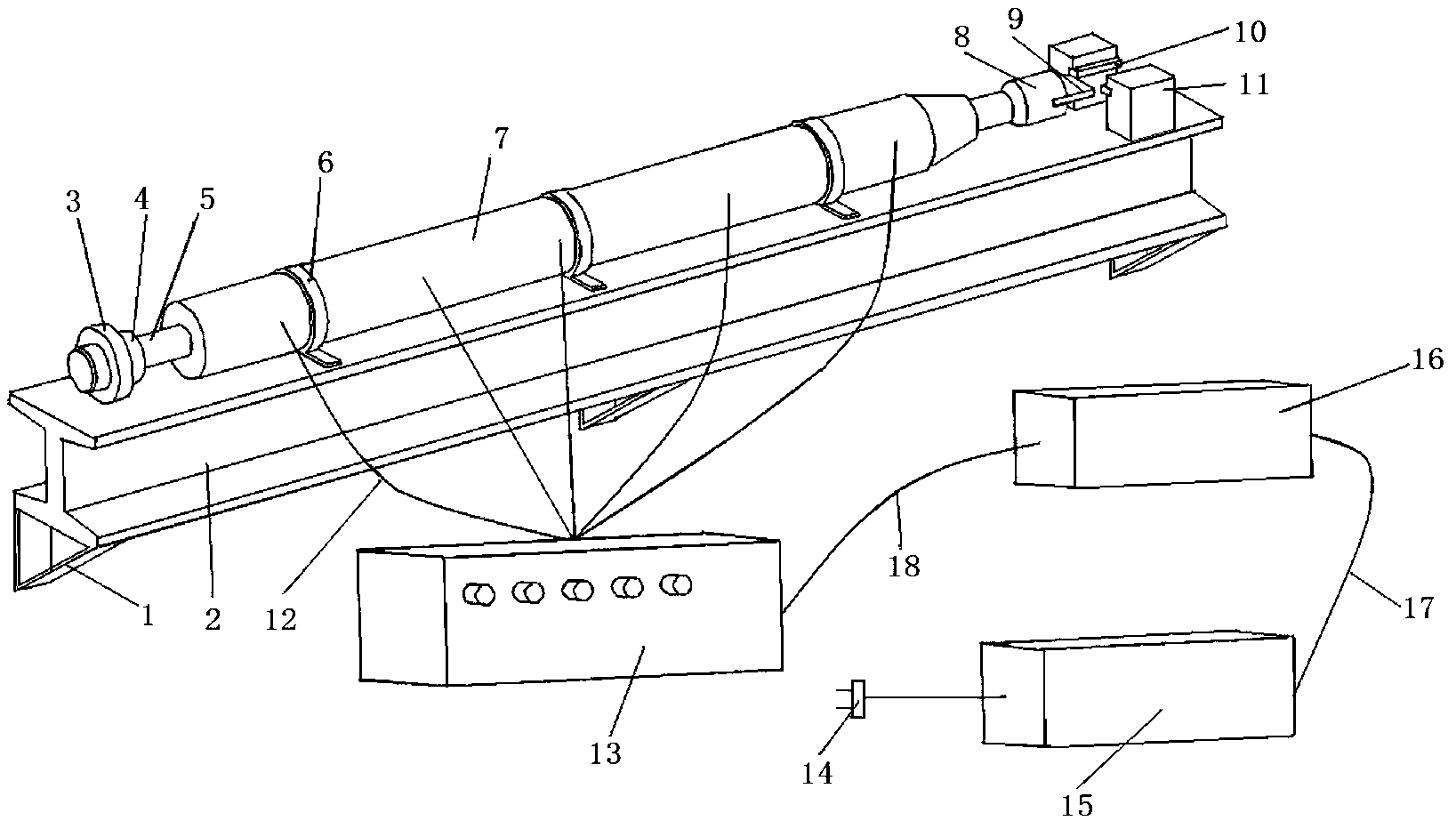

High-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology

ActiveCN103163037AHigh strain rateConstrained Cutting ExperimentInvestigating machinabilityGun barrelVelocity measurement

The invention discloses a high-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology. The high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology comprises a Hopkinson pressure bar loading mechanism which is used for pushing a bullet to move along a scheduled track at a scheduled speed, a laser velocity measurement mechanism which is used for measuring a movement speed before the bullet strikes a restrained cutting mechanism, the restrained cutting mechanism which is used for conducting restrained cutting of different plastic deformation degrees on a to-be-processed workpiece, a restrained cutting slideway mechanism which is used for giving a speed direction of restrained cutting, a fixing mechanism which is used for fixing the to-be-processed workpiece and a cutting stopping mechanism which is used for stopping a restrained cutting process. Different cutting speeds are obtained by adjusting pressure of air gun of the Hopkinson pressure bar and an initial position of the bullet in an acceleration gun barrel, different plastic deformation degrees can be obtained by adjusting the space between a tool of the restrained cutting mechanism and a restraining device, the high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology can be utilized to study a material interior microstructure evolution law when the material is with different strain rates and different plastic deformation degrees.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

2Cr13 heat treatment process

InactiveCN101608252AHigh surface hardnessImprove surface wear resistanceFurnace typesQuenching agentsLong axisMechanical equipment

