Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Guaranteed surface hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

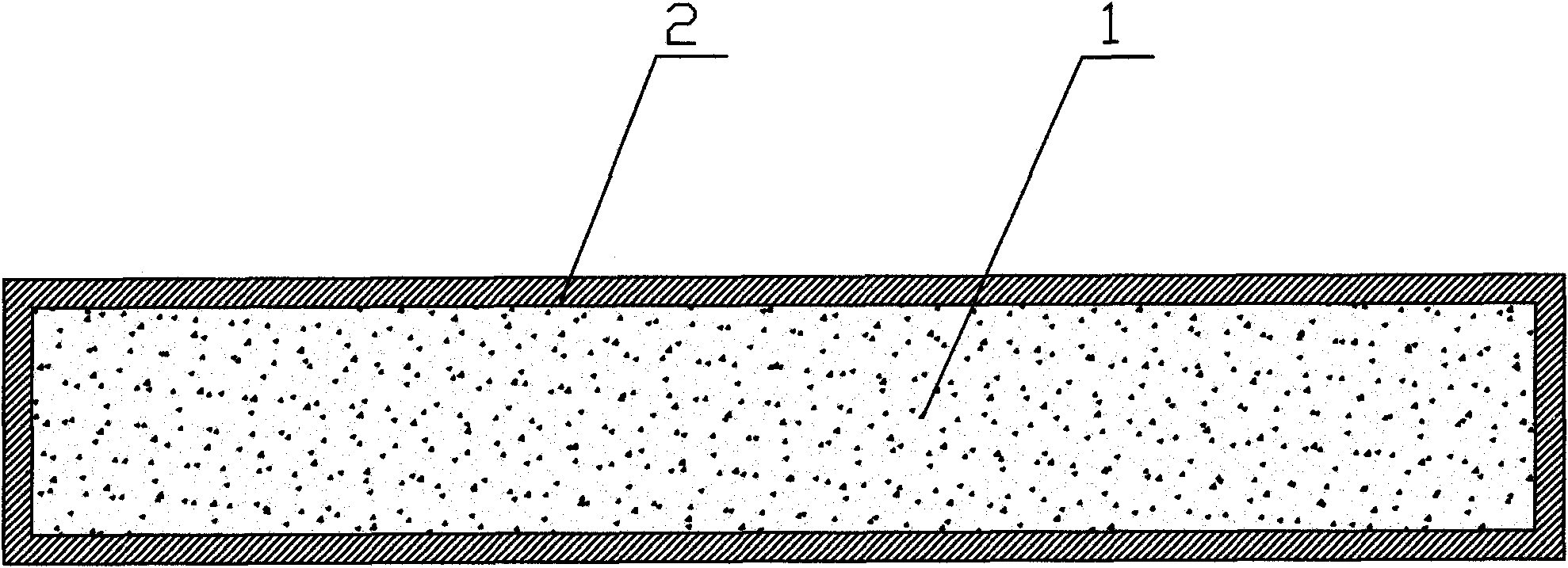

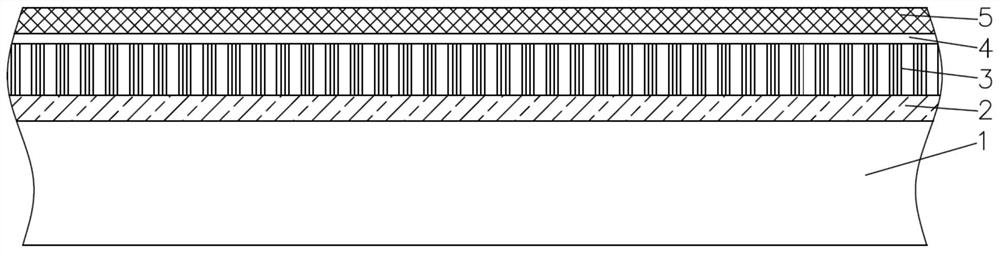

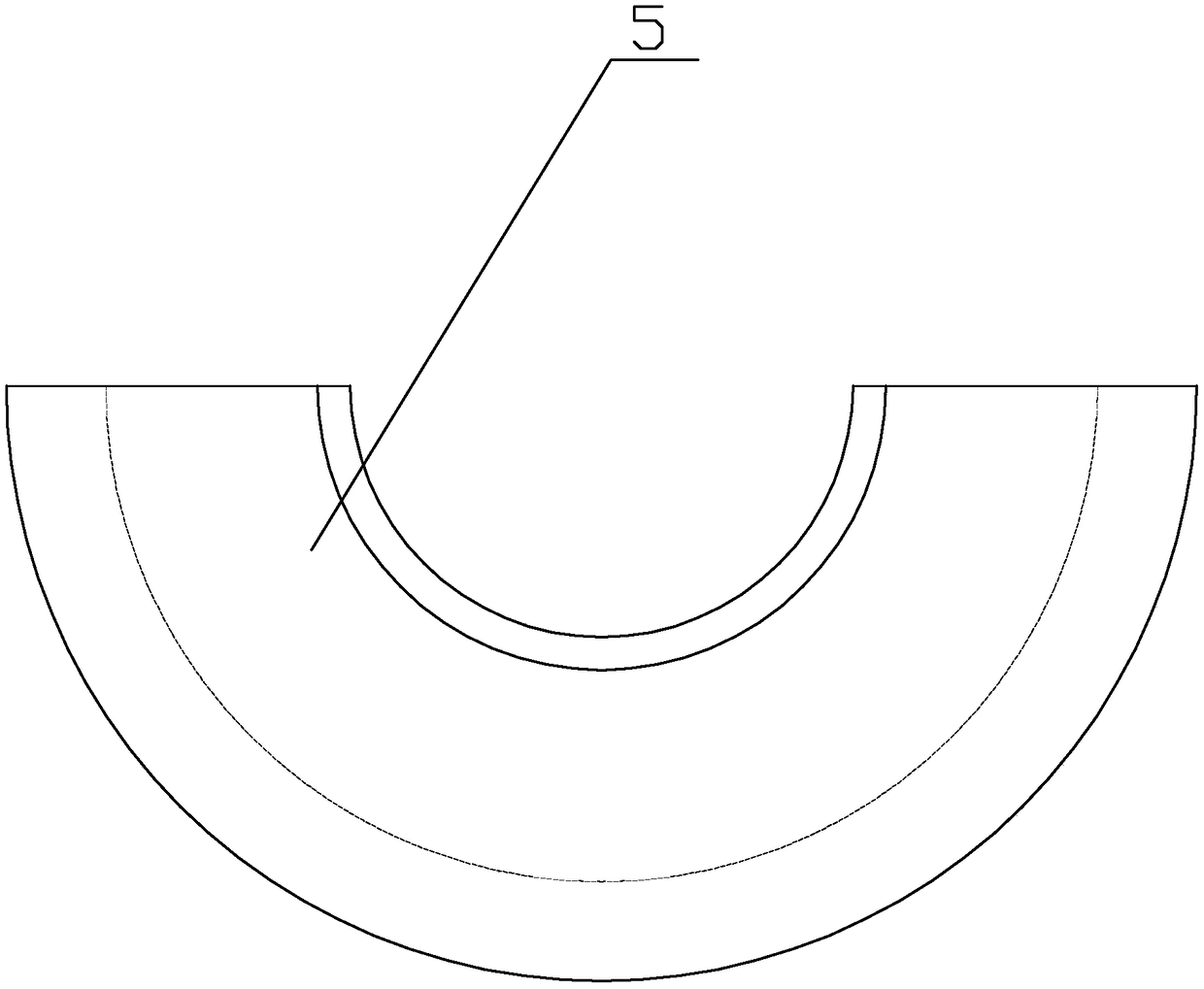

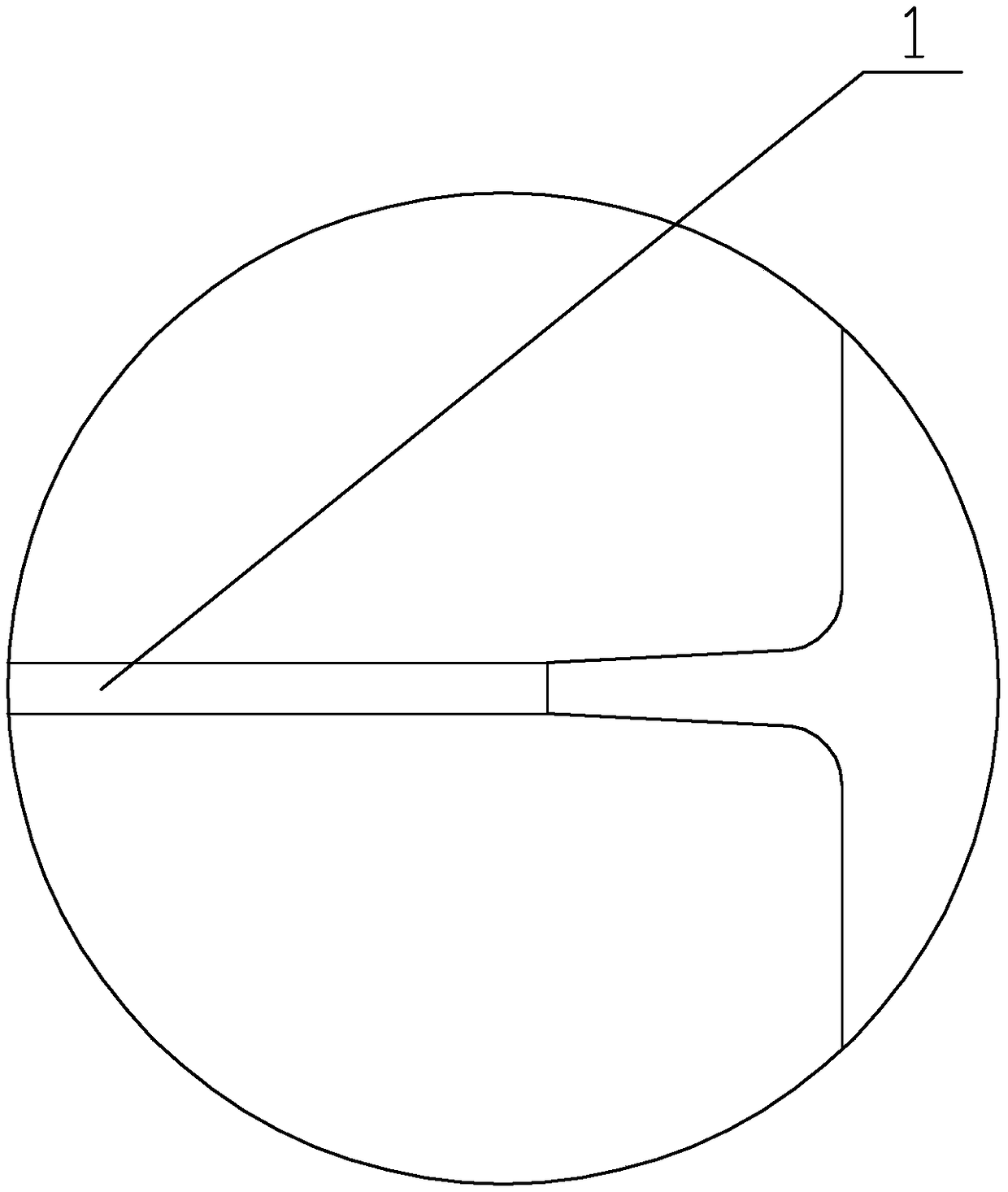

Cover plate, preparation method of cover plate, display panel and display device

PendingCN108831305AImprove bending reliabilityGuaranteed surface hardnessDigital data processing detailsCasings/cabinets/drawers detailsDisplay deviceHardness

The invention relates to the technical field of display, and discloses a cover plate, a preparation method of the cover plate, a display panel and a display device. The bending reliability and deformation recovery reliability of the cover plate are improved. The cover plate comprises a transparent substrate layer and a hardening layer located above the transparent substrate layer, wherein the transparent substrate layer comprises a bent area and a non-bent area; soft hardening materials and rigid hardening materials are alternately arranged on the portion, on the bent area, of the hardening layer; the portion, on the non-bent area, of the hardening layer is provided with a rigid hardening material. In the cover plate, the bent area is provided with the flexible hardening materials so thatthe hardening layer breaking phenomenon cannot occur when the bending radius of the bent area of the cover plate is small, and then the bending reliability of the cover plate can be improved. Meanwhile, the rigid hardening materials of the bent area and the rigid hardening material of the non-bent area are arranged so that the surface hardness of the cover plate can be guaranteed, the cover platecan still restore a flat state after dynamic bending or long-time static bending.

Owner:BOE TECH GRP CO LTD

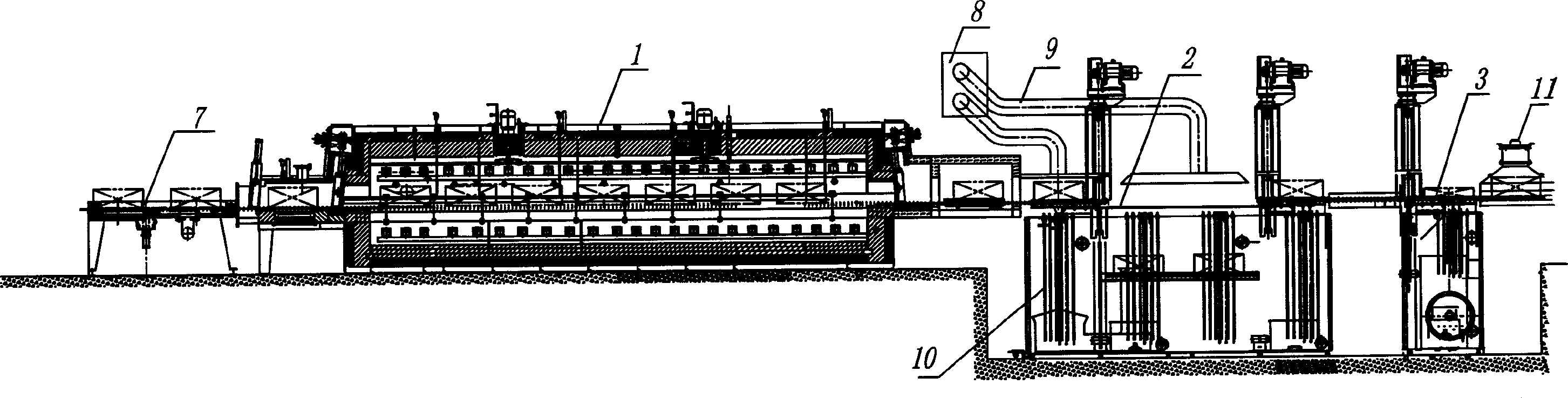

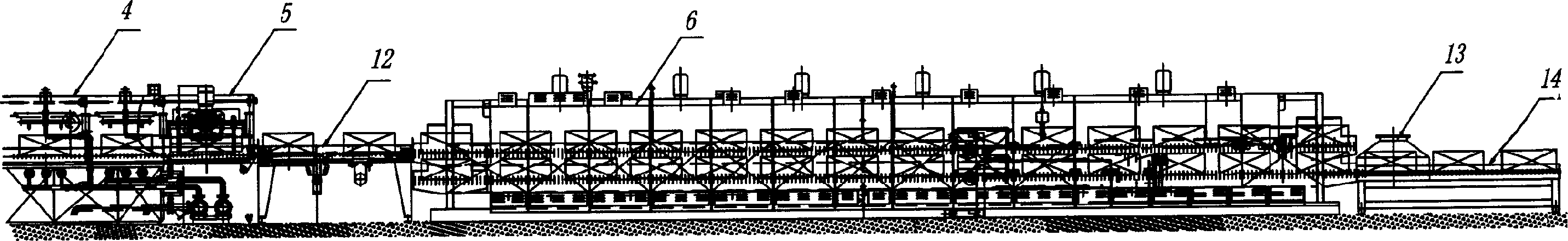

Stepped quenching process and its apparatus suitable for bainite and martensite quenching

InactiveCN1884592ASimple processing methodImprove the quality of heat treatmentQuenching agentsQuenching devicesProduction lineHearth

This invention involves a kind of step quenching process which is suitable for Bainitic and Martensite quenching and the equipment utilizing this step quenching process. The workflow includes: heating, quenching in low-temperature nitrate groove and isothermal; turn to oil grooves to cool down, wash and dry; turn to air furnace for isothermal temper. The above step quenching is performed in roller hearth furnace production line. After adjusting the technology parameter, this production line can undergo Bainitic step quenching and Martensite step quenching. This production line is composed mainly by roller hearth heating furnace, nitrate groove, oil groove, cleaner, dryer and temper furnace. This invention can improve the heat treatment quality; reduce the amount of nitrate and pollution. This production line can undergo normal Martensite quenching, Martensite step quenching and Bainitic step quenching, so to reduce investiment and increase the effeiciency.

