Optimization method and processing step of high-end hot work die steel

A technology of hot work die steel and optimization method, applied in the field of mechanical parts forming, can solve the problems of inconsistent mechanical properties of the die in all directions, die failure, etc., to achieve excellent thermal crack resistance, improved service life, good thermal strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Taking YFH-17 steel as an example,

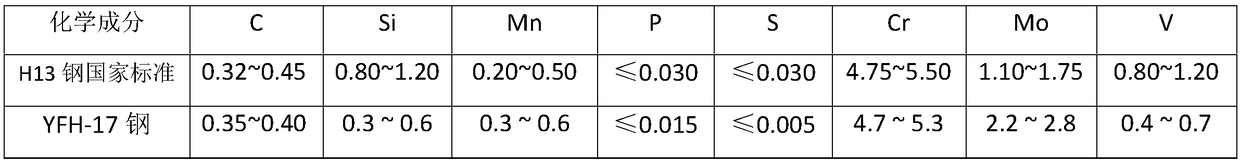

[0030] 1. For the chemical composition formula (weight ratio) of trace elements of YFH-17 mold steel, see the table below.

[0031] chemical composition

C

Si

mn

P

S

Cr

Mo

V

H13 steel national standard

0.32~0.45

0.80~1.20

0.20~0.50

≤0.030

≤0.030

4.75~5.50

1.10~1.75

0.80~1.20

YFH-17 steel

0.35~0.40

0.30~0.60

0.30~0.60

≤0.015

≤0.005

4.70~5.30

2.20~2.80

0.40~0.70

[0032] It can be seen from the above table:

[0033] The molybdenum (MO) content of YFH-17 steel breaks through the H13 standard upper limit of 1.75, and is greatly increased to more than 2.20, which can refine the grain of the steel, improve hardenability and thermal strength, and maintain sufficient strength and creep resistance at high temperatures Variable capacity (long-term work at high temperature, the gradual deformation that occurs, called creep).

[0034] At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com