Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Avoid intergranular corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

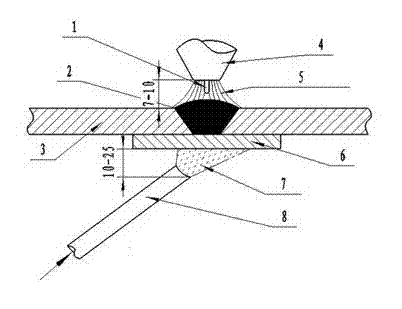

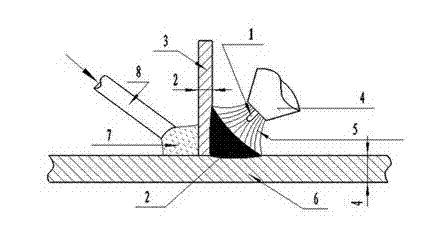

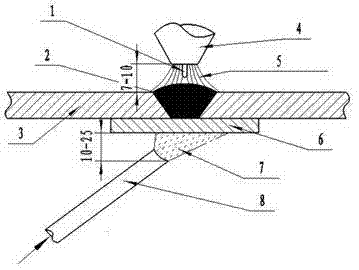

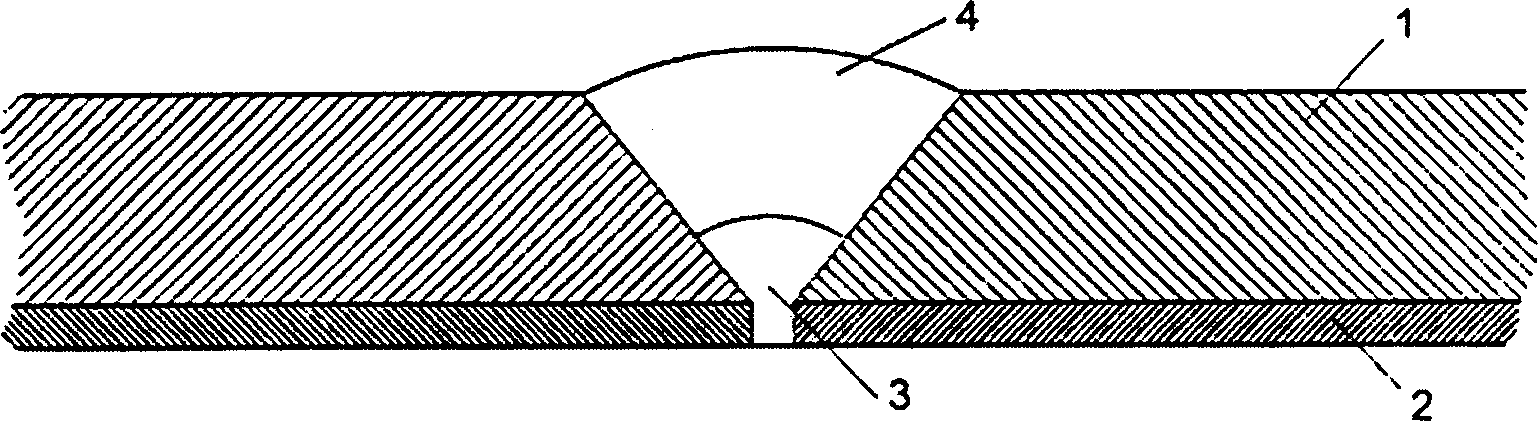

Welding method for ultra-thin composite layer low-carbon steel - austenitic stainless steel multiple tube adaptor

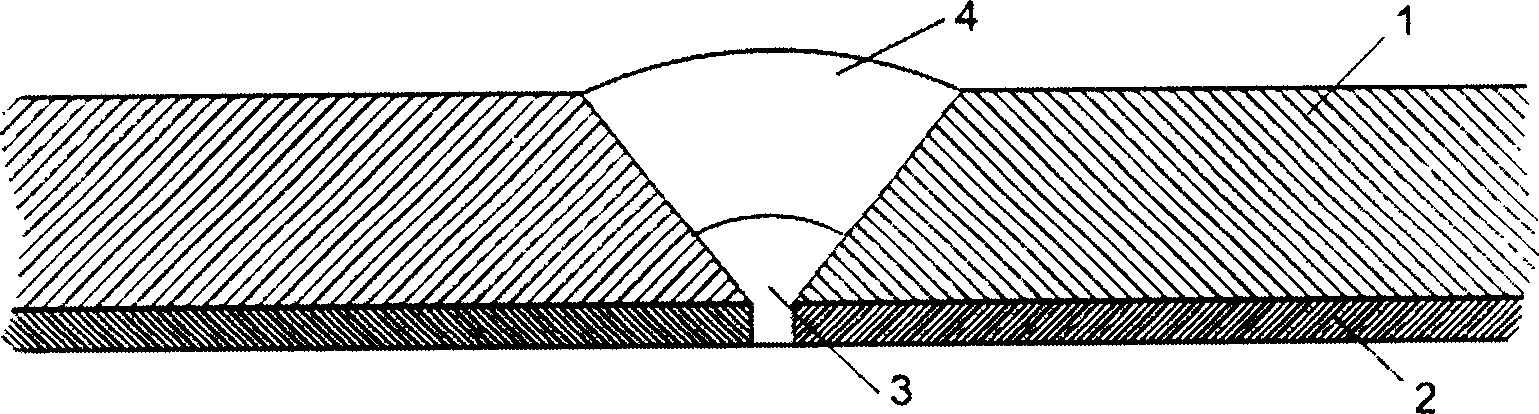

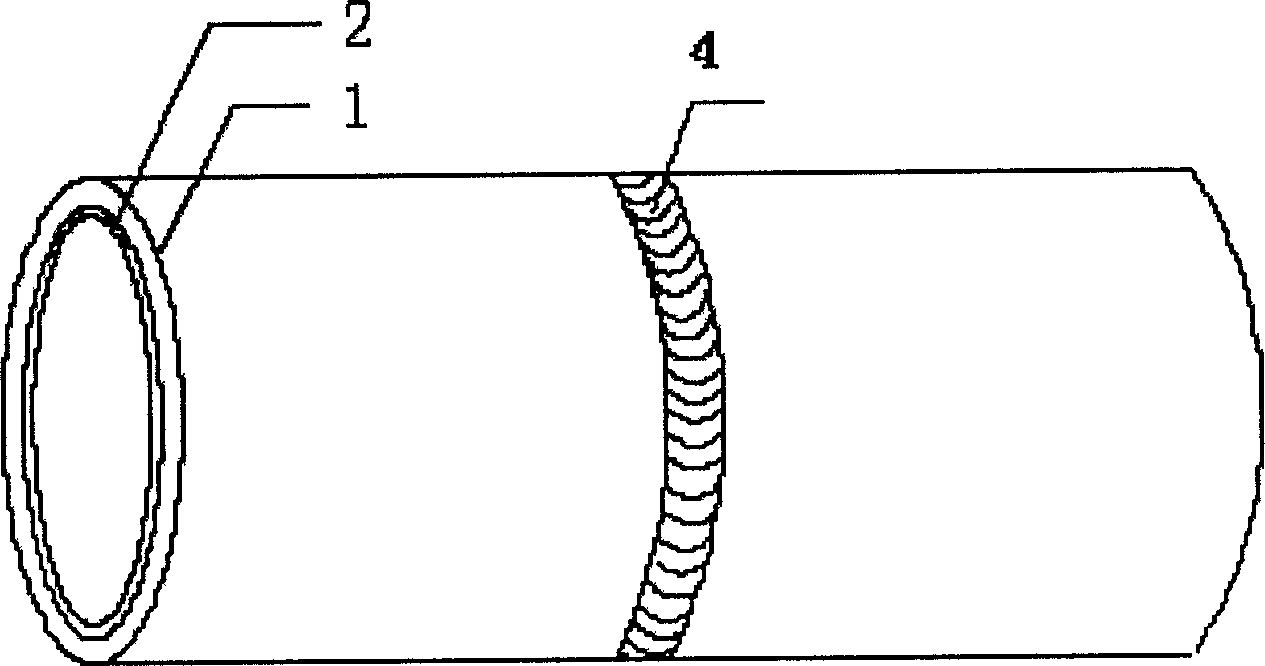

ActiveCN1546267AHigh carbon contentGuaranteed mechanical propertiesArc welding apparatusWelding/cutting media/materialsCarbon steelWeld seam

The invention discloses a welding method for low carbon steel-austenite stainless steel compound pipe of ultra-thin stainless composite bed. The character is: the welding is completed with transition layer welding seam and base layer welding, it hasn't single stainless steel composite bed seam; the welding rod for low carbon steel base layer seam is the same to the one for mother metal; the first welding for stainless steel composite layer and the transition layer between the stainless composite layer and the low carbon steel base layer use argon tungsten-arc welding with back argon filling protection, or uses manual arc welding; the welding wire or welding rod use stainless steel in order to form the transition welding seam; after the transition welding seam is completed, the second time uses manual arc welding to weld the low carbon steel base layer, the welding rod uses low carbon steel in order to form base layer welding seam.