Owner:北京时代新人轴承有限公司 +1

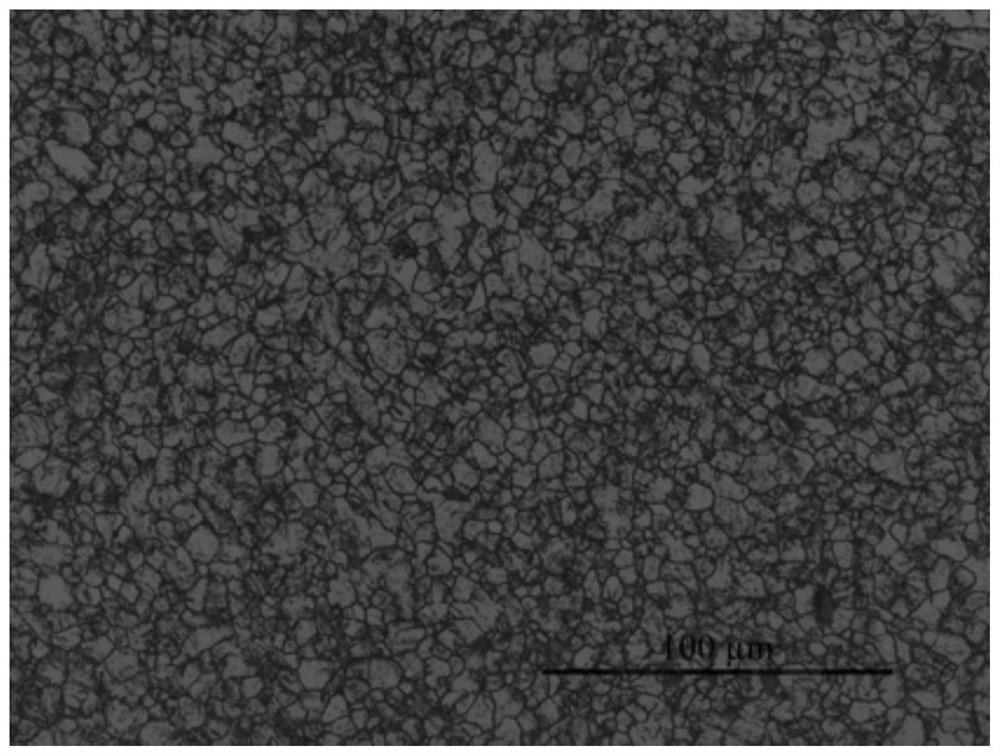

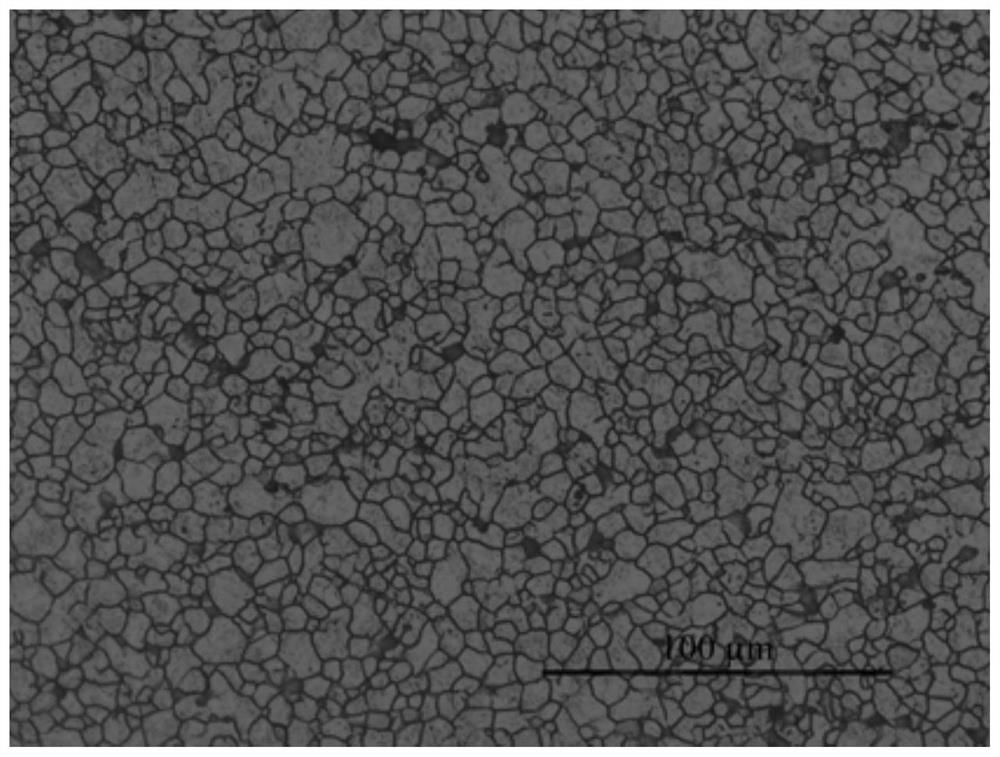

Ultrafine crystal grain semi-trailer axle tube material and processing method of axle tube

InactiveCN101892441AGuaranteed surface hardnessGuaranteed ultra-fine grainRoll mill control devicesMetal rolling arrangementsChemical compositionHardness

The invention discloses an ultrafine crystal grain semi-trailer axle tube material and a processing method of an axle tube. The ultrafine crystal grain semi-trailer axle tube comprises the chemical components by weight percent: 0.23-0.28% of C, 0.15-0.30% of Si, 1.30-1.45% of Mn, less than or equal to 0.03% of P, less than or equal to 0.035% of S, less than or equal to 0.01% of Al, less than or equal to 0.25% of Cu, less than or equal to 0.25% of Ni, less than or equal to 0.25% of Cr, less than or equal to 0.15% of Mo and balance Fe and impurities. By adopting residual heat outer wall atomization and residual heat inner wall tempering technique, the invention guarantees the surface hardness of a steel tube, ensures crystal grains to be ultrafine and the impact toughness to be more superior, greatly improves the strength, guarantees the anti-fatigue property of the ultrafine crystal grain semi-trailer axle tube, greatly prolongs the service life and increases the safety factor.

Owner:ANHUI TIANDA OIL PIPE

Gear ring machining process

The invention discloses a gear ring machining process, which comprises the following steps of forging, rough turning, tempering, fine turning, gear shaping, fine gear broaching, carburizing, press quenching and shot blasting to obtain a finished product. According to the gear ring machining process provided by the invention, the product has the advantages of higher surface hardness, high core hardness and deep hardened layer; meanwhile, the machining cost is reduced, and the gear ring size can be ensured.

Owner:江国辉

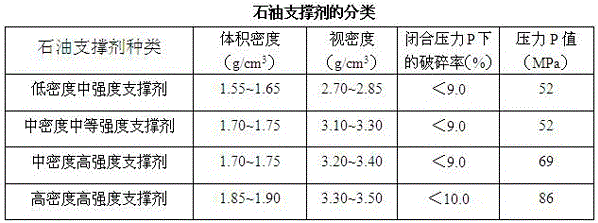

Low-density and moderate-strength oil fracturing propping agent and preparing method thereof

ActiveCN104479667AGood appearanceImprove the ability to resist crushingFluid removalDrilling compositionSlagManganese oxide

The invention relates to a low-density and moderate-strength oil fracturing propping agent and a preparing method thereof, and belongs to the technical field of oil-gas well fracturing in oil production. The low-density and moderate-strength oil fracturing propping agent is made of powder and a silica solution accounting for four percent of the weight of the oil fracturing propping agent. The powder is formed by mixing, by weight, 85-90 parts of raw bauxite, 5-8 parts of molybdenum ore gangue, 2-3 parts of bentonite and 2-5 parts of composite additive. The molybdenum ore gangue and the composite additive composed of manganese oxide powder and ferronickel slag powder are added, good balance is obtained between obvious propping agent density reduction and certain strength keeping, the developed oil propping agent has good comprehensive performance, it is ensured that the propping agent has considerable strength, the firing temperature of the propping agent is reduced, the purposes of saving energy and reducing consumption are achieved, the wasted mineral is fully utilized, and waste resources are repeatedly utilized.

Owner:LUOYANG INST OF SCI & TECH +1

Ultralow-density cordierite petroleum fracturing propping agent and preparation method thereof

ActiveCN106431349AHigh hardnessHigh mechanical strengthFluid removalDrilling compositionCordieriteManganese oxide

The invention provides an ultralow-density cordierite petroleum fracturing propping agent and a preparation method thereof. A principal crystalline phase of the popping agent is of a cordierite structure and is formed by firing coal ash, caustic-burned magnesia powder, Jiaozuo clay and a composite mineralizer, and the composite mineralizer is formed by mixing manganese oxide and barium carbonate according to the equal weight ratio. A large amount of high-silicone, low-aluminum, low-calcium and low-ignition-loss neutral coal ash is adopted as a main raw material, and the density index of the popping agent is effectively reduced; through the special processing and treating processes such as special pre-sintering on an important raw material magnesite and ultrafine grinding on batches and the composite mineralizer technology, it is effectively guaranteed that high-hardness and low-density principal crystalline phase minerals are formed in a system at high temperature, therefore, and it is guaranteed that the finished ultralow-density popping agent has high mechanical strength; the firing temperature of the popping agent is reduced, and the purposes of energy saving and consumption reduction are achieved.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

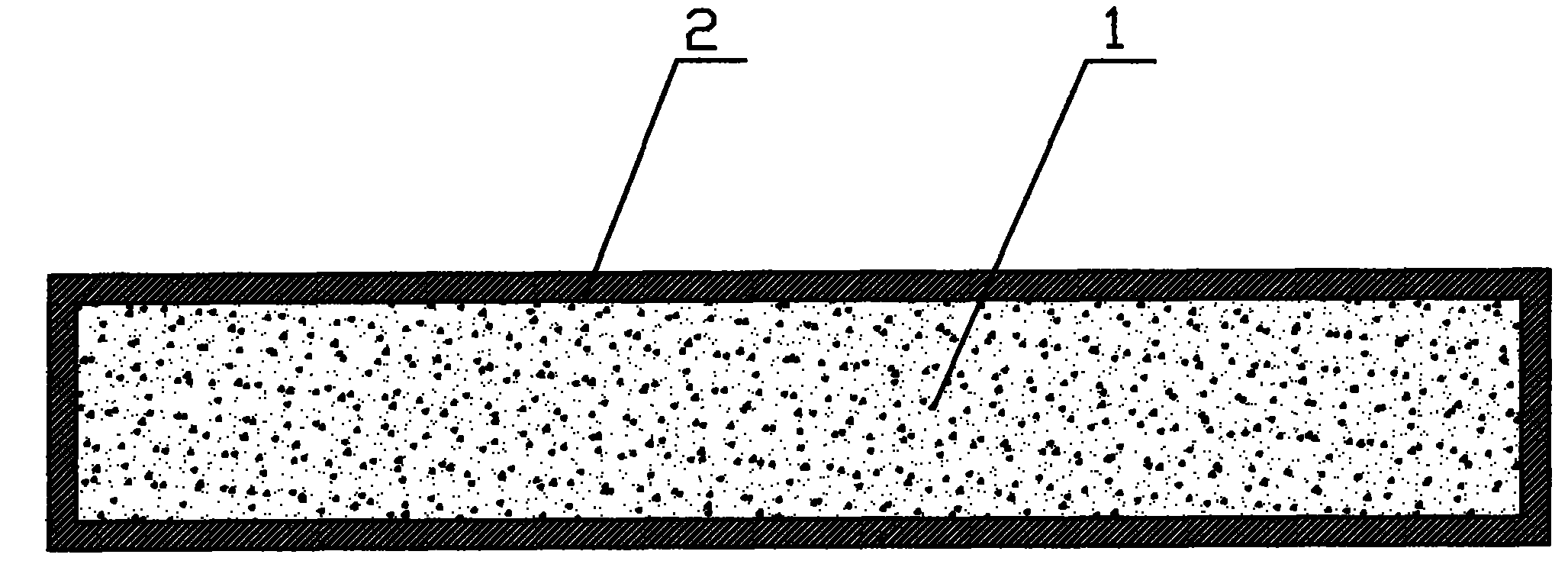

Wood-plastic floor processing method

InactiveCN101787784AGuaranteed surface hardnessGuaranteed surface strengthLayered productsFlooringPolymer scienceHardness

The invention discloses a wood-plastic floor processing method which comprises the following steps that: first, wood-plastic material and polymer foam are respectively extruded through an extruder simultaneously, and then the two extruded materials form the floor with the polymer foam material in the middle part and the wood-plastic material on the surface through a forming mold simultaneously. The middle part of the floor processed through the method is provided with the polymer foam material, and the surface thereof is provided with the wood-plastic material; the weight of the polymer foam material is lighter, the template quality can be effectively reduced, the middle part of the floor is solidly filled, so that the floor looks more beautiful; and the wood-plastic material on the surface of the floor can fully ensure the surface hardness and the strength of the floor, and does not affect the use quality of the floor. Therefore, the wood-plastic floor has the advantages of light weight and attractive appearance.

Owner:昆山吉尔吉新型建材有限公司

Hot-rolled steel plate exhibiting excellent cold workability and excellent surface hardness after working

InactiveCN104903484AGuaranteed surface hardnessExtend your lifeFurnace typesHeat treatment furnacesPearliteImpurity

This hot-rolled steel plate has: a plate thickness of 3 to 20mm; a composition which contains, in mass%, up to 0.3% (exclusive of 0%) of C, up to 0.5% (exclusive of 0%) of Si, 0.2 to 1% of Mn, up to 0.05% (exclusive of 0%) of P, up to 0.05% (exclusive of 0%) of S, 0.01 to 0.1% of Al and 0.008 to 0.025% of N with the balance consisting of iron and unavoidable impurities and which satisfies two relationships, namely, the content of solid-soluted N ≥ 0.007% and 10C+N≤3.0 (wherein C and N represent the contents of C and N respectively); and a structure which contains, in area fraction with respect to the whole structure, less than 20% of pearlite with the balance being ferrite and in which the mean grain diameter of the ferrite is 3 to 35μm. The hot-rolled steel plate exhibits good cold workability during cold working, and exhibits a prescribed surface hardness after the working.

