A method for smelting ultra-pure ferritic stainless steel

A smelting method and stainless steel technology, applied in the direction of improving process efficiency, can solve the problem that the performance of pure ferritic stainless steel cannot meet the demand, and achieve the effect of shortening oxidation time, preventing intergranular corrosion, and improving high temperature corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

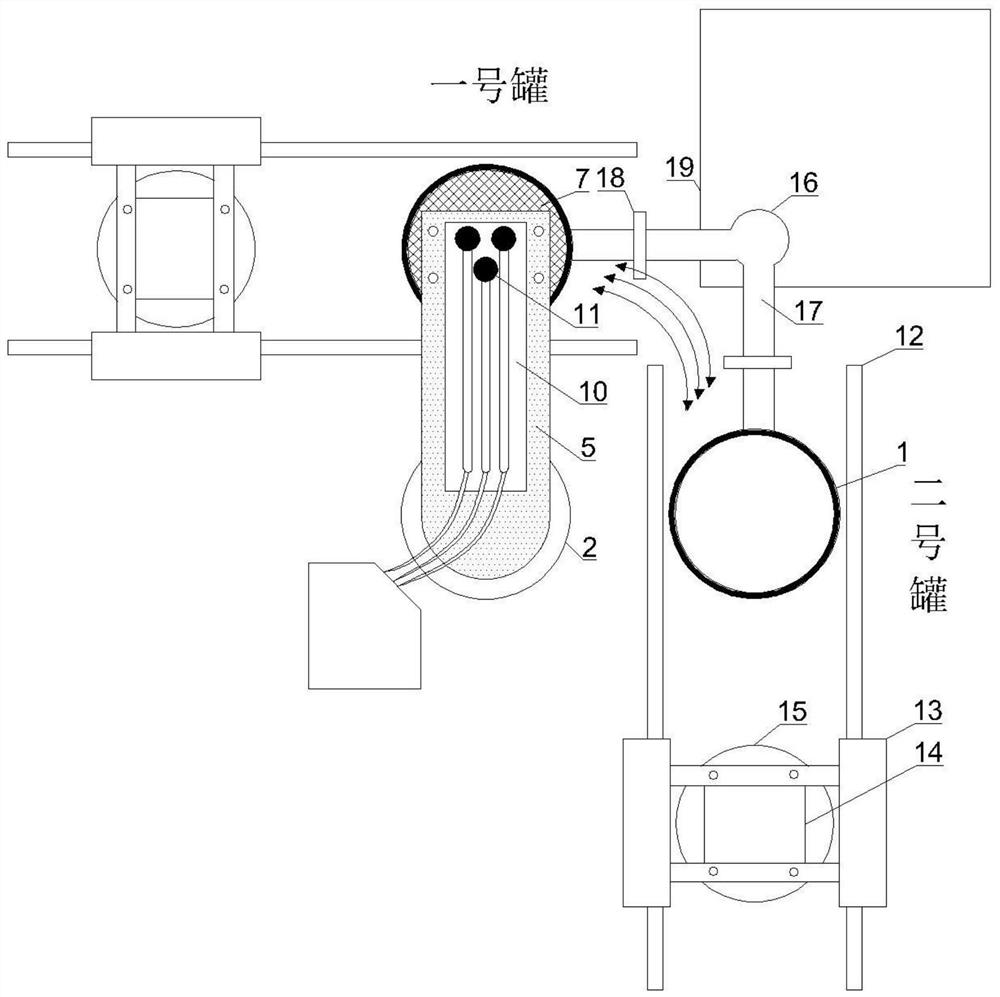

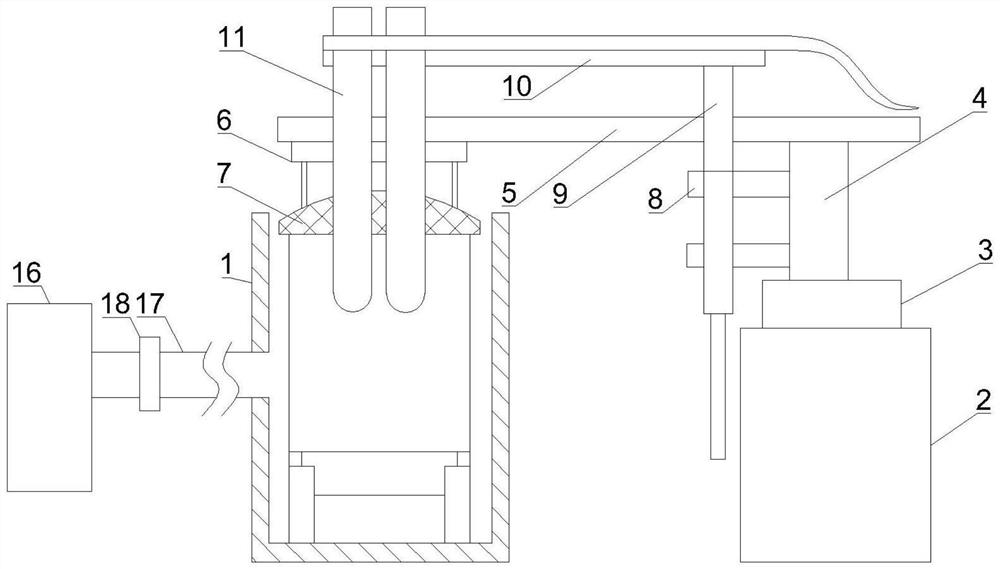

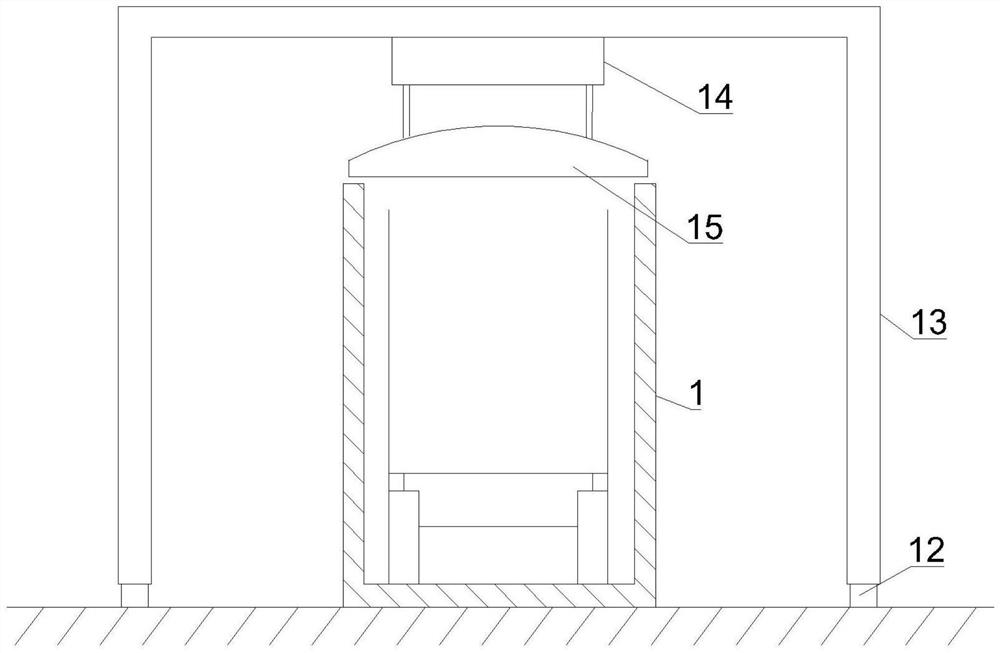

[0033] combine Figure 1-3, this embodiment provides a high-efficiency smelting device for alloy steel, including two vacuum tanks 1 and a base 2, the two vacuum tanks 1 and the base 2 are distributed in an isosceles right-angled triangle structure on the horizontal plane, and the base 2 is in an isosceles At the position of the right-angle point in the right-angled triangle structure, the top of the base 2 is fixed with a rotating device 3. The rotating device 3 can be a turntable structure driven by a motor through gear meshing. It only needs to be able to drive the equipment on it to rotate. ; the top of the rotating device 3 is fixedly installed with a vertical support structure 4 (for structures such as struts), and the top of the vertical support structure 4 is connected with the first horizontal support structure 5 perpendicular to it (in this embodiment, specifically One end of the horizontal plate), and the other end of the first horizontal support structure 5 is hung...

Embodiment 2

[0042] The purpose of this embodiment is to provide a method for smelting ultra-pure ferritic stainless steel so that the C+N content does not exceed 0.015%, and at the same time add appropriate Mo or Ti or Nb or a variety of combinations thereof to achieve the material Various properties required. C+N≤0.015%, can reduce the retained austenite content in the material; Ti and Nb elements can solidify C and N in the material, and Ti and Nb can improve the high temperature corrosion resistance of the material and prevent the material from being exposed to high temperature conditions Intergranular corrosion occurs under the environment; Mo element helps to improve the acid and alkali corrosion resistance of the material, especially the resistance to pitting corrosion.

[0043] Specifically, this embodiment provides that the composition of the ultra-pure ferritic stainless steel element mass percentage is: Si≤1.00%, Mn≤1.00%, P≤0.040%, S≤0.030%, Cr: 10.00%-32.50%, Ni : 0~1.00%, C+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com