Stepped quenching process and its apparatus suitable for bainite and martensite quenching

A technology of martensitic quenching and graded quenching, which is applied in the direction of quenching agents, quenching devices, heat treatment equipment, etc., can solve the problems of limited use of production lines, difficult quality assurance, and high energy consumption of equipment, so as to improve the quality of heat treatment and realize automatic operation , good hardening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

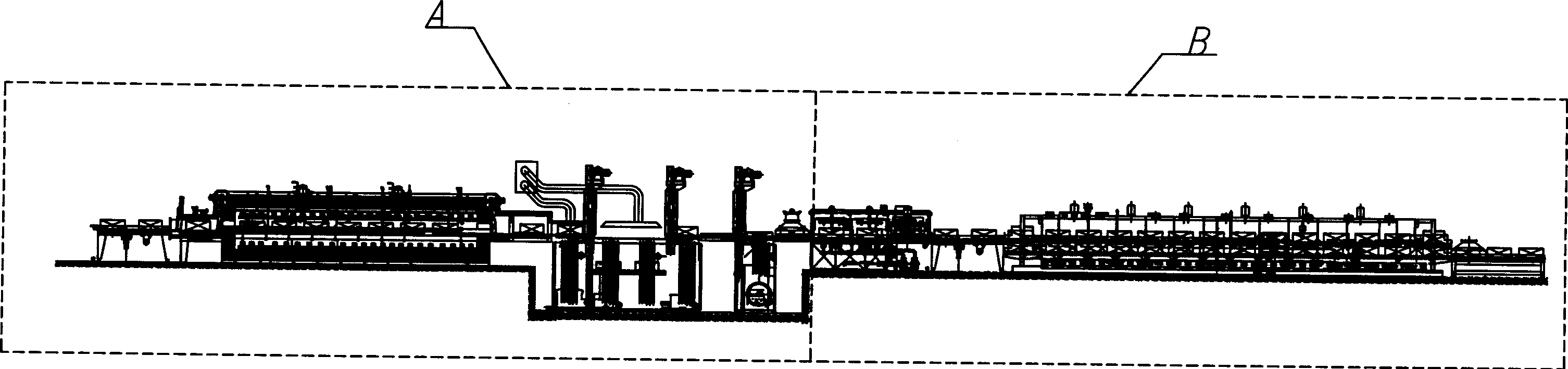

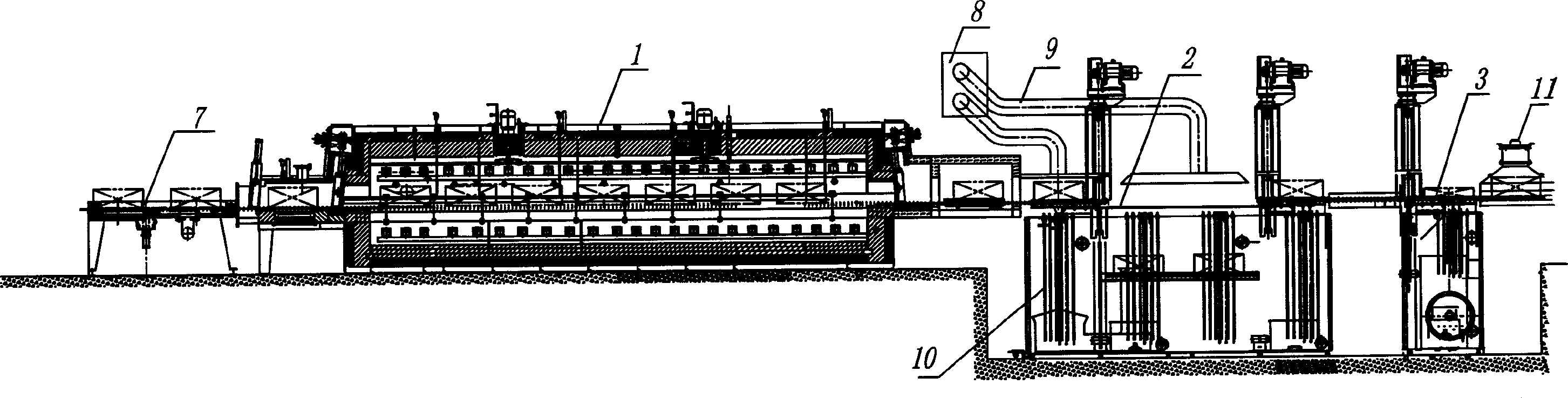

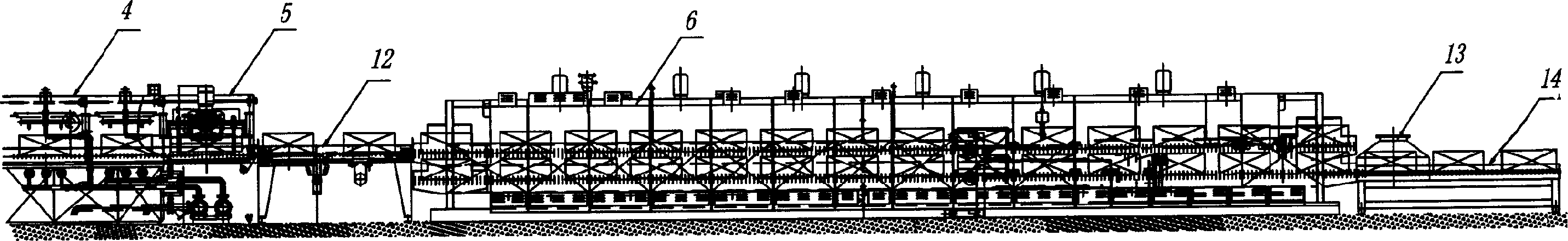

[0027] This embodiment is a stepwise quenching process for bainite, and the whole process is in figure 1 Shown is performed on a roll-bed multi-purpose production line. Its technological process includes the following steps:

[0028] a. Put the heat treatment parts on the material table 7, and send the parts into the roller hearth heating furnace 1 through the roller transmission device. The roller hearth heating furnace 1 is protected by a nitrogen-based controllable atmosphere, and the heating temperature is 860 °C ~870℃, according to the number and size of parts, the holding time is 0.5~3 hours;

[0029] b. The heated parts are sent out from the back door of the roller hearth heating furnace 1, and quickly put on the lifting quenching frame 10 with roller bars in the nitrate tank 2, quenched and isothermal, and the quenching temperature in the nitrate tank is 220 ℃~240℃, holding time is 0.5~1.5 hours;

[0030] In this embodiment, 4 stations are arranged in the nitrate ta...

Embodiment 2

[0037] This embodiment is a stepwise quenching process for martensite, and its process flow is the same as that of Example 1. The specific process parameters are as follows: in step a, the heating temperature of the heat-treated parts in the roller hearth heating furnace 1 is 820°C to 860°C; In step b, the quenching temperature of the parts in the nitrate tank 2 is 160°C to 170°C, and the temperature is kept for 5-10 minutes; in step e, the oil-cooled and cleaned parts are transferred to the air furnace 6 for isothermal tempering, The tempering temperature is 160°C-200°C, and the holding time is 3-5 hours.

[0038] In the roller bottom type multi-purpose production line equipment of the present invention, a high-pressure blower device 11 can be installed between the oil tank 3 and the cleaning machine 4. For some parts, after quenching in the nitrate tank, cooling in the oil tank is not used, and high-pressure air blower device 11 can be installed. The fan device 11 is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com