The invention belongs to the field of a heat treatment process for reciprocating-compressor 2Cr13 piston-rods, and is applicable to all reciprocating compressors adopting a 2Cr13 piston-rod heat treatment process and mechanical equipment which requires high toughness and needs post-order surface heat treatment. The process can solve the problem that the prior heat treatment adopted for 2Cr13 piston rods is low in impact toughness, large in high-frequency quenching deformation of long-axis parts, large in hardening cracks and workpiece residual stress, and the like. The process comprises the forging molding of 2Cr13 piston rods, annealing, quenching-tempering, stabilizing, medium-frequency or high-frequency quenching and low-temperature tempering. The 2Cr13 heat treatment process can completely overcome the disadvantages of the prior heat treatment process such as incapability of eliminating residual stress and serious high-frequency quenching workpiece distortion, and is an ideal heat treatment process for long-axis workpieces.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Butt-joint manual welding method for high-strength bridge steel with thickness of 80 mm

InactiveCN102784998AHigh tensile strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsTO-18Sheet steel

The invention provides a butt-joint manual welding method for high-strength bridge steel with a thickness of 80 mm. The butt-joint manual welding method comprises the following steps of: using an equal-thickness bridge steel to carry out butt joint, wherein the equal-thickness bridge steel has Rm which is more than or equal to 570 MPa, ReL which is more than or equal to 420 MPa, an extension rate A which is more than or equal to 18%, KV2 at minus 40 DEG C which is more than or equal to 120J and the thickness of 80 mm; and the anti-tension strength of a matched welding wire is more than or equal to 600 MPa, and a diameter phi of a welding bar is 4.0 mm; a welding groove is an X type symmetrical groove, a groove angle is 60 degrees; and continuously welding in conditions of current of 165-170 A, voltage of 24-25V, a speed of 14-15 cm / min and linear energy of 16-17 kJ / cm, and controlling an interlayer temperature within a range of 135-145 DEG C. According to the butt-joint manual welding method provided by the invention, although the thickness of the bridge steel is up to 80 mm, no crack is generated through crack detection after a butt-joint connector is subjected to treatment without pre-heating before welding and without heating after welding. Furthermore, the impact power of KV2 of three areas of the connector at minus 40 DEG C reaches to 155-243 J, so that the technical requirements of manufacturing a large-span bridge structure can be entirely met.

Owner:武钢集团有限公司

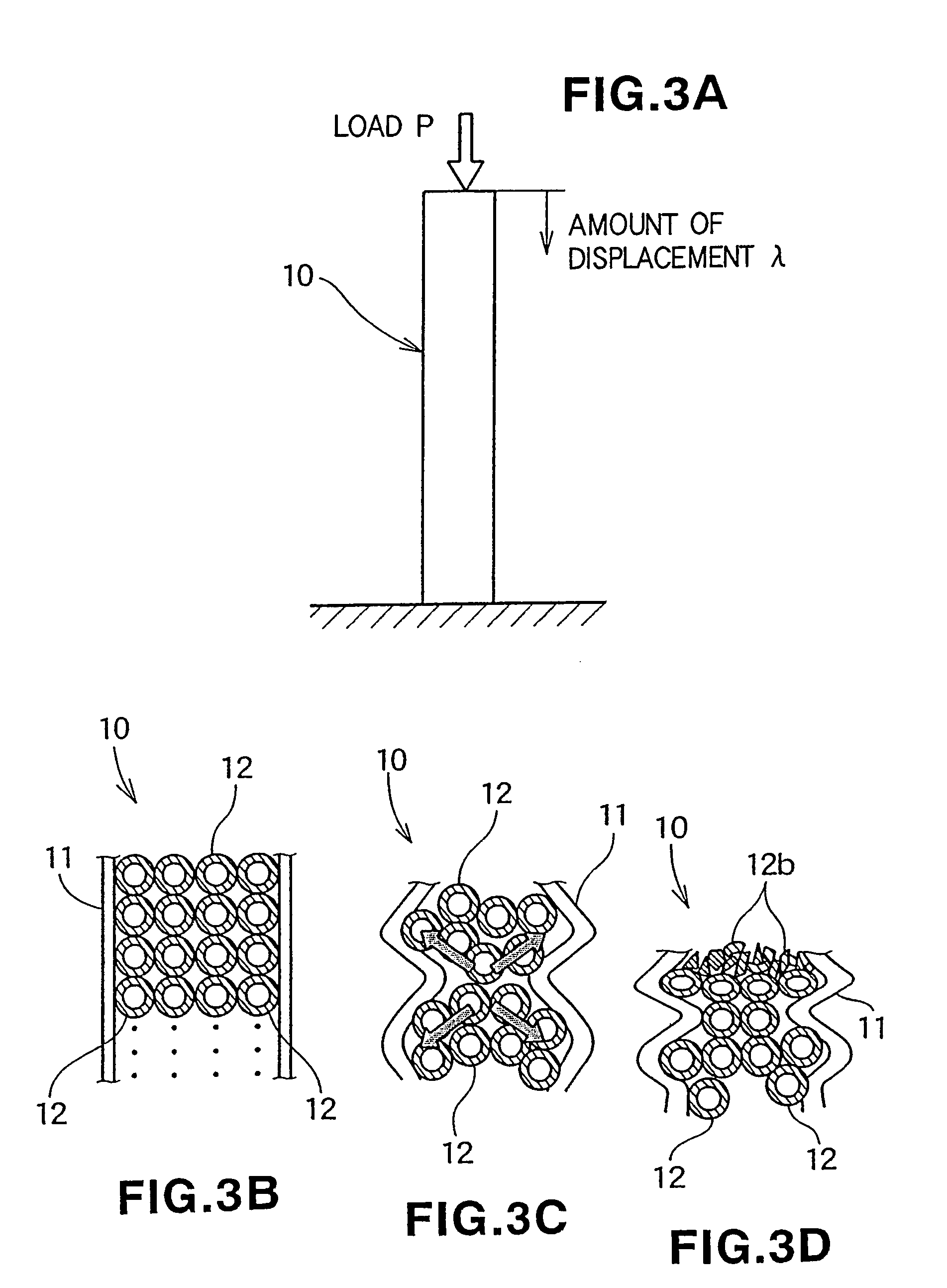

Skeleton member structure

InactiveUS20050124730A1Weight increaseHigh impact energyVehicle seatsElastic dampersMaterials scienceGranular material

