Ternary boride reinforced iron-based wear resistance coating and preparation method thereof

A ternary boride and wear-resistant coating technology, which is applied in coatings, metal material coating processes, etc., can solve problems such as complex coating preparation processes, and achieve high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

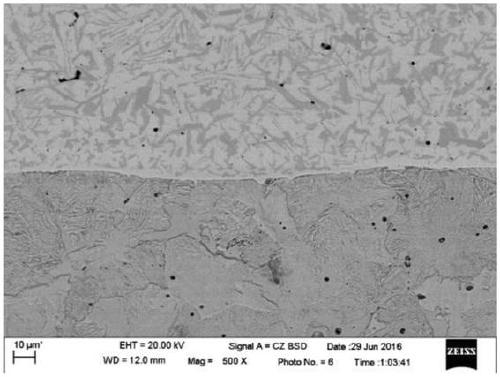

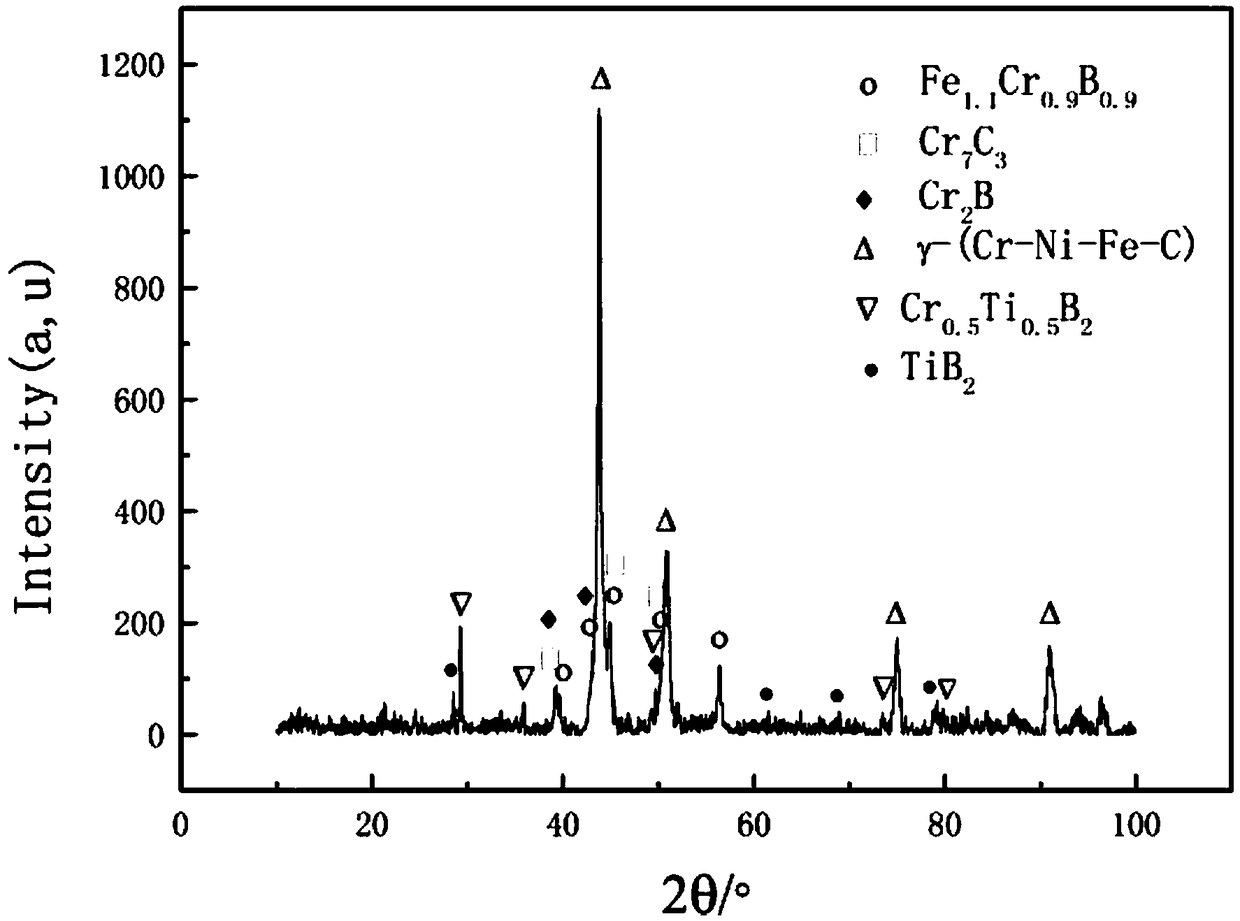

[0034] The ternary boride reinforced iron-based wear-resistant coating of this embodiment is prepared according to the following steps:

[0035] (1) Preparation of ternary boride powder: Weigh TiO 2 Powder 26.6kg, Cr 2 o 3 Powder 35.9kg, B 4 C powder 25.9kg, C powder 11.6kg, Fe powder 2kg, mix to obtain mixed powder 1, add 1.5kg polyvinyl alcohol and 100L pure water to mixed powder 1; Through ball mill mixing, the rotating speed of ball mill is 300r / min, ball milling time 2h, spray granulation, reaction sintering (sintering system: Ar 2 protection, control the temperature at 1300-1350°C, hold for 2 hours, and cool with the furnace) to prepare Cr 0.5 Ti 0.5 B 2 , that is, ternary boride powder (the particle size of the prepared ternary boride powder is 10-150 μm);

[0036] (2) Surface treatment of the Q235 steel substrate: first, use a corundum grinder to grind the Q235 steel substrate to remove the rust on the surface and increase the surface roughness, then polish it w...

Embodiment 2

[0040] The ternary boride reinforced iron-based wear-resistant coating of this embodiment is prepared according to the following steps:

