Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduced retained austenite content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxide dispersion strengthened (ODS) steel preparing method and martensitic steel

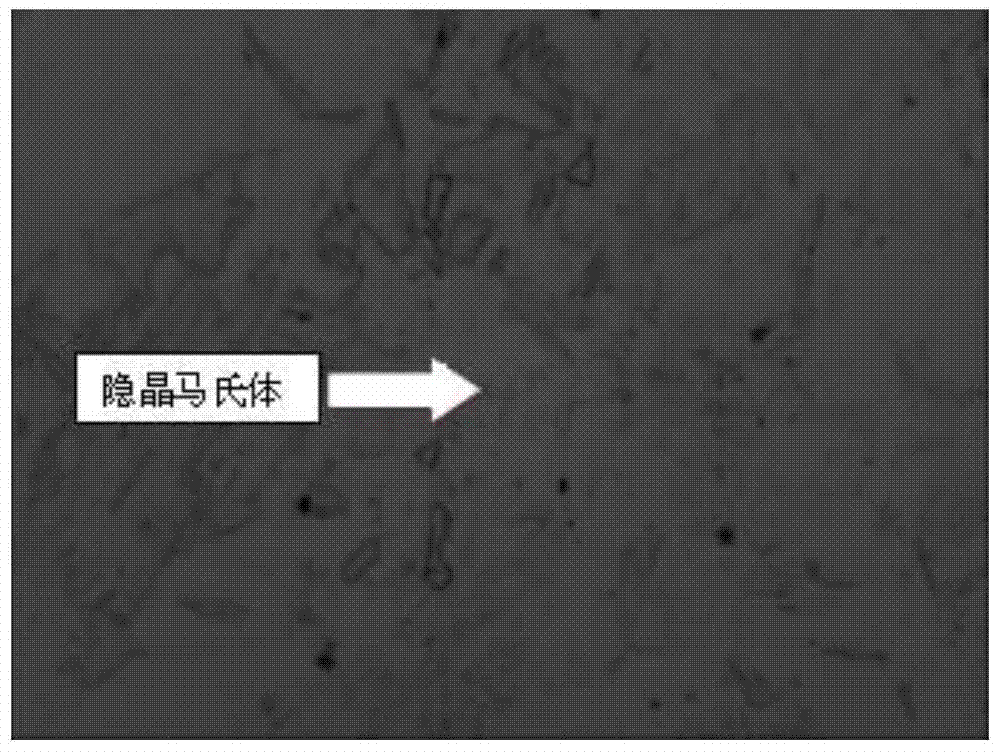

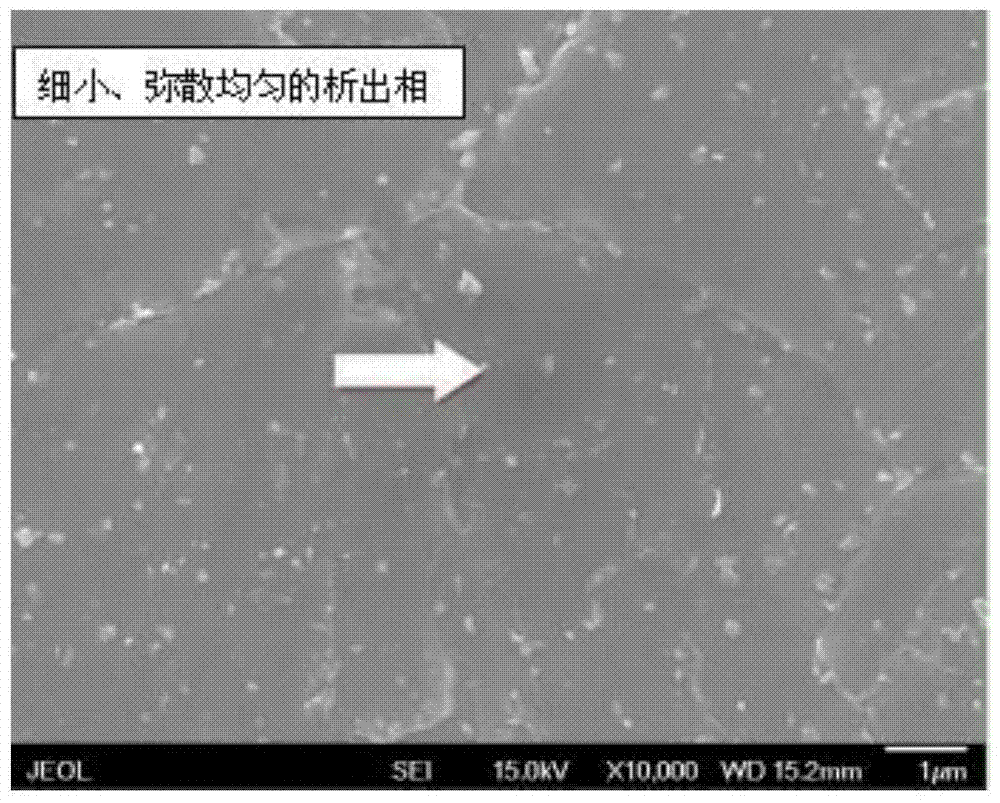

The invention provides an oxide dispersion strengthened (ODS) steel preparing method and martensitic steel. The oxide dispersion strengthened steel preparing method includes the steps that iron oxides are added into a casting mould, a proper number of rare earth elements are added into a fully deoxidized molten steel, the mixture is rapidly cast into the casting mould, and the ODS steel is obtained through the reaction between the rare earth elements and the iron oxides. The martensitic steel is obtained by performing hot forging, hot rolling, hot machining and hot treatment on the ODS steel prepared through the method. The ODS steel prepared through the method is high in hardenability, the residual austenitic content is very low, and a full martensite structure can be obtained. W, V and Ta are strong carbide forming elements and have a remarkable strengthening effect, and the mechanical property is obviously higher than that of steel prepared through a traditional smelting technology. Meanwhile, the ductile-brittle transition temperature (DBTT) value is minus 80 DEG C and minus 90 DEG C, the good toughness of the traditional smelting technology is well inherited, and meanwhile good anti-radiation performance is achieved. By means of the ODS steel preparing method, the demands for preparing ODS steel in batches with stability, short process and low cost can be met.

Owner:UNIV OF SCI & TECH BEIJING

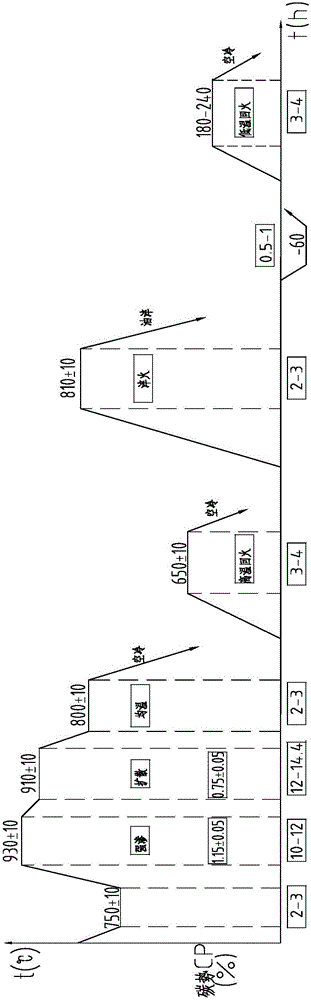

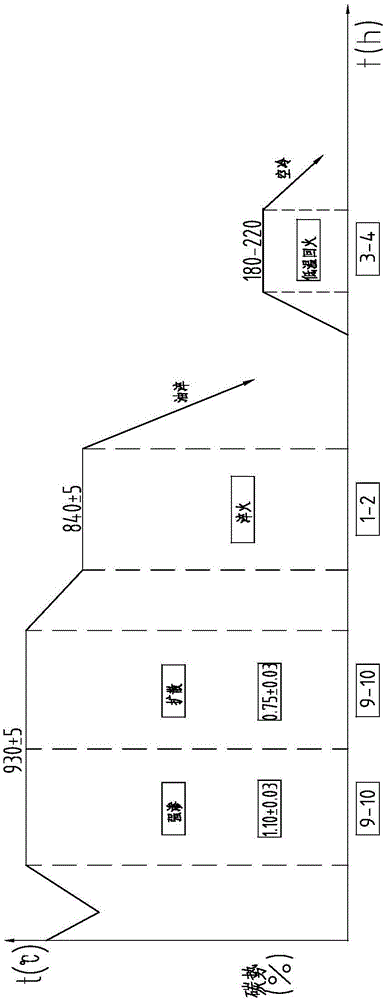

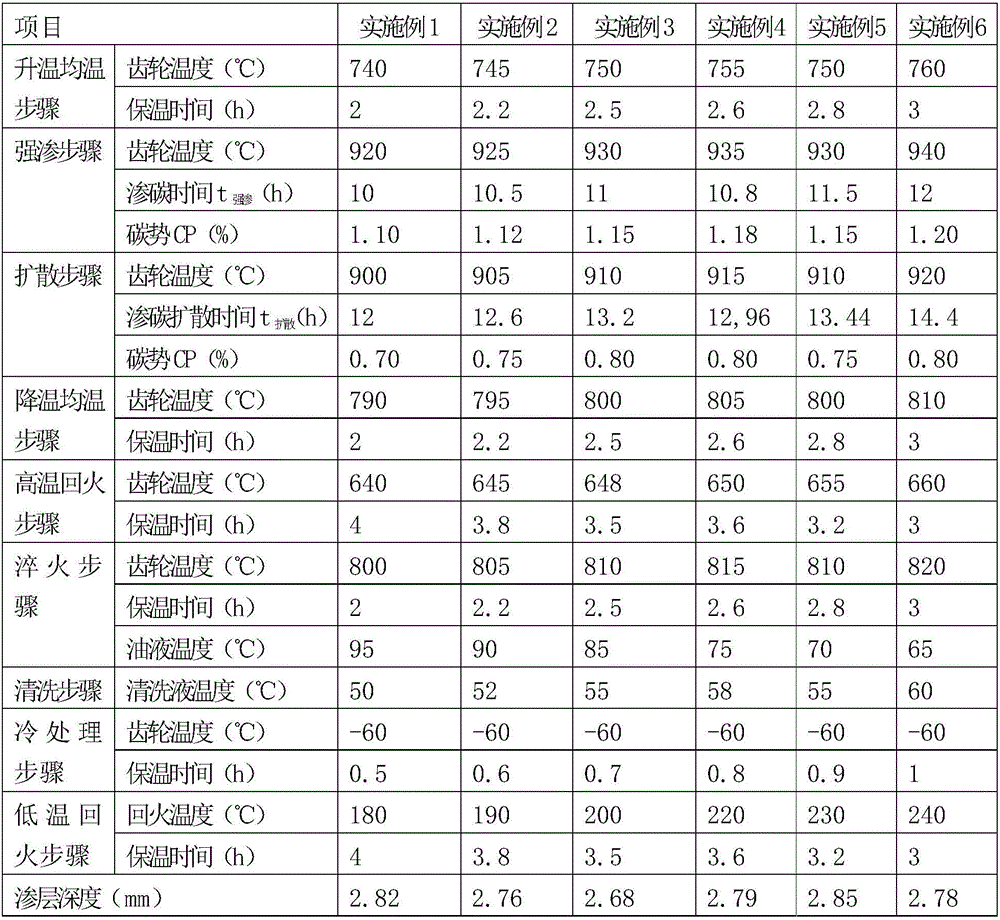

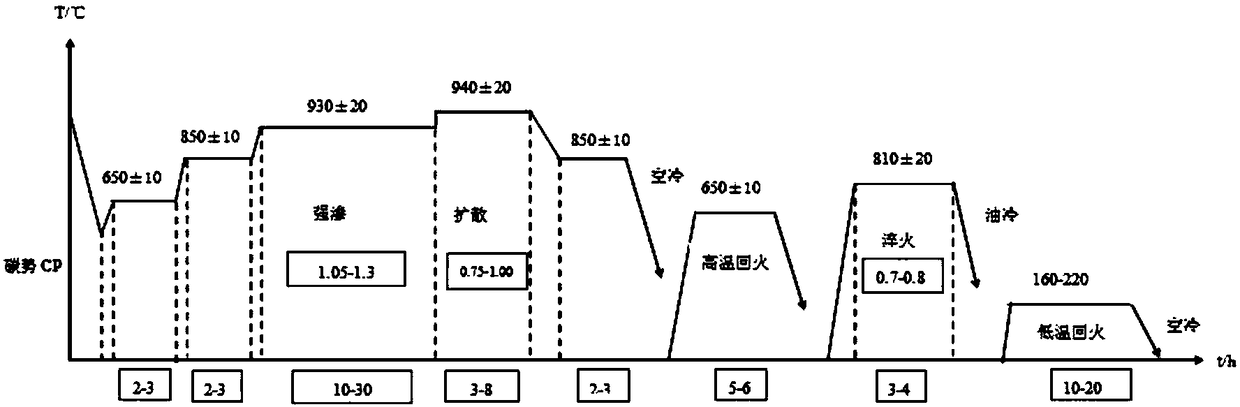

Carburizing and quenching method of low-speed heavy-duty gear

ActiveCN106756753AReduce carbon contentReduce carburizing potentialSolid state diffusion coatingFurnace typesCold treatmentLow speed

The invention relates to a carburizing and quenching method of a low-speed heavy-duty gear. The carburizing and quenching method comprises the steps of (1) temperature increase and temperature uniformization; (2) strong carburizing; (3) diffusion; (4) temperature decrease; (5) high-temperature tempering; (6) quenching; (7) cold treatment; and (8) low temperature tempering. According to the carburizing and quenching method of the low-speed heavy-duty gear, harmful carbide of a gear carburized layer can be effectively removed, dispersively distributed fine granular carbide can be obtained, the content of retained austenite on the surface is greatly decreased, a metallographic structure of the gear surface is improved, the surface hardness and abrasion resistance of the gear are improved, and the heat treatment property of a product is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