Owner:KOBE STEEL LTD

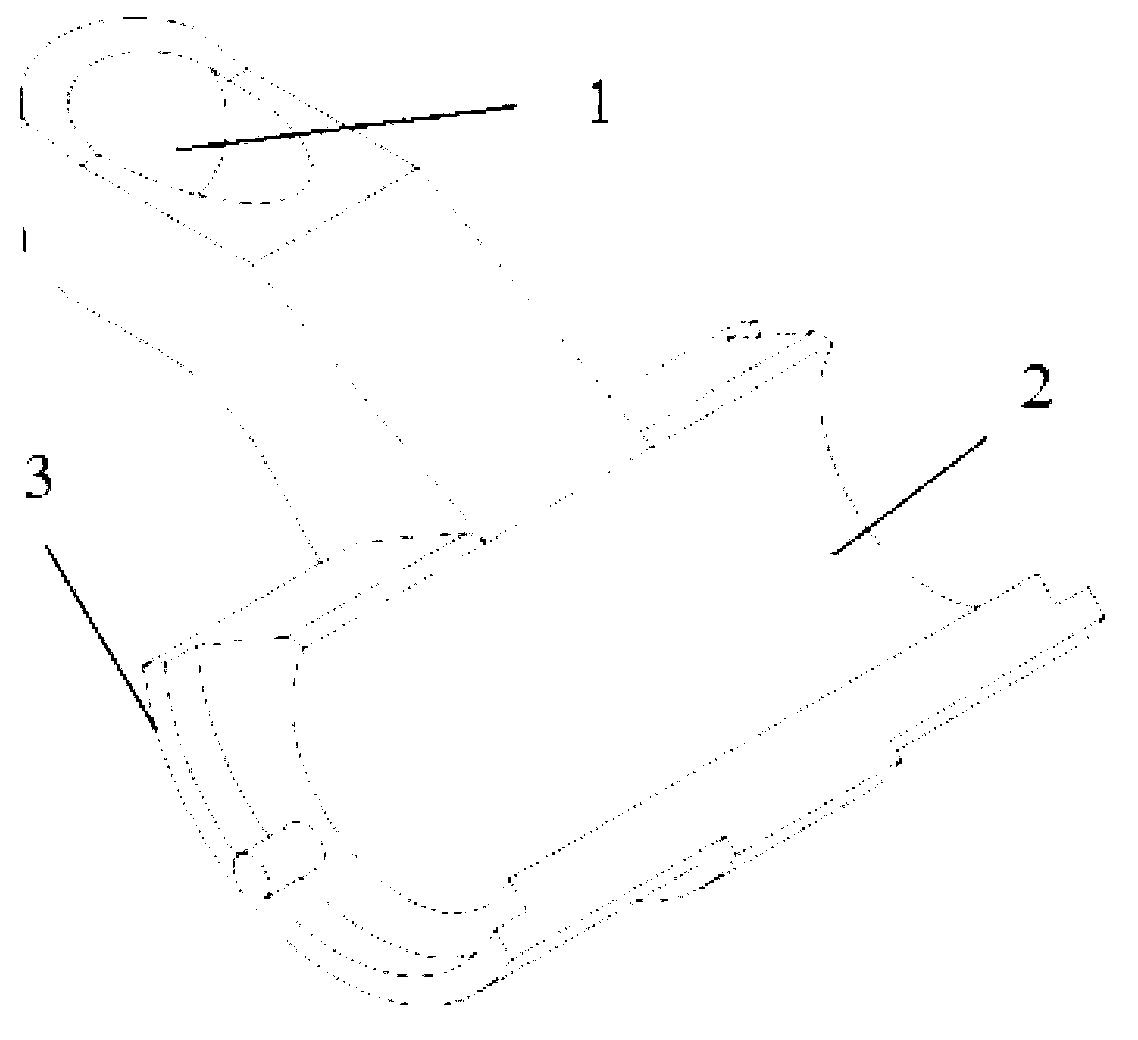

Machining technology of cam reinforcement lever mechanism

The invention relates to a machining technology of a cam reinforcement lever mechanism. The machining technology includes the steps of rough machining, heat treatment and finish machining. Due to the fact that an arc surface of a workpiece is machined through a grinding method, the finish degree of the arc surface of the workpiece is improved, rotation resistance in heavy load of the workpiece is reduced, and product performance and product consistency are improved. Due to the fact that machining devices for linear cutting and the like are replaced by a grinding machine, work efficiency is improved, and volume production is improved beneficially.

Owner:WUHAN QUNFENG MACHINERY

Polypropylene resin composition, molded article produced from the resin composition, and method for production of the molded article

InactiveCN101910287AExcellent gas barrier performanceIncrease freedomFlat articlesPolypropylenePolymer chemistry

Disclosed is a polypropylene resin composition which comprises: a resin component comprising 55 to 99 mass% of polypropylene and 1 to 45 mass% of polyglycolic acid; and a reactive compatibilizing agent in an amount of 0.3 to 30 parts by mass relative to 100 parts by mass of the resin component. Also disclosed is a molded article which is produced from the polypropylene resin composition. In the molded article, a dispersion phase composed of polyglycolic acid is present in a matrix composed of polypropylene, wherein polyglycolic acid is dispersed in the matrix in the form of separate thin films. Further disclosed is a method for producing the molded article.

Owner:KUREHA KAGAKU KOGYO KK

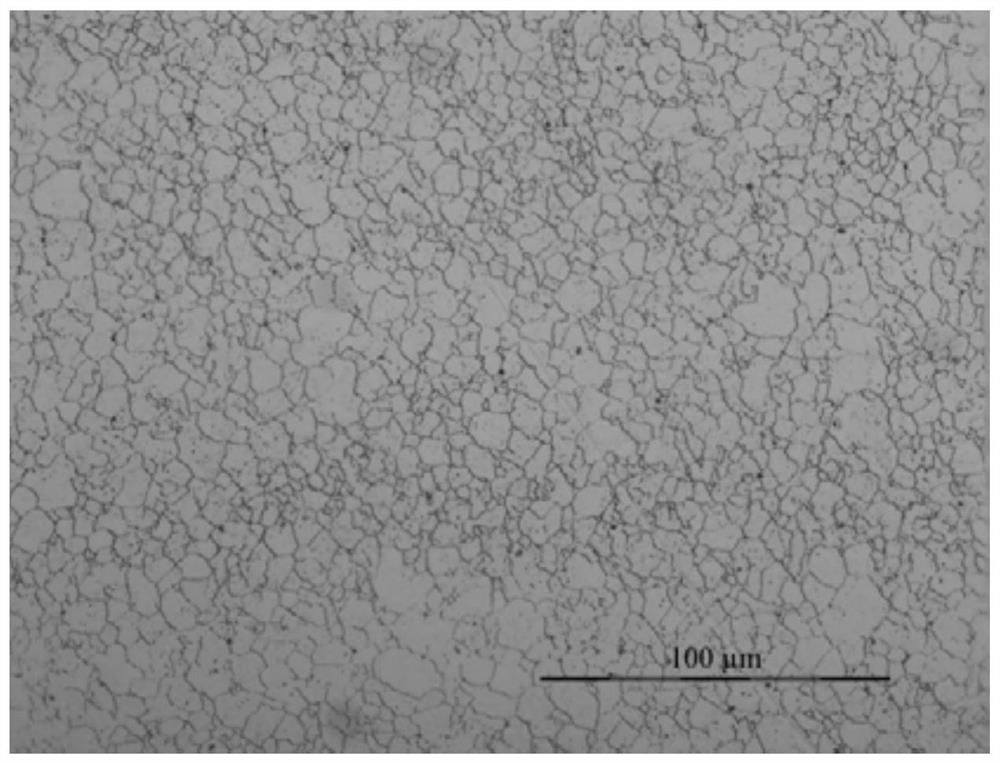

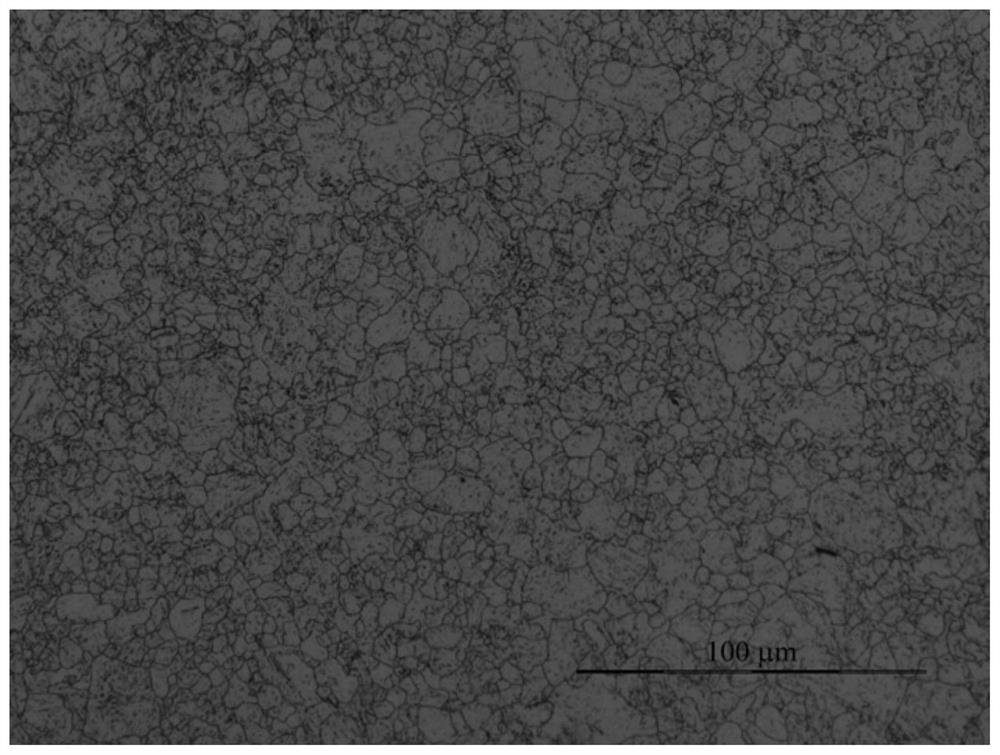

Nb and V microalloyed gear steel, preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel

ActiveCN113430461AGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingProcess efficiency improvementElectric arc furnaceGear wheel

The invention discloses Nb and V microalloyed gear steel, a preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel. Nb and V microalloying is adopted, and the Nb and V microalloyed gear steel with a ferrite and pearlite structure is obtained. The production process comprises the steps of electric arc furnace smelting, LF refining, RH vacuum treatment, continuous casting, hot rolling and slow cooling. After the gear steel subjected to hot rolling and slow cooling is subjected to heat treatment, the Nb and V microalloyed gear steel with the tensile strength larger than or equal to 1465 MPa, the yield strength larger than or equal to 1340 MPa, the ductility larger than or equal to 14%, the percentage reduction of area larger than or equal to 50% and the impact energy KV2 larger than or equal to 95 J is obtained. The Nb and V microalloyed carburized gear steel with high contact fatigue performance is obtained after the gear steel subjected to hot rolling and slow cooling is subjected to carburizing treatment, and under the condition that the pressure stress is 4.0 GPa, the rated fatigue life L10 of the Nb and V microalloyed carburized gear steel is larger than or equal to 5 * 10 < 7 >, and the median fatigue life L50 of the Nb and V microalloyed carburized gear steel is larger than or equal to 8.2 * 10 < 7 >.

Owner:MAANSHAN IRON & STEEL CO LTD

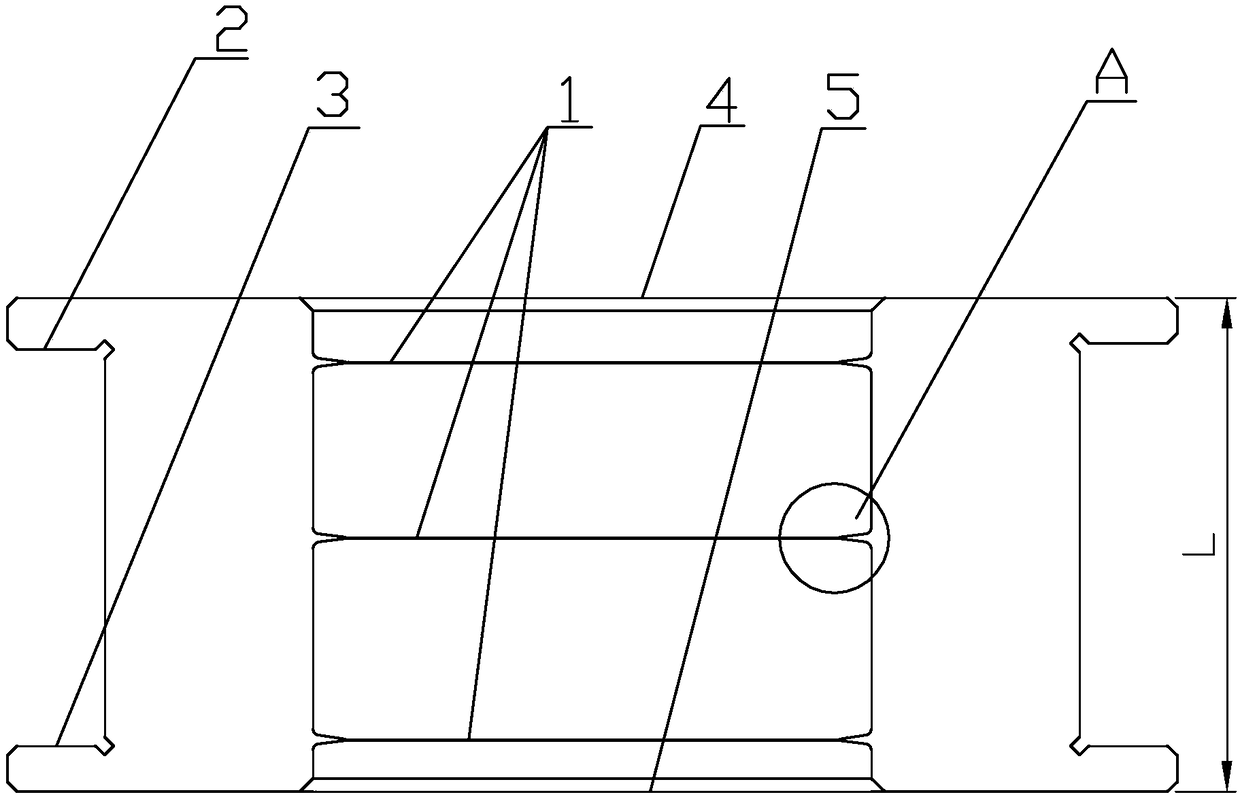

High-temperature-resistant composite ceramic insulating coating and preparation method thereof

ActiveCN112725720AImprove antioxidant capacityImprove long-term reliabilityMolten spray coatingEfficient propulsion technologiesOxide ceramicInter layer

The invention provides a high-temperature-resistant composite ceramic insulating coating. A transition layer (2) made of a metal compound material, a middle layer (3) made of pure ceramic, a metal layer (4) made of a metal compound material and a surface layer (5) with holes sealed by metal oxide ceramic are sequentially arranged on the surface of an alloy matrix (1) outwards. The composite ceramic insulating coating is obtained by sequentially pretreating a base body, sequentially preparing the transition layer (2), the middle layer (3), the metal layer (4) and the surface layer (5) by adopting plasma spraying and finally performing laser cladding on the surface layer (5). The high-temperature-resistant composite ceramic insulating coating is good in high-temperature oxidation resistance, high in insulativity, excellent in environmental adaptability and high in working reliability.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

