Method for preparing oxide dispersion strengthened F/M steel through smelting and casting process

A technology of dispersion strengthening and casting technology, applied in the field of metal materials, can solve the problems of long process, poor single production capacity, complex process, etc., and achieve the effect of reducing the temperature of molten steel and ensuring fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

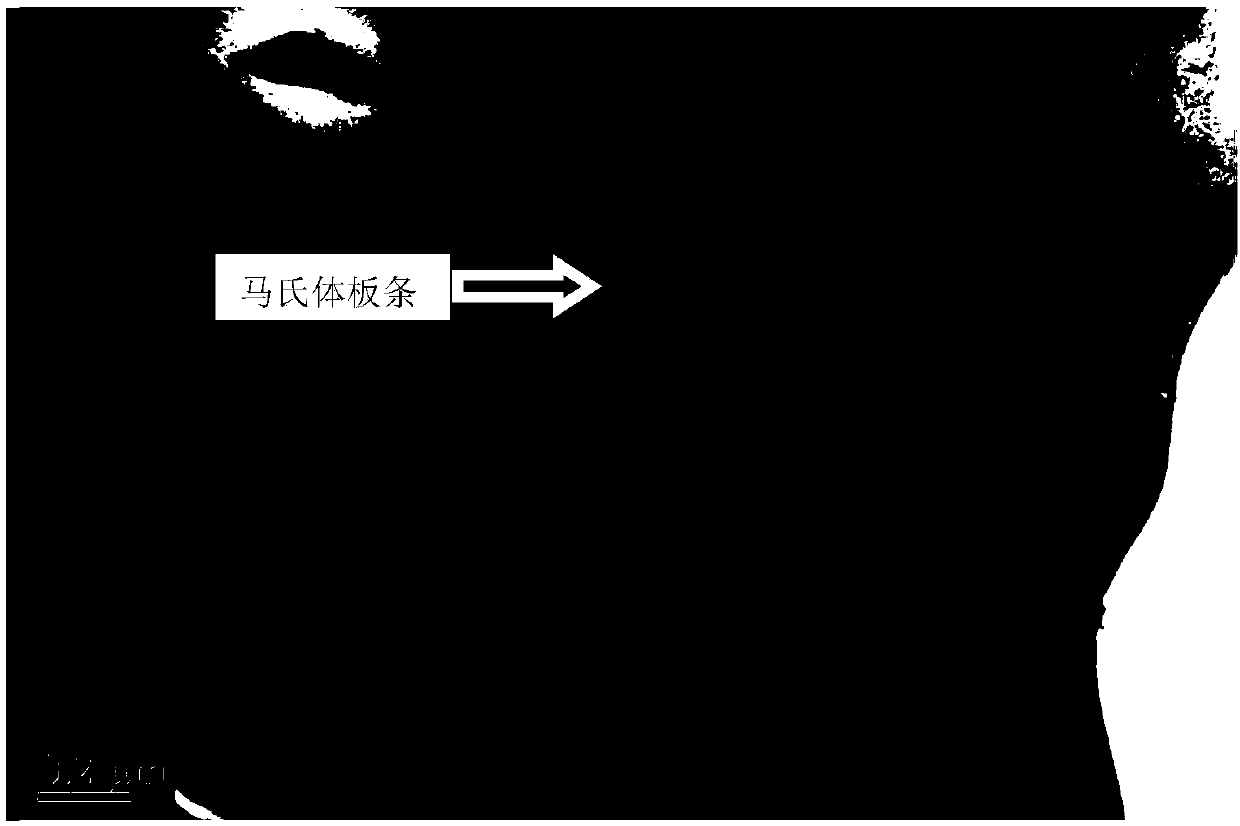

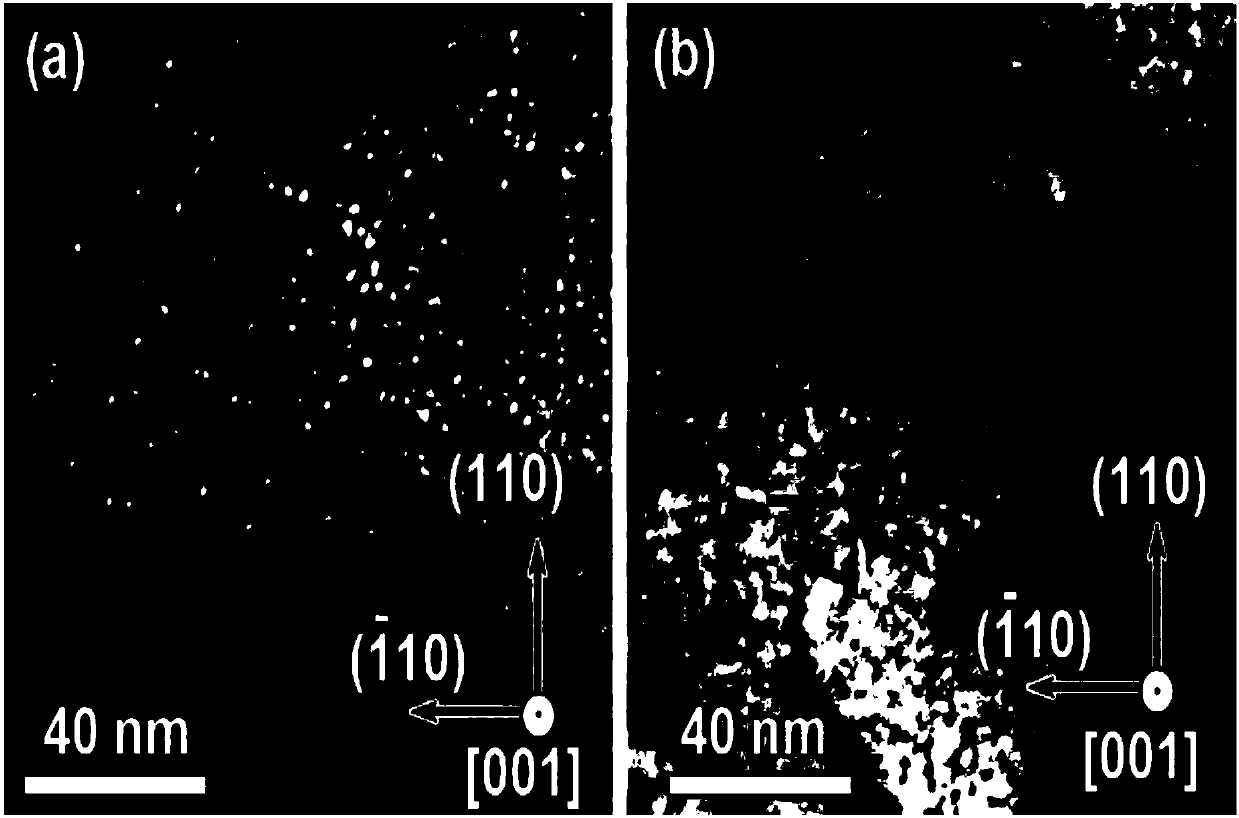

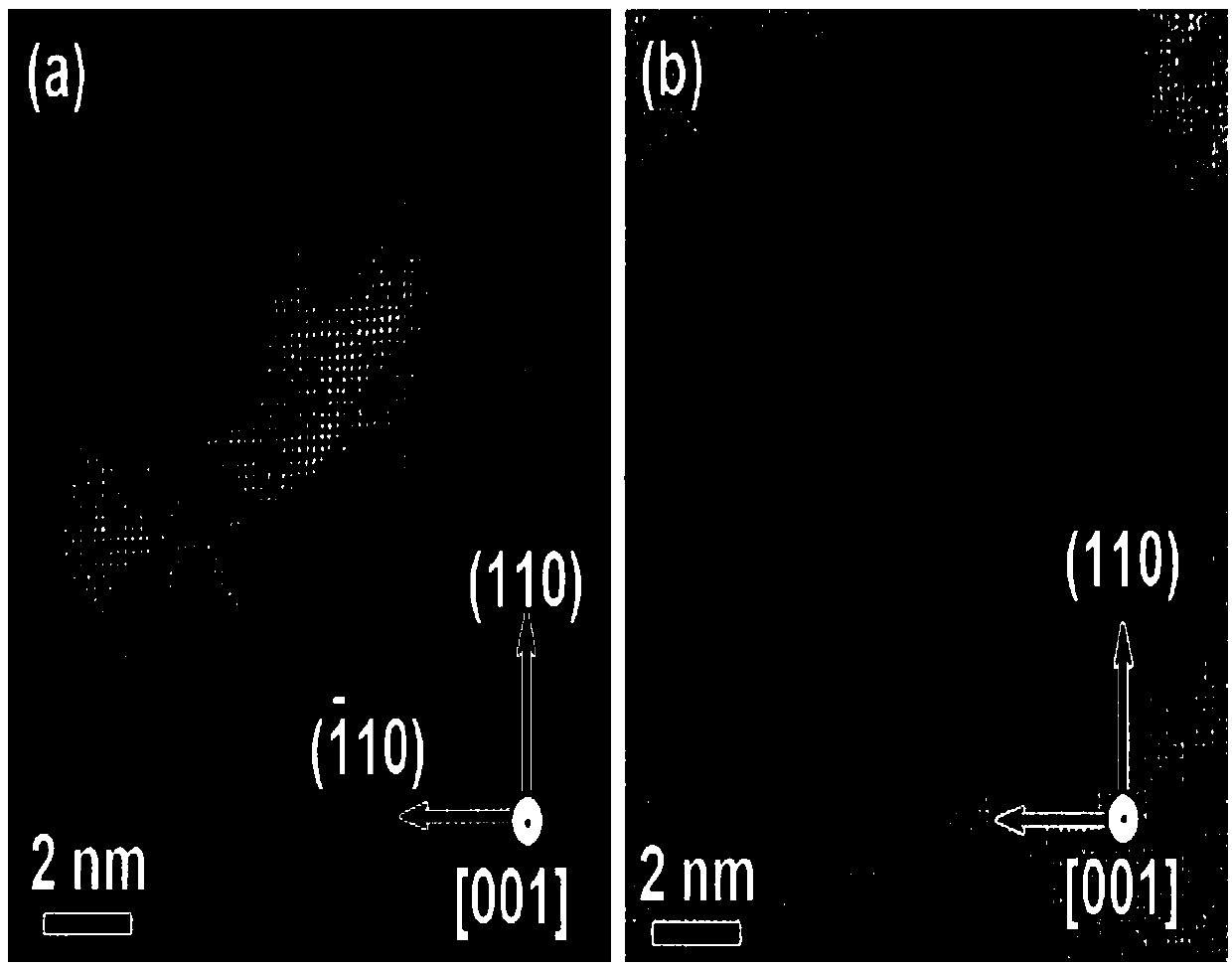

Image

Examples

Embodiment approach 1

[0037] A kind of ODS RAFM steel prepared based on the above-mentioned novel ODS preparation process, its various components account for the percentage of total mass:

[0038] C: 0.08-0.15%, Cr: 8.0-14%, Mn: 0.45-0.6%, W: 1.0-2.5%, N: 0.05-0.07%, Ta: 0.010-0.20%, Ti: 0.02-0.55%, Si : 0.10~0.15%, V: 0.04~0.5%, O: 30~200ppm B<0.001%, S<0.003%, P<0.005%, Fe balance, Y powder in the mold: 0.05%. The finished product is made through the following steps:

[0039] (a) According to steps 1, 2, 3, and 4 of the preparation method in the present invention, vacuum smelting is used to prepare steel ingots or continuously cast steel rods, with the following components accounting for the percentage of the total mass:

[0040] C: 0.08-0.15%, Cr: 8.0-14%, Mn: 0.45-0.6%, W: 1.0-2.5%, N: 0.05-0.07%, Ta: 0.010-0.20%, Ti: 0.02-0.55%, Si : 0.10~0.15%, V: 0.04~0.5%, O: 30~200ppm B<0.001%, S<0.003%, P<0.005%, Fe balance, Y powder in the mold: 0.05%.

[0041] (b) first hot deformation by forging or ...

Embodiment approach 2

[0047] A kind of ODS RAFM steel prepared based on the above-mentioned novel ODS preparation process, its composition accounts for the percentage of total mass:

[0048] C: 0.08-0.15%, Cr: 8.0-14%, Mn: 0.45-0.6%, W: 1.0-2.5%, N: 0.05-0.07%, Ta: 0.010-0.20%, Ti: 0.02-0.55%, Si : 0.10~0.15%, V: 0.04~0.5%, O: 30~200ppm B<0.001%, S<0.003%, P<0.005%, Fe balance, Y powder in the mold: 0.8%,

[0049] And make a finished product through the following steps:

[0050] (a) According to the steps 1, 2, 3, and 4 of the preparation method in the present invention, vacuum smelting is used to prepare steel ingots or continuously cast steel rods, with the following components accounting for the percentage of the total mass: C: 0.08-0.15%, Cr: 8.0 ~14%, Mn: 0.45~0.6%, W: 1.0~2.5%, N: 0.05~0.07%, Ta: 0.010~0.20%, Ti: 0.02~0.55%, Si: 0.10~0.15%, V: 0.04~ 0.5%, O: 30~200ppm B<0.001%, S<0.003%, P<0.005%, Fe balance, Y powder in the mold: 0.8%;

[0051] (b) first hot deformation by forging or roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com