Owner:XI AN JIAOTONG UNIV +1

High-strength corrosion-resistant aluminum alloy profile and preparation method thereof

The invention discloses a high-strength corrosion-resistant aluminum alloy profile and a preparation method thereof. The aluminum alloy profile comprises an aluminum alloy base body and a ceramic coating. The aluminum alloy base body is prepared from Cu, Si, Fe, Cr, Mg, Mn, Zn, Ti, Li, Ni, Zr, Y, W, V and the balance Al. The ceramic coating is prepared from SiC, Cr2O3, NiO, Cr3C2, Al2O3 and Si3N4. According to the high-strength corrosion-resistant aluminum alloy profile, ceramic powder is arranged on the surface of the aluminum alloy base body through plasma cladding, and then laser remelting is conducted, so that the obtained aluminum alloy profile has good mechanical performance such as strength, hardness and impact toughness; and meanwhile, the high-strength corrosion-resistant aluminum alloy profile has the beneficial effects of being resistant to corrosion, good in abrasion resistance, long in service life and the like.

Owner:安徽省煜灿新型材料科技有限公司

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559AImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

SUS304 stainless steel cold-rolled plate producing method omitting annealing before cold rolling

InactiveCN101585046AOptimizing Process ParametersUniform grainTemperature control deviceWork treatment devicesScale structurePrecipitation

The invention relates to an SUS304 stainless steel cold-rolled plate producing method which omits annealing before cold rolling. The method comprises the steps of smelting, casting, hot rolling, cooling, pickling, cold rolling, solution treatment and pickling, wherein a plate blank is heated to a temperature higher than 1270 DEG C, a hot coil-box is used for temperature preservation before the hot rolling, and the finishing temperature is over 1000 DEG C; cooling is carried out after the rolling, the cooling speed is 25-40 DEG C / s, and coiling is carried out until the coiling temperature reaches 601-650 DEG C; and within 60 minutes after the coiling, a hot rolled coil is positioned in a water tank for cooling, and the hot rolled coil is taken out after the cooling is carried out for 5 or more hours. The method ensures that the SUS304 uniforms crystal grains as much as possible in the process of hot working, avoids corrosion caused by carbide precipitation, realizes the same effect as the adoption of off-line solution treatment, leads to the omission of the off-line solution treatment before the process of cold working and solves the problem that the omission of the off-line solution treatment brings changes to the roll scale structure of the SUS304 hot rolled coil.

Owner:BAOSHAN IRON & STEEL CO LTD

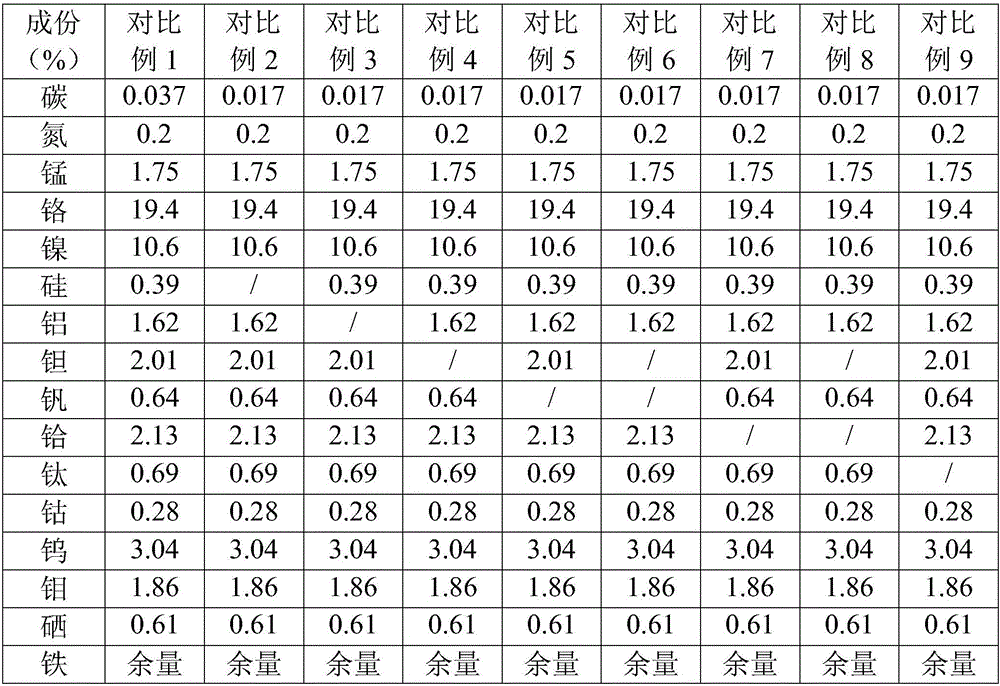

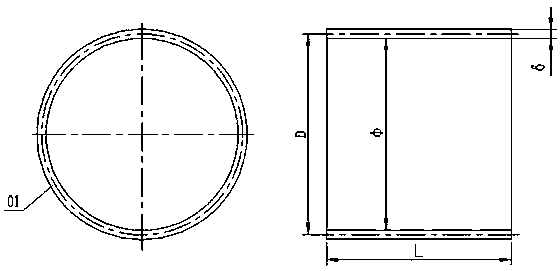

Corrosion-resistance seamless stainless steel pipe and preparation method thereof

InactiveCN106282845AMake up for the lack of strengthImprove corrosion resistanceFurnace typesHeat treatment furnacesManganeseHafnium

The invention discloses a corrosion-resistance seamless stainless steel pipe and a preparation method thereof. The corrosion-resistance seamless stainless steel pipe comprises the following chemical components in percentage by mass: carbon not more than 0.02%, 0.1-0.25% of nitrogen, 1.6-1.8% of manganese, 18-20% of chromium, 9-11% of nickel, 0.3-0.5% of silicon, 1.5-1.7% of aluminum, 1.5-2.3% of tantalum, 0.3-0.8% of vanadium, 1.2-2.6% of hafnium, 0.5-0.8% of titanium, 0.2-0.4% of cobalt, 1.6-3.4% of tungsten, 1-3% of molybdenum, 0.4-0.7% of selenium, and the balance of iron. Tantalum, hafnium and tungsten are added in austenitic stainless steel, and the chemical components can improve the performances of corrosion resistance, hardness, strength and high-temperature resistance of the austenitic stainless steel, so that the austenitic stainless steel is rich in high ductility and toughness.

