Austenite furnace tube welding method

A welding method and austenitic technology, applied in welding equipment, welding accessories, tubular objects, etc., can solve the problems of no welding technology for stainless steel self-shielding flux-cored welding wire, lagging welding operation standards, insufficient knowledge of flux-cored welding wire, etc., to achieve Reduce the amount of dissolved carbon, avoid intergranular corrosion, and reduce the effect of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

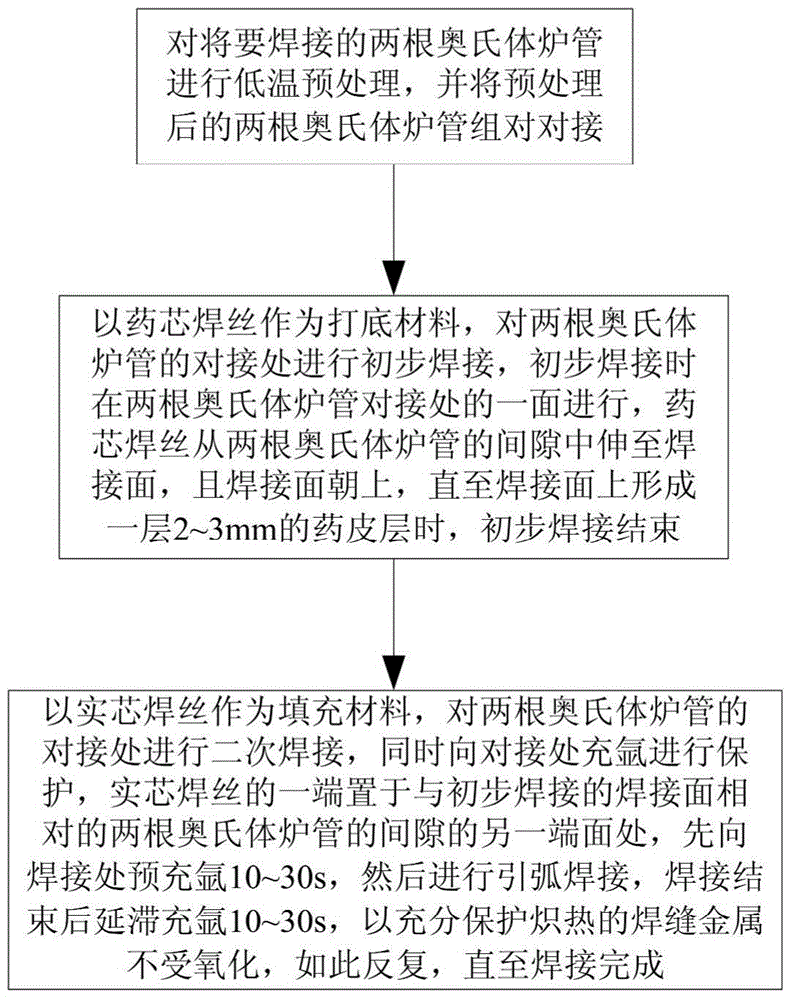

[0018] The invention provides a method for welding an austenitic furnace tube, comprising the following steps:

[0019] Step 1. As the temperature drops, the carbon dissolving ability of austenite decreases, and one of the main measures to avoid intergranular corrosion, reduce residual stress during welding, and prevent hot cracks is to reduce the weld and base metal. Carbon content, perform low-temperature pretreatment on the two austenitic furnace tubes to be welded, place the two furnace tubes in an ice-water mixed bath for 5 to 8 hours, and put the pretreated two austenitic furnace tubes Placed on a horizontal workbench for pairing and docking;

[0020] Step 2. Use flux-cored wire as the base material, and conduct preliminary welding on the butt joint of two austenitic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com