A skeleton member structure having a tubular structural member (11, 211) filled with granular materials for absorbing impact energy. The granular materials includes a granular material having a hollow portion (12a, 212a) or a porous granular material. When the skeleton member receives an impact, the granular materials are deformed or collapsed, and impact energy is stably absorbed. Since the granular materials are hollow or porous, the weight of the skeleton member filled with the granular materials is reduced.

Owner:HONDA MOTOR CO LTD

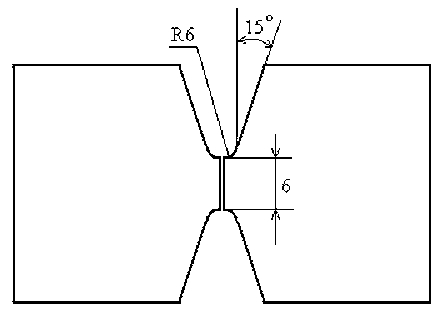

High-linear-energy submerged-arc welding method for bridge steel with yield strength higher than or equal to 500MPa

InactiveCN103317220AImprove low temperature toughnessImprove crack resistanceArc welding apparatusHeat-affected zoneButt joint

The invention discloses a high-linear-energy submerged-arc welding method for bridge steel with the yield strength higher than or equal to 500MPa. The high-linear-energy submerged-arc welding method includes that properties of an applicable base plate includes that the yield strength R<eL> is higher than or equal to 500MPa, the tensile strength R<m> is higher than or equal to 650MPa, the elongation is higher than or equal to 18%, and impact energy KV<2> at the temperature of -40 DEG C is higher than or equal to 120J; plate thickness combinations have equal thicknesses of 32mm; welding grooves are double-faced U-shaped symmetric grooves, an angle of each groove is 60 degrees, and the dimensions of each truncated edge is 6mm and R6mm; the tensile strength of each matched welding wire is higher than or equal to 650MP, and the diameter of each matched welding wire is phi4.0mm; a welding current ranges from 700A to 750A, a welding voltage is 32V, a welding speed ranges from 30cm / min to 26cm / min, welding linear energy ranges from 45kJ / cm to 55kJ / cm, and flux is baked at the temperature of 350 DEG C for 1 hour; multilayer multiple continuous welding procedures are implemented. The high-linear-energy submerged-arc welding method has the advantages that requirements on high-linear-energy submerged-arc welding for medium-thickness plate structures in construction for large-span road and highway dual-purpose bridges with the span larger than 1000 meters can be met, the tensile strength R<m> of each butt joint welding seam is not lower than 690MPa, joint cold bending d is 3a at the angle of 180 degrees and is qualified, impact energy KV<2> of each welding seam at the temperature of -40 DEG C is not lower than 134J, impact energy KV<2> of each weld line at the temperature of -40 DEG C is not lower than 95J, and impact energy KV<2> of a heat-affected zone (with the size of 1mm) at the temperature of -40 DEG C is not lower than 72J; three zones of the joints are high in impact toughness capacity and safety margin, preheating is omitted before welding, and heat treatment is omitted after welding.

Owner:武汉钢铁有限公司

A heat treatment process for low carbon alloy materials

InactiveCN102277581AImprove bending performanceReduced retained austenite contentSolid state diffusion coatingCarbon alloyCryogenic treatment

The invention discloses a heat treatment process of a low-carbon alloy material, and the heat treatment process comprises the steps of carbonitriding treatment, quenching treatment, cryogenic treatment and tempering treatment. The low-carbon alloy material, in particular 12Cr2Ni4 alloy material after the treatment through the process can obtain the surface with higher hardness and the heart part with strong toughness, and under the condition of keeping the higher toughness in a workpiece, a surface layer with high hardness and high strength can be obtained, thereby improving the abrasion resistance and the strength of the workpiece and enabling the service life of the workpiece to be in a close relationship with the toughness of the surface layer and good matching of the strong toughness of the surface layer and the heart part. After adopting the cryogenic treatment, the service life can be well prolonged and the hardness and the strength of a matrix can be improved.

Owner:MEISHAN HENGSHENG MECHANICAL EQUIP

Low-carbon high-tenacity super-thick steel plate and manufacturing method thereof

ActiveCN104988435AExcellent room temperature stretchExcellent Z direction performanceChemical compositionMetallurgy