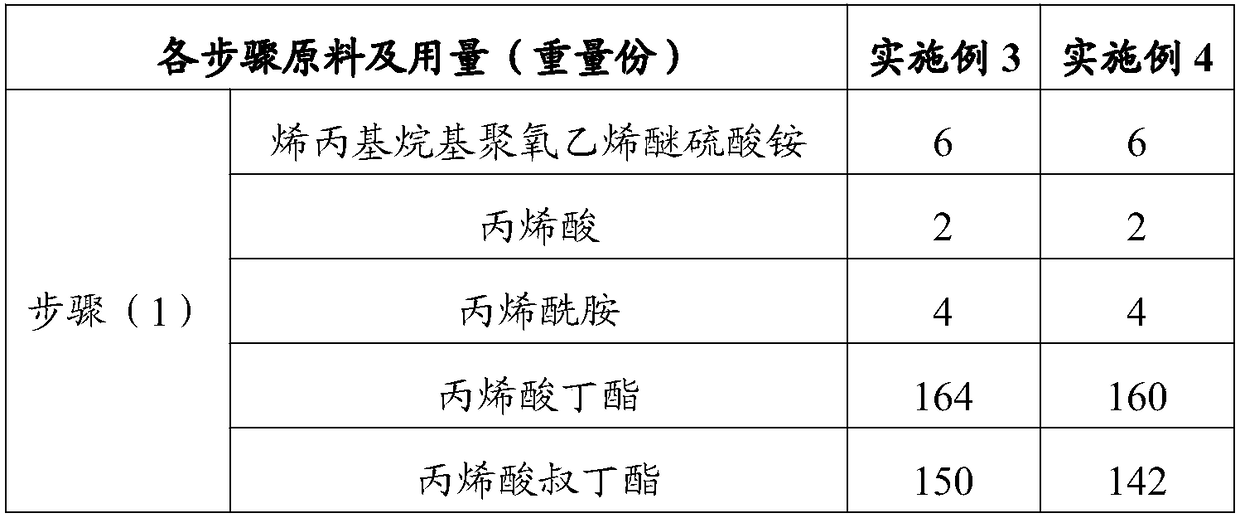

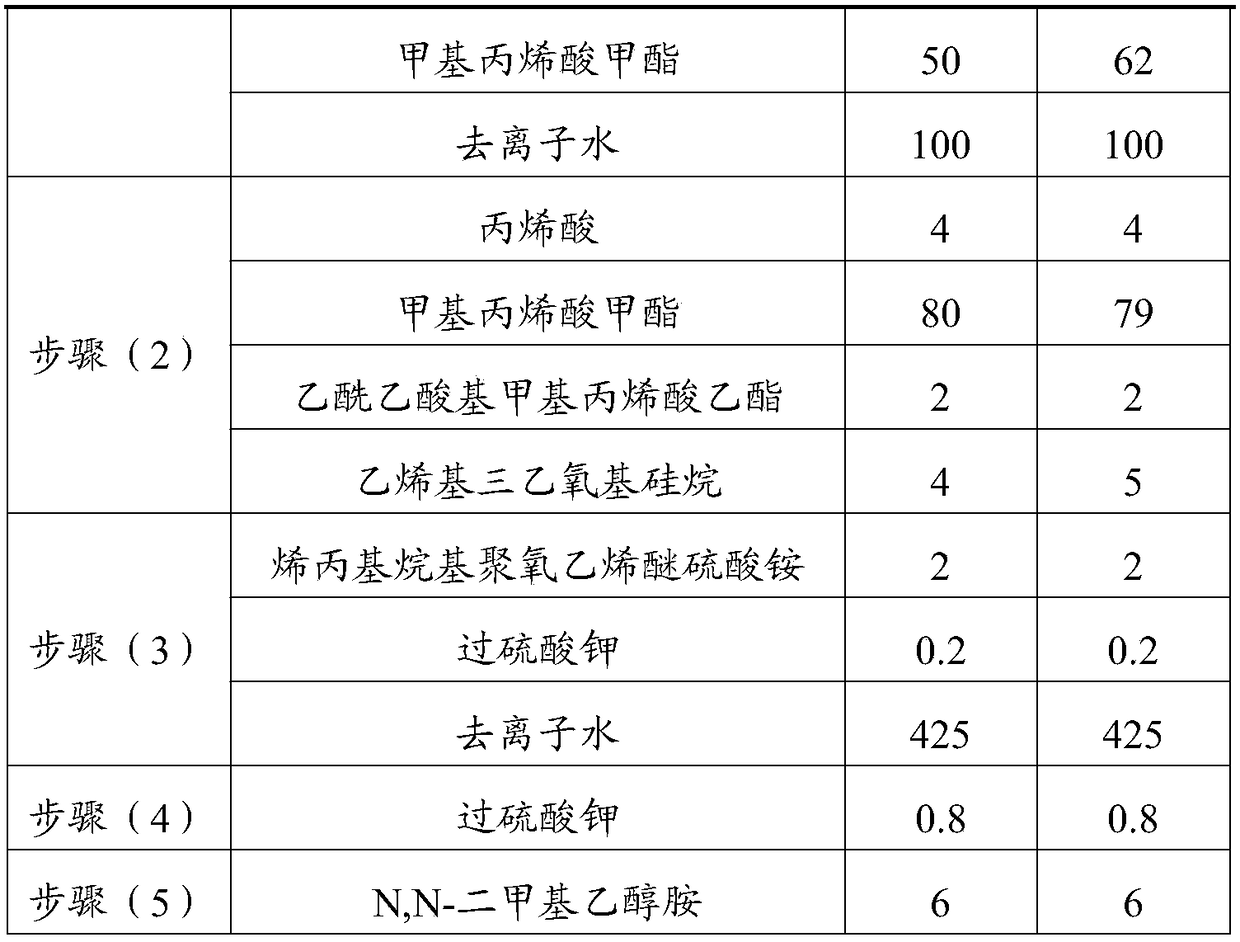

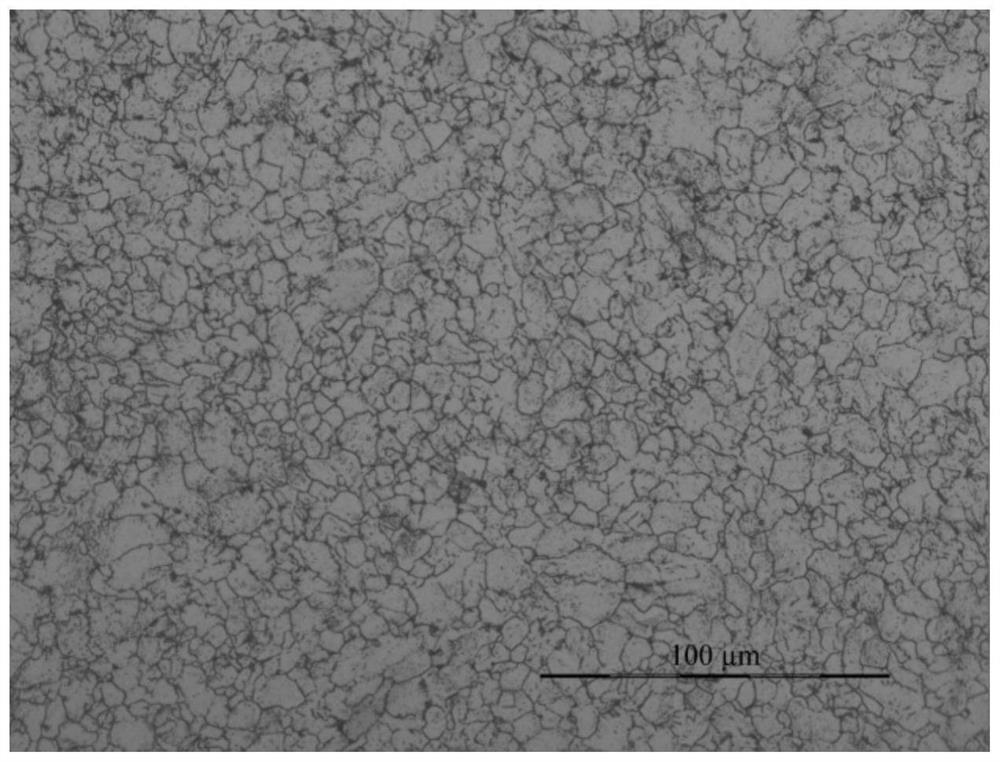

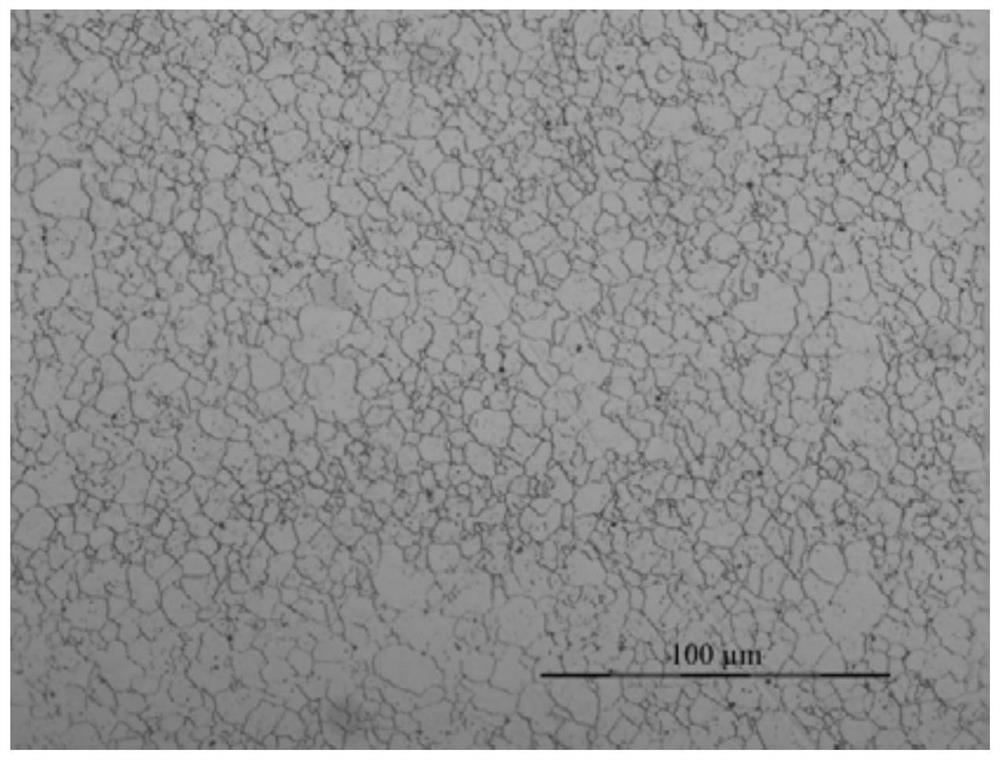

Acrylic emulsion specially used for stone-like coating as well as preparation method and application of acrylic emulsion

The invention provides acrylic emulsion specially used for a stone-like coating as well as a preparation method and application of the acrylic emulsion, belonging to the technical field of the stone-like coating. The acrylic emulsion is prepared from the following raw materials in parts by mass: 6-8 parts of acrylic acid, 4 parts of acrylamide, 160-170 parts of butyl acrylate, 130-150 parts of methyl methacrylate, 130-150 parts of a special acrylate monomer, 4-8 parts of a reactive emulsifier, 2-4 parts of a room-temperature self-crosslinking monomer, 3-5 parts of a silane coupling agent, 1-2parts of persulfate, 5-6 parts of a pH adjuster and 500-550 parts of water, wherein the special acrylate monomer is tert-butyl acrylate. The minimum film formation temperature (MFT) of the acrylic emulsion is 0 DEG C; when being used for film formation of the stone-like coating, a film can be formed at 0 DEG C without adding a film-forming aid; when the acrylic emulsion is used for the stone-likecoating, the obtained stone-like coating is excellent in performance, and the standard bonding strength is 1.0-1.3MPa.

Owner:浙江科力森化学有限公司

Nb and B microalloyed gear steel, preparation method, heat treatment method and carburizing treatment method thereof and carburized gear steel

ActiveCN113416899AGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingElectric arc furnaceGear wheel

The invention discloses Nb and B microalloyed gear steel, a preparation method, a heat treatment method and a carburizing treatment method thereof and carburized gear steel. Nb and B microalloying is adopted, and the Nb and B microalloyed gear steel with a ferrite and pearlite structure is obtained; the production process of electric arc furnace smelting, LF refining, RH vacuum treatment, continuous casting, hot rolling and slow cooling is adopted; after the gear steel subjected to hot rolling and slow cooling is subjected to heat treatment, the Nb and B microalloyed gear steel with the tensile strength larger than or equal to 1450 MPa, the yield strength larger than or equal to 1340 MPa, the ductility larger than or equal to 14%, the percentage reduction of area larger than or equal to 50% and the impact energy KV2 larger than or equal to 95J is obtained; and the gear steel subjected to hot rolling and slow cooling is subjected to carburizing treatment to obtain Nb and B microalloyed carburized gear steel with high contact fatigue performance, and under the condition that the pressure stress is 4.0 GPa, the rated fatigue life L10 of the Nb and B microalloyed carburized gear steel is larger than or equal to 5 * 10 < 7 >, and the median fatigue life L50 of the Nb and B microalloyed carburized gear steel is larger than or equal to 8.2 * 10 < 7 >.

Owner:MAANSHAN IRON & STEEL CO LTD

Nb, V and Ti microalloyed gear steel and preparation method thereof, heat treatment method and carburizing treatment method thereof and carburized gear steel

ActiveCN113388783AGuaranteed contact fatigue performanceHigh carbon contentSolid state diffusion coatingElectric arc furnaceGear wheel

The invention discloses Nb, V and Ti microalloyed gear steel and a preparation method thereof, a heat treatment method, a carburizing treatment method and carburized gear steel. By adopting Nb, V and Ti microalloying, the Nb, V and Ti microalloyed gear steel with a ferrite and pearlite structure is obtained; the process of electric arc furnace smelting, LF refining, RH vacuum treatment, continuous casting, hot rolling and slow cooling is adopted for production; the Nb, V and Ti microalloyed gear steel with the tensile strength of larger than or equal to 1455 MPa, the yield strength of larger than or equal to 1320 MPa, the elongation rate of larger than or equal to 15%, the percentage reduction of area of larger than or equal to 50% and the impact energy KV2 of larger than or equal to 95 J is obtained after the gear steel subjected to hot rolling and slow cooling is subjected to heat treatment; after the gear steel subjected to hot rolling and slow cooling is subjected to carburizing treatment, Nb, V and Ti microalloyed carburizing gear steel with high contact fatigue performance is obtained; and under the condition that the pressure stress is 4.0 GPa, the rated fatigue life L10 of the gear steel is larger than or equal to 5*10<7>, and the median fatigue life L50 of the gear steel is larger than or equal to 8.2*10<7>.

Owner:MAANSHAN IRON & STEEL CO LTD

Surface boriding method capable of maintaining high strength of titanium alloy

InactiveCN108950470AGuaranteed surface hardnessGuaranteed surface abrasion resistanceSolid state diffusion coatingWater rinsingBoron carbide

The invention belongs to the technical field of metal surface treatment, and particularly relates to a surface boriding method capable of maintaining high strength of a titanium alloy. The method comprises the following steps: S1, boron carbide powder and cerium oxide powder are weighed to prepare a boriding agent; S2, deoiling, water rinsing, grinding, polishing and ultrasonic cleaning pretreatment is performed on a cut titanium alloy sample and a titanium alloy sample tension component; and S3, the treated titanium alloy sample and titanium sample tension component are subjected to boridingby utilizing the prepared boriding agent. By adopting the surface boriding method, the surface hardness and abrasion resistance of the titanium alloy are ensured; the high strength and plasticity of the titanium alloy material are also ensured by controlling temperature and heat preservation time according to the substrate structure change of the titanium alloy; and the application range of the titanium alloy is expanded.