Owner:ZHEJIANG HENGYUAN STEEL CO LTD

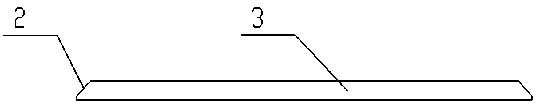

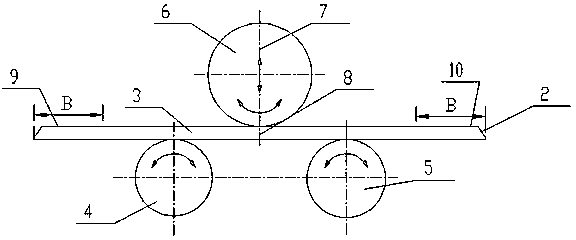

Multi-curvature forming method for stainless steel cylinder

The invention discloses a multi-curvature forming method for a stainless steel cylinder. The method is characterized by comprising the following steps: performing scribing and blanking according to the developed length of the medium diameter of a cylinder to be wound; machining peripheral welding grooves of a plate; rolling-forming a first-curvature circular arc, namely reserving a straight section, not to be wound for the formation of a circular arc, with a width B of 200 to 600 mm at each of the two ends of the cylindrical plate, and bending and winding the middle part of the cylindrical plate into a large circular arc with a curvature radius R of more than or equal to 0.5 Phi to form the first-curvature circular arc of the cylinder; rolling-forming second-curvature circular arcs, namely rolling the parts between the roots of the straight sections with the widths B of 200 to 600 mm and the large circular arc into circular arcs with curvature radiuses r of 0.2 to 0.5 Phi to form second-curvature circular arcs; rolling transition parts between the second-curvature circular arcs and the first-curvature circular arc into smooth transition; performing rolling until the grooves 2 in the two ends of the straight sections get close to each other; performing longitudinal seam assembly and welding on the cylinder, placing the cylindrical body at a horizontal position, and welding longitudinal seams; performing roundness correction on the cylinder after welding.

Owner:SHANGHAI TONGHUA STAINLESS STEEL PRESSURE VESSEL ENG

Continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel

ActiveCN103243339AAvoid intergranular corrosionSpeed up the formation of passivation filmHydrofluoric acidConcentration ratio

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

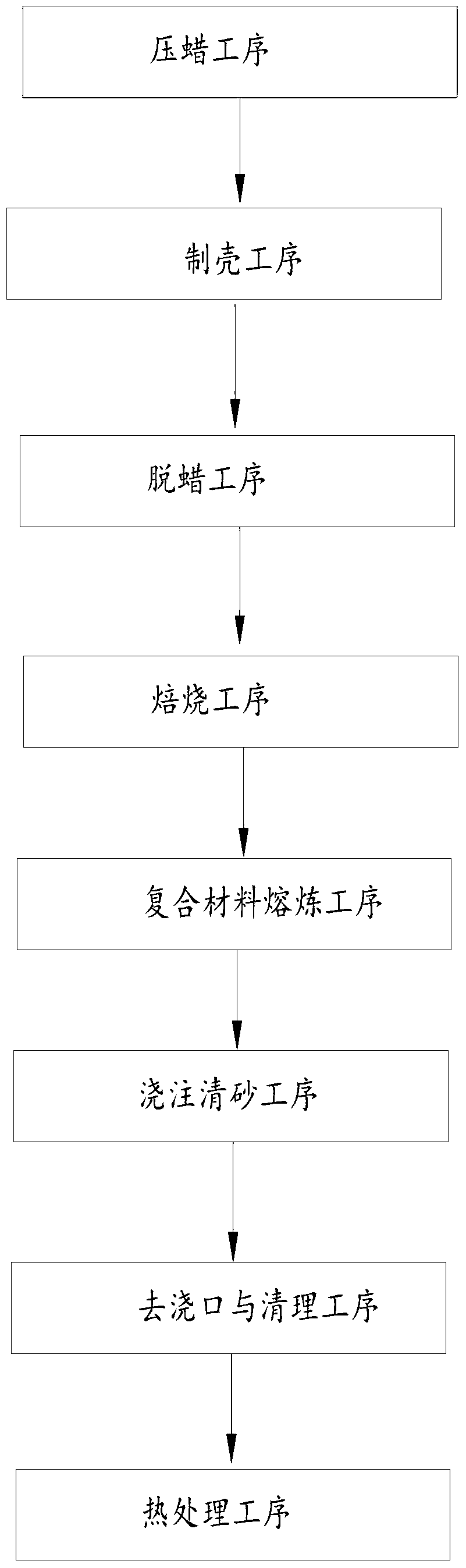

Production method of composite material stirring wing

InactiveCN103252449AImprove mechanical propertiesImprove mechanical properties; adding C can improve the compactness of the material structureFoundry mouldsFoundry coresWaxSmelting process

The invention provides a production method of a composite material stirring wing. The method comprises the following steps of: (1) wax pressing process; (2) shell making process; (3) dewaxing process; (4) roasting process; (5) composite material smelting process; (6) clean sand pouring process; (7) sprue removing and cleaning process; and (8) heat treatment process. The production method can be used for producing the stirring wing with high safety and reliability, and the high-quality composite material stirring wing can be produced by the method.