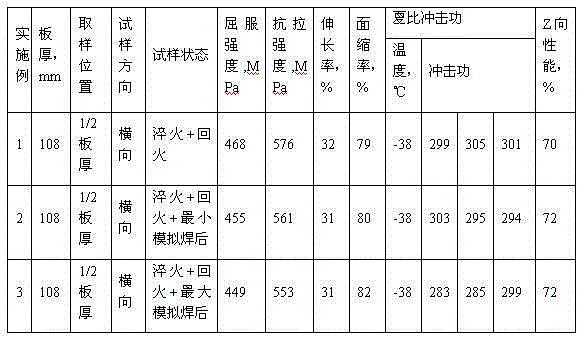

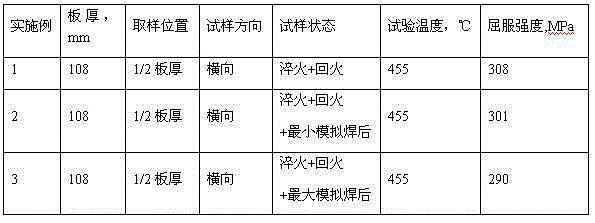

The invention discloses a large-thickness high-tenacity vessel steel plate, comprising the following chemical components by mass percent: 0.08 to 0.12 percent of C, 0.15 to 0.40 percent of Si, 0.40 to 0.70 percent of Mn, smaller than or equal to 0.005 percent of P, smaller than or equal to 0.003 percent of S, smaller than or equal to 0.40 percent of Ni, smaller than or equal to 0.20 percent of Cu, 0.80 to 1.20 percent of Cr, 0.45 to 0.60 percent of Mo, smaller than or equal to 0.003 percent of Sb, smaller than or equal to 0.010 percent of Sn, smaller than or equal to 0.012 percent of As, smaller than or equal to 0.0002 of H and the balance of Fe and investable impurity elements. The prepared low-carbon high-tenacity steel plate has the advantages that the thickness can reach 100 to 110 mm, the core part performance is excellent, particularly a low-temperature impact value at minus 38 DEG C is over 120J, and the Z-direction performance is good and is higher than the highest requirement, namely Z-direction performance being 35 percent, of a standard steel plate.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

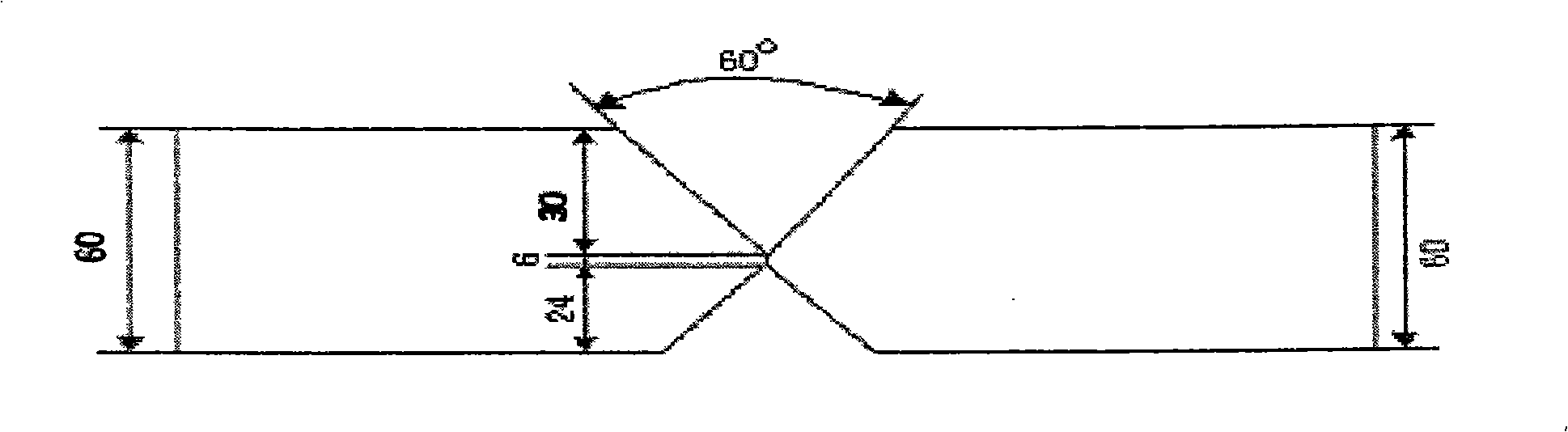

Submerged arc welding process for low-temperature high-toughness niobium micro-alloy steel and welding wire thereof

InactiveCN101722352AImprove impact toughnessHigh impact energyArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingVoltage

The invention relates to a welding process and a welding wire thereof, in particular to a submerged arc welding process for low-temperature high-toughness niobium micro-alloy steel and a welding wire thereof. The process comprises the following steps of: performing a welding heat simulation experiment on steel plates to determine the welding line energy range which can be adopted during the welding; adopting an X-shaped symmetrical groove as a submerged arc welding groove, wherein the angle of the groove is 60 degrees, and the length of a truncated edge is 6mm; adopting a welding wire with the tensile strength of between 540 and 620MPa and the impact work Akv of between 120 and 170J; ensuring that the welding current is between 500 and 580A, the welding voltage is between 31 and 35V, the welding speed is between 30 and 45cm / min, and the baking rule of a welding flux is 350 DEG C*1h; and ensuring that the submerged arc welding adopts multi-layer multi-channel continuous welding and the inter-layer temperature is controlled to between 100 and 150 DEG C, and immediately performing stress relief treatment at the temperature of 580 DGE C after the welding. The method has excellent welding processing properties, and can ensure that the mechanical property of a welding joint of the low-temperature high-toughness niobium micro-alloy steel meets design requirement and particularly various positions of the joint maintain higher low-temperature impact toughness.

Owner:NANJING IRON & STEEL CO LTD

Energy management beam

InactiveUS20070187960A1High impact energyPedestrian/occupant safety arrangementElastic dampersEnergy managementEngineering

A tube comprising an outer tube section with a stepped outer surface and an inner tube section, with the inner tube section being located within the outer tube section. The tube also comprises a spanning section connecting an end of the outer tube section to an end of the inner tube section. The outer tube section is longer than the inner tube section, whereby, upon undergoing a longitudinal impact, the outer tube section crushes predictably and sooner than the inner tube section upon the energy management tube receiving forces from the longitudinal impact, to thereby create a first energy absorption level during crushing of the outer tube section alone and a second energy absorption level during crushing of the outer tube section and the inner tube section.