Owner:NORTHEASTERN UNIV

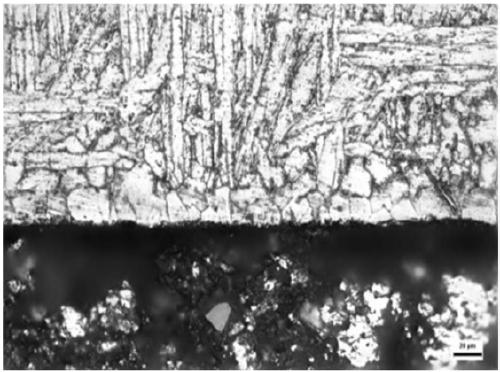

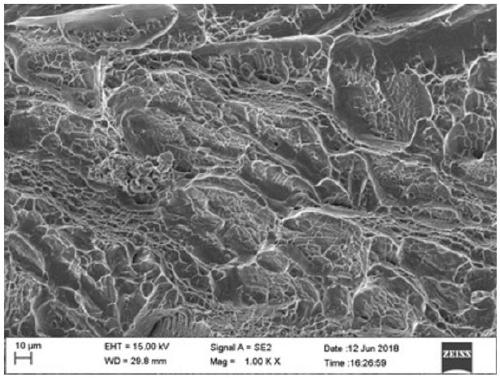

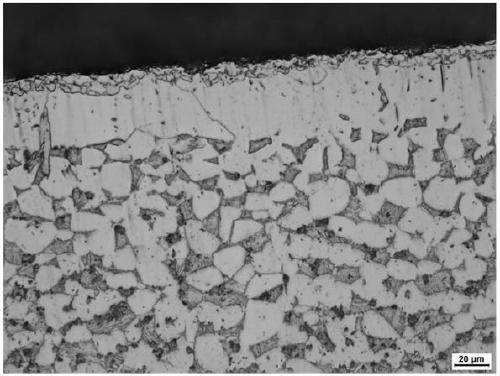

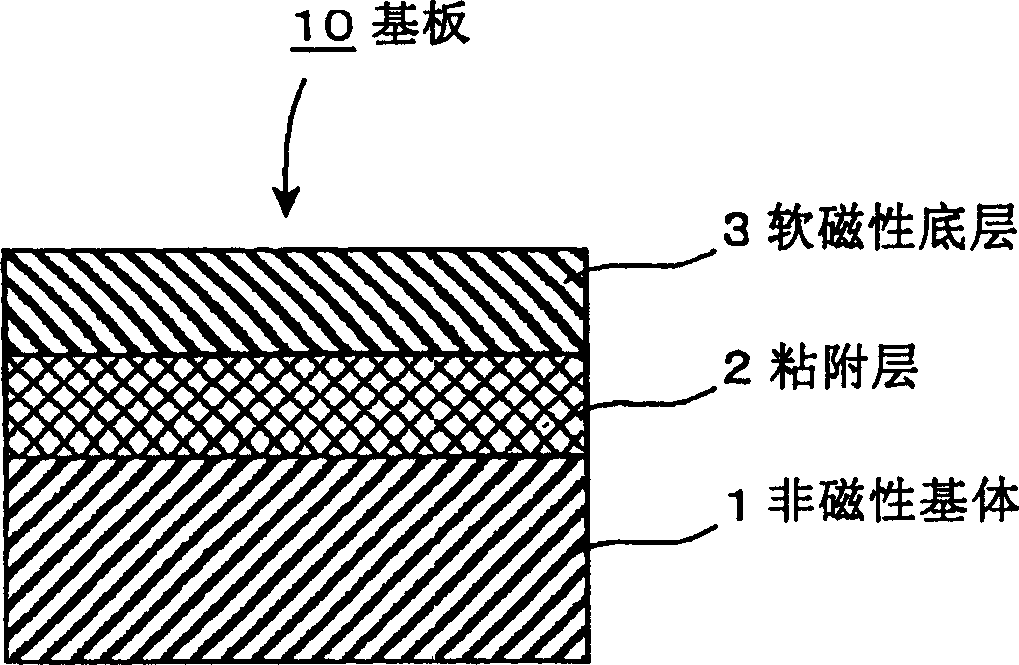

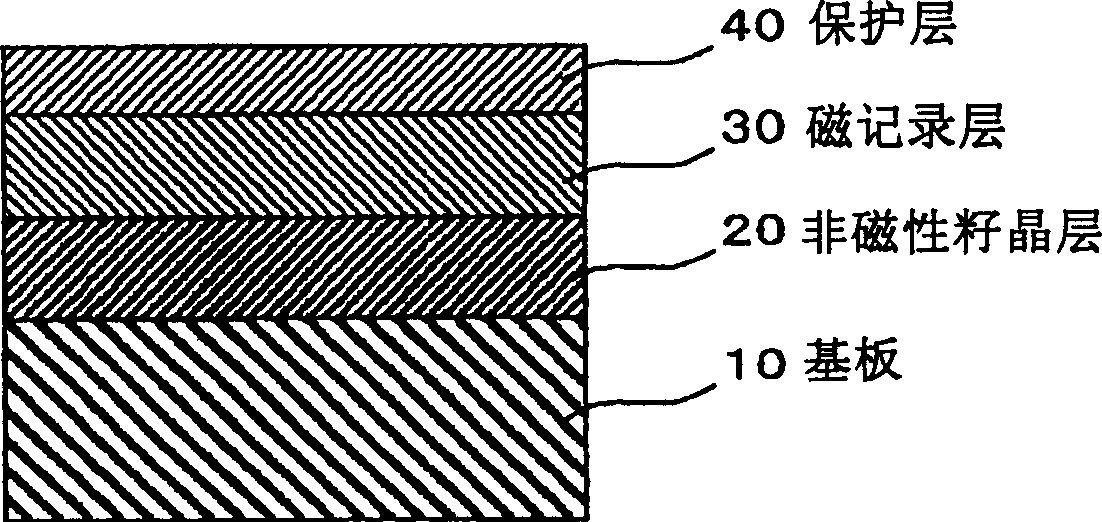

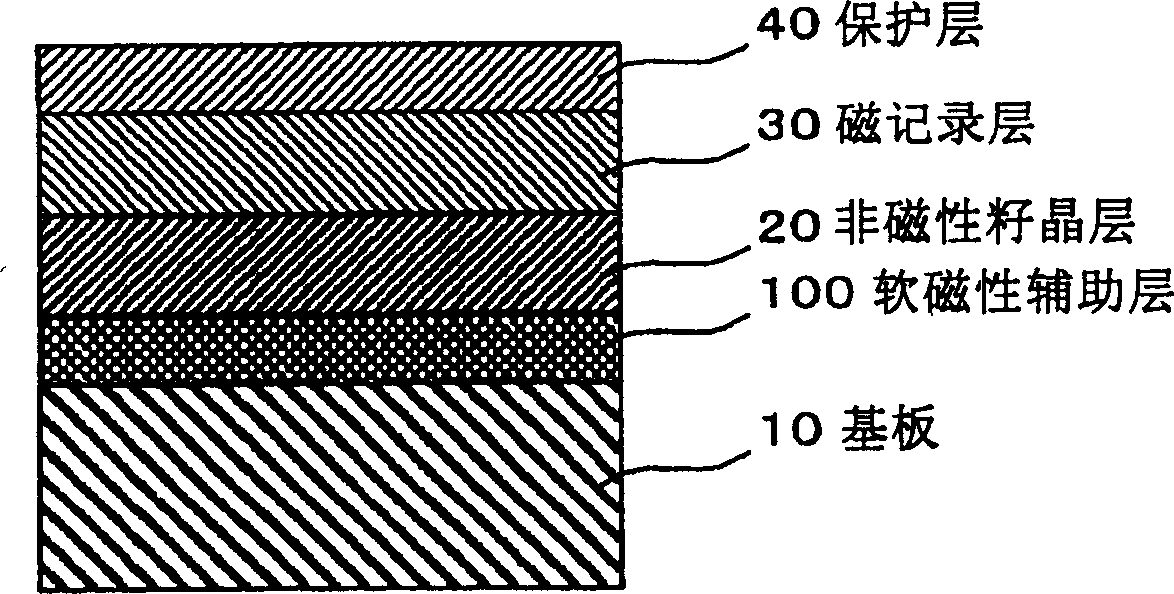

Substrate for a perpendicular magnetic recording medium and a perpendicular magnetic recording medium using the substrate

InactiveCN1677509AGuaranteed surface hardnessAllow mass productionTelevision system detailsMaterial analysis using wave/particle radiationHardnessNon magnetic