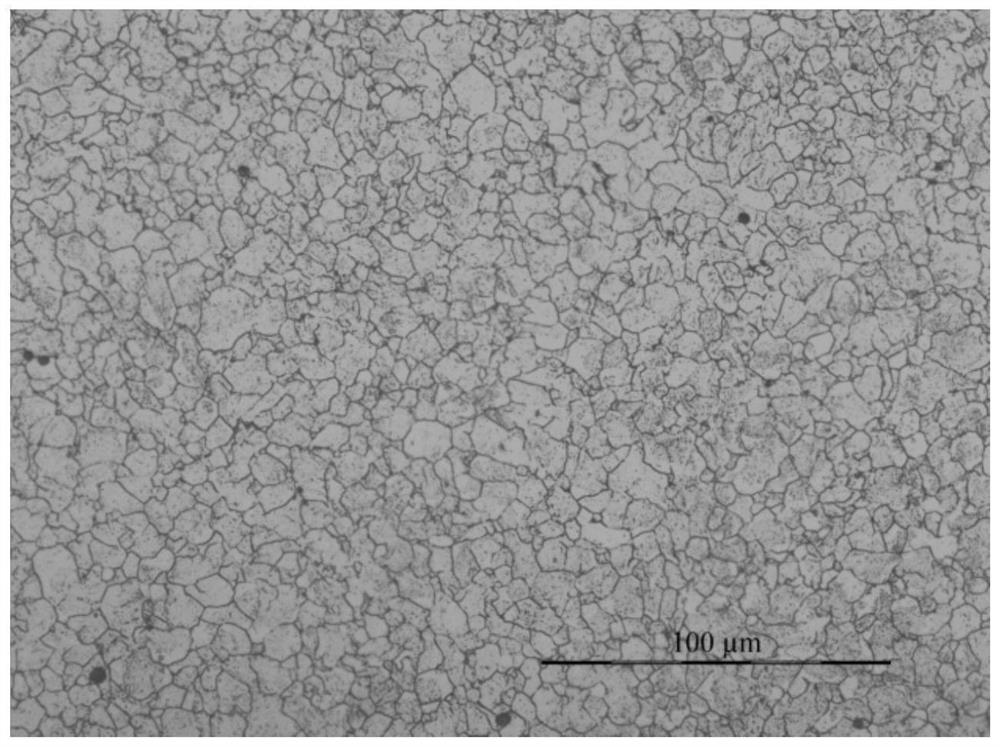

Method for preparing oxide dispersion strengthened F/M steel through smelting and casting process

The invention provides a method for preparing oxide dispersion strengthened F / M steel through the smelting and casting process and belongs to the field of metal materials. The steel comprises 0.08-0.15% of C, 8.0-14% of Cr, 0.45-0.6% of Mn, 1.0-2.5% of W, 0.05-0.07% of N, 0.010-0.20% of Ta, 0.02-0.55% of Ti, 0.10-0.15% of Si, 0.04-0.5% of V, 30-200 ppm of O, less than 0.001% of B, less than 0.003%of S, less than 0.005% of P, 0.01-1% of Y powder in a casting die, and the balance Fe. The rolling temperature of the steel is 800 DEG C-1100 DEG C. The steel is subjected to thermal treatment afterrolling, specifically, is subjected to quenching at 850-1100 DEG C / 15-120 min and is subjected to tempering at 710-800 DEG C / 90-120 min. The oxide dispersion strengthened F / M steel is high in high-temperature strength and low in ductile-brittle transition.

Owner:UNIV OF SCI & TECH BEIJING

Surface strengthening heat treatment method capable of improving hardness gradient

InactiveCN108118283ARaise the hardness gradientHigh surface hardnessSolid state diffusion coatingCarbideHardness

The invention discloses a surface strengthening heat treatment method capable of improving hardness gradient. The surface strengthening heat treatment method comprises the following steps: sectional warming and temperature equilibrium, high carbon potential strong permeability, temperature diffusion improvement, sectional cooling and temperature equilibrium, high-temperature tempering, quenching and low-temperature tempering. According to the surface strengthening heat treatment method provided by the invention, the surface hardness and abrasive resistance of parts can be improved, the hardness gradient is improved, the up-to-standard hardness depth is increased, fine granular carbides with dispersed distribution are obtained, the comprehensive mechanical property of parts is promoted, theheat treatment time is shortened, the production efficiency is improved, and the energy consumption is reduced.

Owner:NANJING INST OF TECH

Gear carburization quenching technology

InactiveCN103643241AReduced retained austenite contentReduce thicknessFurnace typesHeat treatment furnacesGasolineLayer thickness

A disclosed gear carburization quenching technology comprises the following steps: 1) carburizing with a temperature of 830-840 DEG C; 2) performing pre-cooling on a gear to 730-740 DEG C and keeping the temperature for 2-3 h; 3) performing primary quenching, immersing the gear into quenching oil, keeping the temperature at 110-120 DEG C, and stirring the quenching oil; 4) cleaning the gear with gasoline; 5) performing high tempering, heating the gear to 720-730 DEG C, keeping the temperature for 2-3 h, performing high tempering within 1 hour after primary quenching; 6) performing preheating on the gear to 730-740 DEG C, and keeping the temperature for 2-3 h; 7) performing secondary quenching, immersing the gear into quenching oil, keeping the temperature at 125-130 DEG C, and stirring the quenching oil; 8) cleaning the gear with gasoline; and 9) performing low tempering, heating the gear to 160-170 DEG C, keeping the temperature for 2-3 h, and performing low tempering within 1 hour of the secondary quenching. The provided gear carburization quenching technology helps to reduce the residual austenite content and the non-martensite layer thickness on the gear surface.

Owner:常熟市东风齿轮厂

A heat treatment process for low carbon alloy materials

InactiveCN102277581AImprove bending performanceReduced retained austenite contentSolid state diffusion coatingCarbon alloyCryogenic treatment

The invention discloses a heat treatment process of a low-carbon alloy material, and the heat treatment process comprises the steps of carbonitriding treatment, quenching treatment, cryogenic treatment and tempering treatment. The low-carbon alloy material, in particular 12Cr2Ni4 alloy material after the treatment through the process can obtain the surface with higher hardness and the heart part with strong toughness, and under the condition of keeping the higher toughness in a workpiece, a surface layer with high hardness and high strength can be obtained, thereby improving the abrasion resistance and the strength of the workpiece and enabling the service life of the workpiece to be in a close relationship with the toughness of the surface layer and good matching of the strong toughness of the surface layer and the heart part. After adopting the cryogenic treatment, the service life can be well prolonged and the hardness and the strength of a matrix can be improved.

Owner:MEISHAN HENGSHENG MECHANICAL EQUIP

Low-alloy super-strength steel and heat treatment technique for the same

InactiveCN101078088ANo change in mechanical propertiesImprove hardenabilityBearing componentsHeat treatment process controlMartensiteUltimate tensile strength

A kind of low alloy martensite steel with high strength, the character of it is the component range as following, quality percent: C0.3-0.6,Mn0.8-2.0,i0.1-0.4,r0.8-2.0,o0.1-0.4,l1.0-2.5,S<0.0l,P<0.01, the other is Fe. The steel will be stabilized after quenching and backfire at low temperature. The low alloy steel in this patent, can own very high strength and certain tenacity after a simple heat treatment, as a result the cost of it is lower.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Precipitation-Hardening Stainless Steel Powder and Sintered Compact Thereof

ActiveUS20160333450A1Sufficient age-hardenabilityHigh age-hardenabilityAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMartensite

There is provided a precipitation hardening stainless steel powder including, in percentage by mass: Si: ≦1.0%; Mn: ≦1.8%; Ni: 3.0 to 8.5%; Cr: 12.0 to 20.0%; Mo: 0.1 to 2.5%; Cu: 1.0 to 5.0% and / or Ti+Al: 1.0 to 5.0%; Nb+Ta≧5C or Nb≧5C; N≦350 ppm; and the balance being Fe and incidental impurities. A sintered compact fabricated from the steel powder has a martensite content of 90% or more. The precipitation hardening stainless steel powder provides a sintered compact that exhibits high strength after aging.

