Hot-rolled steel sheet having excellent drawability and post-processing surface hardness

A technology of surface hardness and hot-rolled steel plate, which is applied in the field of hot-rolled steel plate to achieve the effect of prolonging life and improving deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

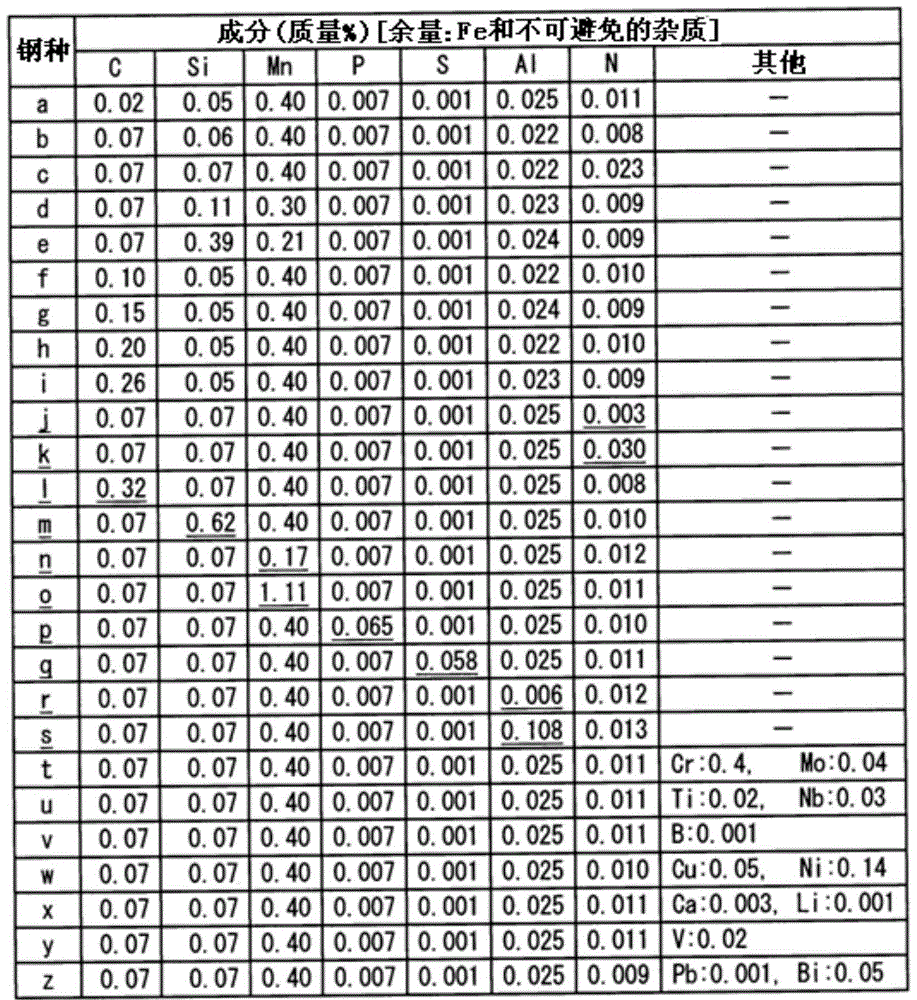

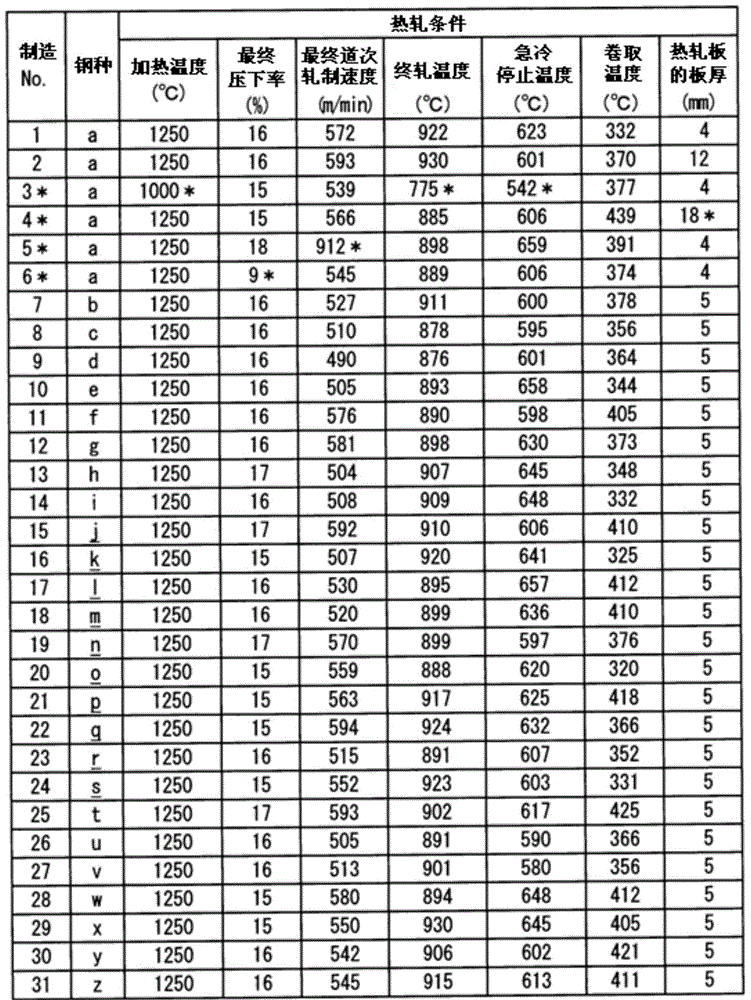

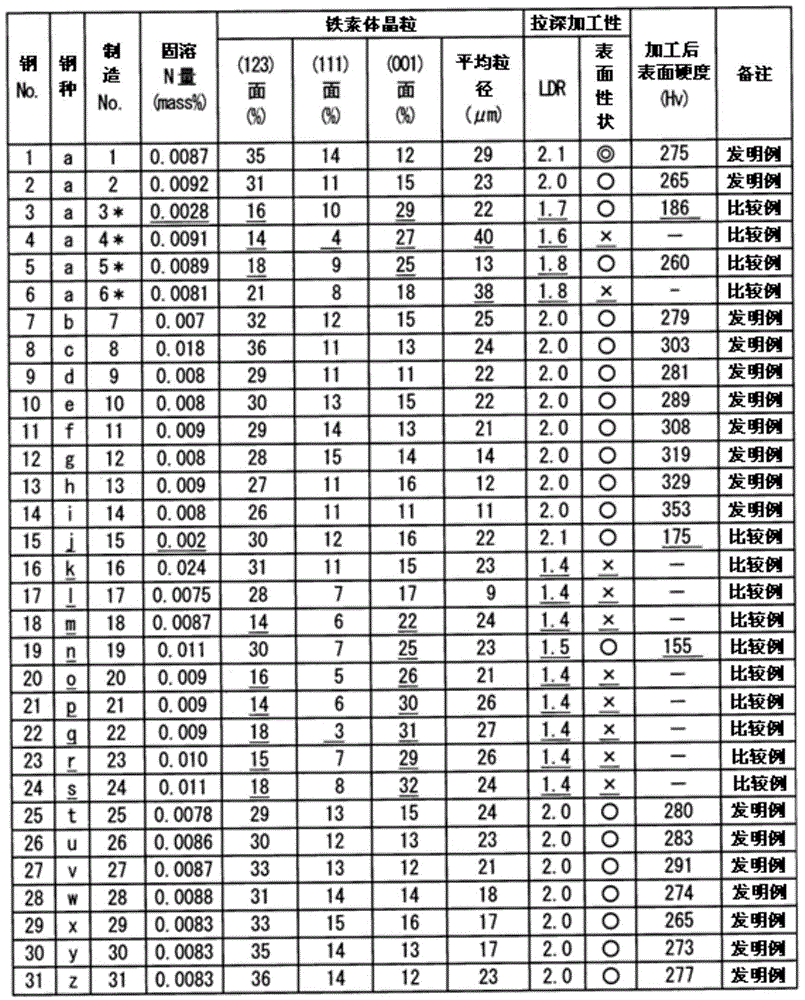

[0073] Hereinafter, the hot-rolled steel sheet of the present invention (hereinafter also referred to as "steel sheet of the present invention" or simply "steel sheet") will be described in more detail. The steel plate of the present invention is in common with the hot forging material described in the above-mentioned Patent Document 2 in that the N solid solution content is ensured. The aspect of miniaturization is different.

[0074] [Thickness of the steel plate of the present invention: 2 to 15 mm]

[0075] First, the steel plate of the present invention is intended to be a steel plate with a plate thickness of 2 to 15 mm. When the plate thickness is less than 2 mm, rigidity as a structural body cannot be ensured. On the other hand, if the sheet thickness exceeds 15 mm, it will be difficult to achieve the microstructure defined in the present invention, and the desired effect of improving drawing workability will not be obtained. The preferred plate thickness is 3 to 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com