Owner:FUJI ELECTRIC CO LTD

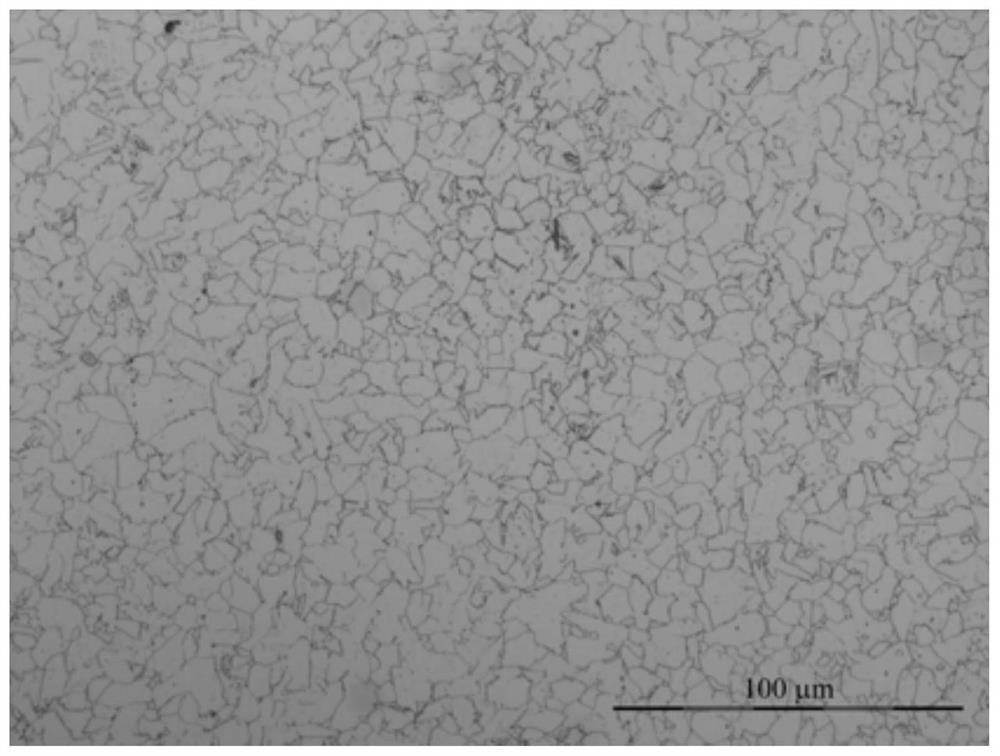

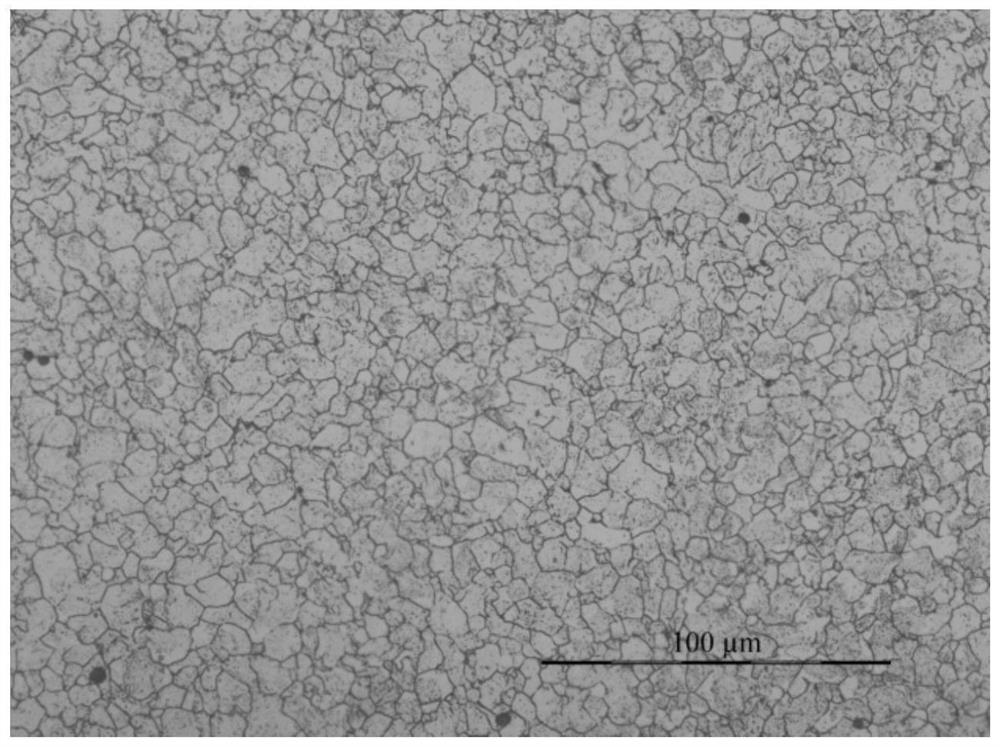

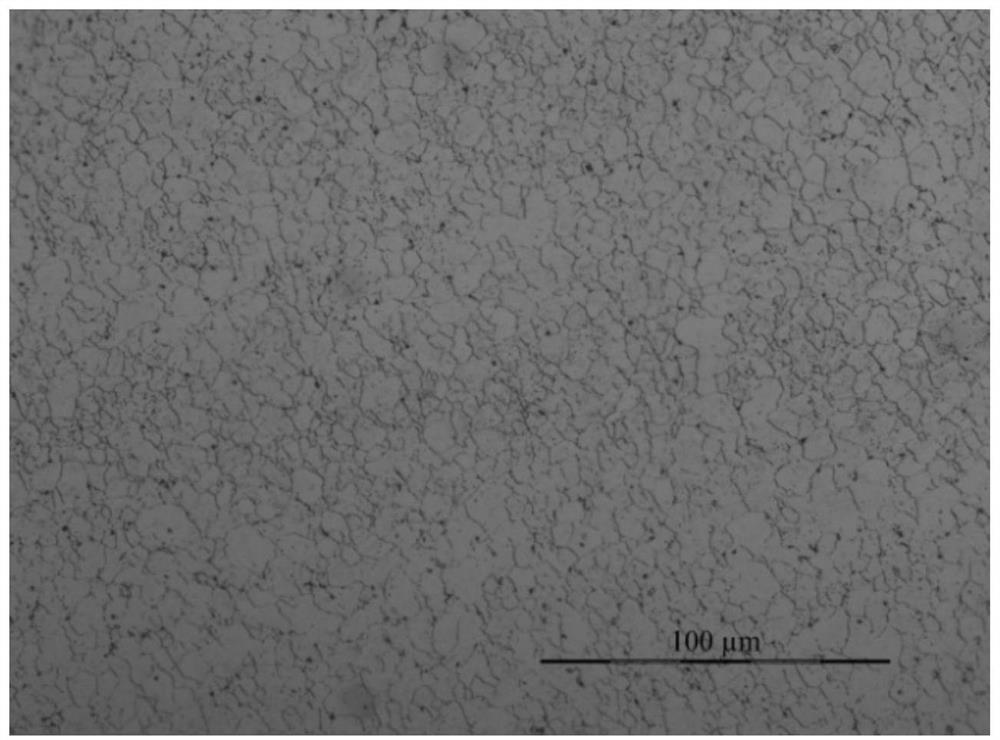

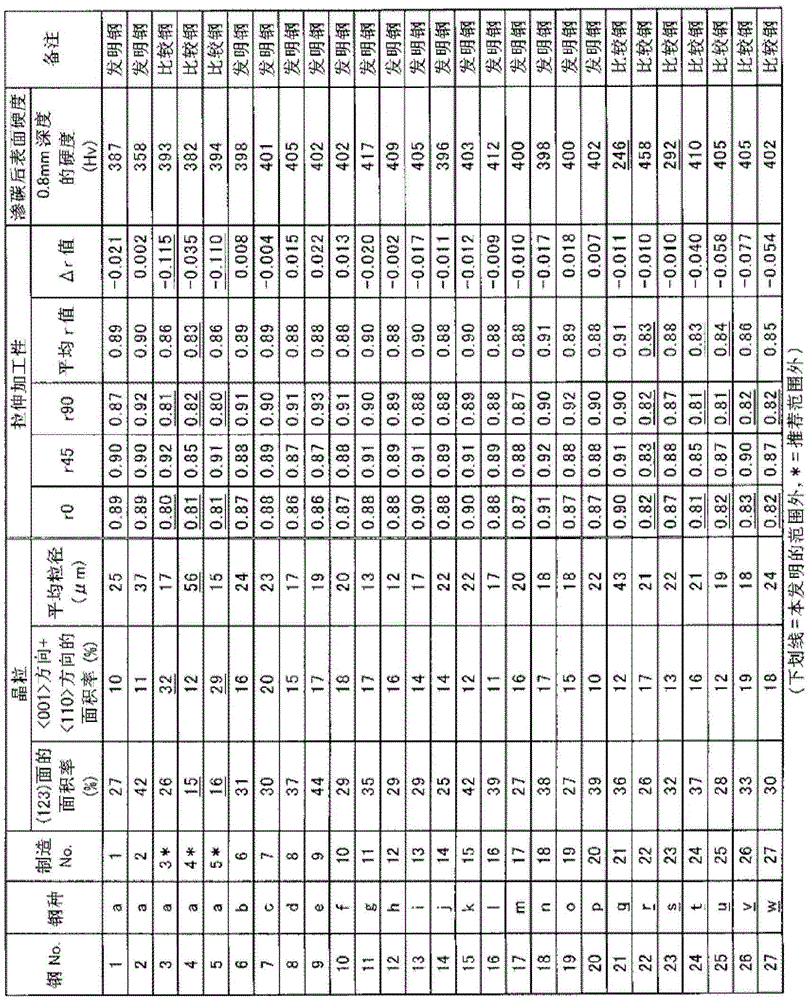

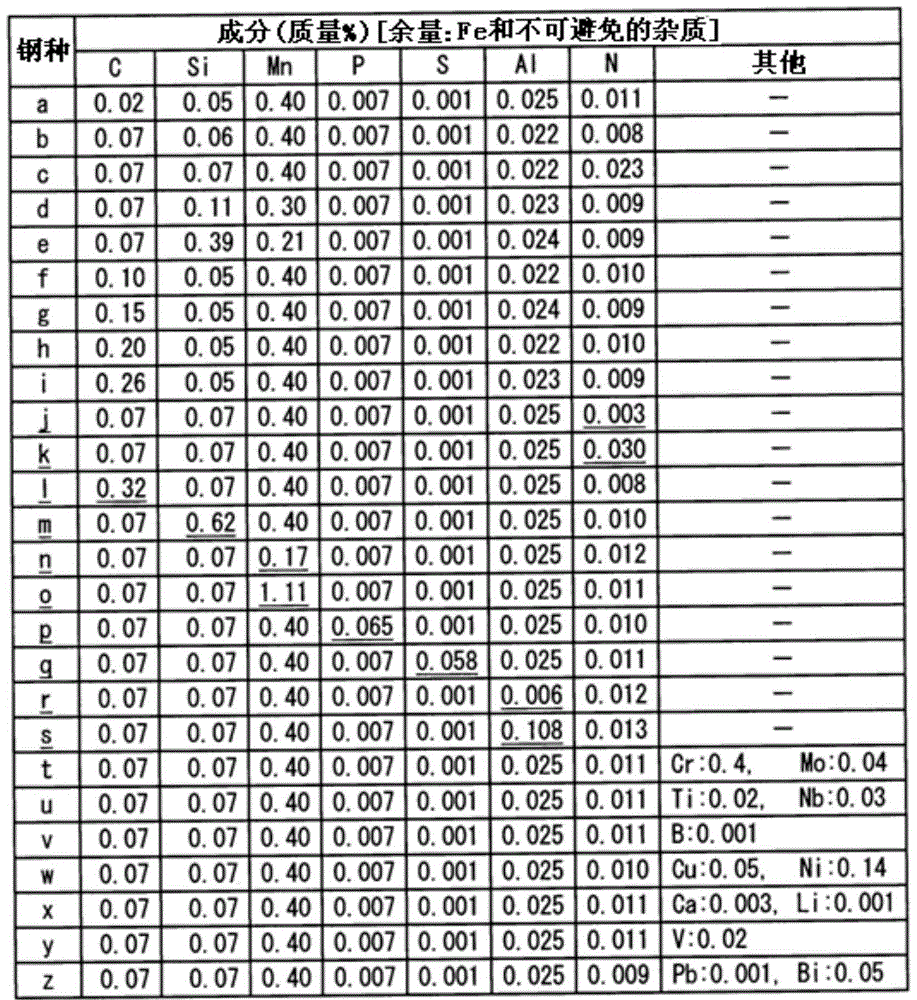

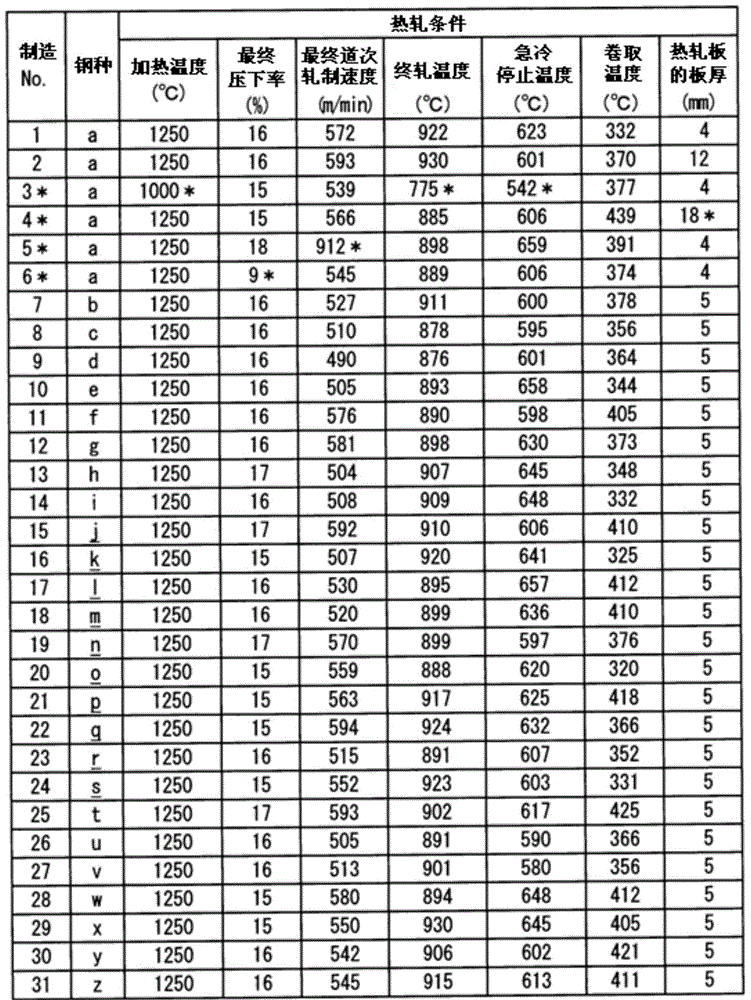

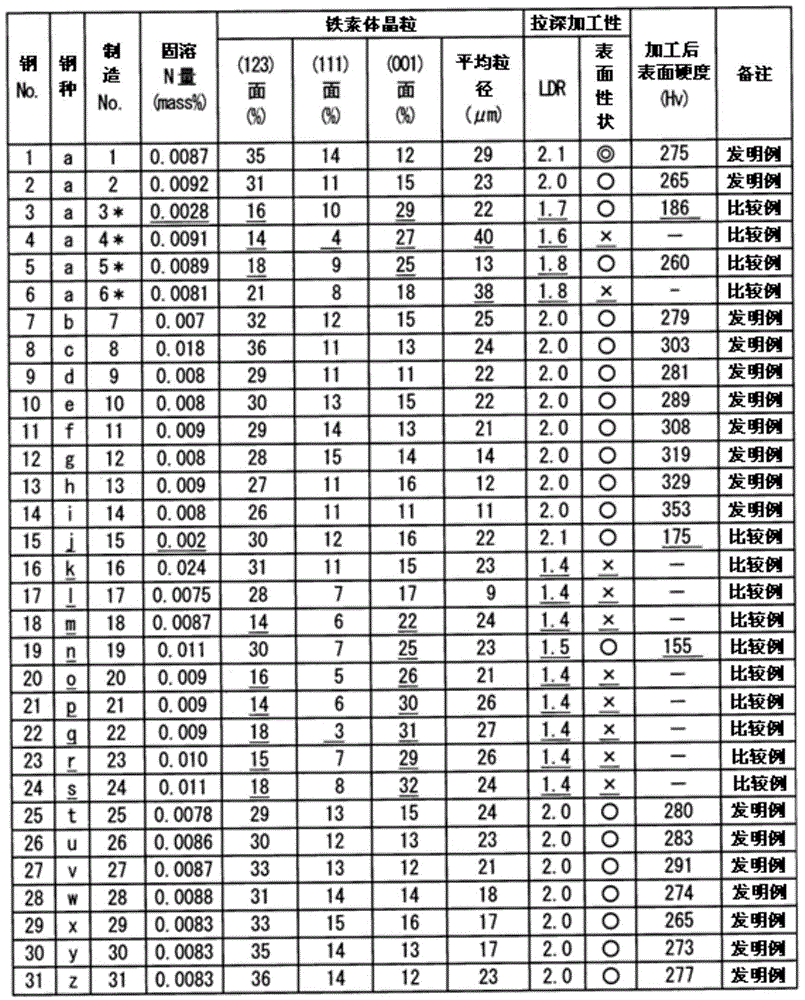

Hot-rolled steel sheet having excellent surface hardness after carburizing heat treatment and excellent drawability

InactiveCN105658830AGuaranteed surface hardnessExtend your lifeSolid state diffusion coatingFurnace typesSheet steelPlane orientation

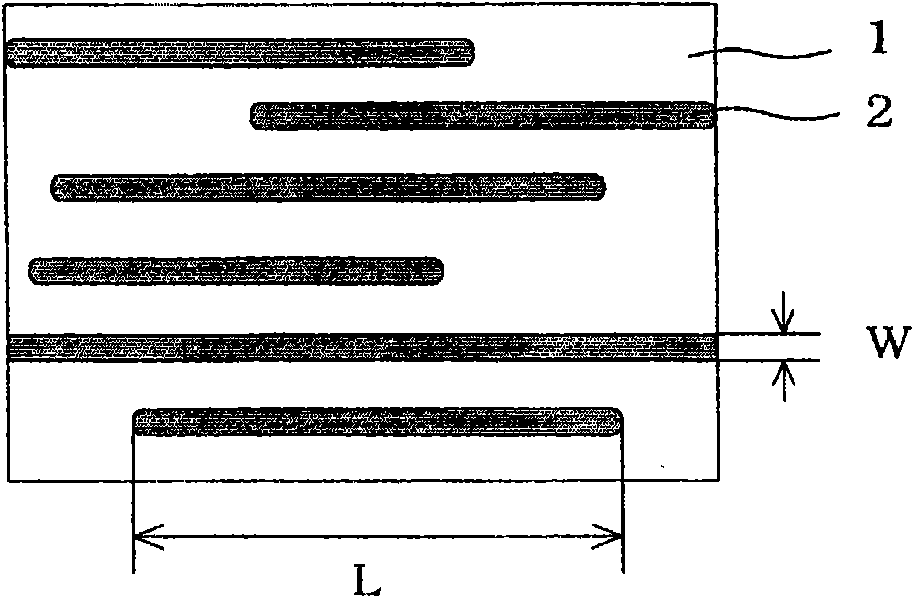

A hot-rolled steel sheet that has a sheet thickness of 2-10 mm and that contains specific amounts of C, Mn, Al, and N, the remainder comprising iron and unavoidable impurities. With regard to all crystal grains that exist at a depth of t / 4 (t being sheet thickness), the average grain diameter of all of the crystal grains is 3-50 [mu]m, the area ratio of crystal grains that have a sheet-plane orientation that is within 10 DEG of a (123) plane is 20% or more, and the total area ratio of crystal grains that, in the rolling direction, have a crystal direction that is within 10 DEG of a <001> direction and crystal grains that, in the rolling direction, have a crystal direction that is within 10 DEG of a <110> direction is 25% or less.

Owner:KOBE STEEL LTD

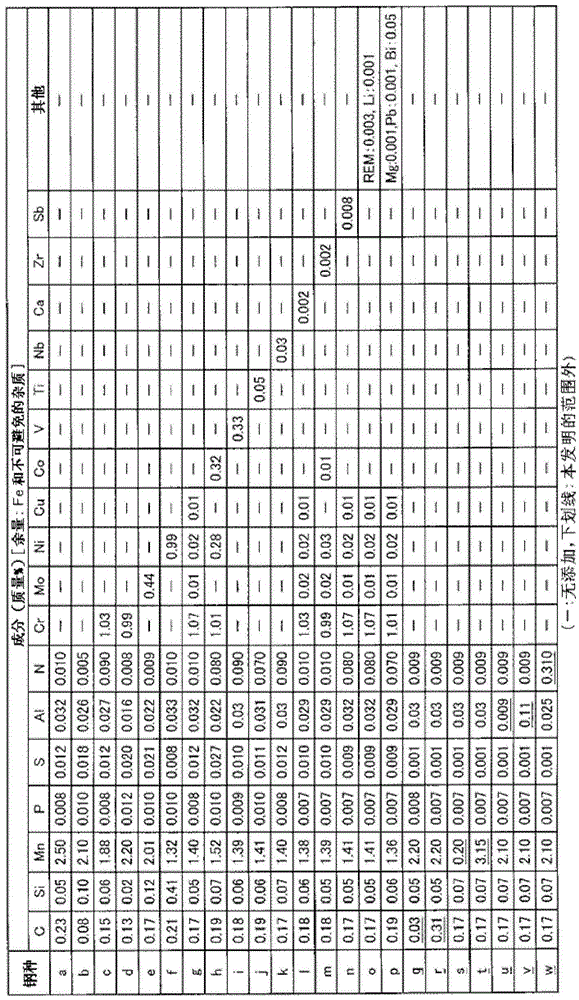

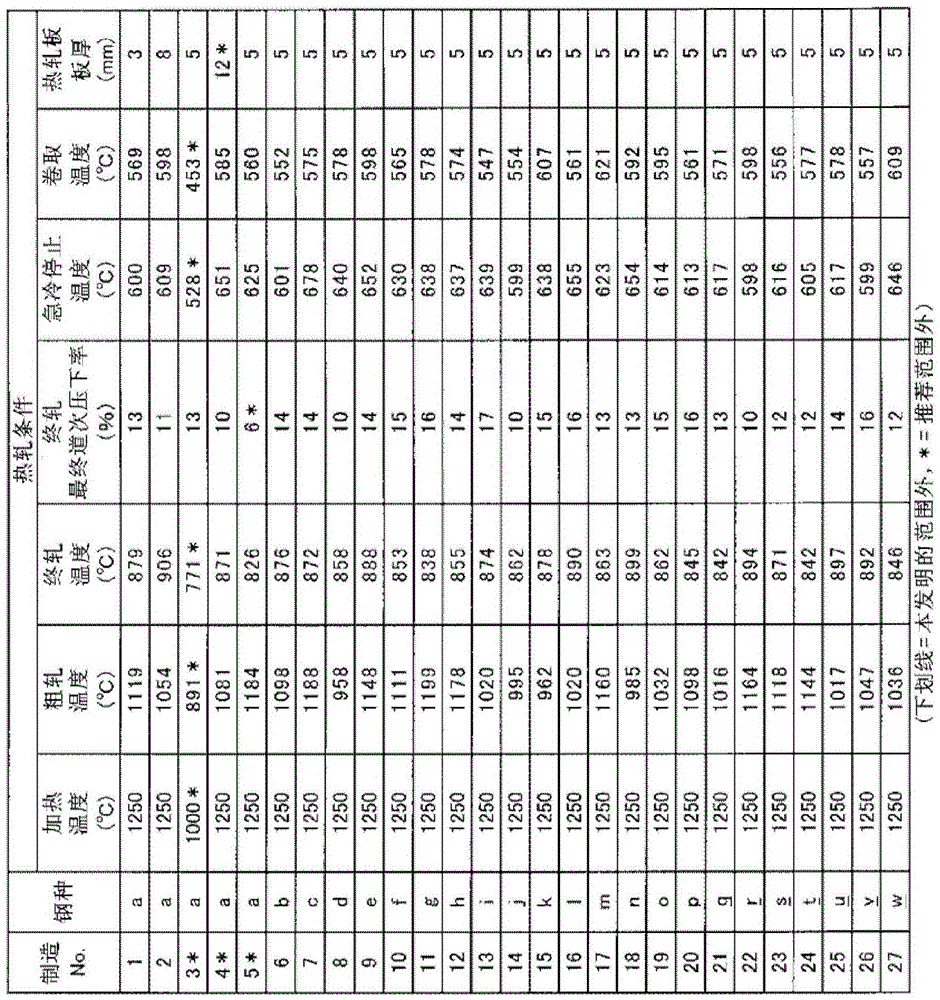

Hot-rolled steel sheet having excellent drawability and post-processing surface hardness

InactiveCN105026596AGuaranteed surface hardnessExtend your lifeFurnace typesHeat treatment furnacesPlane orientationHardness

A hot-rolled steel sheet having a sheet thickness of 2 to 15 mm and having a component composition, by mass, of 0.3% or less of C, 0.5% or less of Si, 0.2 to 1% of Mn, 0.05% or less of P, 0.05% or less of S, 0.01 to 0.1% of Al, and 0.008 to 0.025% of N, with the remainder made up by iron and unavoidable impurities, the solid-solution N being at least 0.007%. In ferrite crystal grains located at the position of depth t / 4 (where t is the thickness of the hot-rolled steel sheet), the area ratio of crystal grains within a plane orientation of 10º from the (123) plane is at least 20%, the area ratio of crystal grains within a plane orientation of 10º from the (111) plane is at least 5%, the area ratio of crystal grains within a plane orientation of 10º from the (001) plane is no more than 20%, and the average grain diameter of ferrite crystal grains located at the position of depth t / 4 is 3 to 35 μm.