Owner:SANYO SPECIAL STEEL COMPANY

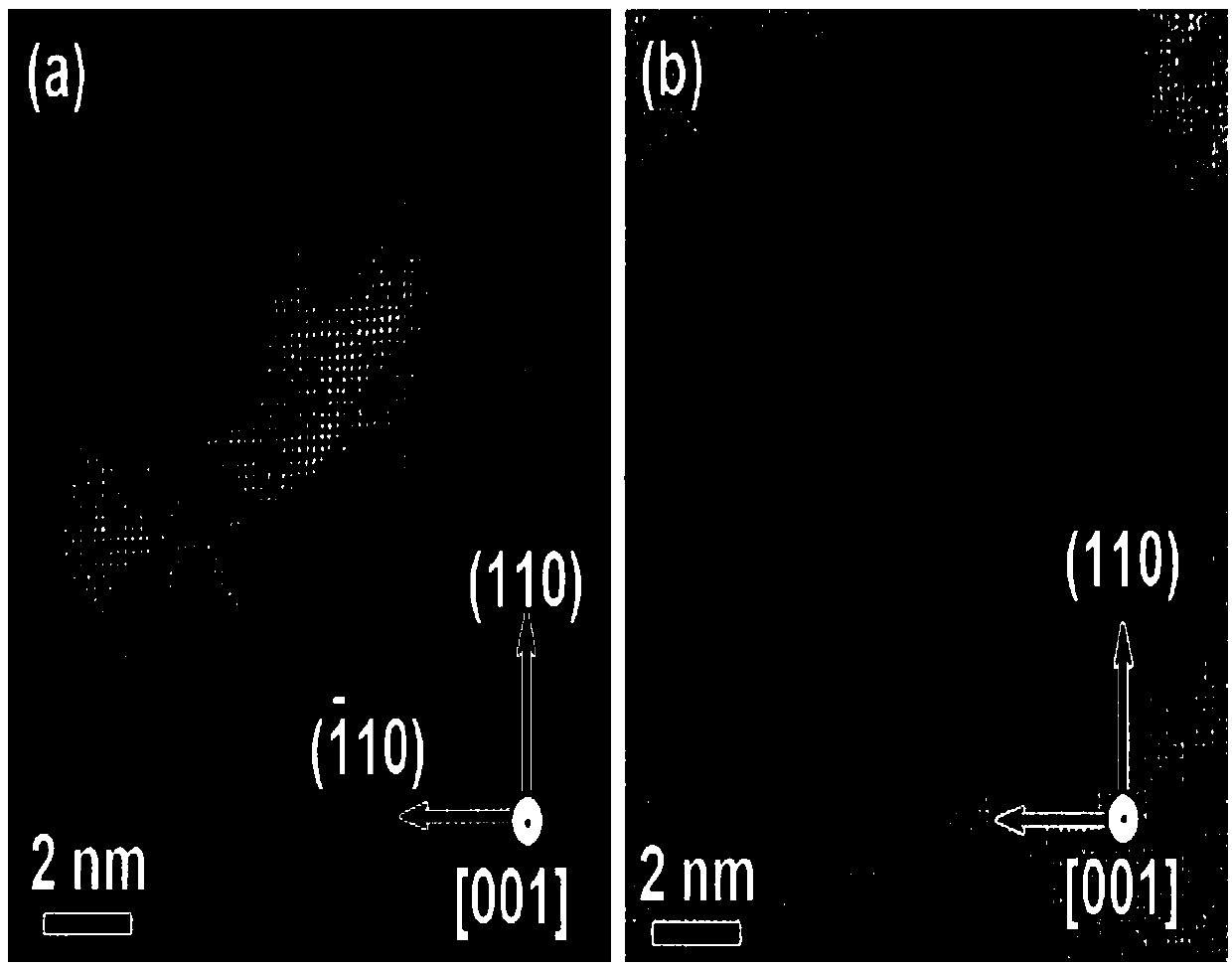

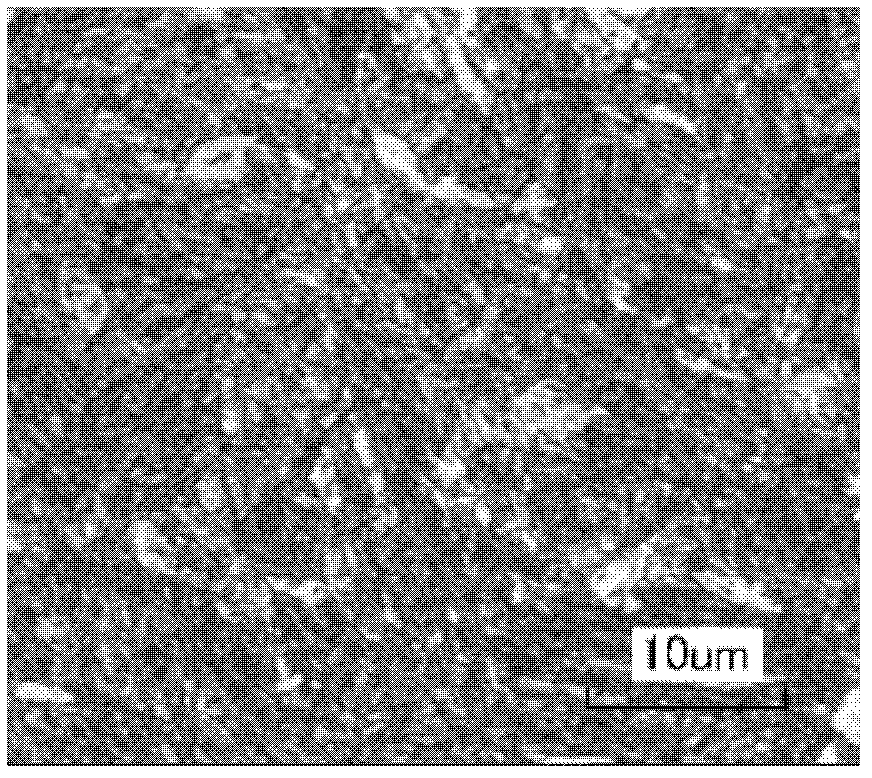

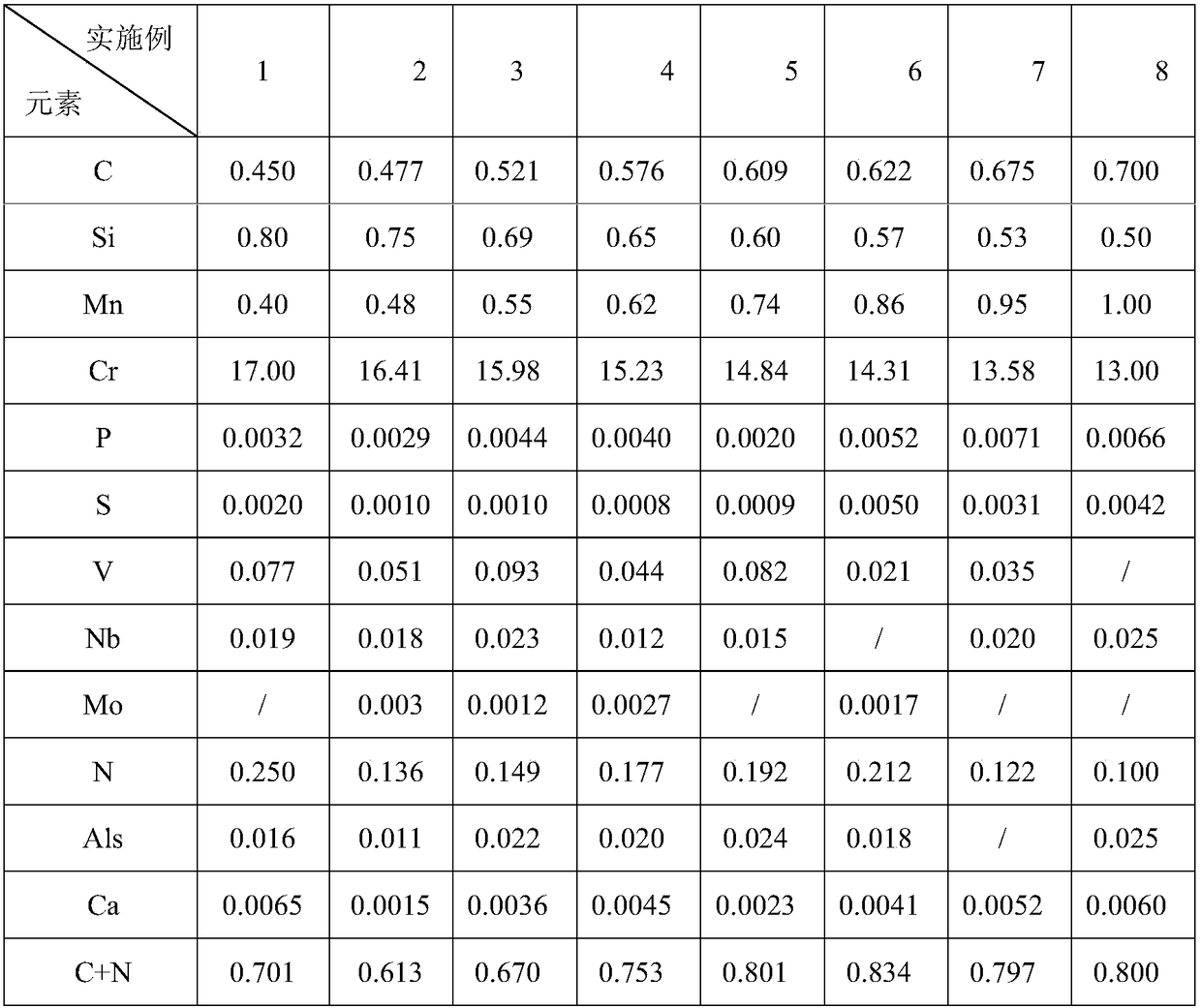

Nitrogen containing martensitic stainless steel for cutting tool and manufacturing method of nitrogen containing martensitic stainless steel

InactiveCN108277432AImprove corrosion resistanceImprove plasticityMartensitic stainless steelNitrogen

The invention relates to nitrogen containing martensitic stainless steel for a cutting tool and a manufacturing method of the nitrogen containing martensitic stainless steel. According to the technical scheme, chemical components of the nitrogen containing martensitic stainless steel for the cutting tool comprise 0.45wt%-0.70wt% of C, 13.0 wt%-17.0wt% of Cr, 0.10wt%-0.25wt% of N, 0.50wt%-0.80wt% of Si, 0.40wt%-1.0wt% of Mn, 0.0015wt%-0.0065wt% of Ca, not larger than 0.20wt% of V, not larger than 0.025wt% of Nb, not larger than 0.025wt% of Als, not larger than 0.03wt% of Mo, not larger than 0.008wt% of P, not larger than 0.005wt% of S and the balance Fe and inevitable elements. Meanwhile, the above chemical components meet the condition that C+N is 0.60-0.85wt%. The manufacturing method ofthe nitrogen containing martensitic stainless steel for the cutting tool comprises the steps of vacuum induction smelting, normal-pressure nitrogen increasing, casting, casting blank heating, rolling,quenching and tempering. The nitrogen containing martensitic stainless steel has the advantages that the alloy components are simple, the process is simple and convenient, the production cost is low,and large-scale production is easy. The manufactured nitrogen containing martensitic stainless steel for the cutting tool is high in hardness and good in toughness.

Owner:WUHAN UNIV OF SCI & TECH

Treatment method for improving strength of 20CrMnMo steel

The invention discloses a treatment method for improving strength of 20CrMnMo steel. The treatment method comprises the following steps: 1, putting 20CrMnMo steel workpieces which are subjected to carburizing and quenching and are cooled to the room temperature into low-temperature equipment, wherein certain gaps are formed among the steel workpieces; 2, powering on the refrigeration system of the low-temperature equipment, precooling at minus 40+ / -5 DEG C, keeping the temperature, and setting the temperature keeping time according to sizes of the steel workpieces; 3, cooling the steel workpieces to minus 230 DEG C to minus 100 DEG C at a velocity of 5-20 DEG C / minute, and keeping the temperature for 6-48 hours; 4, powering off the refrigeration system of the low-temperature equipment, naturally increasing the temperature of the steel workpieces, and taking out the steel workpieces when the temperature is increased to minus 45 DEG C or greater, and cooling to the room temperature. The treatment method is simple and convenient to operate, low in cost and free of waste emission or environment pollution, the strength, the hardness and the wearing resistance of the 20CrMnMo steel can be effectively improved, and the service life of the 20CrMnMo steel can be prolonged.

Owner:SOUTHWEST UNIV

Gear production process facilitating improvement of production efficiency and product quality

InactiveCN104128775ASimple processAppropriate impact resistanceSolid state diffusion coatingFurnace typesAdditive ingredientSlow cooling

The invention discloses a gear production process facilitating the improvement of production efficiency and product quality. The gear production process includes the steps of blank casting, cutting, heat treatment, finishing cutting and ground finish, wherein blank casting, cutting, heat treatment, finishing cutting and ground finish are sequentially conducted. Raw materials for blank casting are 20CrMnTiH, a continuous casting machine is adopted in the blank casting process, the pulling rate of the continuous casting machine ranges from 0.6 m / min to 0.72 m / min, electromagnetic stirring of a crystallizer is adopted in the blank casting process, electromagnetic stirring currents are 400 A, and electromagnetic stirring frequency is 2.5 Hz. The heat treatment step includes the procedures that a cut blank is heated and carburized, heating in stages, namely, preheating at the first stage, carburization at the second stage, diffusion for 1 h to 1.2 h at the third stage and slow cooling at the fourth stage is adopted, the blank is slowly cooled to the temperature ranging from 500 DEG C to 600 DEG C and then quenched, the quenched blank is heated to the temperature ranging from 170 DEG C to 200 DEG C and then tempered after heat is preserved for not less than 3 h. The gear production process is simple in steps and short in process time, and product ingredients are even.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Nb and V microalloyed gear steel, preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel

ActiveCN113430461AGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingProcess efficiency improvementElectric arc furnaceGear wheel

The invention discloses Nb and V microalloyed gear steel, a preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel. Nb and V microalloying is adopted, and the Nb and V microalloyed gear steel with a ferrite and pearlite structure is obtained. The production process comprises the steps of electric arc furnace smelting, LF refining, RH vacuum treatment, continuous casting, hot rolling and slow cooling. After the gear steel subjected to hot rolling and slow cooling is subjected to heat treatment, the Nb and V microalloyed gear steel with the tensile strength larger than or equal to 1465 MPa, the yield strength larger than or equal to 1340 MPa, the ductility larger than or equal to 14%, the percentage reduction of area larger than or equal to 50% and the impact energy KV2 larger than or equal to 95 J is obtained. The Nb and V microalloyed carburized gear steel with high contact fatigue performance is obtained after the gear steel subjected to hot rolling and slow cooling is subjected to carburizing treatment, and under the condition that the pressure stress is 4.0 GPa, the rated fatigue life L10 of the Nb and V microalloyed carburized gear steel is larger than or equal to 5 * 10 < 7 >, and the median fatigue life L50 of the Nb and V microalloyed carburized gear steel is larger than or equal to 8.2 * 10 < 7 >.

Owner:MAANSHAN IRON & STEEL CO LTD

Machining method of 20CrMnTi brake shoe roller shaft

InactiveCN110872678AIncrease profitImprove mechanical propertiesSolid state diffusion coatingFurnace typesMachine partsTempering

The invention discloses a machining method of a 20CrMnTi brake shoe roller shaft and belongs to the technical field of machine part machining. The machining method sequentially comprises the followingsteps of feeding, annealing, shot blasting treatment, softening treatment, extruding, rough turning, finish turning, carburizing treatment, precooling quenching, low temperature tempering, second-time shot blasting and fine grinding. According to the machining method, the grains and the martensitic needle can be effectively refined to reduce the content of retained austenite on the surface layerthrough two-time warming, the temperature-reduction precooling quenching and two-time tempering, so that the mechanical property and the indexes of the ductility and toughness of a high-alloy carburizing steel gear are greatly and obviously improved.

Owner:谷城天兴机械有限公司

Nb and B microalloyed gear steel, preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel

ActiveCN113416899AGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingElectric arc furnaceGear wheel

The invention discloses Nb and B microalloyed gear steel, a preparation method, a heat treatment method and a carburizing treatment method thereof and carburized gear steel. Nb and B microalloying is adopted, and the Nb and B microalloyed gear steel with a ferrite and pearlite structure is obtained; the production process of electric arc furnace smelting, LF refining, RH vacuum treatment, continuous casting, hot rolling and slow cooling is adopted; after the gear steel subjected to hot rolling and slow cooling is subjected to heat treatment, the Nb and B microalloyed gear steel with the tensile strength larger than or equal to 1450 MPa, the yield strength larger than or equal to 1340 MPa, the ductility larger than or equal to 14%, the percentage reduction of area larger than or equal to 50% and the impact energy KV2 larger than or equal to 95J is obtained; and the gear steel subjected to hot rolling and slow cooling is subjected to carburizing treatment to obtain Nb and B microalloyed carburized gear steel with high contact fatigue performance, and under the condition that the pressure stress is 4.0 GPa, the rated fatigue life L10 of the Nb and B microalloyed carburized gear steel is larger than or equal to 5 * 10 < 7 >, and the median fatigue life L50 of the Nb and B microalloyed carburized gear steel is larger than or equal to 8.2 * 10 < 7 >.

Owner:MAANSHAN IRON & STEEL CO LTD

Nb, V and Ti microalloyed gear steel and preparation method thereof, heat treatment method and carburizing treatment method thereof and carburized gear steel

ActiveCN113388783AGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingElectric arc furnaceGear wheel

The invention discloses Nb, V and Ti microalloyed gear steel and a preparation method thereof, a heat treatment method, a carburizing treatment method and carburized gear steel. By adopting Nb, V and Ti microalloying, the Nb, V and Ti microalloyed gear steel with a ferrite and pearlite structure is obtained; the process of electric arc furnace smelting, LF refining, RH vacuum treatment, continuous casting, hot rolling and slow cooling is adopted for production; the Nb, V and Ti microalloyed gear steel with the tensile strength of larger than or equal to 1455 MPa, the yield strength of larger than or equal to 1320 MPa, the elongation rate of larger than or equal to 15%, the percentage reduction of area of larger than or equal to 50% and the impact energy KV2 of larger than or equal to 95 J is obtained after the gear steel subjected to hot rolling and slow cooling is subjected to heat treatment; after the gear steel subjected to hot rolling and slow cooling is subjected to carburizing treatment, Nb, V and Ti microalloyed carburizing gear steel with high contact fatigue performance is obtained; and under the condition that the pressure stress is 4.0 GPa, the rated fatigue life L10 of the gear steel is larger than or equal to 5*10<7>, and the median fatigue life L50 of the gear steel is larger than or equal to 8.2*10<7>.

Owner:MAANSHAN IRON & STEEL CO LTD

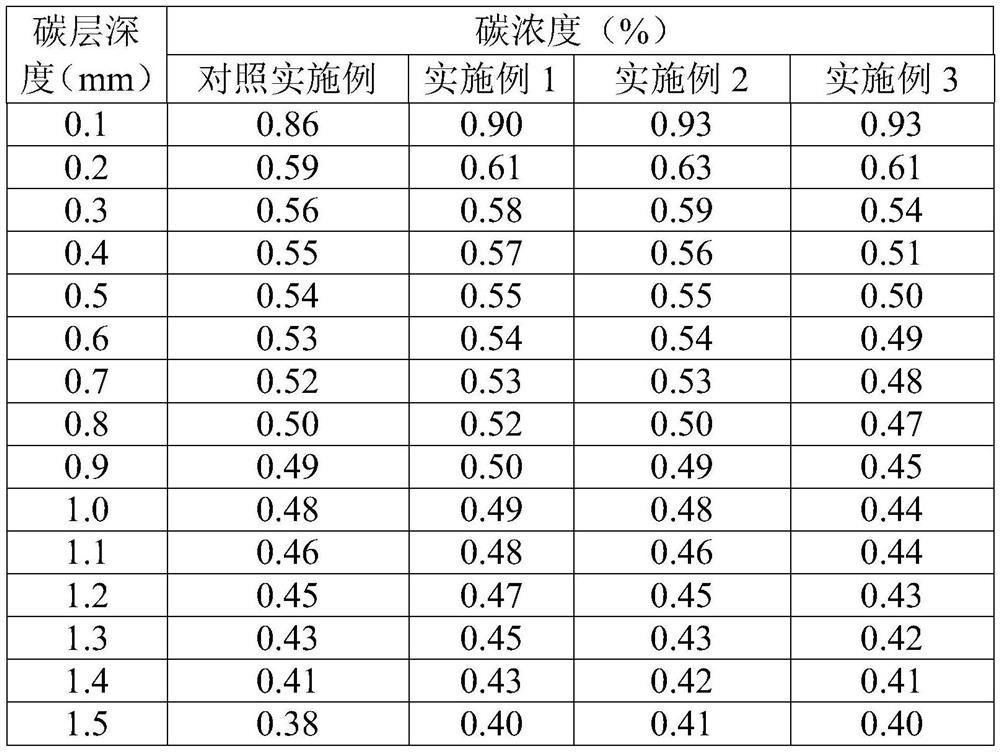

Carburizing heat treatment process of alloy steel casting

InactiveCN110184561AAdd depthCarbon concentration declineSolid state diffusion coatingCarbon potentialCarbide

The invention relates to a carburization heat treatment process of an alloy steel casting. The carburization heat treatment process specifically comprises the following steps that S1, the carburized working surface of the casting is turned to remove the adsorption layer, the oxidation layer and the machining strain layer, the non-carburized working surface of the casting is subjected to anti-seepage treatment after cleaned, and a layer of non-copper metal film is plated on the working surface after turning; S2, a furnace is installed, gas is discharged, and the methanol and acetone are selected the carburization medium; S3, heating is carried out until the carburizing temperature is subjected to first carburizing, the carbon potential is 1.0+ / -0.05%, and then oil quenching is carried outto be below Ac1; S4, the carburizing temperature is rapidly heated to carry out secondary carburization, the carbon potential is 0.75 + / -0.05%, then the furnace is cooled to 800-820 DEG C, and thetemperature is kept constant; S5, the steps S3 and S4 are repeatedly circulated for multiple times, the coasting is slowly cooling to 350-400 DEG C, the casting is subjected air cooling after being discharged from the furnace, and then the quenching and low-temperature tempering are carried out. By adopting the scheme, the carburized layer does not generate the network carbide, so that the hardness and wear resistance of the surface of a workpiece are improved.