Owner:QINGDAO YUXIN VEHICLE ENG

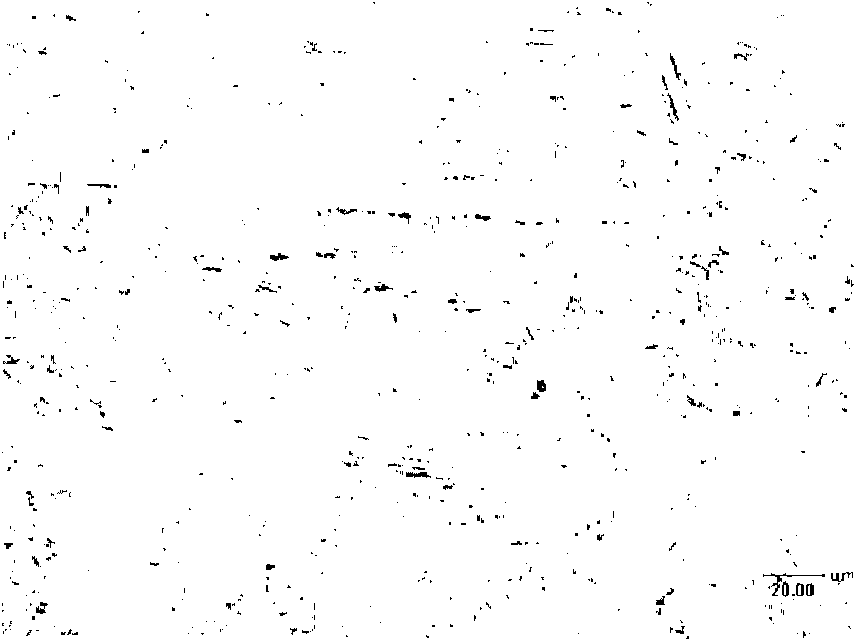

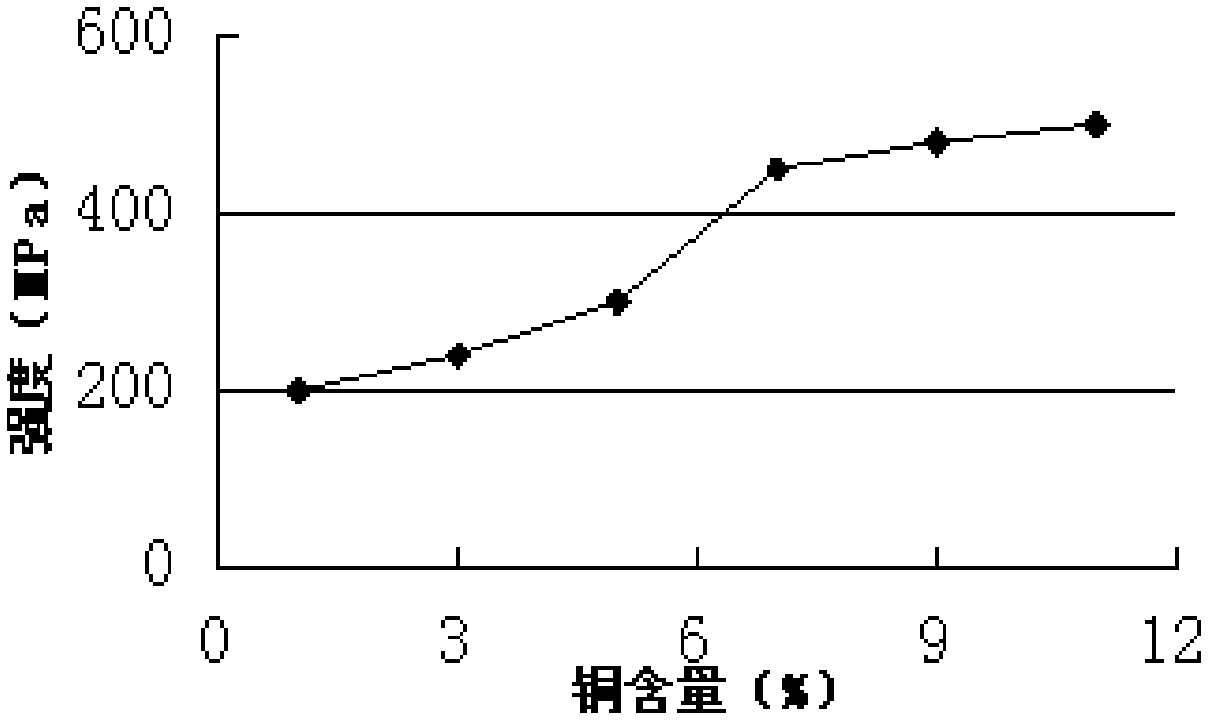

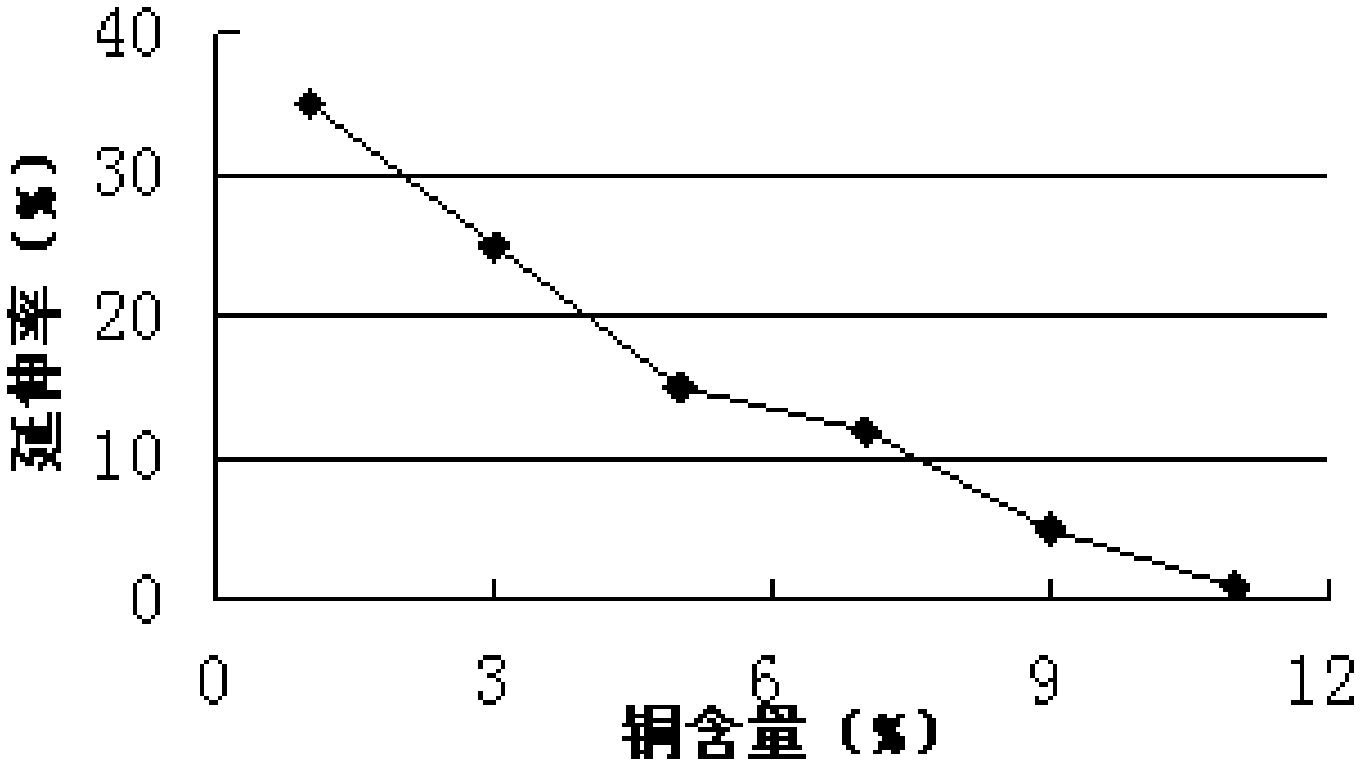

Deformation zinc alloy, as well as manufacturing method and application thereof

The invention relates to a deformation zinc alloy, as well as a preparation method and a use thereof. The deformation zinc alloy comprises 2.0-9.5% of Cu, 0.01-0.5% of Mn, 0-0.1% of Co and the balance of zinc and inevitable impurity elements, wherein the total amount of the inevitable impurity elements is less than 0.01. The microstructure of the zinc alloy mainly comprises a zinc matrix primary phase and intermetallic compounds dispersed in the primary phase, wherein the primary phase is of an HCP (hexagonal close-packed) structure, and the intermetallic compounds are of small Zn4Cu and Zn9Mn; the volume content of the Zn4Cu phase is 5%-55%, the volume content of the Zn9Mn phase is 0.1%-5%, and the balance is of the primary phase; and the average grain size of the primary phase is 15-35 mu m, and the average grain size of the intermetallic compounds is 5-15 mu m. The alloy can be produced into screw nuts and screw caps for air conditioners for replacing traditional brass and further solving the problem of being short of brass resources through post-processing technologies, such as melting-casting, extrusion, drawing and the like under certain process conditions.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Welding method for manufacturing jet pump by using ultra-low carbon austenitic stainless steel

InactiveCN102225487AControl deformationExtended service lifeWelding/cutting auxillary devicesArc welding apparatusRoom temperatureFiller metal

The invention provides a welding method of an ultra-low carbon austenitic stainless steel and in particular relates to a welding method for manufacturing a jet pump by using an ultra-low carbon austenitic stainless steel. The method comprises the following steps: welding a weldment by means of a welding gun through manual tungsten electrode argon arc welding, wherein a welding wire made of a material same as the ultra-low carbon austenitic stainless steel is taken as a filler metal; carrying out welding and cold-water quick cooling simultaneously, wherein the temperature of welding is below 80 DEG C, and the speed of welding is 45-50 cm / min; after extinguishing the arc, cooling the weldment is reduced to the room temperature within 2 seconds, wherein the weldment is less than or equal to 12 mm thick; and after welding, carrying out pickling and passivation treatment. The welding method has the following outstanding advantages: the welding and cooling of the weld joint by virtue of cold water are carried out simultaneously, thus reducing the welding temperature, so that the stainless steel is free of transformation of internal molecules and atoms (crystals, therefore, the service life of the weldment is greatly prolonged; and the integrated deformation of the weldment is effectively controlled.

Owner:唐山三友集团兴达化纤有限公司

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Welding method for ultra-thin composite layer low-carbon steel - austenitic stainless steel multiple tube adaptor

ActiveCN1267234CHigh carbon contentGuaranteed mechanical propertiesArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingWeld seam

The invention discloses a welding method for low carbon steel-austenite stainless steel compound pipe of ultra-thin stainless composite bed. The character is: the welding is completed with transition layer welding seam and base layer welding, it hasn't single stainless steel composite bed seam; the welding rod for low carbon steel base layer seam is the same to the one for mother metal; the first welding for stainless steel composite layer and the transition layer between the stainless composite layer and the low carbon steel base layer use argon tungsten-arc welding with back argon filling protection, or uses manual arc welding; the welding wire or welding rod use stainless steel in order to form the transition welding seam; after the transition welding seam is completed, the second time uses manual arc welding to weld the low carbon steel base layer, the welding rod uses low carbon steel in order to form base layer welding seam.