Owner:KOBE STEEL LTD

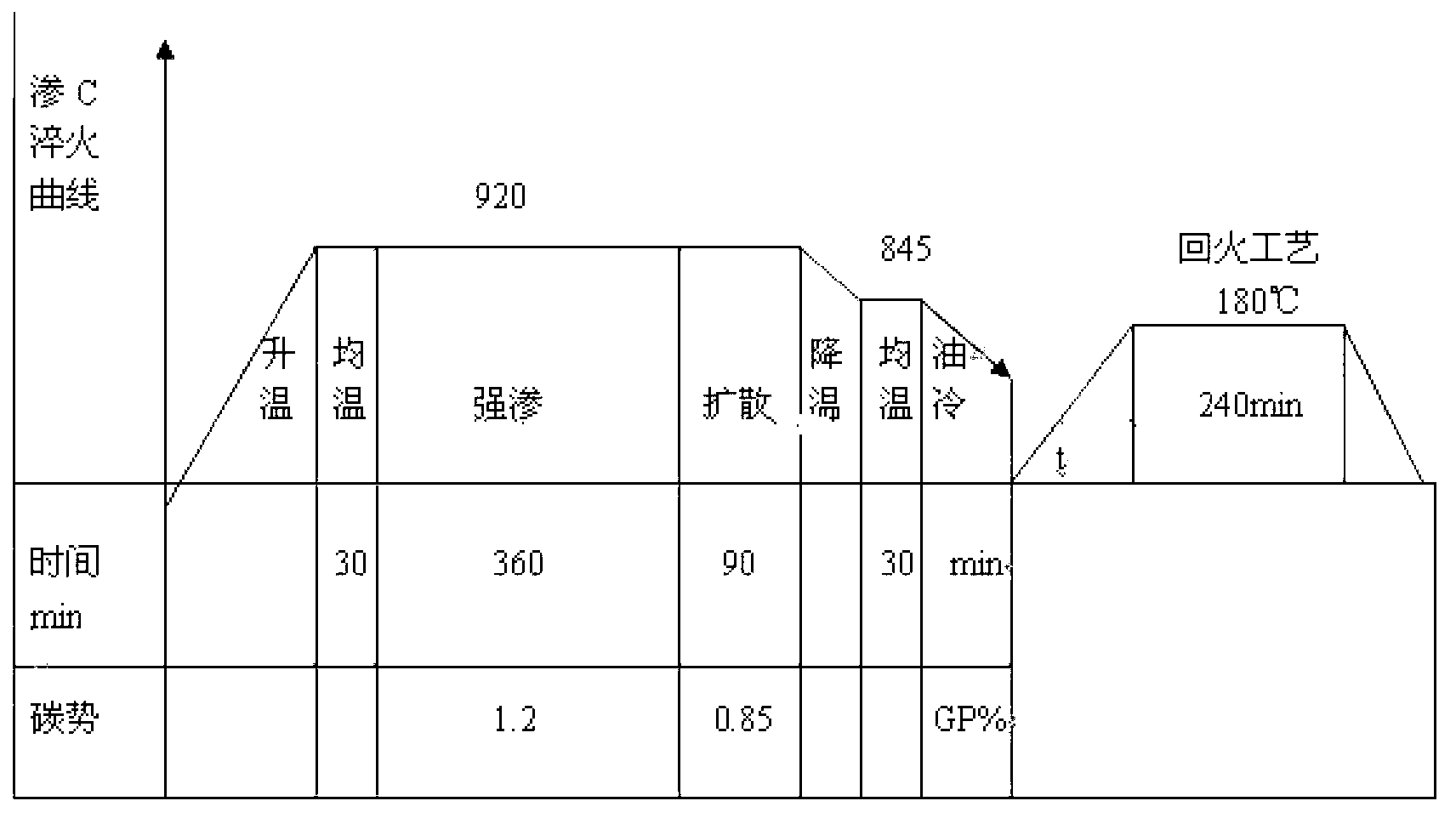

Carburizing and quenching heat treatment method

InactiveCN112593183AGuaranteed technical requirementsEnsure carburizing efficiencySolid state diffusion coatingHeat treatment process controlTemperingCarbon potential

The invention discloses a carburizing and quenching heat treatment method which is applied to gas carburizing and quenching production normally required by common low-carbon steel and low-carbon alloysteel workpieces. The carburizing and quenching heat treatment method specifically comprises the following steps of S1, firstly, putting the workpieces into a carburizing furnace, and strong carburizing section treatment and diffusion section treatment are performed on the workpieces in the carburizing furnace, wherein the carburizing temperature of the strong carburizing section treatment is 915DEG C-925 DEG C, the carbon potential of the strong carburizing section treatment is 1.1%-1.2%, the carburization temperature of the diffusion section treatment is 905 DEG C-915 DEG C, the carbon potential of the diffusion section treatment is 0.8%-0.9%, and the carburizing heat preservation time ratio of the strong carburizing section treatment to the diffusion section treatment is 11: 9; S2, performing cooling and quenching along with the carburizing furnace; S3, performing quenching oil cooling; and S4, performing tempering. By means of the method, the hardness and the hardened layer depthof the low-carbon alloy steel workpieces are guaranteed, meanwhile, it is guaranteed that the refined metallographic structure meets the national standard, and the carburizing and quenching quality is stably improved.

Owner:JIANGSU JUYUAN ELECTRICAL

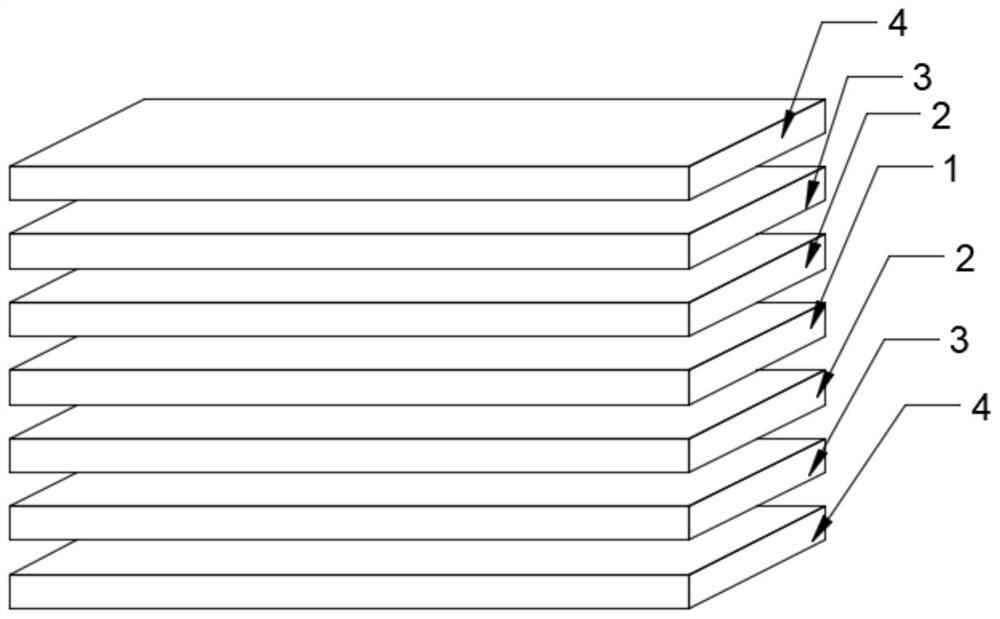

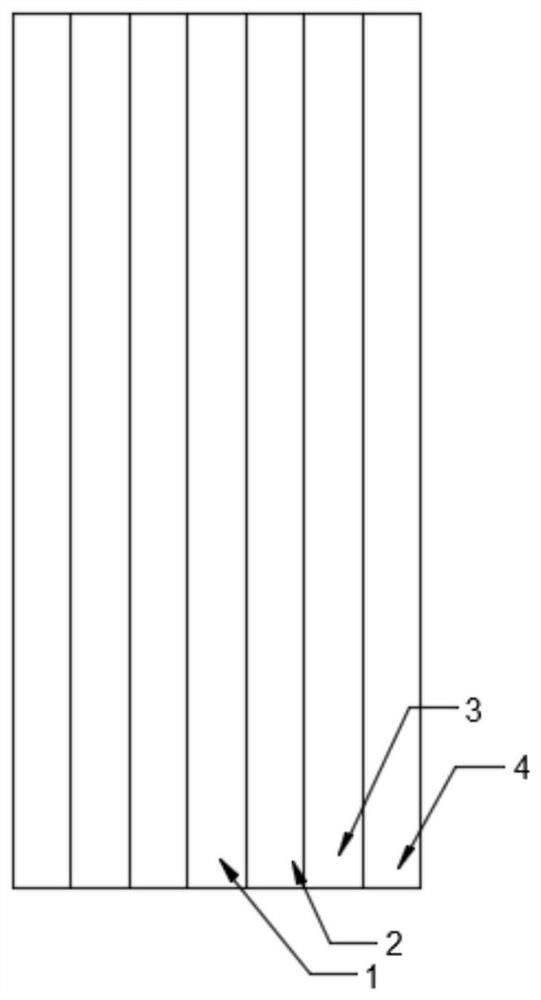

Multi-layer co-extrusion composite light diffusion plate and preparation method thereof

PendingCN113291024AGuaranteed light energy effect characteristicsGuaranteed Optical Performance CharacteristicsSynthetic resin layered productsHigh heatCeramic materials

The invention discloses a multi-layer co-extrusion composite light diffusion plate and a preparation method thereof. The multi-layer co-extrusion composite light diffusion plate comprises flexible diffusion master batch PC material layers, flexible PMMA material layers, high-elasticity light diffusion PET material layers and high-temperature-resistant light diffusion PC material layers, the flexible PMMA material layers are arranged on the two sides of the flexible diffusion master batch PC material layers, the high-elasticity light diffusion PET material layers are arranged on one side of the flexible PMMA material layers, and the high-temperature-resistant light diffusion PC material layers are arranged on one side of the high-elasticity light diffusion PET material layers. The bending performance of the whole composite light diffusion plate can be basically provided through the flexible diffusion master batch PC material layer, and the bending performance of the composite light diffusion plate can be further guaranteed through the flexible PMMA material layer; the elasticity of the composite light diffusion plate can be guaranteed on the basis of the bending performance through the high-elasticity light diffusion PET material layer, the high-temperature resistance of the whole composite light diffusion plate can be guaranteed through the high-temperature-resistant light diffusion PC material layer, and the performance of the plate can be improved to the maximum extent through composite manufacturing of various materials.

Owner:浙江赛宁新材料科技有限公司

Transfer printing base paper suitable for ink printing

InactiveCN111826992AApplicable transfer processImprove hydrophobicityPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperTextile printerCellulose

The invention provides transfer printing base paper suitable for ink printing. Paper pulp forming the transfer printing base paper comprises 30-35 parts of sisal hemp pulp, 16-20 parts of kudzu vine pulp, 8-12 parts of polyurethane fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-5 parts of carbon fiber powder, 1-2 parts of calcium stearate, 1-2 parts of sodium alginate, 1-2 parts of carboxymethyl starch, 0.8-1 part of guar gum and 3-5 parts of calcium carbonate. According to the invention, sisal hemp pulp and kudzu pulp are used as main fiber components, mutually cross-linked plant fibers are used to construct a main structure of the paper, and a certain amount of hydrophobic polyurethane fibers are added; on the basis, guar gum and sodium alginate are utilized to fully increase thecrosslinking degree between fibers, and calcium stearate, calcium carbonate and other components are introduced to ensure the surface hardness. According to the improved transfer printing base paper,the affinity with ink is effectively reduced, the paper strength is improved, and the improved transfer printing base paper is particularly suitable for the transfer printing process of the ink.

Owner:淄博圣泉纸业有限公司

Vapor seal measuring tool machining method

ActiveCN109014773AGuaranteed surface hardnessGuaranteed machining accuracyMeasurement devicesMachine toolHeat treated

The invention discloses a vapor seal measuring tool machining method, and solves the problem of difficult precision guarantee in a traditional vapor seal measuring tool. The vapor seal measuring toolmachining method comprises the following steps: all parts are roughly turned on a general lathe; the single-surface release quantity of each outer circle and end surface is 3 mm; the single-surface release quantity of each inner hole and vapor seal tooth surface is 3 mm; heat treatment: workpieces are heated to HRC 31-35; all the parts are finely turned by a numerical control lathe; the release quantity of each surface of an end surface A, an end surface B, an end surface C and an end surface D is 0.3 mm; the rest parts are finely turned to stated sizes; the end surface C and the end surface Dare grinded on a plane grinding machine; middle surface lines are drawn by bench workers; a linear cutting machine tool cuts off vapor seal measuring tools along the middle surface lines; a broach grinding machine grinds a surface A firstly, and then, grinds a surface B, so that the surface A and the surface B meet the standards; and each edge is rounded to finish machining. The vapor seal measuring tool machining method is used for machining of the vapor seal measuring tools.

