Surface boriding method capable of maintaining high strength of titanium alloy

A titanium alloy, high-strength technology, applied in the field of metal surface treatment, to achieve high strength and plasticity, prevent oxidation, ensure surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for surface boronizing capable of maintaining the high strength of titanium alloys, comprising the steps of:

[0043] S1. Preparation of boronizing agent: Take boron carbide powder and cerium oxide powder, weigh the boron carbide powder and cerium oxide powder according to the mass percentage of 19:1-99:1, mix them evenly, grind and screen, and obtain boron carbide powder with a particle size of less than 45 μm. Boronizing agent.

[0044] Preferably, the boron carbide powder is boron carbide powder with a purity of 93% to 97% produced by Mudanjiang Jinggong Abrasive Boron Carbide Co., Ltd., and the cerium oxide powder is cerium oxide powder with a purity of 99.95% produced by Sinopharm Chemical Reagent Co., Ltd.

[0045] Adding an appropriate amount of rare earth as a penetrating agent in the boronizing agent can further improve the surface hardness and wear resistance of the titanium alloy. The cerium oxide added in the present invention can improve the activ...

Embodiment 2

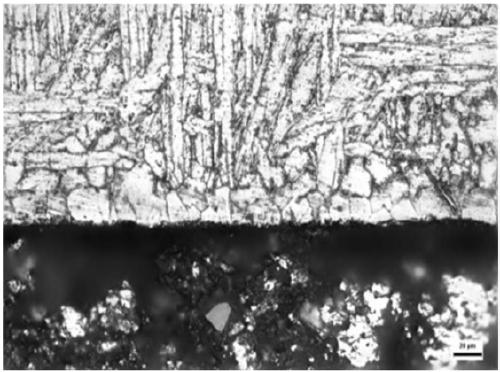

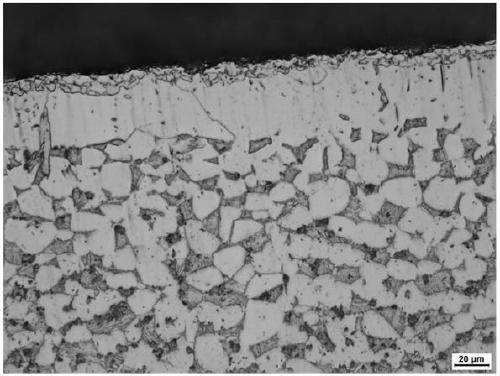

[0058] The steps of Example 2 are basically the same as those of Example 1, except that the heating temperature in Step S3 is 950° C., and the holding time is 40 h. Such as image 3 As shown, in this case, the infiltration layer at the boundary of the titanium alloy sample is very obvious, with a thickness of about 40 μm, which is caused by the increase of boronizing time. At this time, the titanium alloy matrix structure is a two-state structure, and the plasticity is relatively good.

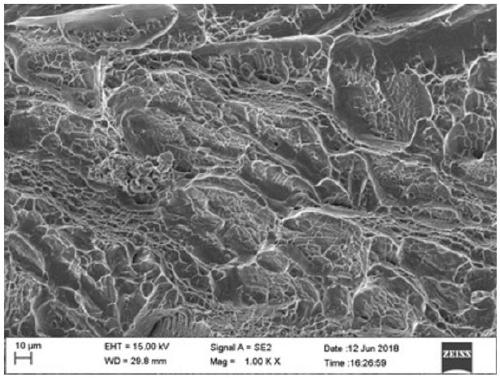

[0059] Such as Figure 5 Shown is the physical picture of the titanium alloy tensile sample after infiltration. The tensile test of the titanium alloy tensile sample was carried out using a material universal testing machine. The test showed that the tensile strength of the titanium alloy tensile sample was 973.47MPa, and the elongation rate was 8%, indicating that the tensile strength of the titanium alloy tensile sample after boronizing Higher, better plasticity. After the titanium alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com