[0041] (1) Preparation of ternary boride powder: Weigh TiO 2 Powder 26.6kg, Cr 2 o 3 Powder 35.9kg, B 4 C powder 25.9kg, C powder 11.6kg, Fe powder 2kg, mix to obtain mixed powder 1, add 1.5kg polyvinyl alcohol and 100L pure water to mixed powder 1; Through ball mill mixing, the rotating speed of ball mill is 300r / min, ball milling time 2h, spray granulation, reaction sintering (sintering system: H 2 protection, control the temperature at 1350-1400°C, hold for 2 hours, and cool with the furnace) to prepare Cr 0.5 Ti 0.5 B 2 , that is, ternary boride powder (the particle size of the prepared ternary boride powder is 90-140 μm);

[0042] (2) Surface treatment of the Q235 steel substrate: first, use a corundum grinder to grind the Q235 steel substrate to remove the rust on the surface and increase the surface roughness, then polish it wi...

Embodiment 3

[0046] The ternary boride reinforced iron-based wear-resistant coating of this embodiment is prepared according to the following steps:

[0047] (1) Preparation of ternary boride powder: Weigh TiO 2 Powder 26.6kg, Cr 2 o 3 Powder 35.9kg, B 4 C powder 25.9kg, C powder 11.6kg, Fe powder 2kg, mix to obtain mixed powder 1, add 1.5kg polyvinyl alcohol and 100L pure water to mixed powder 1; Through ball mill mixing, the rotating speed of ball mill is 100r / min, ball mill time 5h, spray granulation, reaction sintering (sintering system is: Ar 2 protection, control the temperature at 1400-1450°C, hold for 2 hours, and cool with the furnace) to prepare Cr 0.5 Ti 0.5 B 2 , that is, ternary boride powder (the particle size of the prepared ternary boride powder is 100-150 μm);

[0048] (2) Surface treatment of the Q235 steel substrate: first, use a corundum grinder to grind the Q235 steel substrate to remove the rust on the surface and increase the surface roughness, then polish it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com