Nb and V microalloyed gear steel, preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel

A heat treatment method and micro-alloying technology, applied in the field of gear steel, can solve the problem of not being able to adapt to materials with high contact fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

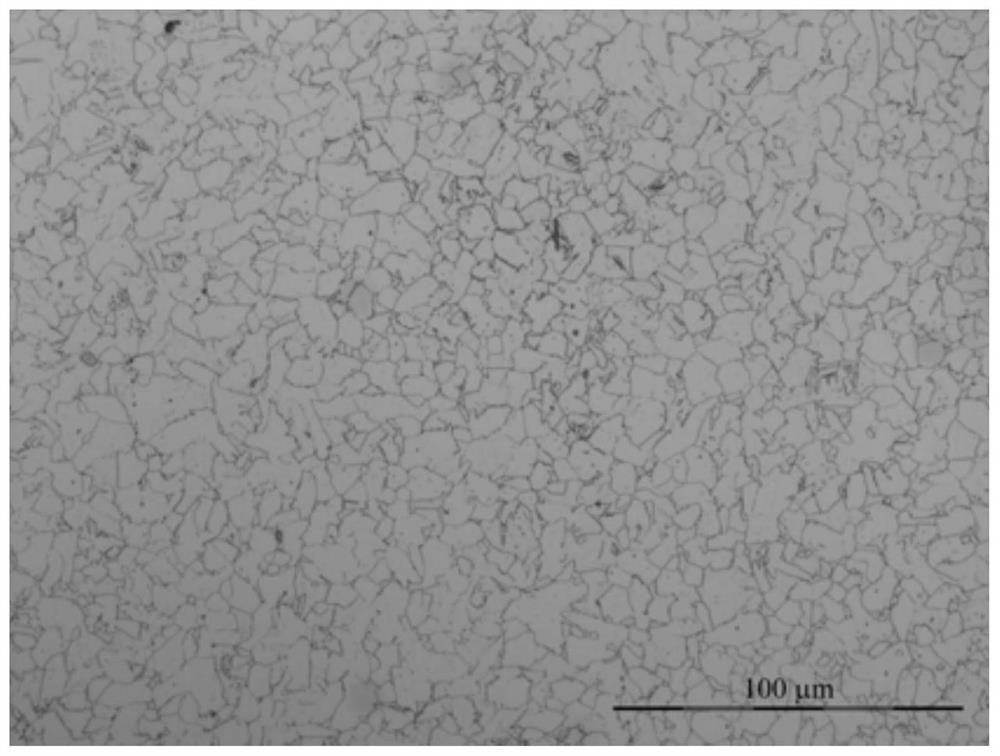

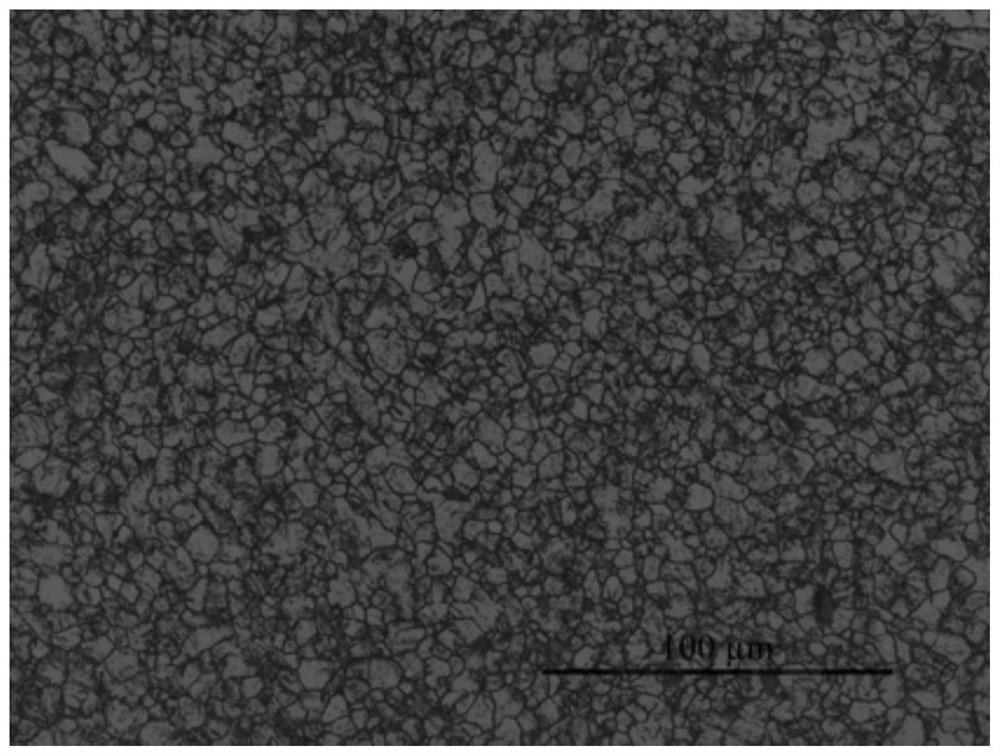

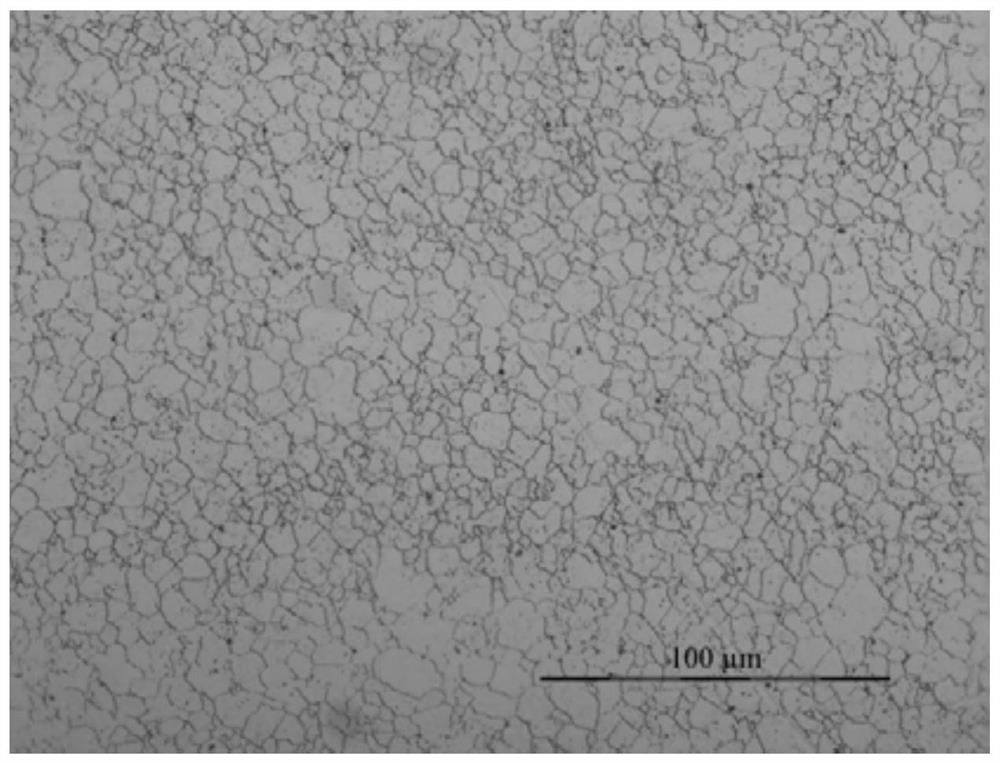

Image

Examples

Embodiment Construction

[0073]A kind of Nb, V micro-alloyed gear steel, comprising the following chemical composition in weight percentage: C: 0.15-0.19%, Si: 0.15-0.30%, Mn: 0.60-0.90%, Cr: 1.60-1.80%, Mo: 0.20 ~0.35%, Nb: 0.025~0.040%, Ni: 1.50~1.70%, Al: 0.020~0.040%, P: ≤0.010%, S: ≤0.010%, V: 0.05~0.20%, T.O: ≤10ppm, [ H]: ≤1.0ppm, [N]: 80-120ppm, Al / [N]: 2.5~5.0, the rest are Fe and unavoidable impurity elements, among them, Km=C+Mn / 6+(Cr+Mo+ V) / 5+(Ni+Cu) / 15+10Nb, and Km: 0.97-1.37.

[0074] It adopts the process of electric arc furnace smelting-LF refining-RH vacuum treatment-continuous casting-hot rolling-slow cooling, as follows:

[0075] The continuous casting slab is heated and kept at 1230-1280°C for ≥5 hours before round steel rolling. The rolling start temperature is 1120-1180°C and the final rolling temperature is 930-980°C. After rolling, it is cooled by a cooling bed to ≤650°C and slowly cooled , the slow cooling time is 48 hours, and the skin is ground and peeled after leaving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com