Owner:SHAPE CORP

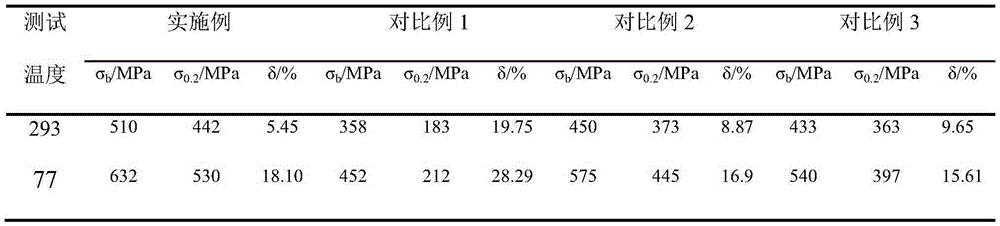

Cold-processing technology of Al-Mg alloys at liquid nitrogen temperature region

The invention relates to a cold-processing technology of Al-Mg alloys at a liquid nitrogen temperature region, and belongs to the technical field of nonferrous metal. The cold-processing technology comprises the following steps of firstly performing hot rolling on cast ingots containing Er aluminum magnesium alloys at 390-430 DEG C, wherein the rolling reduction achieves 90%, and air cooling the cast ingots to room temperature so as to obtain intermediate hot rolled plates; and then, rolling the intermediate hot rolled plates at low temperature. The step of cold rolling at low temperature is performed through immersing the intermediate hot rolled plates in liquid nitrogen for about half an hour, so that the intermediate hot rolled plates are cooled to the temperature of the liquid nitrogen, then, rapidly taking out the cooled rolled plates, and cold rolling the cooled rolled plates at room temperature in the rolling direction; when each rolling pass is completed, immediately putting the rolled plates in the liquid nitrogen for cooling, wherein the rolling reduction of each rolling pass is 10%-15%, and the total rolling reduction is 60%; and finally, respectively performing a stretching test on the cold rolled plates at room temperature, and performing an impact test on the cold rolled plates at the temperature of the liquid nitrogen, wherein the tensile strength, the yield strength and the elongation rate of the rolled plates at the temperature region of the liquid nitrogen are notably higher than those of the rolled plates at the room temperature, and the impact power of the rolled plates at the temperature of the liquid nitrogen is higher than that of the rolled plates under the room temperature state. According to the preparation technology, not only can the intensity of the alloys at low temperature be obviously improved, but also a certain low temperature extension rate of the alloys can be guaranteed, so that an aluminum alloy material with excellent comprehensive properties at the low temperature is obtained.

Owner:BEIJING UNIV OF TECH

High-toughness radiation-proof multi-element alloy and preparation method thereof

The invention provides a high-toughness radiation-proof multi-element alloy and a preparation method thereof. The atomic-ratio expression of the prepared AlxMCrFeNi series multi-element alloy is AlxMCrFeNi, wherein x refers to the atomic ratio, and is greater than or equal to 0 and less than or equal to 50%, and M is any one of V, Mn and Co. The multi-element alloy is excellent in toughness and radiation resistance, and has no ductile-brittle transition temperature. At a room temperature, the impact energy is 294.34J, and the lower the temperature is, the higher the impact toughness is; within th-196 DEG C temperature zone of liquid nitrogen, the impact energy is 371.45J, and the impact toughness is improved by 360% in contrast with the impact toughness of TWIP steel and by 364% in contrast with the impact toughness of a nuclear-grade 316LN pure austenitic steel weld metal. When the irradiation dose is about 0-60dpa, the irradiation swelling rate of the multi-element alloy is 95.8% lower than the irradiation swelling rate of Fe-15Cr-20Ni stainless steel. The high-toughness radiation-proof multi-element alloy has wide application prospect on the aspects of low-temperature materials and irradiation-proof materials.