Owner:晋江鹏发机械有限公司

Gear production technology facilitating reducing composition segregation in gear thickness

InactiveCN104128768ASimple processAppropriate impact resistanceSolid state diffusion coatingFurnace typesCase hardeningSlow cooling

The invention discloses a gear production technology facilitating reducing composition segregation in gear thickness. The technology comprises the steps of blank casting, cutting, heat treatment, finish cutting and grinding in sequence. A raw material for blank casting is 20CrMnTiH. A continuous caster is adopted in the blank casting process, and the pulling rate of the continuous caster is 0.6 m / min-0.72 m / min. The heat treatment comprises the steps that blanks obtained through cutting are heated to 600 DEG C-920 DEG C for carburizing, wherein during carburizing, the hold time of the temperature is not less than 3 h, heating is staged heating composed of first-stage preheating, second-stage carburizing, third-stage diffusing for 1 h-1.2 h and fourth-stage slow cooling; the blanks are quenched after slow cooling and tempered after quenching. The technology is simple in step, the composition segregation in gear thickness is small, technology time is short, and gears which have the advantages that surface hardening layers do not easily come off, and impact resistance, abrasion resistance and intensity are suitable are convenient to obtain.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Production process facilitating optimization of gear surface quality and segregation degree

InactiveCN104128765ASimple processAppropriate impact resistanceSolid state diffusion coatingFurnace typesAdditive ingredientEngineering

The invention discloses a production process facilitating optimization of gear surface quality and the segregation degree. The production process includes the steps of blank casting, cutting, heat treatment, finishing cutting and ground finish, wherein blank casting, cutting, heat treatment, finishing cutting and ground finish are sequentially conducted. Bars are made of 20CrMnTiH. The heat treatment step includes the procedures that a cut blank is heated, carburized and then slowly cooled to the temperature not higher than 550 DEG C, secondarily heated, quenched after heat is preserved for not less than 2 h, heated to the temperature ranging from 170 DEG C to 200 DEG C for the third time and tempered after heat is preserved for not less than 3 h, wherein the blank is secondarily heated to the temperature ranging from 840 DEG C to 870 DEG C, the carburization procedure includes the preheating stage, the strong carburization stage and the diffusion stage, wherein the preheating stage, the strong carburization stage and the diffusion stage are sequentially conducted. The production process is simple in steps, product ingredients are even, and gears with surface hardened layers not prone to being disengaged and with the proper impact resistance, abrasion resistance and strength can be conveniently obtained.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Spiral spring quenching heat treatment process adopting water-soluble quenching medium

InactiveCN104805257ASpeed up coolingAvoid the risk of prone to crackingFurnace typesHeat treatment furnacesQuenchingMechanical property

The invention discloses a spiral spring quenching heat treatment process adopting a water-soluble quenching medium. The spiral spring quenching heat treatment process comprises the following steps of placing a spiral spring in a resistance furnace and heating to 850DEG C to 900DEG C and keeping the temperature for 30 minutes; then taking out the spiral spring and placing the spiral spring into a PAG (Poly Alkylene Glycol) water-soluble quenching medium for performing quenching treatment; uniformly stirring in the quenching process and enabling the temperature to reduce to room temperature; taking out the spiral spring and placing the spiral spring into an isothermal furnace with the temperature of 440 to 480DEG C and keeping the isothermal state for 1.5 hours; finally, taking out the spiral spring and performing oil cooling to room temperature. According to the spiral spring quenching heat treatment process disclosed by the invention, by using the characteristic that the cooling speed of the PAG water-soluble quenching medium is higher, residual austenitic is reduced, the substructure of a martensitic structure is refined, the separation of carbide along the crystal boundary and the boundary of martensite lath is avoided, and the spiral spring obtains comprehensive mechanical properties superior to those obtained by a traditional oil quenching heat treatment process.

Owner:GUIZHOU UNIV

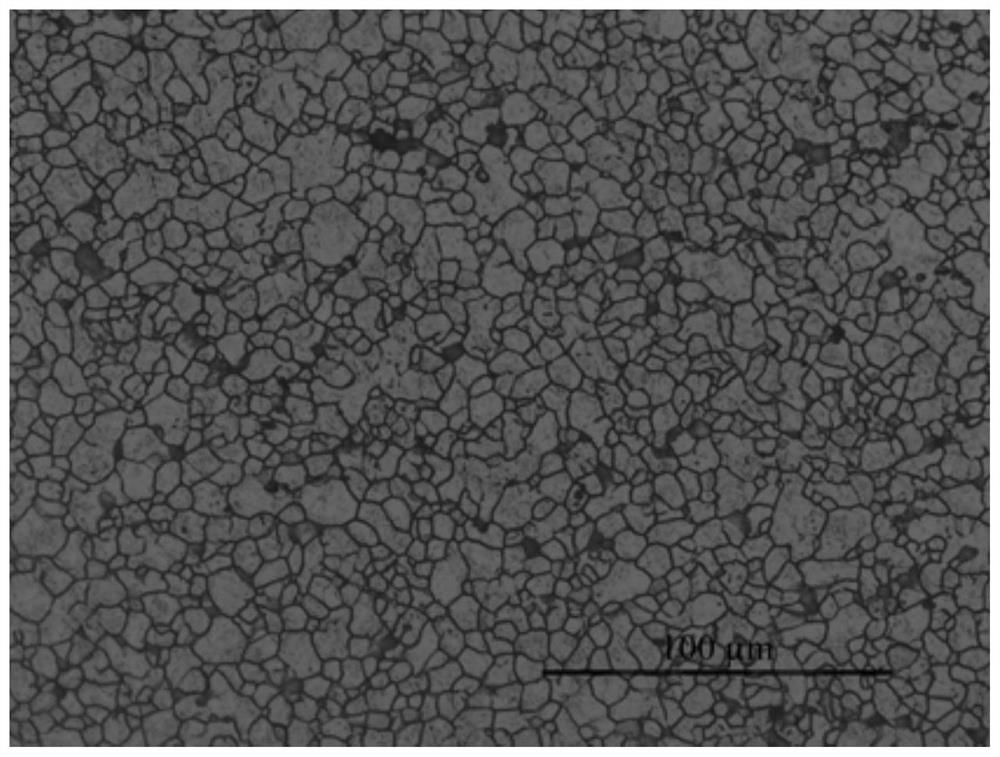

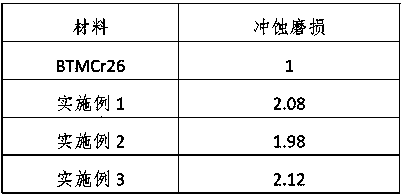

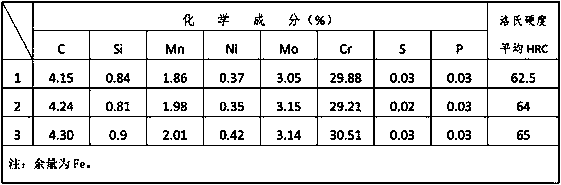

A kind of ultra-high wear-resistant hypereutectic high-chromium cast iron material, preparation method and application thereof

ActiveCN110079725BImprove toughnessImprove yieldProcess efficiency improvementCarbideWear resistance

The invention relates to an ultra-high wear-resistant hypereutectic high chromium cast iron material which comprises the following chemical components in percentage by mass: 4.0-5.0% of C, 25-35% of Cr, 0.5-1.0% of Si, 1.5-2.5% of Mn, less than or equal to 1% of Ni, 2-4% of Mo, and the balance Fe. The invention also relates to a preparation method of the ultra-high wear-resistant hypereutectic high chromium cast iron material, and relates to a smelting technology and an application of stable production of slurry pump flowing parts. Compared with BTMCr26 and Cr15Mo3 materials, the ultra-high wear-resistant hypereutectic high chromium cast iron material has a high carbon content and a high chromium content and a large amount of carbides, and the wear resistance of the material can be effectively improved.

Owner:SHIJIAZHUANG IND PUMP FACTORY CO LTD

Gear production process facilitating gear surface quality

InactiveCN104120378ASimple processAppropriate impact resistanceSolid state diffusion coatingFurnace typesCase hardeningSlow cooling

The invention discloses a gear production process facilitating gear surface quality. The gear production process comprises the bar blanking, the cutting, the heat treatment, the fine cutting and the grinding performed in sequence; the material of a bar is 20CrMnTiH; the heat treatment comprises the following steps: when a blank obtained by the cutting is heated to 830-920 DEG C, the carburizing treatment is performed; and in the carburizing treatment, the temperature keeping time is not lower than 3 h; the slow cooling is performed after the carburizing treatment; when the blank is slowly cooled not higher than 550 DEG C, the secondary heating is performed, and the insulation is performed not lower than 2 h; then, the quenching is performed; the quenched blank is heated for the third time to 170-200 DEG C; the insulation is performed not lower than 3 h; then, the tempering is performed; the blank is heated to 840-870 DEG C in the secondary heating; and the carburizing treatment comprises the preheating phase, the strong carburizing phase and the dispersing phase performed in sequence. The process is simple in steps, and is convenient to obtain a gear with differently released surface hardened layer and proper impact resistance, wear resistance and strength.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Heat treatment process of steel workpiece

InactiveCN112359178AReduce energy consumptionChange hardnessSolid state diffusion coatingHeat treatment bathsTemperingCarbon potential

The invention discloses a heat treatment process of a steel workpiece. The heat treatment process comprises the following steps of S1, normalizing treatment: S11, normalizing; S12, air cooling, wherein the steel workpiece obtained after normalizing heat treatment is taken out of a furnace, and air cooling is conducted till the surface temperature of the steel workpiece is reduced to 600-650 DEG C;S13, heat preservation treatment, wherein the steel workpiece is returned to the furnace, and the temperature in the furnace rises; when the temperature in the furnace is higher than 700 DEG C, stepS12 is repeated; and when the final temperature in the furnace is 675-690 DEG C, step S14 is executed; and S14, cooling along with the furnace; S2, carburizing: S21, strong carburizing treatment, wherein the workpiece treated in step S1 is transferred into a carburizing furnace, the temperature is increased to 900-930 DEG C, and strong carburizing treatment is conducted for 4.5-5.5 h; S22, diffusion treatment, wherein after strong carburizing treatment is completed, the temperature of the carburizing furnace is kept unchanged, and diffusion treatment is started for 5.5-7 h after the carbon potential of the workpiece is reduced to the preset diffusion carbon potential; S23, temperature equalization treatment; and S24, high-temperature tempering; S3, quenching; and S4, low-temperature tempering. According to the heat treatment process of the steel workpiece, heat preservation treatment is conducted through waste heat of the steel workpiece after normalizing, and energy consumption is reduced by about one third; and the carburized layer peeling phenomenon is avoided, and the workpiece quality is good.

Owner:CHANGSHA WONTECH ENG MACHINERY CO LTD

Precipitation-hardening stainless steel powder and sintered compact thereof

ActiveUS10011894B2Sufficient age-hardenabilityHigh age-hardenabilityAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyHigh intensity

There is provided a precipitation hardening stainless steel powder including, in percentage by mass: Si: ≤1.0%; Mn: ≤1.8%; Ni: 3.0 to 8.5%; Cr: 12.0 to 20.0%; Mo: 0.1 to 2.5%; Cu: 1.0 to 5.0% and / or Ti+Al: 1.0 to 5.0%; Nb+Ta≥5C or Nb≥5C; N≤350 ppm; and the balance being Fe and incidental impurities. A sintered compact fabricated from the steel powder has a martensite content of 90% or more. The precipitation hardening stainless steel powder provides a sintered compact that exhibits high strength after aging.

Owner:SANYO SPECIAL STEEL COMPANY

A kind of nb, b microalloyed gear steel and its preparation method, heat treatment method, carburizing treatment method and carburized gear steel

ActiveCN113416899BGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingElectric arc furnaceGear wheel

The invention discloses a Nb, B micro-alloyed gear steel and its preparation method, heat treatment method, carburizing treatment method and carburized gear steel, which adopts Nb and B micro-alloying to obtain ferrite + pearlite structure Nb, B micro-alloyed gear steel; it is produced by the process of electric arc furnace smelting-LF refining-RH vacuum treatment-continuous casting-hot rolling-slow cooling; the gear steel after hot rolling and slow cooling has been heat-treated to obtain resistance Nb, B microalloyed gear steel with tensile strength ≥ 1450MPa, yield strength ≥ 1340MPa, elongation ≥ 14%, reduction of area ≥ 50%, impact energy KV2 ≥ 95J; carburizing the gear steel after hot rolling and slow cooling The Nb, B microalloyed carburized gear steel with high contact fatigue performance was obtained. Under the condition of compressive stress of 4.0GPa, its rated fatigue life L 10 ≥5×10 7 , median fatigue life L 50 ≥8.2×10 7 .