Owner:HARBIN TURBINE +1

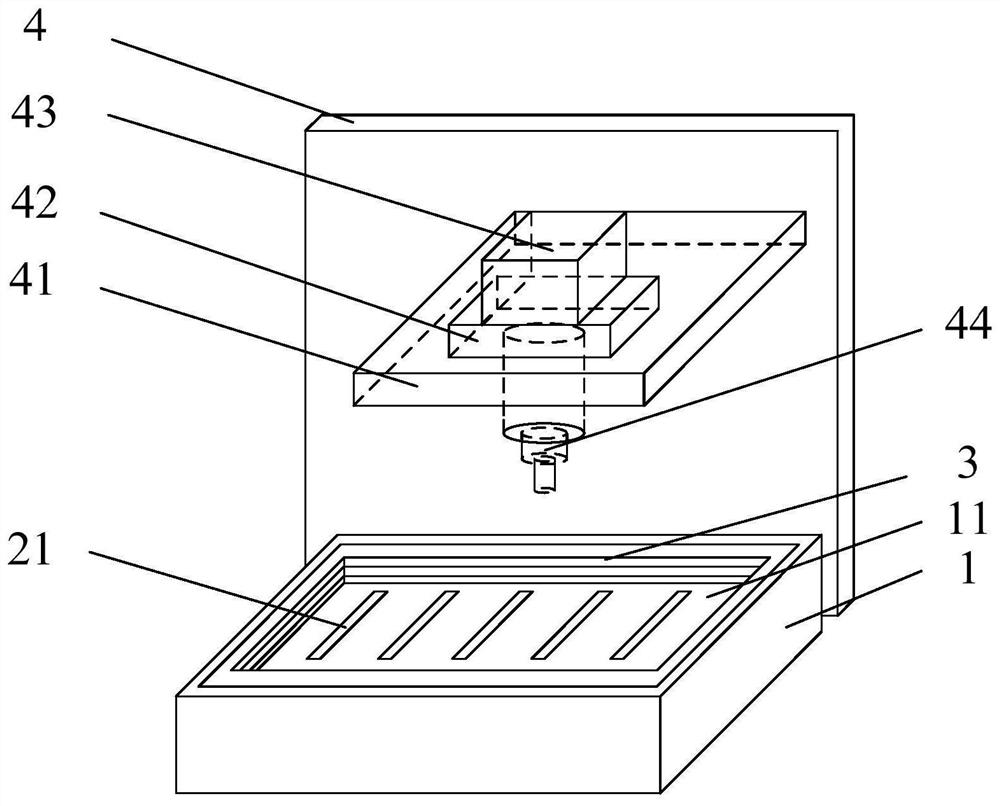

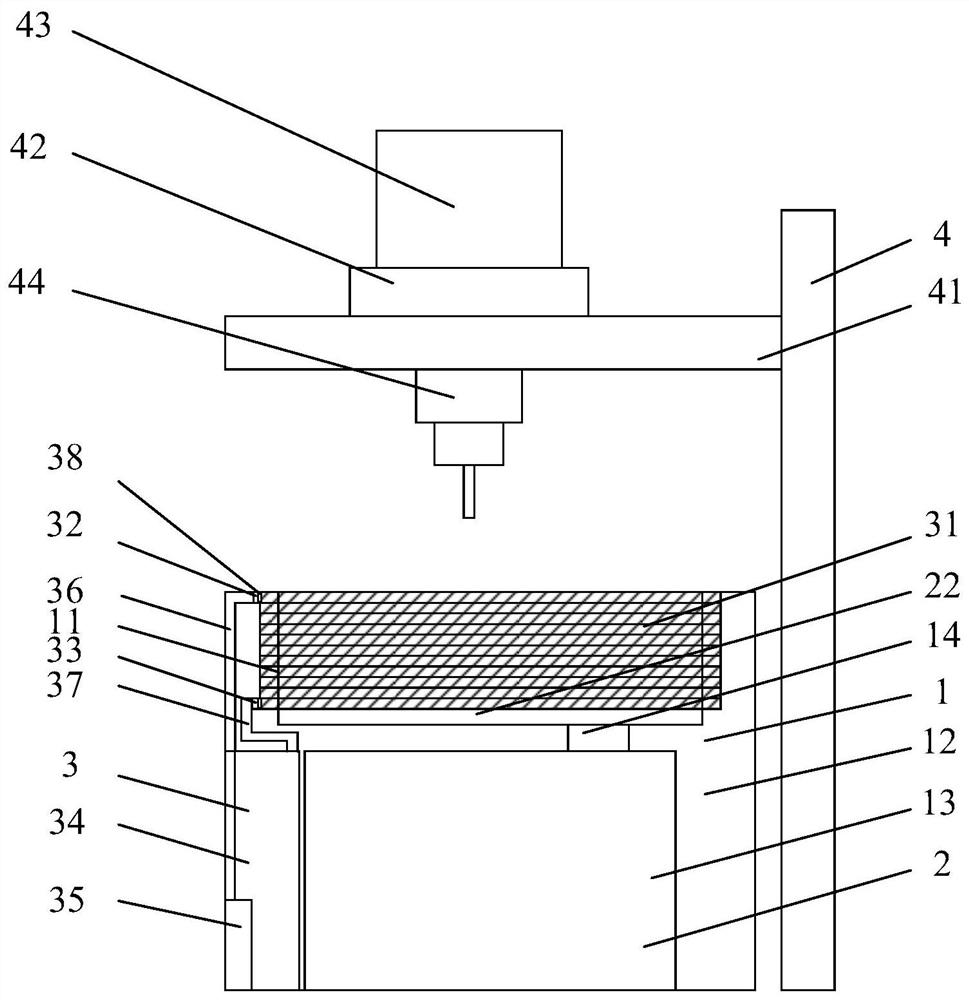

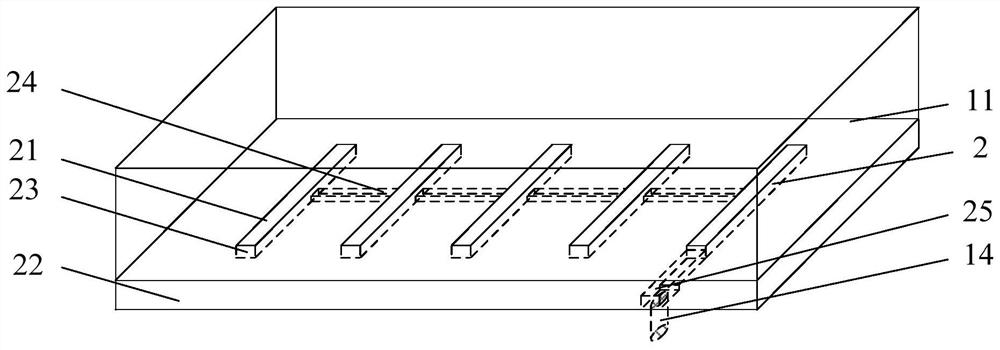

CNC-based machined part cooling device

InactiveCN112355708AReduce the temperatureGuaranteed surface hardnessPositioning apparatusMaintainance and safety accessoriesMachine partsElectric machinery

The invention discloses a CNC-based machined part cooling device. The device comprises a workbench for allowing a machined part to be fixed, a groove matched with the machined part is formed in the upper end face of the workbench, the bottom of the groove is connected with a vacuum mechanism, and a cooling mechanism is wound on the side wall, located in the workbench, of the groove. A side plate is vertically arranged on any side of the workbench, a fixed plate is horizontally arranged on the side, facing the workbench, of the side plate, a rotating motor and a hydraulic air cylinder are arranged on the upper end face of the fixed plate, the rotating motor and the hydraulic air cylinder are connected with a machined rod part, and the machined rod part is located over the groove. Accordingto the CNC-based machined part cooling device, the to-be-machined part is embedded in the matched groove, vacuum adsorption fixing is completed through groove channels communicating with a vacuum pump, meanwhile, a circulating water pipe wound around the side wall, located in the workbench, of the groove can supply cooling liquid through a circulating water pump, the temperature of the machined part is reduced, the surface hardness of the machined part is ensured, the rejection rate is reduced, and the production efficiency is improved.

Owner:苏州特莱富精密机械有限公司

Method for machining ZC-shaped worm-gear pair

ActiveCN108058000AAppropriate thicknessGuaranteed surface hardnessToothed gearingsGear toothMachining

The invention relates to a method for machining a ZC-shaped worm-gear pair. The method for machining a worm includes: (a) forming a worm central hole, and machining a bearing installation position ofthe worm with the central hole as a positioning reference; (b) machining various shaft sections with the bearing installation position as a positioning reference, milling worm teeth, and performing coarse grinding and heat treatment on the worm teeth; (c) performing accurate grinding on the central hole with the bearing installation position; and (d) performing accurate grinding on various shaft sections of the worm with the accurately grinded central hole as a positioning reference. The gear is machined by using a diameter-increasing hob, and an oil box for holding lubricating oil is formed on an engagement region. Compared with the prior art, the machining method can reduce bending deformation of the worm, can improve the centring performance of the worm shaft, can fully ensure the machining precision, and can improve the accuracy of the machining size of the worm; and the gear can form the oil box during engagement between the worm teeth and the gear teeth, lubricating is ensured, and the driving efficiency and the service life can be improved.

Owner:SHANGHAI LONGYU ELEVATOR ACCESSORIES

Preparation technology of formaldehyde-free waterproof composite board

ActiveCN106553258AIncrease elasticityHigh compressive strengthOther plywood/veneer working apparatusWood treatment detailsWood shavingsEmulsion

The invention discloses a preparation technology of a formaldehyde-free waterproof composite board. The technology comprises processing steps as follows: bamboo and wood materials are crushed and then dried, and bamboo shavings and wood shavings are formed; the bamboo shavings, the wood shavings, sodium carboxymethylcellulose, rosin, a silicone acrylic emulsion and an adhesive are mixed in different proportions, and a mixed core material and a mixed surface material are formed; the mixed core material and the mixed surface material are laid and hot-pressed respectively, and a core material blank board and surface material blank boards are formed; and the core material blank board is arranged between the two surface material blank boards, and a finished product is formed after hot-pressing, airing, sanding and edge cutting. The composite board processed with the technology can have the advantages of being completely free of formaldehyde emission, high in waterproofness, high in strength and light in mass.

Owner:益阳万维竹业有限公司

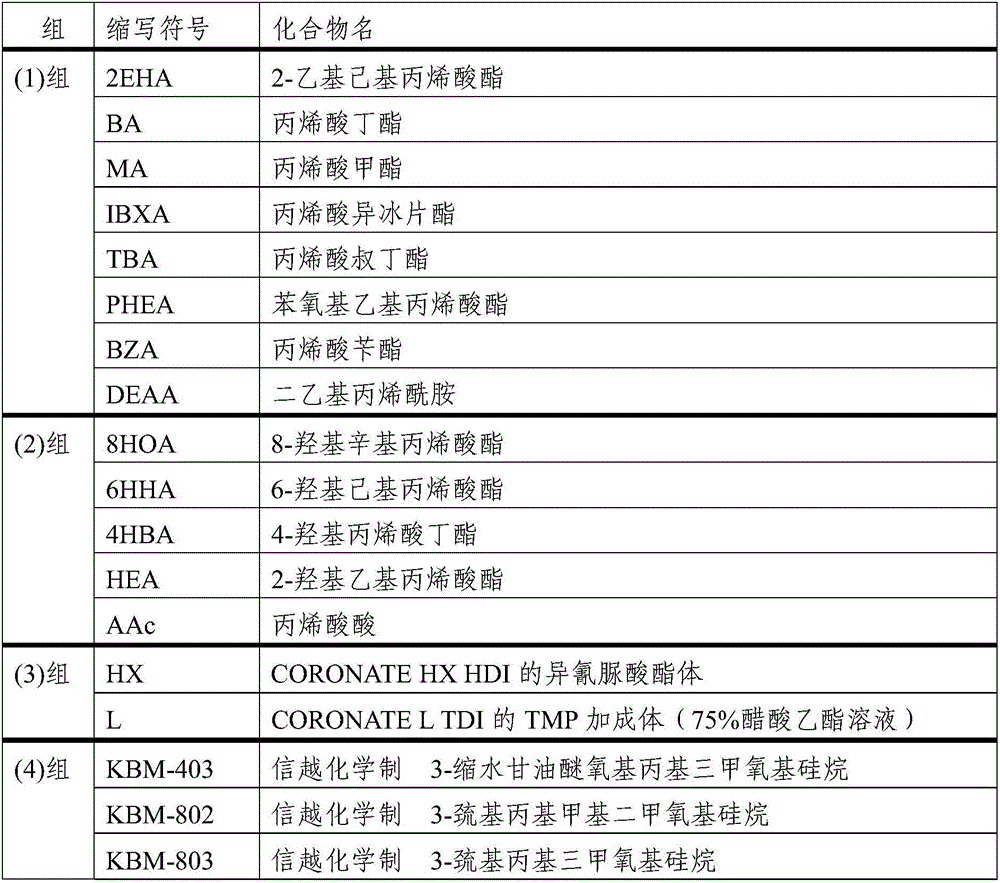

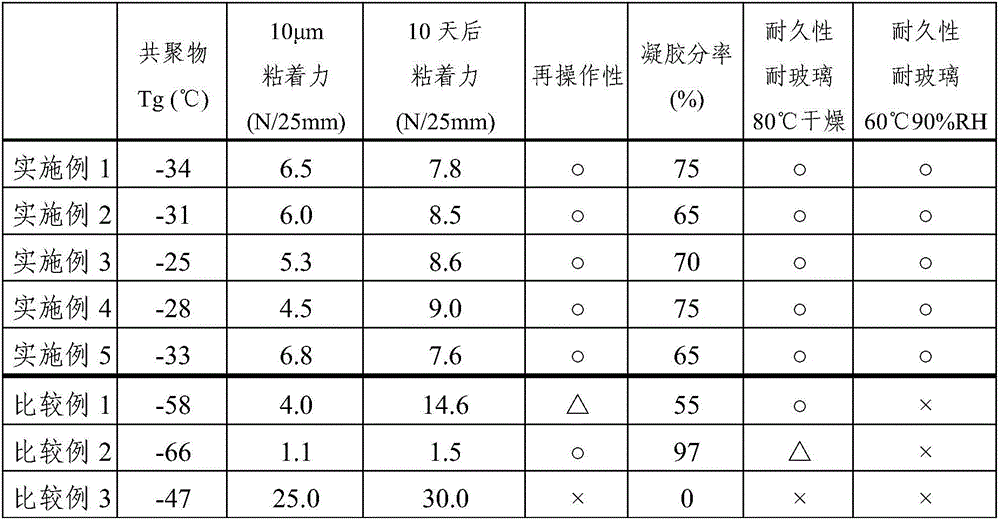

Adhesive layer and adhesive film

ActiveCN106118554ADurableReoperabilityNon-macromolecular adhesive additivesFilm/foil adhesivesMicrometerAcid value

The present invention provides an adhesive layer and anadhesive film which are used to bond layers of anoptical member and are durable and operable and free from errors for the measurement values of the surface hardness of the laminated body with attached optical member. The pencil hardness of the surface of the optical member attached to non-alkali glass through the adhesive layer and the pencil hardness of surface of the optical member are not less than 2H.In the adhesive layer,the gel fraction of acrylic polymer after being crosslinked with0.01 to 1.0 parts by weight of the crosslinking agentisocyanate compound reaches 40-85%, the thickness is 1 to 20 micrometers. The adhesive force of the adhesive layer in the thickness of 10 micrometers is 1.5-8.0N / 25M. The main component of the acrylic polymer is 100 parts by weight of (Meth) acrylic monomer and 0.1 to 10 parts by weight of a hydroxyl group-containing copolymerizable vinyl monomer, the acid value being 0.1 or less, and the weight-average molecular weight beingone million or more.

Owner:FUJIMORI KOGYO CO LTD

Quenching oil capable of enabling screw to blacken automatically after quenched and quenching method thereof

ActiveCN105925770AGuaranteed surface hardnessGuaranteed internal metallographic structureFurnace typesMetallic material coating processesAntioxidantFatty alcohol

The invention discloses quenching oil capable of enabling an screw to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 6-10 parts of cooling catalyzed composite agent, 0.4-0.6 parts of blackening composite agent, 0.3-0.7 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The cooling catalyzed composite agent is a mixture of dialkyl naphthalene and petroleum sulfonate; the blackening composite agent the mixture of short oil alkyd resin, colouring agent and wetting agent; the brightening agent is the mixture of imidazoline oleate and methyl terpene resin; the surface activating agent is span-80. The colouring agent is disperse black 9; the wetting agent is fatty alcohol-polyoxyethylene ether. The best using temperature of the quenching oil is between 75 DEG C and 80 DEG C. Between 75 DEG C and 80 DEG C, the cooling speed of the quenching oil for the screw is moderate, the surface can be blackened automatically and a protective film can be formed while the quenching, so that the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

Composite material for manufacturing spectacle frame by adopting acetate fibers and forming process of composite material

The invention discloses a composite material for manufacturing a spectacle frame by adopting acetate fibers and a forming process of the composite material. The forming process comprises the followingsteps of P2, baking; P3, hot melting; P4, mixing the materials; P5, injection molding; P6, polishing; P7, electroplating; and P8, carrying out post-treatment. According to the composite material formanufacturing the spectacle frame by adopting the acetate fibers and the forming process of the composite material, impurities can be effectively removed by cleaning and drying the raw material, and the composite material is compounded by adding barium sulfate after partially melting, so that the heat-conducting property can be effectively improved, sufficient melting is guaranteed, deteriorationis avoided, framework quality and structural strength are guaranteed, meanwhile, surface electroplating is carried out subsequently, surface hardness can be guaranteed, scratches are reduced, smoothness and attractiveness are improved, machining production and use are facilitated, and application and popularization are facilitated.

Owner:RUIAN JIAYI GLASSES CO LTD

Heat treatment method of steel shallow carburizing

ActiveCN111424230ASolution depthSolve problems such as serious deformation of partsSolid state diffusion coatingCarbon potentialTempering

The invention relates to the field of heat treatment, in particular to a heat treatment method of steel shallow carburizing. The method comprises the steps that a non-carburizing area of a part is subjected to copper plating protection, the part comprises the non-carburizing area and a carburizing area, a carburizing surface of the carburizing area is cleaned, in a controlled atmosphere furnace, the carburizing surface is subjected to first-time carburizing, in a second segment of first-time carburizing, the carbon potential range is 0.75+ / -0.05%C, first-time carburizing comprises two segments, and after carburizing, the part is subjected to quenching, high-temperature tempering and copper removal. The problems that in conventional process parameters, a part carburizing layer depth is prone to being overproof, and part deforming is serious can be solved.

Owner:HARBIN DONGAN ENGINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com