Owner:UNIV OF SCI & TECH BEIJING

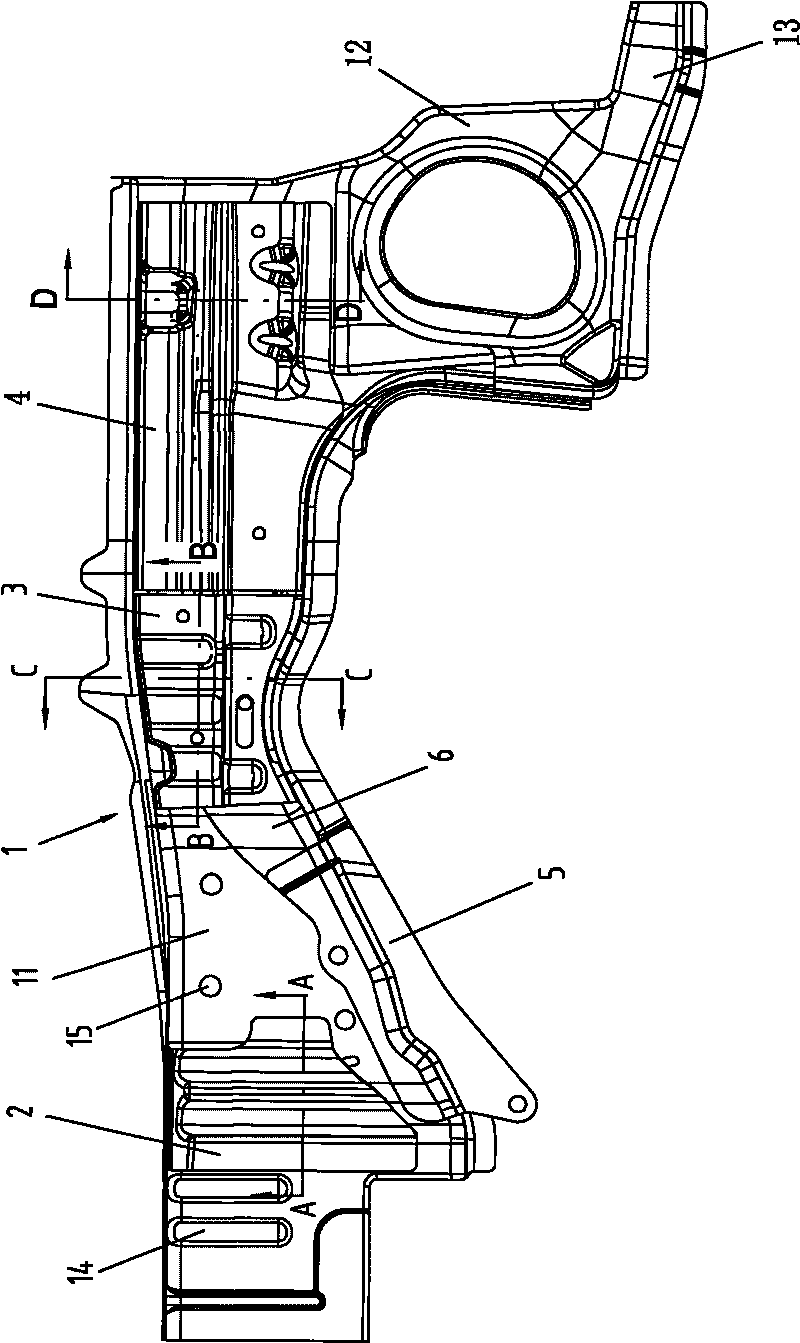

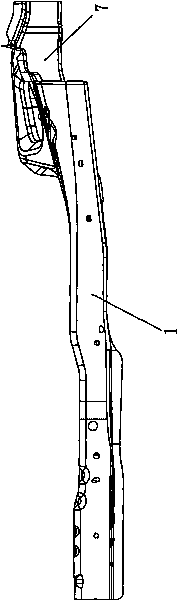

Front rail structure of automobile body

InactiveCN101708737AImprove energy absorptionAbsorb impact energyUnderstructuresEngineeringMechanical engineering

The invention discloses a front rail structure of an automobile body, which has a Z-shaped front rail extending along the fore and aft direction of the automobile body. The front rail comprises a transverse upper section and the cross section of the front rail in the fore and aft direction is of trench structure. The front rail structure is characterized in that a front reinforcing plate, a middle reinforcing plate and a rear reinforcing plate are respectively welded on the front, middle and rear parts in a trench on the upper section of the front rail; the upper edges of the three reinforcing plates are provided with turnup edges which are welded with the turnup edge of the upper edge of the upper section in a sticking manner; the front rail between the front side and the rear side of the front reinforcing plate is a buffer energy absorbing zone; the middle reinforcing plate and the rear reinforcing plate respectively encircle cavities with the front rail; a gap is reserved between the middle reinforcing plate and the rear reinforcing plate; and the rear end of the rear reinforcing plate is close to the rear end of the front rail. The invention is strengthened as a whole and can effectively absorb and attenuate the impact energy generated during automobile crash. In addition, the force transmission property of the rear force bearing zone is greatly enhanced and the rear force bearing zone can absorb more impact energy during deformation.

Owner:力帆科技(集团)股份有限公司

Skeleton member structure

InactiveUS7226120B2Weight increaseHigh impact energyVehicle seatsElastic dampersMaterials scienceGranular material

A skeleton member structure having a tubular structural member (11, 211) filled with granular materials for absorbing impact energy. The granular materials includes a granular material having a hollow portion (12a, 212a) or a porous granular material. When the skeleton member receives an impact, the granular materials are deformed or collapsed, and impact energy is stably absorbed. Since the granular materials are hollow or porous, the weight of the skeleton member filled with the granular materials is reduced.

Owner:HONDA MOTOR CO LTD

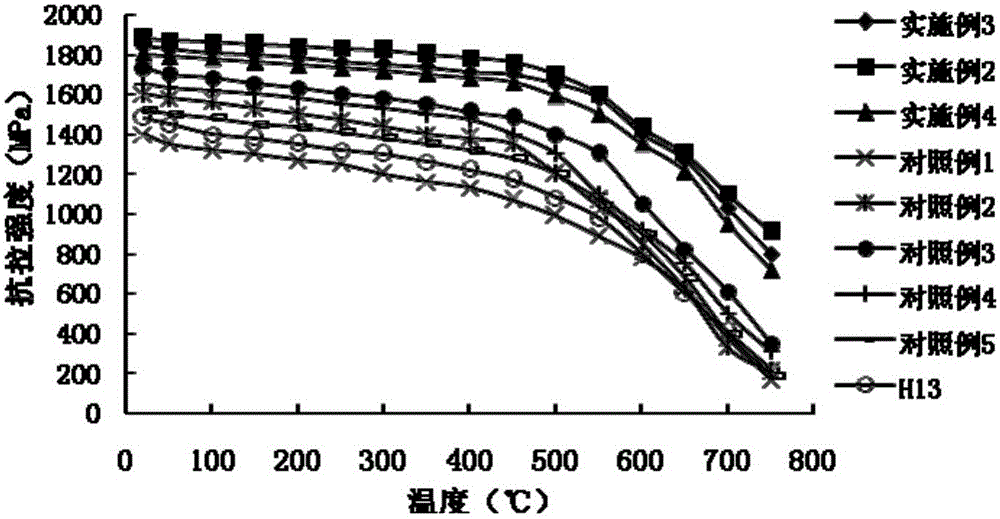

High-grade hot work die steel with high performance and manufacturing method of high-grade hot work die steel