Owner:XI AN JIAOTONG UNIV +1

Medium chromium base ferrite stainless steel erosion agent and preparing and erosion methods thereof

InactiveCN106400019ALower erosion temperatureImprove erosion efficiencyPreparing sample for investigationAlcoholDistilled water

The invention discloses a medium chromium base ferrite stainless steel erosion agent and preparing and erosion methods thereof, and belongs to the technical field of medium chromium base ferrite stainless steel tissue erosion observation. The erosion agent comprises, by volume, 10-80 parts of ethyl alcohol, 20-90 parts of nitric acid, 50-100 parts of hydrochloric acid and 50-200 parts of distilled water. The preparing method of the erosion agent includes the steps that the ethyl alcohol and diluent nitric acid are evenly mixed to prepare a nitric acid and ethyl alcohol mixing solution; then the distilled water and the hydrochloric acid are evenly mixed to prepare a hydrochloric acid and distilled water mixing solution; and finally, the nitric acid and ethyl alcohol mixing solution and the hydrochloric acid and distilled water mixing solution are evenly mixed to prepare the erosion agent. According to the creative technical scheme, the effective erosion agent and erosion method are provided for medium chromium base ferrite stainless steel, and therefore technical supports are provided for observation of macrostructures in the medium chromium base ferrite stainless steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Zn-Al-Mg alloy layer used for being hot-dipped to bridge steel wire surface and manufacturing method for Zn-Al-Mg alloy layer

ActiveCN105420653AReduced corrosion resistanceImprove corrosion resistanceHot-dipping/immersion processesAlloyZinc

The invention relates to a Zn-Al-Mg alloy layer used for being hot-dipped to a bridge steel wire surface and a manufacturing method for the Zn-Al-Mg alloy layer. The alloy layer comprises, by mass, 30%-97% of Zn, 5%-60% of Al and 0.02%-11% of Mg, wherein the sum of the percentages of all the components is 100%. The manufacturing method includes the steps that a bridge steel wire is unoiled and derusted; the alloy layer is hot-dipped; and stabilizing treatment is conducted. According to the alloy plating layer, the corrosion resistance is superior to that of an existing zinc plating layer and that of an existing zinc aluminum alloy plating layer, the alloy plating layer is easy to use, meets the requirements of the special environments, such as the requirement for bridge steel wires in the marine corrosion atmosphere environment and has wide market prospects.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

Erosion-resistant copper alloy utilized in ocean working condition and preparation method thereof

The invention relates to the field of ocean engineering, and particularly discloses an erosion-resistant copper alloy utilized in an ocean working condition and a preparation method thereof. The copper alloy comprises the following elements by mass percent: 7% to 10% of Ni, 5% to 10.5% of Al, 0.15% to 1% of Fe, 0.5% to 1.5% of Mn, 0.15% to 1% of Ti, 0.05% to 0.15% of P, 0.2% to 0.6% of Mg and 0.005% to 0.01% of B, and the balance being copper. The preparation method comprises the steps of sequentially adding electrolytic copper, a covering agent, a CnMn intermediate alloy, a CuCo intermediate alloy, CuFe intermediate alloy, electrolytic nickel, pure chromium, electrolytic aluminium, pure silicon and the covering agent; and then, carrying out phosphor copper deoxidation, stirring slag salvaging, temperature increasing and discharging. The preparation method has the advantages that cost is low and efficiency is high, the copper alloy material has performance like sandy seawater erosion corrosion resistance, ocean organism corrosion resistance and seawater high-speed flow corrosion resistance, and the requirement of ocean engineering on corrosion-resistant and abrasion-resistant materials can be met.

Owner:HENAN UNIV OF SCI & TECH

High-strength wear-resistant nonmagnetic stainless steel and preparation method thereof

The invention discloses a high-strength wear-resistant nonmagnetic stainless steel and a preparation method thereof. The high-strength wear-resistant nonmagnetic stainless steel is composed of the following components in percentage by weight: 0.1%-0.18% of carbon, 8%-11% of nickel, 19%-21% of chromium, 1%-2% of manganese, 0.5%-1% of silicon, 0.48%-0.65% of niobium, 0.11%-0.14% of vanadium, 1.2%-2.0% of molybdenum, 0.021%-0.03% of titanium, 0.01%-0.1% of aluminum, 0.8%-2% of nitrogen, 0.2%-0.3% of rare earth, not more than 0.035% of phosphorus and sulfur, and the balance of iron thereof inevitable impurities. The high-strength wear-resistant nonmagnetic stainless steel has the advantages of favorable corrosion resistance, favorable intercrystalline corrosion resistance, favorable oxidation resistance, favorable acid / alkali resistance, high strength and high hardness.

Owner:何鹏

Non-nickel low-chromium austenite 0CR13Mn14CuN stainless acid-resistant steel

InactiveCN101250670AGood for low temperature dephosphorizationImprove toughnessMinor elementLead smelting

The invention relates to a nickel-free low-chrome austenite 0Cr13Mn14CuN acid-resistant stainless steel, which is characterized in that the main chemical components comprise C<=0.08%, Si<=1.00%, Mn13.0%-15.0%, Cr12.0%-14.0%, Cu 1.0%-2.0%, N 0.15%-0.25%, P<=0.035% and S<=0.030%. The invention is new steel, which is tested to be austenite metallurgical structure through engineer tests for few decades, and the chemical components, acid resistance, corrosion resistance, oxidation resistance and mechanical property all reach the technical standard of stainless steel, in particular to minor element which is added, and crystal grain is led to be refined, toughness of steel is increased, and the functions of deoxidizing, desulfurizing, eliminating non-metal impurity in steel, preventing intergranular corrosion and the like. The cid-resistant stainless steel utilizes manganese and nitrogen to replace expensive nickel, which leads smelting cost to be lower more than 60%, and can be applied in producing acid-resistant stainless seamless steel pipes, various round bars, sheet material and acid-resistant stainless steel casting which is minutely casted.

Owner:陆平

Explosion-proof type fixed ammonia gas detection probe and manufacturing method thereof

InactiveCN105039787AHigh elastic limitIncrease yield pointMaterial analysisRare-earth elementPhysical chemistry

The invention discloses an explosion-proof type fixed ammonia gas detection probe used on an ammonia gas detector. The explosion-proof type fixed ammonia gas detection probe comprises a displayer and a probe tube extending out of the displayer. The probe tube comprises the following components of C, Mn, P, S, Mo, Ni, Cu, Si, Ti, Cr, Mn, Fe, Pb, Nb, V, rare earth elements and the balance Al. The rare earth elements comprise La, Y, Sc, Gd, Sm, Ho, Tb and the balance lanthanide. The invention further provides a manufacturing method for the explosion-proof type fixed ammonia gas detection probe. The manufacturing method is simple and easy to implement, manufacturing cost is low, pollutants cannot be generated in the manufacturing process, the corrosion resistance of the manufactured fixed ammonia gas detection probe is good, the explosion-proof performance is good, service life is prolonged, and cost is reduced.

Owner:JIANGSU JINDI ELECTRONICS TECH

Corrosion resistance and high temperature resistance magnesium alloy wheel hub and preparation method thereof

ActiveCN110331320AAvoid breakingImprove performanceWheel manufactureDisc wheelsMicro arc oxidationTemperature resistance

The invention relates to a corrosion resistance and high temperature resistance magnesium alloy wheel hub and a preparation method thereof. A magnesium alloy comprises, by mass, 4.0-6.5% of Al, 1.2-3.0% of Zn, 0.8-1.5% of Mn, 0.1-3.3% of Yb, 0.3-0.8% of N, 0.8-2.3% of Si, 18-25% of Cr, less than or equal to 2.5% of W, 0.2-0.6% of Zr, and the balance Mg and inevitable impurity elements. The outer surface of the wheel hub is treated by micro arc oxidation to form a ceramic film on the product surface and then baked and coated with paints. According to the corrosion resistance and high temperature resistance magnesium alloy wheel hub and the preparation method thereof, the ceramic film is formed on the product surface through the micro arc oxidation treatment, so that the surface strength isstrengthened, the damage of a protective layer caused by the wear, bump and scratch of a wheel is avoided, and the corrosion resistance, high temperature resistance and aesthetics of the wheel hub aregreatly improved.

Owner:内蒙古中钰镁合金锻造轮毂有限公司

Machining method for improving abrasion and corrosion resistance of valve

InactiveCN107385433AImprove mechanical propertiesImprove fatigue resistanceMetallic material coating processesProcess optimizationSand blasting

The invention discloses a machining method for improving abrasion and corrosion resistance of a valve. The machining method comprises the following steps that firstly, the valve is arranged in activation liquid to be immersed, then the valve is washed to be neutral, grinding is conducted, then washing is conducted, drying is conducted, and a material A is obtained; secondly, the material A is subjected to sand blasting treatment, and a material B is obtained; thirdly, the material B is subjected to plasma cladding treatment, and a material C is obtained; and fourthly, the material C is subjected to heat treatment. According to the provided machining method for improving abrasion and corrosion resistance of the valve, through process optimization, a plating material and a base body are tightly combined, distribution is uniform, the high temperature resistance, corrosion resistance and creeping resistance of the valve are effectively improved, and the service life of the valve is effectively prolonged.