Owner:MAANSHAN IRON & STEEL CO LTD

Gear carburizing process

InactiveCN104831022AReduced retained austenite contentReduced non-martensitic layer thicknessSolid state diffusion coatingFurnace typesQuenchingPre cooling

The invention discloses a gear carburizing process. The gear carburizing process comprises the following steps: (1) carburizing; (2) pre-cooling; (3) performing primary quenching; (4) cleaning; (5) performing high-temperature tempering; (6) pre-heating; (7) performing secondary quenching; and (8) performing low-temperature tempering. The gear carburizing process has the beneficial effects that the content of residual austenite and the thickness of non-martensite layer on the gear surface are reduced.

Owner:吴芳吉

Heat treatment process of resistance strain gauge force transducer stainless steel elastomer

InactiveCN111394556AReduce gas impuritiesReduce the temperatureFurnace typesHeat treatment furnacesElastomerMartensitic stainless steel

The invention discloses a heat treatment process of a resistance strain gauge force transducer stainless steel elastomer, and belongs to the technical field of a heat treatment process of a metal material. The heat treatment process mainly comprises steps of pretreatment, vacuum degassing, vacuum high-pressure gas quenching, deep cooling treatment, vacuum aging treatment and vacuum stabilizing treatment. Before vacuum high-pressure gas quenching, vacuum degassing is added for reduce gas impurities of martensitic stainless steel, under the low heating temperature, long-time vacuum degassing iscarried out, temperature and time needed by vacuum high-pressure gas quenching austenitizing can be reduced, a fine uniform austenite structure can be obtained, through procedures of slow heating before vacuum hihg-pressure gas quenching, uniform rapid cooling of a cooling stage, reducing of heating and cooling speed of deep cooling treatment and vacuum aging treatment, adding of the vacuum stabilizing treatment procedure after vacuum aging treatment and the like, the material inner stress can be greatly removed, the process can obviously reduce hysteresis of the elastomer until the it is notlarger than 70 ppm, and needs of the C6 level for the low-hysteresis resistance strain gauge force transducer stainless steel elastomer can be met.

Owner:苏州思传电子测量技术有限公司

Forging and heat treatment method for improving mechanical property of Cr17Ni2 stainless steel forged piece

The invention discloses a forging and heat treatment method for improving a mechanical property of a Cr17Ni2 stainless steel forged piece. The forging and heat treatment method comprises the steps that firstly forging forming is conducted on Cr17Ni2 stainless steel at the temperature of 1150 DEG C, the deformation is 30%-50%, and the finish forging temperature is higher than or equal to 900 DEG C;after forging is conducted, the Cr17Ni2 stainless steel forged piece is placed into a heating furnace, and furnace cooling is conducted; then the Cr17Ni2 stainless steel forged piece is heated to be1020 DEG C, heat preservation is conducted for one hour, oil cooling is conducted, and the oil temperature is higher than or equal to 50 DEG C; the Cr17Ni2 stainless steel forged piece is taken out and air-cooled to be the room temperature; and the Cr17Ni2 stainless steel forged piece is heated to be 520 DEG C again, heat preservation is conducted for two hours, the Cr17Ni2 stainless steel forgedpiece is subjected to water cooling to be the room temperature, and the Cr17Ni2 stainless steel forged piece with the good mechanical property is taken out and obtained. According to the forging and heat treatment method, residual austenite structures of the Cr17Ni2 stainless steel forged piece can be completely removed, the performance of the forged piece is improved, and the forging and heat treatment method is used for the Cr17Ni2 stainless steel forged piece.

Owner:GUIZHOU ANDA AVIATION FORGING

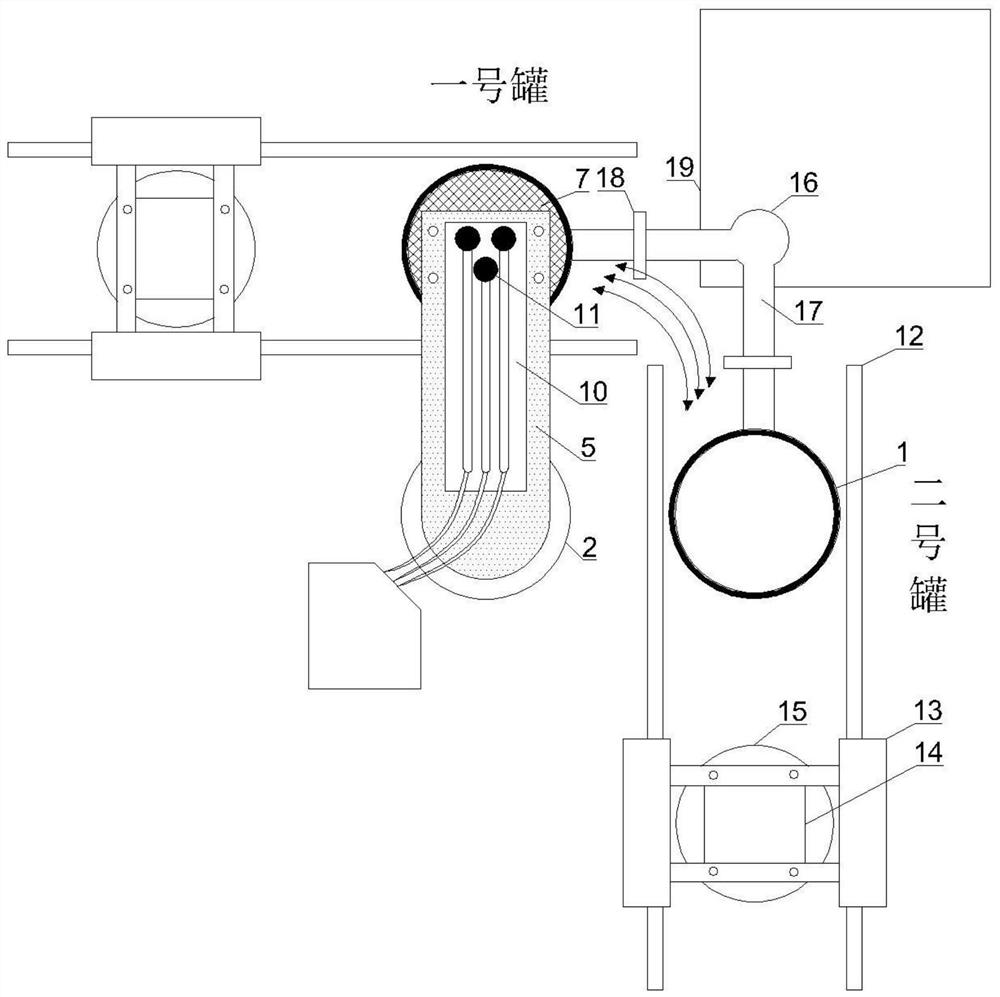

A method for smelting ultra-pure ferritic stainless steel

ActiveCN113106322BReduce the number of rotationsShort oxidation timeProcess efficiency improvementElectric arc furnaceProcess integration

The invention discloses a method for smelting ultra-pure ferritic stainless steel, which relates to the technical field of metal smelting, and adopts two vacuum tanks, a base, a rotating device, multiple supporting structures, a ladle water-cooled furnace cover, multiple driving devices, and vacuum pumping The gas device, guide rail, frame guide rail car, etc. constitute a circulation system, which realizes the process integration of LF furnace and VD vacuum furnace, and uses the integrated equipment to process pure ferritic stainless steel, and controls tapping during the electric arc furnace melting process C and Si content, effective removal of C in the AOD furnace and other operations have achieved the goal of C+N content ≤ 0.015%. At the same time, adding Mo or Ti or Nb or various combinations thereof to pure ferritic stainless steel, Can effectively meet a variety of performance requirements.

Owner:ANHUI FUKAI STAINLESS STEEL

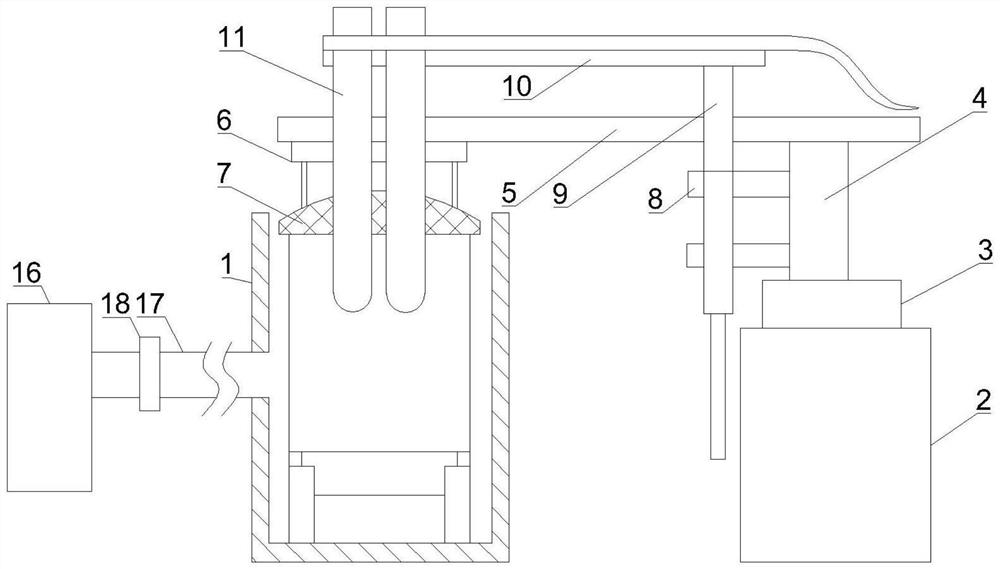

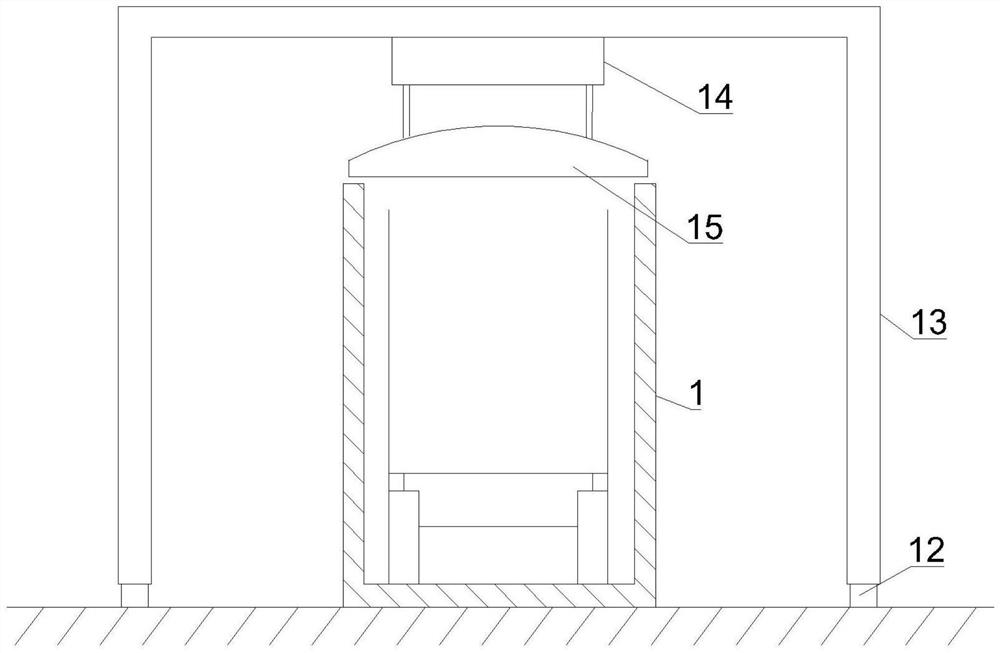

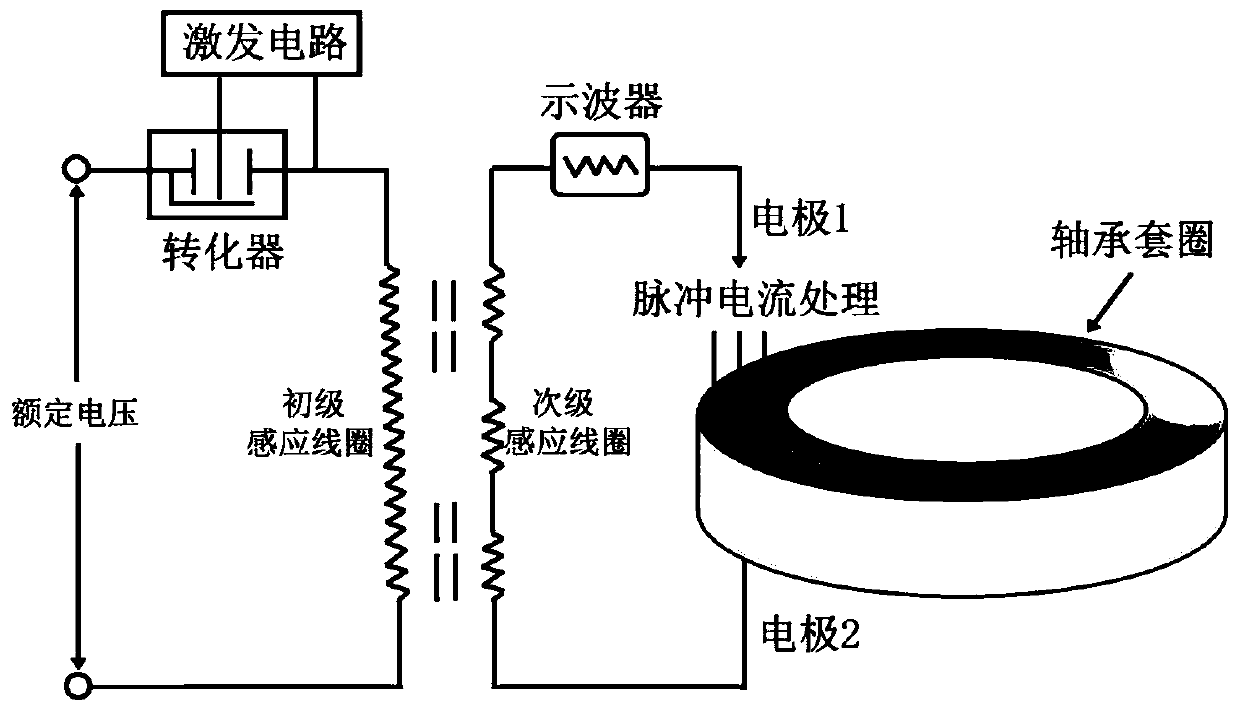

A method for regulating the dimensional stability of a bearing assembly

ActiveCN110042209BReduced retained austenite contentImprove organizational stabilityFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention discloses a bearing assembly dimensional stability control method. The bearing assembly dimensional stability control method comprises the following steps of first, carrying out heat treatment on a bearing ring or rolling element; second, carrying out grinding and polishing on the upper end surface and the lower end surface of the bearing ring or rolling element subjected to heat treatment; third, placing the bearing assembly into an impulse current generator, starting up the impulse current generator, reasonably setting the impulse current intensity and the number of times for continuously inputting electric impulses according to the dimensions and the material characteristics of the bearing assembly, and carrying out impulse current treatment at the room temperature; directly carrying out multiple-time continuous impulse current treatment when the part subjected to heat treatment is the rolling element; and when the part subjected to heat treatment is the bearing ring,evenly dividing the part of the bearing ring into a plurality of subzones in the circumferential direction, and carrying out multiple-time continuous impulse current treatment on each subzone of the bearing ring. With the bearing assembly dimensional stability control method, the dimensional stability of the bearing assembly can be effectively controlled by having control over the residual stressand the retained austenite content of the bearing assembly, and the service life of a bearing is obviously prolonged.