ActiveCN105803314AImprove high temperature strengthImprove stabilityHot workUltimate tensile strength

The invention provides high-grade hot work die steel with high performance. The die steel mainly comprises, by weight percent, 0.32%-0.41% of C, 0.2%-0.6% of Si, 0.6%-0.9% of Mn, 2.5%-4.5% of Cr, 2.5%-3.5% of Mo, 0.5%-1.1% of V, smaller than 0.02% of P, smaller than 0.0005% of S, and the balance Fe. The die steel has excellent high-temperature strength, temper resistance and heat conductivity performance, the structure AS1 grade in the NADCA#229-2011 standard can be obtained, the oxygen and sulfur content is lower than 10 ppm, and the ballistic work of the die steel is higher than H13 die steel by 30% under high hardness.

Owner:TIANJIN CISRI HARDER MATERIALS & TECH

Submerged-arc welding method of high-intensity steel thick plate for nuclear power

InactiveCN103341686AHigh tensile strengthHigh impact energyArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingVoltage

The invention relates to a submerged-arc welding method of a high-intensity steel thick plate for nuclear power. The submerged-arc welding method of the high-intensity steel thick plate for nuclear power includes the following steps that high-intensity steel is utilized, the Rm of the high-intensity steel is no less than 645Mpa, the ReL of the high-intensity steel is no less than 535Mpa, the ductility A of the high-intensity steel ranges from 20% to 40% and the -45oCKV2 ballistic work of the high-intensity steel is larger than 54J. Two plates with the same width ranging from 36mm to 48mm are combined and connected in an abutted mode. A matched welding stick has the tensile strength of more than 600MPa and the diameter of 4mm. U-shaped submerged-arc welding grooves are symmetric, the angles of the grooves are 60 degrees and the truncated edges are 6mm long. Under the condition that currents are 650A to 700A, the voltage is 33V to 31V, the rate is 45cm per minute to 35 cm per minute and linear energy is 31kJ per cm to 35kJ per cm, continuous welding is performed. The submerged-arc welding method of the high-intensity steel thick plate for nuclear power solves the problems that when steel thick plates with the tensile strength of no less than 585Mpa for a nuclear power (AP1000) pressure bearing device is welded, a submerged-arc welding butt joint is not pre-heated before welding and does not undergo heat treatment after welding in an existing welding technology method, the tensile strength and joint ballistic work of the submerged-arc welding joint reach high levels and the joint has high impact toughness reserve and high safety margin.

Owner:武汉钢铁有限公司

Valveless single-cylinder low or middle wind pressure downhole air hammer

InactiveCN101575941AGuaranteed uptimeExpand the effective working diameterBorehole drivesCheck valveAir cavity

A valveless single-cylinder low or middle wind pressure downhole air hammer comprises an outer sleeve with one end being a rear joint and the other end being a drill bit. A check valve is arranged in the outer sleeve and internally provided with a flexible spring. One end of an air distribution pole is provided with a radial hole and matched with a piston in which a central pore path is arranged. The central pore path is provided with an inner ring groove thereon. The lower part of the piston is provided with an upper air hole that is communicated with the inner ring groove through a slant hole, while the upper part thereof is provided with an air duct. One end of an upper slant hole is communicated with the air duct, while the other end thereof is matched with the radial hole. The piston is matched with the drill bit and a guide sleeve. A valve seat is provided with a locating device. The air hammer enlarges the effective working diameter of the cylinder body, causes the piston to obtain high impact energy, simplifies an air distribution path, reduces gas pressure loss, can be used under low or middle wind pressure to improve the down-the-hole rock drilling efficiency and reduce energy consumption. The locating device solves the locating and guiding problem of the air distribution pole, thus causing the hammer to operate with high efficiency and stability.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Steel for longitudinal resistance welded pipe with low yield ratio and manufacturing method thereof

The invention discloses steel for a longitudinal resistance welded pipe with a low yield ratio and a manufacturing method thereof. The steel comprises the following chemical components in percentage by weight: 0.15 to 0.22 percent of C, 0.10 to 0.30 percent of Si, 1.20 to 1.60 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.008 percent of S, 0.005 to 0.025 percent of Ti, 0.20 to 0.30 percent of Cr, 0.010 to 0.045 percent of Als, less than or equal to 0.008 percent of N and the balance of Fe and inevitable impurities. The manufacturing method comprises molten iron pretreatment, molten steel smelting, external refining and slab continuous casting, and heating, rolling, cooling and reeling of a continuous cast slab, wherein the continuous cast slab is heated to between 1,180 and 1,280 DEG C in a heating furnace, and then rolled into a hot rolled strip; the finishing temperature of the strip is between 760 and 820 DEG C; the rolled strip is rapidly cooled at a speed of between 9 and 14 DEG C per minute; and the strip is rolled into a coiled sheet at the temperature of between 560 and 620 DEG C. The problem that industrial production cannot be realized due to a slow cooling speed after rolling and the problem that the requirement of a user on the impact toughness of the coiled sheet cannot be met in the prior art are solved.