Owner:ANHUI WODE VALVE MFG

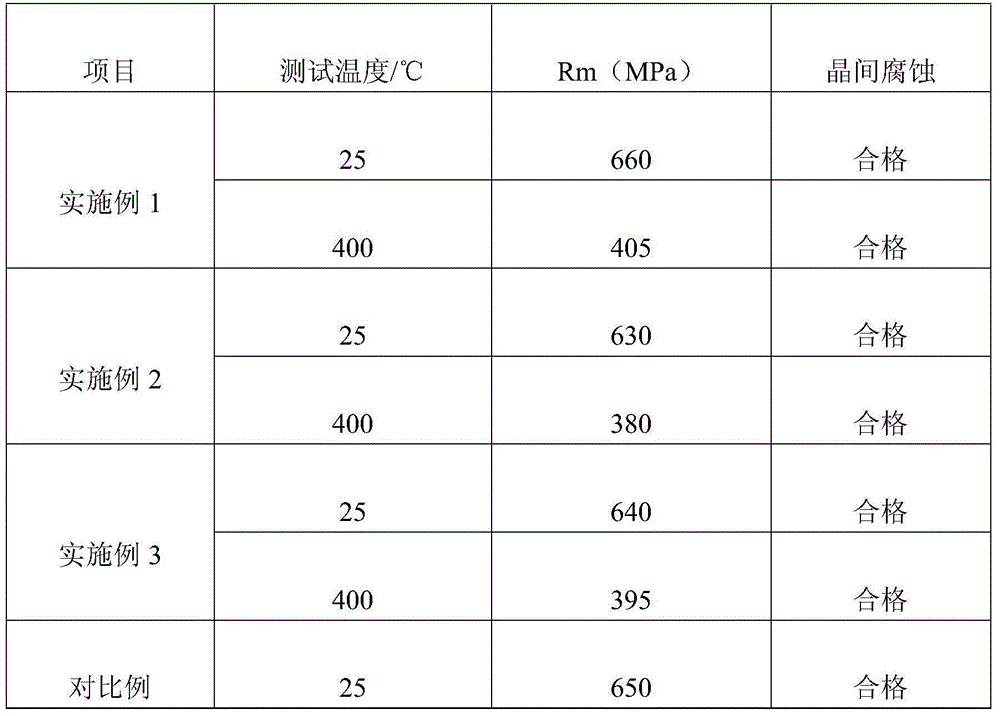

110ksi-grade stainless steel oil pipe and manufacture method thereof

ActiveCN106048421AGood corrosion resistanceImprove corrosion resistanceDrilling rodsDrilling casingsForgingSmelting

The invention discloses a 110ksi-grade stainless steel oil pipe and a manufacture method thereof. The 110ksi-grade stainless steel oil pipe consists of the following chemical components in a percent by mass: smaller than or equal to 0.02 of C, smaller than or equal to 0.20 of Si, 1.00-1.50 of Mn, 18-20 of Cr, 9-12 of Ni, 0.1-0.3 of N and the balance of Fe and trace impurity elements, and the 110ksi-grade stainless steel oil pipe is finally obtained after the chemical components are treated by the procedures of smelting, forging, pipe blank making, extrusion and rolling, solid solution treatment, cold deformation, heat treatment, non-destructive detection and pipe end machining. The yield strength Rp0.2 of the 110ksi-grade stainless steel oil pipe is 758-828MPa, the tensile strength Rm is larger than 862MPa, and the elongation A50 is larger than 12%. The 110ksi-grade stainless steel oil pipe meets the requirements of API Spec 5CT standards on 110ksi strength grade and is suitable for meeting the requirements of deep and superdeep wells and oil wells in severe corrosive environments.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

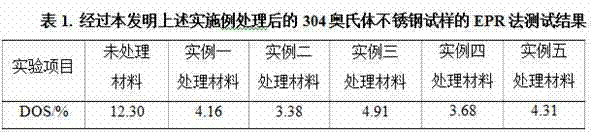

Heat treatment process for reducing sensitization degree of austenitic stainless steel

The present invention discloses a heat treatment process for reducing the sensitization degree of an austenitic stainless steel, wherein an austenitic stainless steel is subjected to segmented annealing treatment under a reduced protection atmosphere, and then water cooling is performed to achieve a room temperature. According to the present invention, with the heat treatment process, the residence time of the austenitic stainless steel in the sensitization temperature zone during the austenitic stainless steel heat treatment process can be reduced, the formation of the partial chromium carbide can be effectively inhibited, the carbide formed at the grain boundary position can be re-dissolved into the austenite to form the appropriate amount of the delta-ferrite, the sensitization degree of the austenitic stainless steel can be reduced, and the intergranular corrosion resistance can be improved; and the heat treatment process has advantages of simple process, remarkable effect and strong operability, and can be used for large-scale industrial production.

Owner:SHANGHAI UNIV

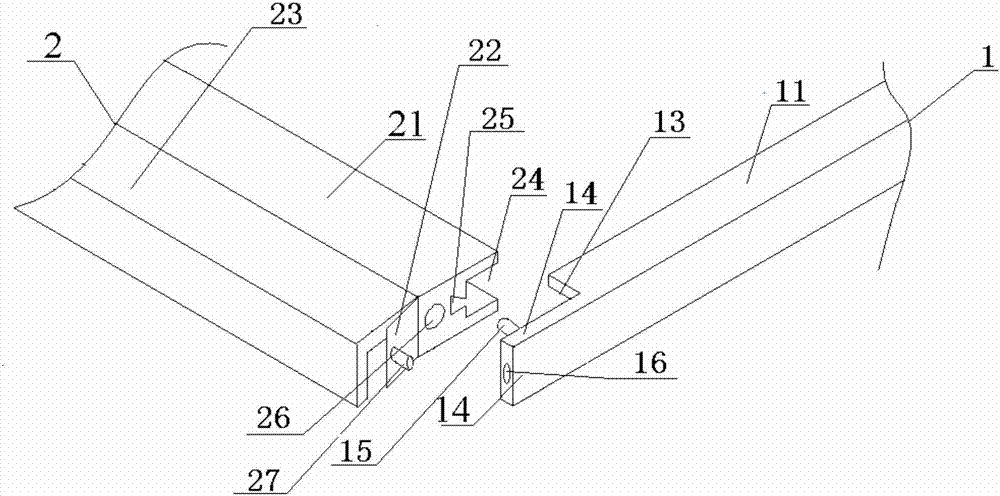

Combined photovoltaic module aluminium frame and production process thereof

PendingCN107196591AImprove performancePlay the effect of purifying castingsPhotovoltaicsPhotovoltaic energy generationEngineeringPhotovoltaics

The invention discloses a combined solar photovoltaic module frame. The combined solar photovoltaic module frame comprises a main body frame; the main body frame is composed of a long frame, a short frame and a U-shaped fixing block; the long frame and the short frame are matched; the short frame is composed of a first concave profile, fixing edges and a first connection block; the fixing edges are arranged at two ends of the first concave profile; the first connection block is formed by extension from one side of the first concave profile; a first groove and a glue injecting groove are also arranged at the notch of the first concave profile; locating holes are also arranged at two ends of the first concave profile; a fixing block is also arranged on the fixing edge; the long frame mainly comprises a second concave profile; a second groove is arranged at the notch of the second concave profile; extension plates extend from two ends of the second concave profile; a locating column is arranged on the extension plate; and a fixing hole is also formed on the side surface of the extension plate. The invention further designs a production process of the combined solar photovoltaic module frame. The aluminium frame is simple in structure, good in protection performance, low in cost and convenient to disassemble and install; furthermore, the aluminium frame can be individually used; and furthermore, multiple aluminium frames can be used in a combined manner.

