Submerged-arc welding method of high-intensity steel thick plate for nuclear power

A welding method and submerged arc welding technology, applied in the direction of arc welding equipment, welding medium, welding equipment, etc., to achieve the effects of high impact energy, excellent low-temperature impact toughness and crack resistance, high impact toughness reserve and safety margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

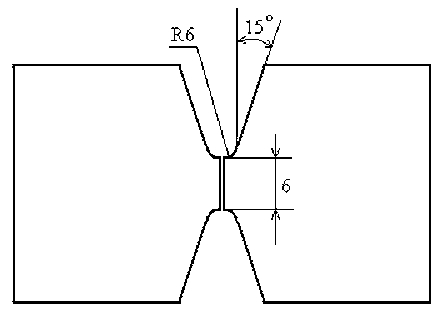

[0021] Base material: -50℃ nuclear power steel with tensile strength of Rm620MPa and yield strength Rel of 520MPa, the thickness of the steel plate is 36mm+36mm; Symmetrical U-shaped groove, groove angle is 60°, blunt edge 6mm, R6mm;

[0022] Welding material matching: WGX1 welding wire, wire diameter Ф4.0mm, flux is CHF105, mechanical properties of deposited metal are R el =560MPa, R m =650 MPa, A=24%, Z=66%, impact energy -50℃KV 2 =117J.

[0023] Butt joint welding is carried out, the welding current is 700~695A, the welding voltage is 33V, the welding speed is 45~42cm / min, and the welding line energy is 31~32kJ / cm; The temperature is controlled at 160~165℃, no preheating before welding and no heat treatment after welding.

[0024] After testing, the mechanical properties of the welded high-strength nuclear power steel thick plate butt joint are as follows: the tensile strength of the weld is R m =665MPa, joint cold bending (side bending) d=3a, 180° qualified, weld imp...

Embodiment 2

[0026] Base material: -50℃ nuclear power steel with tensile strength of Rm645MPa and yield strength Rel of 550MPa, the thickness combination of the steel plate is 48mm+48mm; the size of the test plate is 600mm×400mm×48mm;

[0027] The submerged arc welding groove adopts a double-sided symmetrical U-shaped groove, the groove angle is 60°, and the blunt edge is 6mm and R6mm;

[0028] Welding material matching: WGX1 welding wire, wire diameter Ф4.0mm; flux is CHF105, mechanical properties of deposited metal are R el =560MPa, R m =650 MPa, A=24%, Z=66%, impact energy -50℃KV 2 =117J;

[0029] For butt joint welding, the welding current is 680~670A, the welding voltage is 33V, the welding speed is 41~39cm / min, and the welding line energy is 32~33J / cm. At 170~180(℃), no preheating before welding and no heat treatment after welding.

[0030] After testing, the mechanical properties of the butt joints of the welded high-strength nuclear power steel thick plates, the tensile strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com