Owner:ANGANG STEEL CO LTD

Mechanical underground vibration-absorption punching drilling tool

ActiveCN102536114AHigh impact energySimple structureDrilling drivesBorehole drivesPunchingWell drilling

A mechanical underground vibration-absorption punching drilling tool comprises a spline mandrel, a spline cylinder, a vibration-reducing return spring outer cylinder, and a punching assembly outer cylinder, wherein an upper part matching joint is connected to the top end of the spline mandrel; the spline cylinder is connected with the vibration-reducing return spring outer cylinder and the punching assembly outer cylinder into a whole; the spline mandrel is arranged in the spline cylinder, the vibration-reducing return spring outer cylinder and the punching assembly outer cylinder; the lower end of the spline mandrel is connected with a shunting structure; the spline mandrel is connected with a plunger through the shunting structure; the lower end of the plunger is arranged in a punching cylinder; the lower part of the punching cylinder is arranged in a punching bearing structure; the lower end of the punching bearing structure is connected with a lower part matching joint; and a spacing structure is arranged at the lower end of the punching assembly outer cylinder. According to the invention, the vibration reduction for a drill string is combined with the high-frequency low-punching power of a drill bit, and longitudinal vibration easy to cause fatigue rupture of the drill string is converted into internal energy of a vibration-reducing return spring and punching power providing convenience for improving drilling speed, so as to fulfill rotary punching drilling and improve rock breaking efficiency.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Gas shielded arc welding method for high intensity bridge heavy plate K type joint

InactiveCN101549429AImprove toughnessImprove securityArc welding apparatusWelding/cutting media/materialsEngineeringHigh intensity

The present invention discloses a gas shielded arc welding method for high intensity bridge heavy plate K type joint which welds wide span high intensity bridge steel K type joint with perfect weld joint property, and does not need pre-warming and post heat-treated. The method is that: using Rm: 570-650 MPa, Rel: 420-490MPa, A:18-24%, -40 deg c A(KV): 120-270J bridge steel with thickness 36-50mm; a matching welding wire Rm: more than 600MPa, the welding wire diameter 1.2mm; a gas shielded arc welding bevel angle is two-sided k type symmetrical, the bevel angle 50-55 degree, blunted edge 2mm; wealthy argon is used as protective gas and flow quality is 18-20 L / min for welding continuously in condition of current 260-250A, voltage 23-22V, welding speed 29-20cm / min and welding weld line energy 12-17 kj / cm for filling the weld joint, an interlayer temperature is controlled between 100-150 deg c.

Owner:武钢集团有限公司

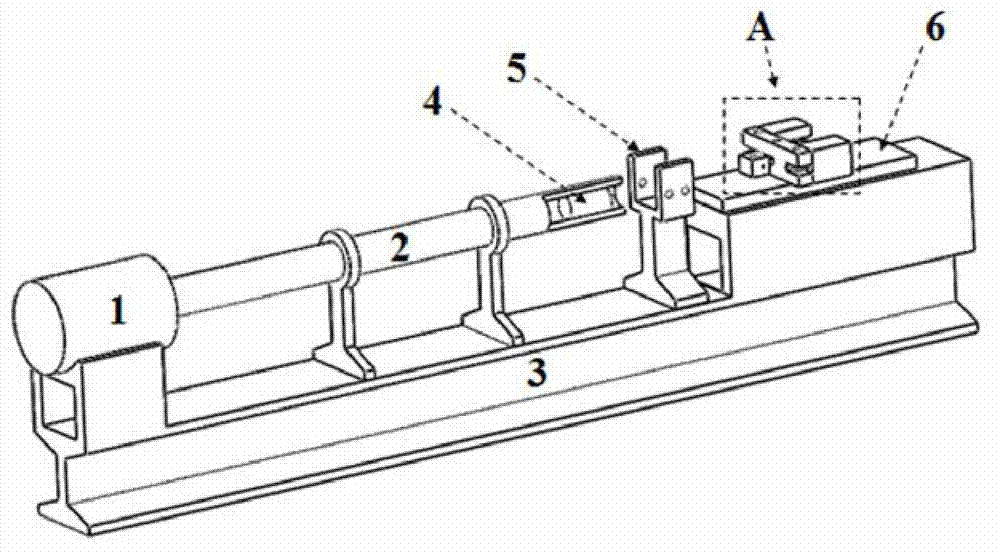

Electromagnetically driven high-speed cutting simulation experimental device

InactiveCN103163038AMeet the requirements of high-speed cutting experimentsWide cutting speed rangeInvestigating machinabilityImaging processingDynamometer

The invention discloses an electromagnetically driven high-speed cutting experimental device which comprises an actuating mechanism, a cutting mechanism and a fixing mechanism, wherein the actuating mechanism is used for producing electromagnetic thrust to drive the cutting mechanism to move at a high speed so as to enable a cutter to cut a workpiece fixed on the fixing mechanism, and the cutter can be rapidly stopped by a cushion and an aluminum alloy end check block on the actuating mechanism. The whole experimental device provided by the invention is constructed based on an electromagnetically driving technology, thus being economical, environment-friendly and good in stability, the experimental device can achieve a very high cutting speed, the cutting speed is adjustable, and a high-speed camera is additionally arranged and can be used for carrying out image processing and analysis on a high-speed cutting process. By matching with instruments such as a laser velocimeter and a dynamometer, the electromagnetically driven high-speed cutting experimental device can meet the requirements of high-speed cutting experiments of various materials.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com