Owner:镇江神飞新能源科技有限公司

Alloy ring forge piece for ultra-high pressure turbine and manufacturing method of alloy ring forge piece

InactiveCN110358895AImprove corrosion resistanceMake up for the lack of strengthFurnace typesEngine componentsUltra high pressureHafnium

The invention discloses an alloy ring forge piece for an ultra-high pressure turbine and a manufacturing method of the alloy ring forge piece. The alloy ring forge piece is manufactured from the chemical components of carbon, nitrogen, manganese, chromium, nickel, silicon, copper, aluminum, tantalum, niobium, hafnium, cobalt, tungsten, molybdenum, titanium, tin, tellurium, lutetium, scandium and iron; and the forge piece is a 2Cr11MoVNbN forge piece. The manufacturing method comprises the following stepsofblanking, heating, forging, machining, tempering heat treatment and stress relief annealing, specifically, the tempering step includes the steps ofa, carrying out scanning irradiation on the surface of a rolled ring piece by using a laser beam emitted by a laser heat treatment machine; b,heating the ring piece obtained after laserscanningand irradiationto 620-640 DEG C at a temperature rising speed beingless than or equal to 150 DEG C per hour, keeping the temperature for primary tempering for 16 hours, and then preforming air cooling; and c, again, heating the ring piece to 620-640 DEG C at the temperature rising speed beingless than or equal to 150 DEG C per hour, keeping the temperature for secondary tempering for 16 hours, and performing air cooling. According to the ring forge piece and the manufacturing method, the ring forge piece has good high-pressure resistance, themechanical property of the ring piece can be remarkably improved, the machining and manufacturing cost is low, and the machining process is simple.

Owner:JIANGYIN HENGRUN RING FORGING

High-strength wear-resisting flux-cored wire

InactiveCN107309572AReduce pollutionImprove scalabilityWelding/cutting media/materialsSoldering mediaHigh intensityWear resistance

The invention discloses a high-strength wear-resisting flux-cored wire. The high-strength wear-resisting flux-cored wire is composed of a flux core and a sheath coating the outer side of the flux core. The flux core comprises following components of Si, B, Cu, C, Mn, Ni, Al, Ti, Mo, V, Sn, Sr, Hf, Nd, Ce, Y, Eu and the balance Fe and inevitable impurities. According to the high-strength wear-resisting flux-cored wire, the components of the flux core are reasonable; after welding, deposited metal has excellent toughness, strength and wear resistance; and the service life of a metal component is remarkably prolonged.

Owner:天长市通联焊业有限公司

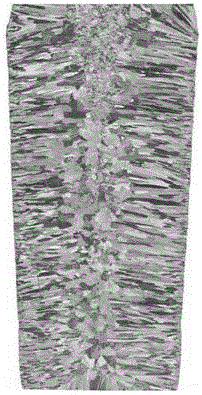

Preparing method for medium-chromium-based ferritic stainless steel low power structure

InactiveCN106400020ALower erosion temperatureImprove erosion efficiencyPreparing sample for investigationAlcoholDistilled water

The invention discloses a preparing method for a medium-chromium-based ferritic stainless steel low power structure, and belongs to the technical field of medium-chromium-based ferritic stainless steel structure preparing. An erosion agent comprises, by volume, 10-80 parts of ethyl alcohol, 20-90 parts of nitric acid, 50-100 parts of hydrochloric acid and 50-200 parts of distilled water. The preparing method for the low power structure comprises the steps that firstly, the ethyl alcohol, the hydrochloric acid, the nitric acid and the distilled water are evenly mixed, and the erosion agent is prepared; then, an eroded stainless steel sample is cut and polished, and an erosion surface is obtained; after erosion is finished, the steel sample is placed in an alkaline solution to be cleaned, and acid removing treatment is conducted; and finally, the steel sample is placed in the ethyl alcohol solution to be cleaned, the steel sample is blown dry after cleaning, the erosion face is scanned through a scanner, and a picture of a low-power condensation structure is prepared. An effective method is provided for preparing and observing of the medium-chromium-based ferritic stainless steel low power structure, the prepared structure picture is clear and visible, and the quality of the steel sample is effectively represented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Corrosion-resisting austenitic stainless steel submerged-arc welding wire and production method thereof

InactiveCN106563892AReduce manufacturing costHigh tensile strengthWelding/cutting media/materialsSoldering mediaFerrosiliconAustenite

The invention relates to a corrosion-resisting austenitic stainless steel submerged-arc welding wire and a production method thereof. The corrosion-resisting austenitic stainless steel submerged-arc welding wire is composed of, by mass, 0.015%-0.025% of C, 1.00% of Si or the less, 2.50% of Mn or the less, 0.020% of P or the less, 0.010% of S or the less, 12.00%-14.00% of Ni, 18.00%-20.00% of Cr, 2.00%-3.00% of Mo, 0.05%-0.10% of N and 0.05%-0.10% of Ti. The production method comprises the following steps that dosing, vacuumizing, argon gas filling, energizing, fine melting, cooling, ferrosilicon adding, carbon adding, titanium adding, power cutting and pouring are conducted, and a steel ingot is obtained after cooling; and then steel forging, steel rolling, welding wire finishing drawing and finished product heat treatment are carried out. According to the corrosion-resisting austenitic stainless steel submerged-arc welding wire, an element Nb is replaced with an element Ti, coarsening of austenite crystal grains can be effectively prevented, refining of ferrite crystal grains is achieved, intercrystalline corrosion is avoided, and the corrosion resistance of a welding wire deposited metal is improved. Meanwhile, due to the effect of nickel equivalent elements such as Ni, Mn, C and N which are favorable for formation of austenitic stainless steel, strength of the welding wire deposited metal can be effectively improved, and additionally, the price of titanium is low, so that the production cost can be reduced.