Owner:WUHAN UNIV OF TECH

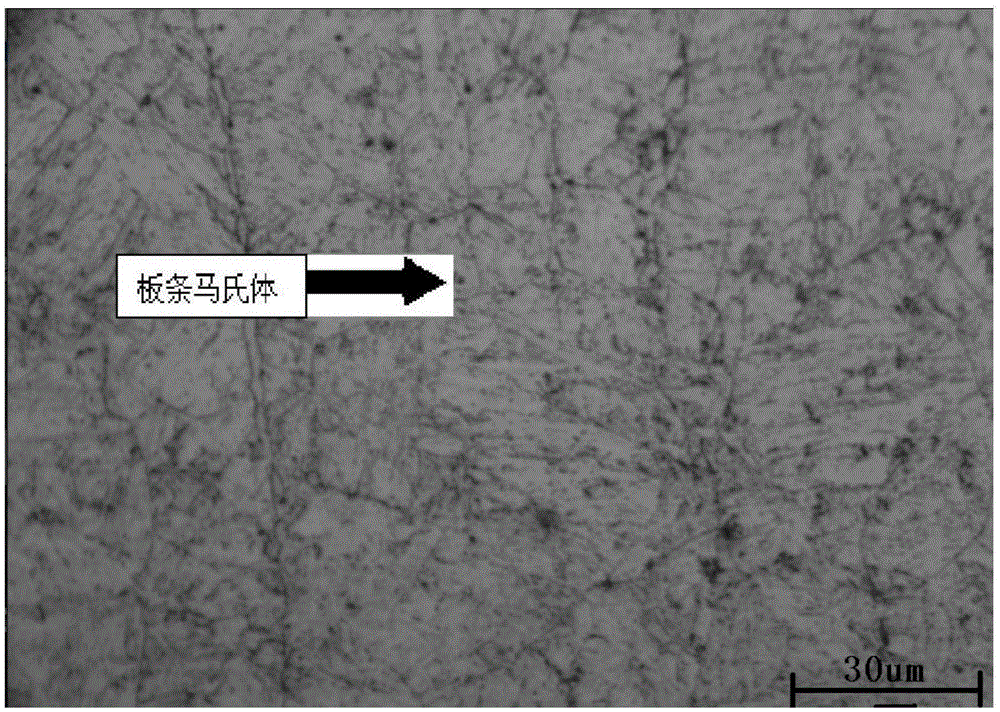

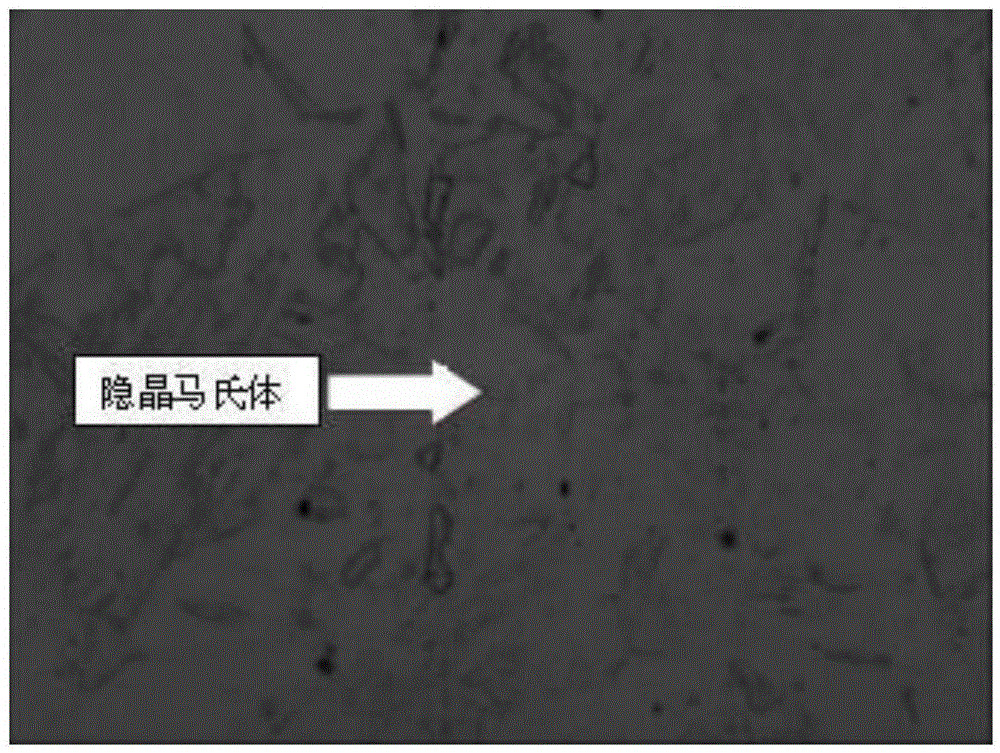

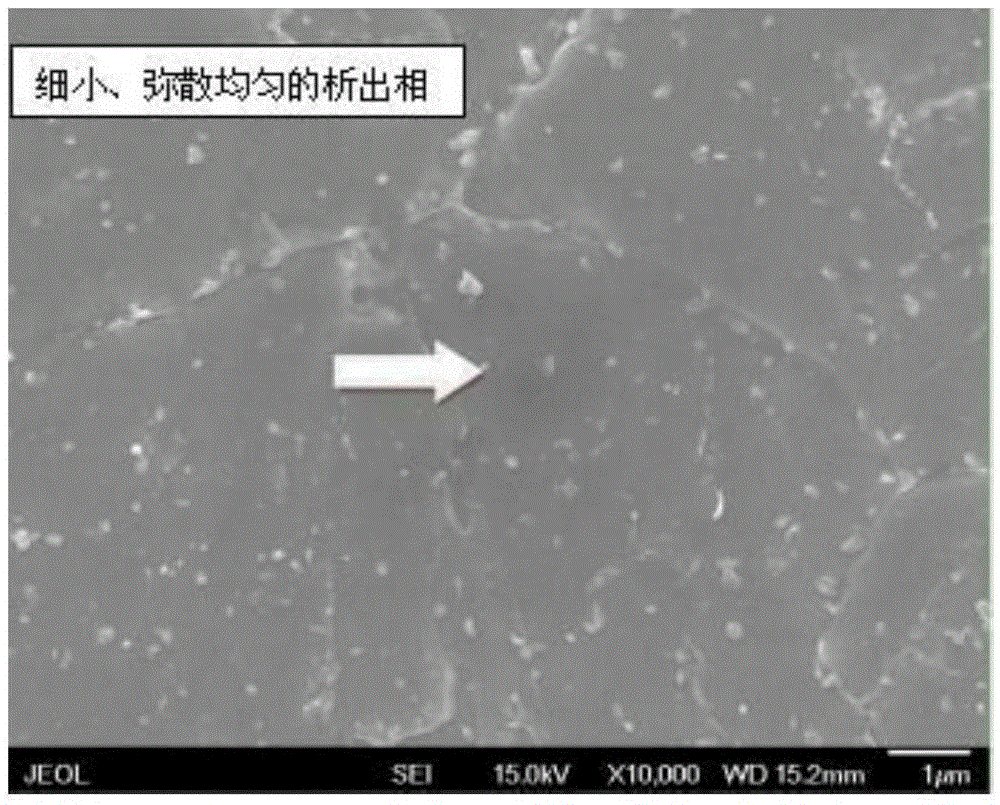

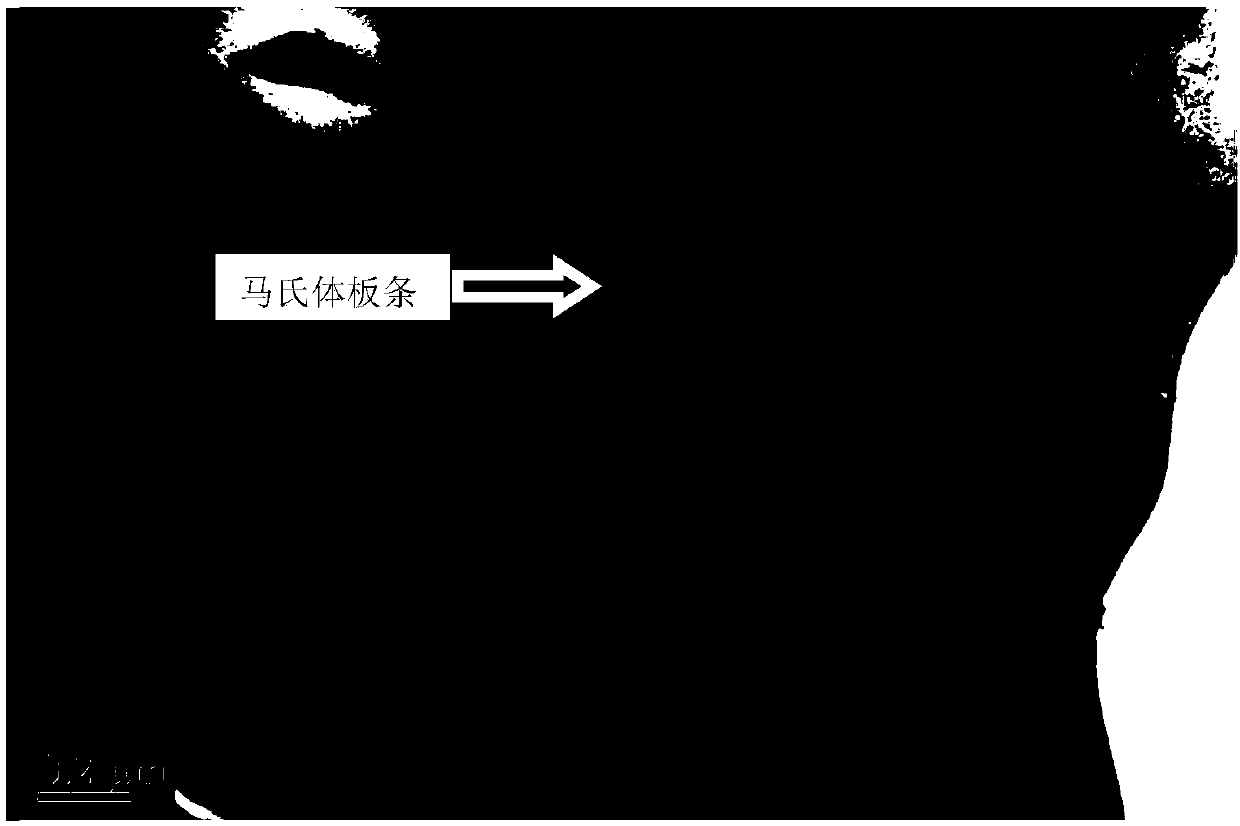

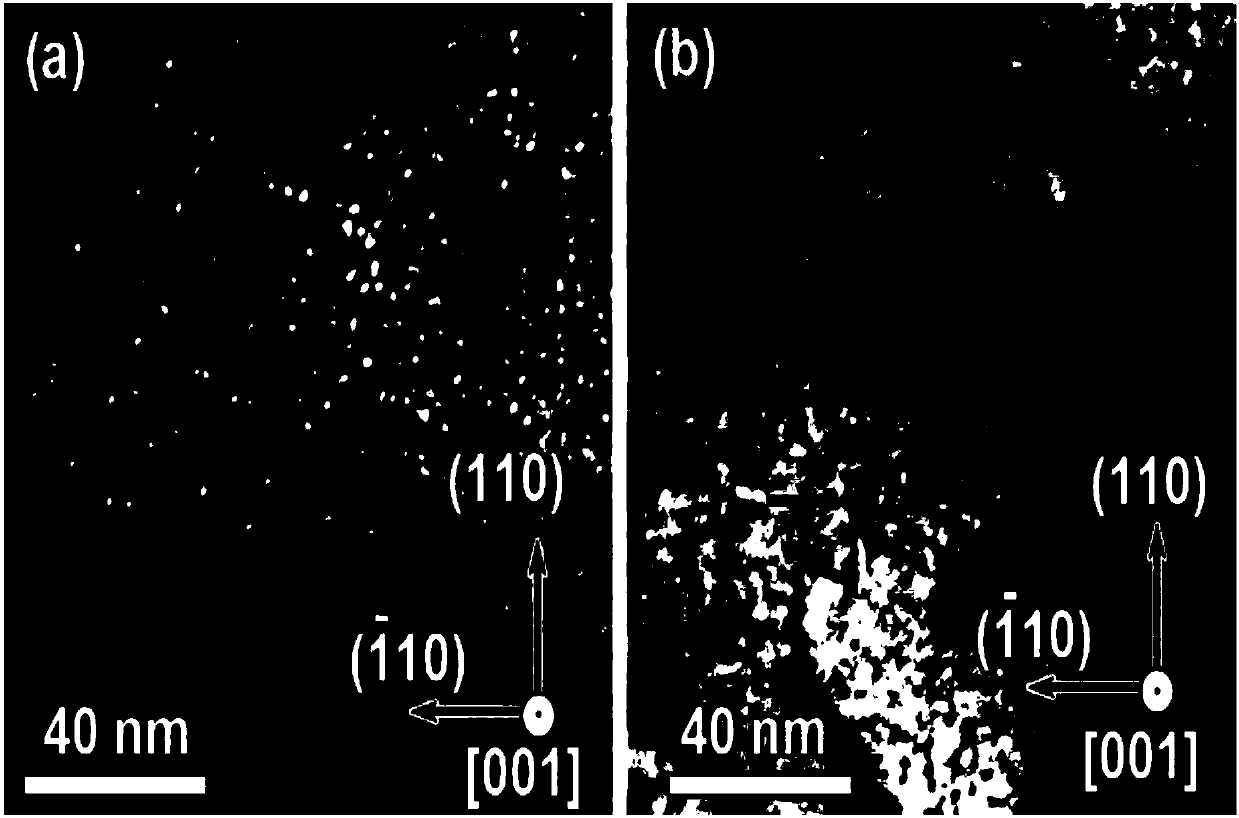

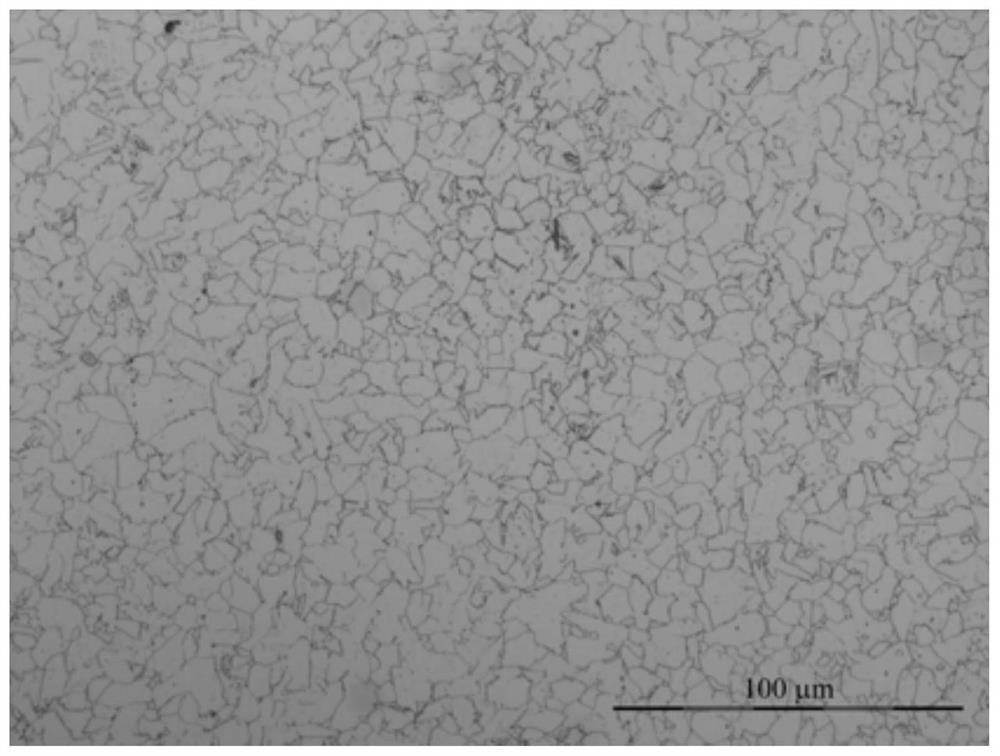

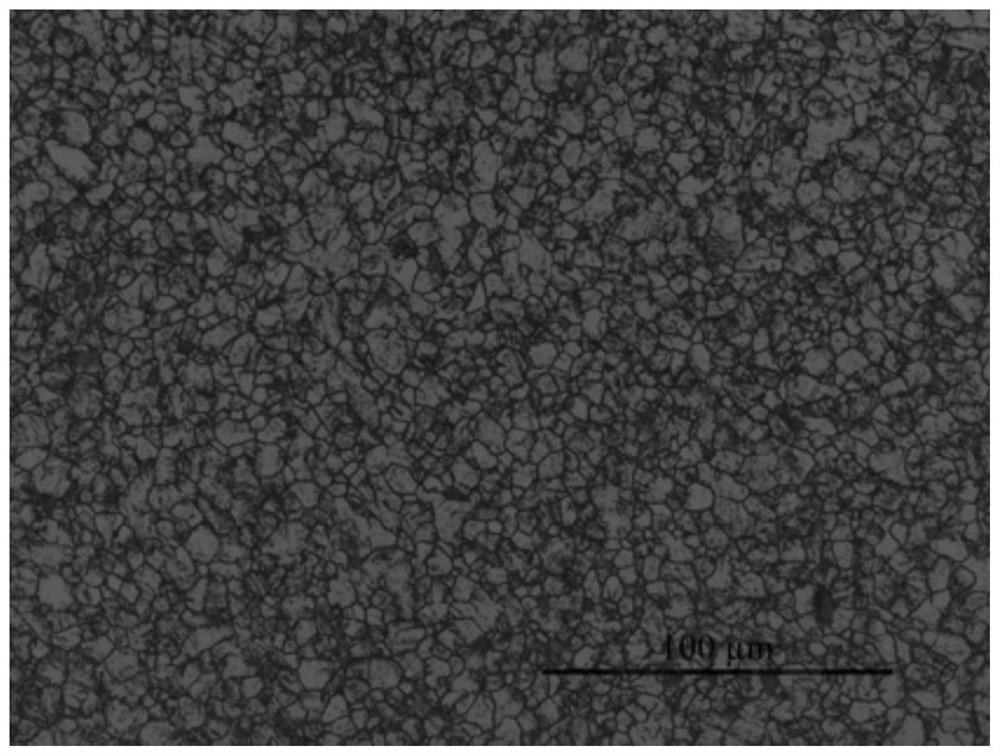

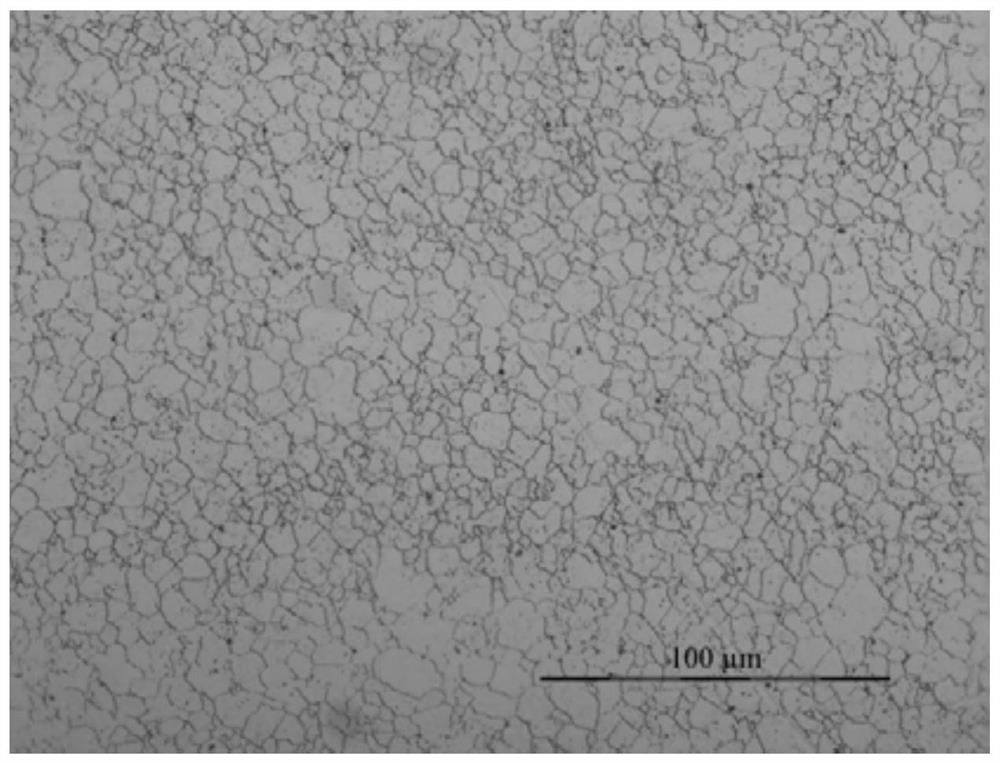

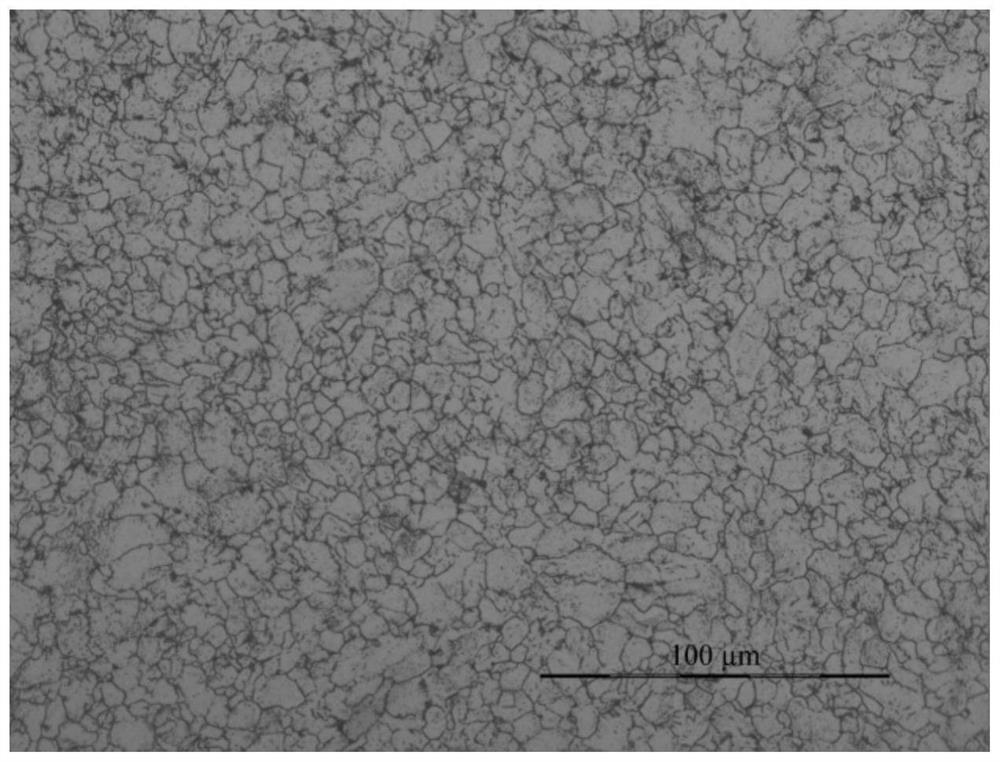

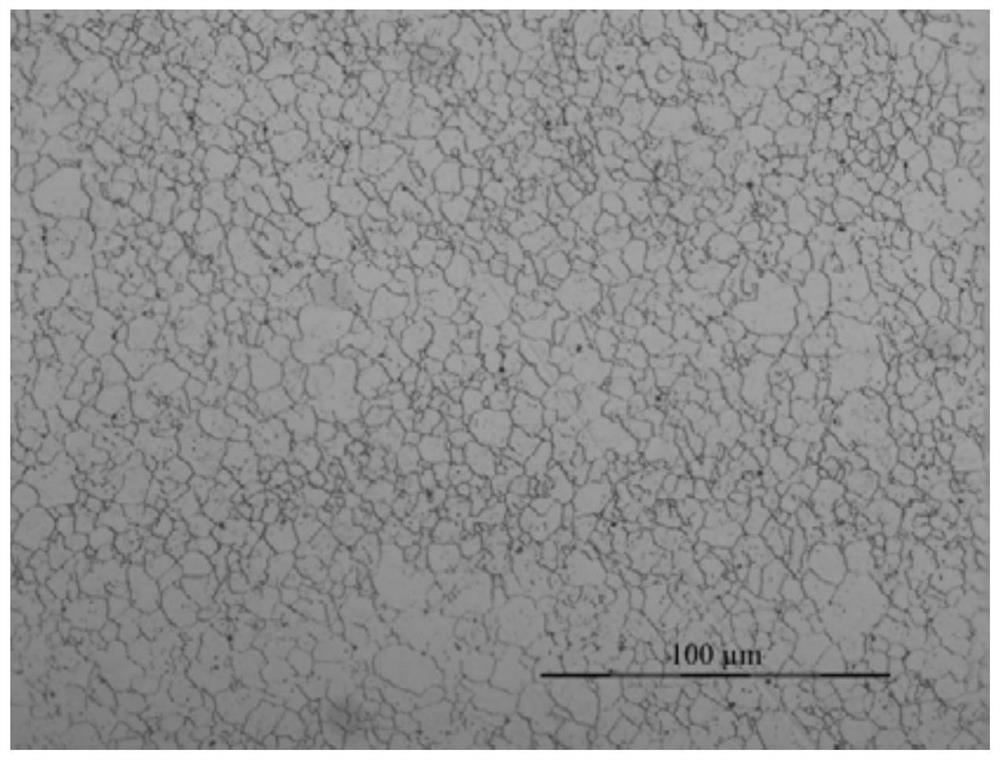

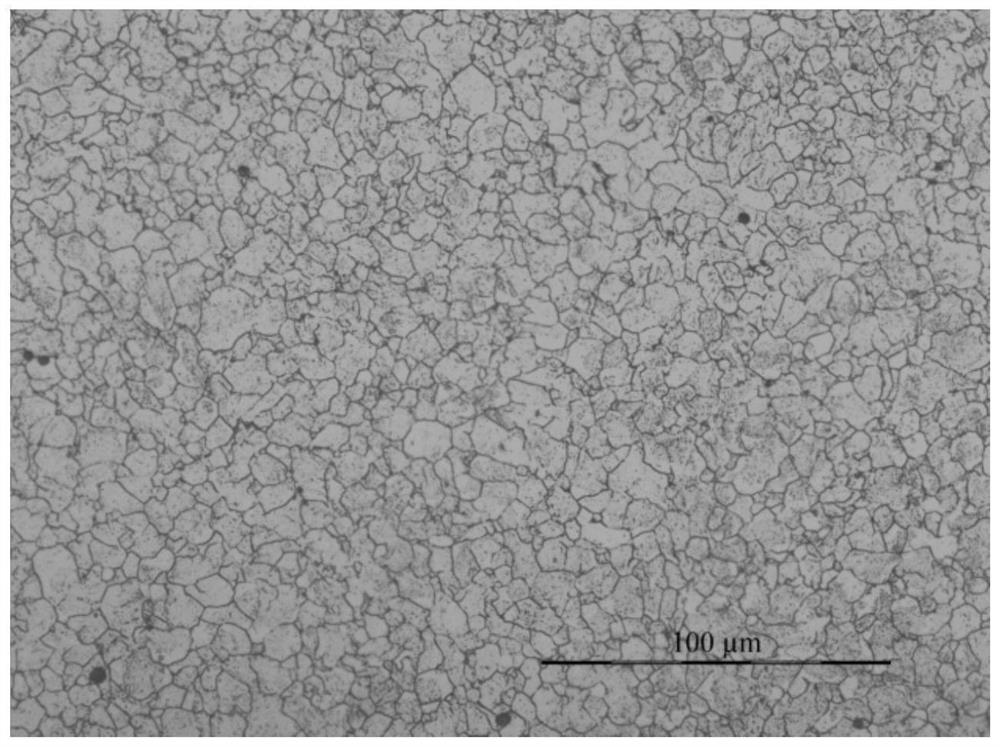

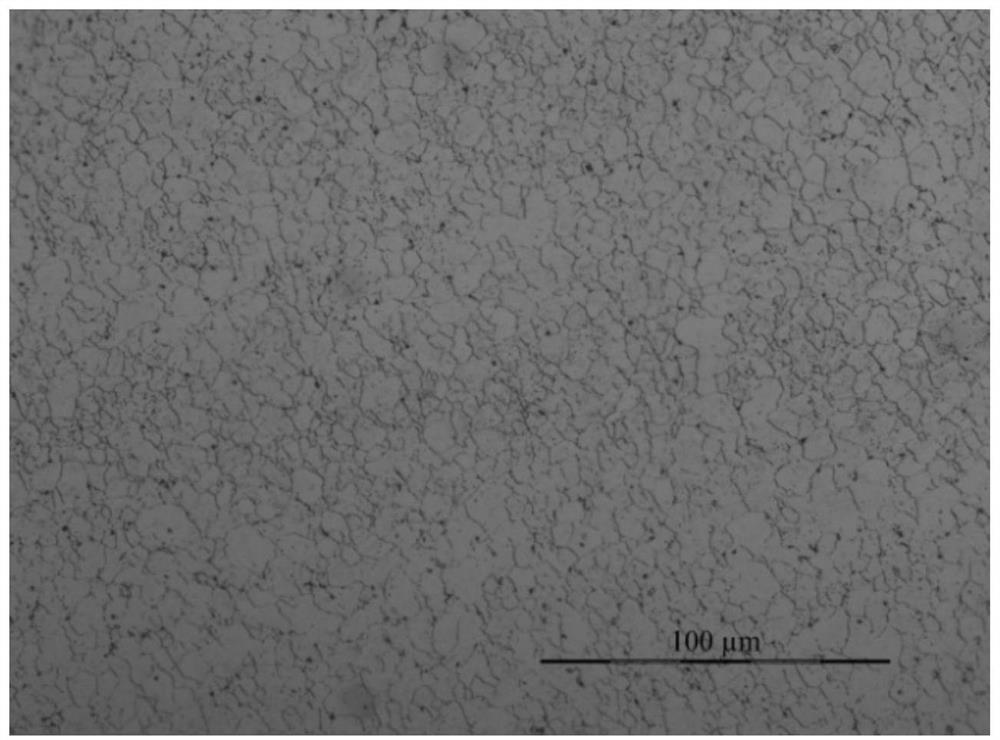

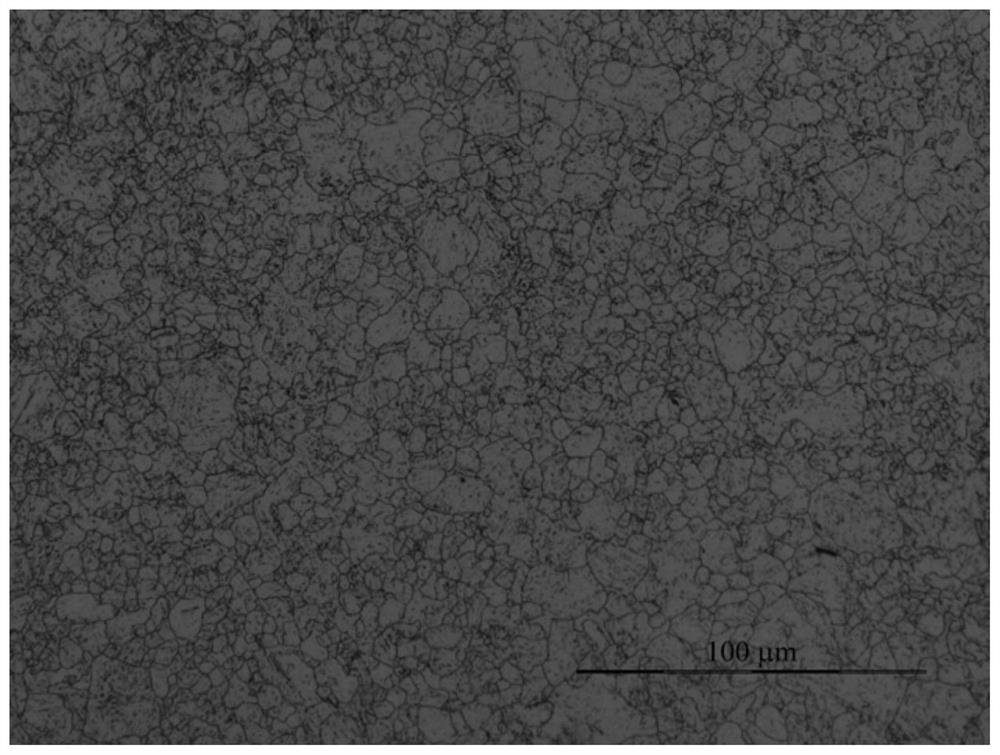

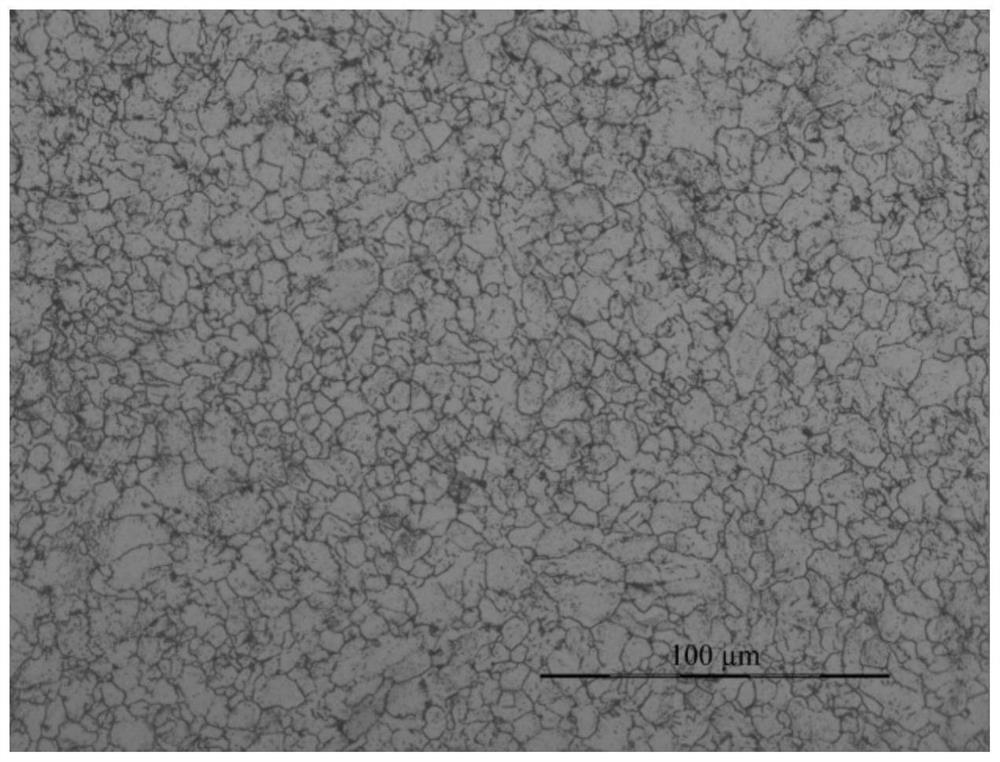

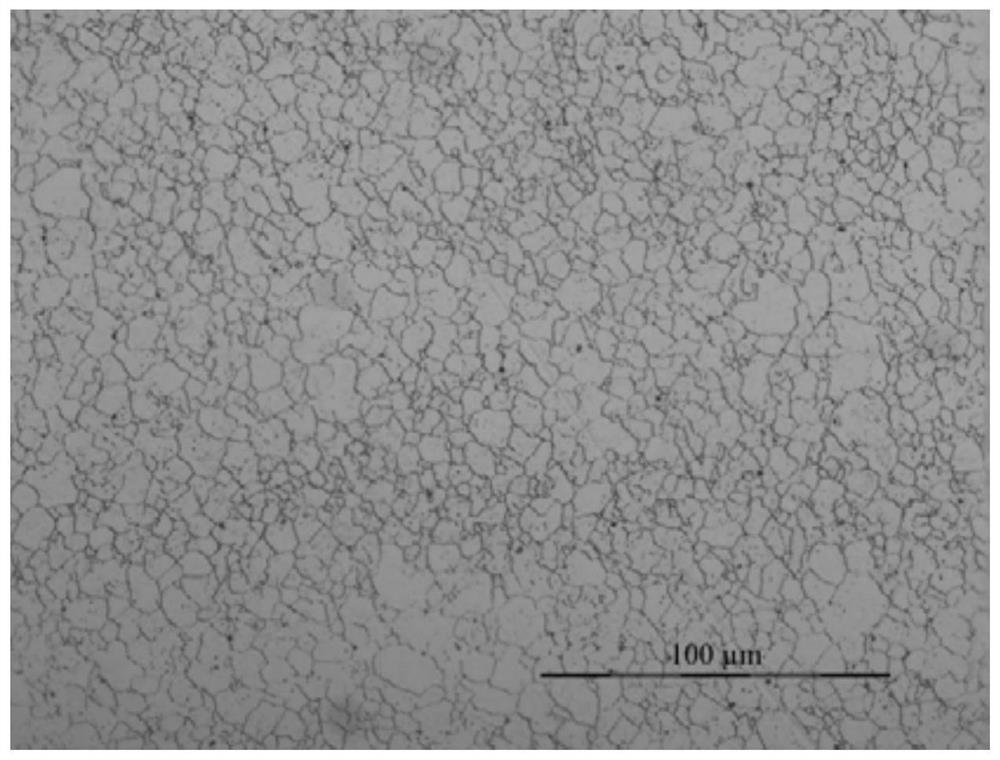

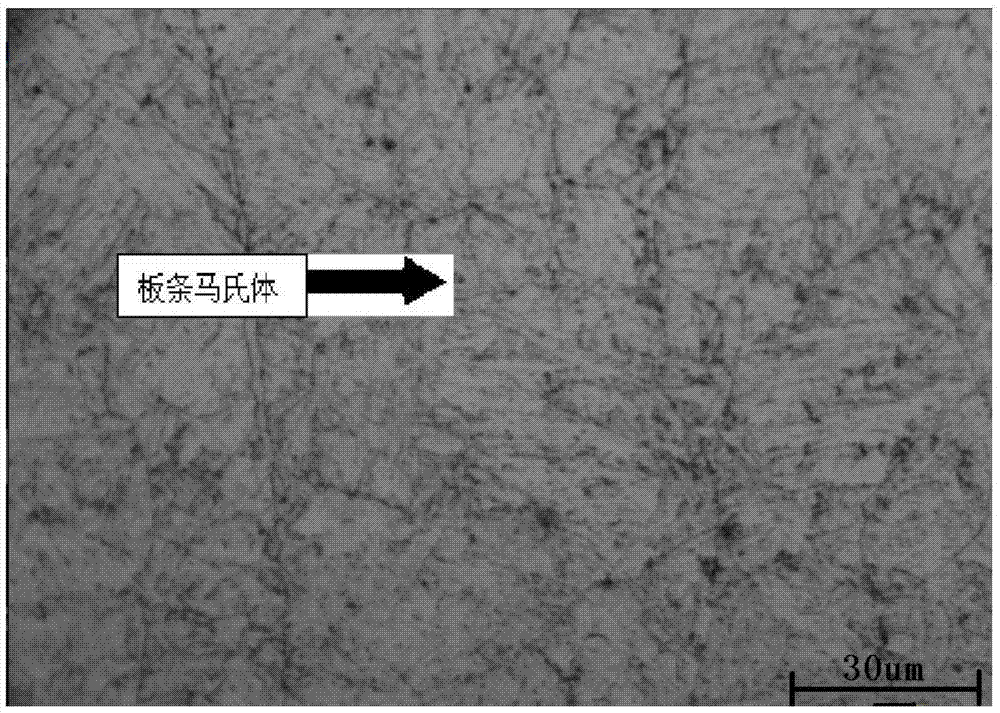

A preparation method of oxide dispersion strengthened steel and a kind of martensitic steel

ActiveCN105274440BImprove hardenabilityReduced retained austenite contentRare-earth elementMechanical property

The invention provides an oxide dispersion strengthened (ODS) steel preparing method and martensitic steel. The oxide dispersion strengthened steel preparing method includes the steps that iron oxides are added into a casting mould, a proper number of rare earth elements are added into a fully deoxidized molten steel, the mixture is rapidly cast into the casting mould, and the ODS steel is obtained through the reaction between the rare earth elements and the iron oxides. The martensitic steel is obtained by performing hot forging, hot rolling, hot machining and hot treatment on the ODS steel prepared through the method. The ODS steel prepared through the method is high in hardenability, the residual austenitic content is very low, and a full martensite structure can be obtained. W, V and Ta are strong carbide forming elements and have a remarkable strengthening effect, and the mechanical property is obviously higher than that of steel prepared through a traditional smelting technology. Meanwhile, the ductile-brittle transition temperature (DBTT) value is minus 80 DEG C and minus 90 DEG C, the good toughness of the traditional smelting technology is well inherited, and meanwhile good anti-radiation performance is achieved. By means of the ODS steel preparing method, the demands for preparing ODS steel in batches with stability, short process and low cost can be met.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com