Owner:DANYANG HUALONG SUPERIOR STEEL

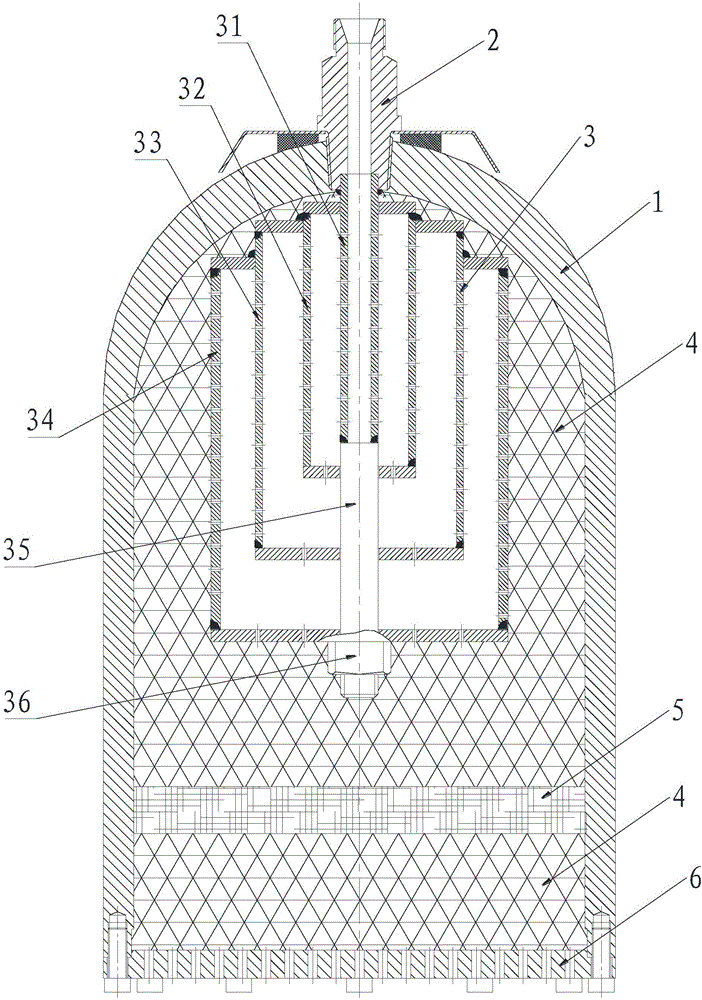

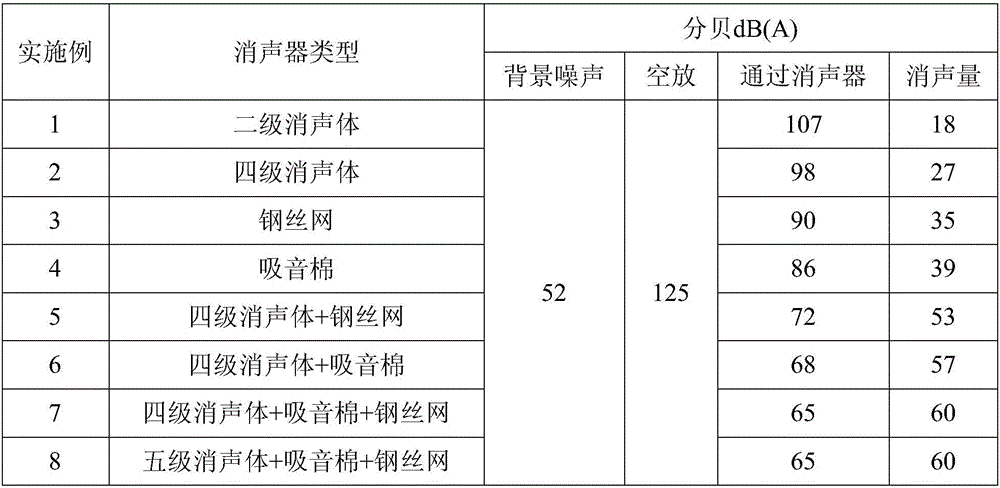

High-pressure silencer

ActiveCN106014542AReduce noiseHigh precisionSilencing apparatusMachines/enginesEngineeringHigh pressure

The invention discloses a high-pressure silencer suitable for performing noise elimination and noise lowering on discharged high-pressure gas. The high-pressure silencer comprises a shell, noise eliminating bodies and a silencing material; one end of the shell is a cylinder of a spherical end socket which is provided with a gas inlet connection nozzle; the other end of the shell is closed through a hole plate with exhausting holes; the portion, close to one end of the spherical end socket, in the shell is provided with the noise eliminating bodies with the noise eliminating level number being N; one end of the first level of noise eliminating body is connected with the gas inlet connection nozzle; the noise eliminating bodies of all the levels are each provided with a vent hole, are each in a round pipe shape and are arranged in a concentric sleeved manner; and the portions between the inner wall of the shell and the outer sides of the noise eliminating bodies are filled with the silencing material, wherein N is larger than or equal to 4 and is a natural number. High-pressure gas flow enters the noise eliminating bodies from the gas inlet connection nozzle, the volume is gradually increased, the density is continuously decreased, noise is gradually weakened, the weakened gas flow enters the silencing material and is further weakened, and when the gas flow reaches the hole plate, the noise is finally weakened substantially. The high-pressure silencer is good in silencing effect, simple in structure, high in strength, convenient to install and easy to maintain.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

Corrosion-resistant and wear-resistant high strength electrophoretic aluminum profile and preparation process thereof

InactiveCN110453119AImprove wear resistanceImprove corrosion resistanceAnodisationElectrophoretic coatingsWear resistantThermal stability

The invention discloses a corrosion-resistant and wear-resistant high strength electrophoretic aluminum profile and a preparation process thereof and belongs to the field of aluminum profile preparation. The corrosion-resistant and wear-resistant high strength electrophoretic aluminum profile is prepared from the following raw materials in percent by weight: 0.8-1.2% of Mg, 0.4-0.6% of Si, 0.2-0.4% of Ti, 0.22-0.3% of Fe, 0.06-0.1% of Cu, 0.08-0.12% of Zn, 0.06-0.08% of Cr, 0.12-0.18% of Mo and the balance of Al and inevitable impurities. The preparation process is simple and effective and convenient and rapid in process operation. By controlling the contents of Mg, Si, Fe, Cu and Zn reasonably, strengthening phases such as Al2Cu, Al2CuMg, Mg2Si, MgZn2 and the like are formed in the electrophoretic aluminum profile to strengthen the synergistic effect, refine crystals and improve grain distribution, so that performance, such as wear resistance and corrosion resistance, of the electrophoretic aluminum profile is improved. By matching Si, Ti, Fe, Cr and Mo, the grains are refined, the cast structure and the weld joint structure are refined, the recrystallization temperature is increased, the thermal stability of a material is improved, the intergranular corrosion is avoided, and the corrosion performance of the electrophoretic aluminum profile is improved.

Owner:ANHUI XIN FA ALUMINUM PROD

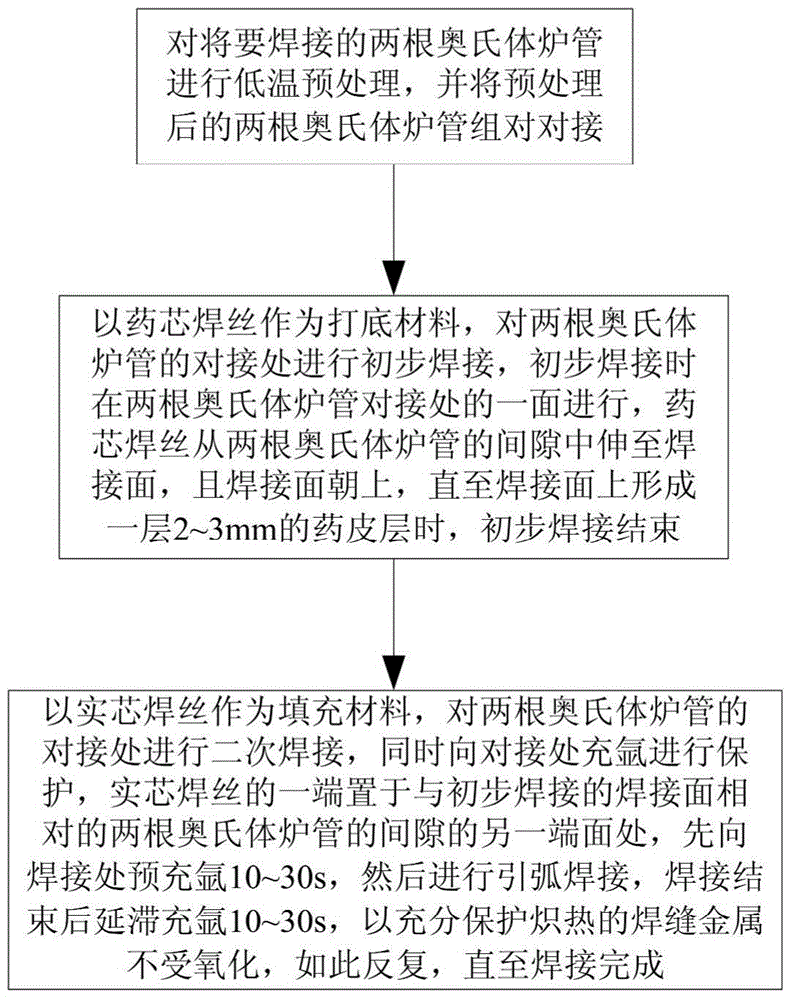

Austenite furnace tube welding method

ActiveCN104439631AReduce dissolved carbonAvoid corrosionMetal working apparatusTubular articlesFilling materialsEngineering

The invention relates to the field of furnace tube welding, in particular to an austenite furnace tube welding method. The method comprises the steps that two preprocessed austenite furnace tubes are assembled and connected in an abutting mode; a flux-cored wire is used as backing welding materials, preliminary welding is carried out on one face of the position where the two austenite furnace tubes are connected in the abutting mode, the flux-cored wire extends from a gap between the two austenite furnace tubes to the welding face, the welding face faces upwards, and preliminary welding is ended when a coating layer is formed on the welding face; a flux-cored wire is used as filling materials, secondary welding is carried out on the position where the two austenite furnace tubes are connected in the abutting mode, meanwhile, the abutting connection position is filled with argon for protection, one end of the flux-cored wire is placed on the other end face, opposite to the welding face where the preliminary welding is carried out, of the gap between the two austenite furnace tubes, the flux-cored wire is molten constantly until welding is completed. According to the austenite furnace tube welding method, inconvenience brought when furnace tube bottoming welding tubes are filled with argon for protection is omitted, argon is saved, working efficiency is improved, meanwhile, crystal corrosion is avoided, residual stress in the welding process is reduced, and hot cracks are prevented from being generated.

Owner:CHINA NAT CHEM ENG NO 16 CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com