Preparation method for drug crushing shaft

A technology for crushing shafts and medicines, applied in the field of medical equipment and alloy heat treatment, can solve the problems of broken parts damage, research on broken parts, high prices, and achieve the effect of strengthening hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

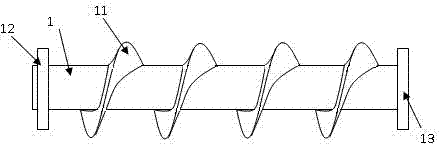

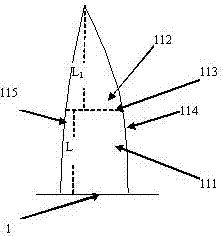

[0028] Such as figure 1 and figure 2 Shown:

[0029] A method for preparing a medicine crushing shaft, the medicine crushing shaft includes a crushing shaft body, a spiral crushing knife, a top bearing and a bottom bearing.

[0030] The top end bearing and the bottom end bearing are respectively arranged around the two ends of the crushing shaft body, the crushing shaft body is cylindrical, and the spiral crushing knife surrounds the crushing shaft body in a spiral downward manner and It is integrally formed with the crushing shaft body.

[0031] The surface of the spiral crushing knife close to the top bearing is the crushing knife surface (main working surface), the surface close to the bottom bearing is the crushing knife back side (secondary working surface), and the arc of the crushing knife surface is smaller than the Describe the arc of the back side of the crushing knife; the middle end of the crushing knife is the arc change node of the respective arcs of the two ...

Embodiment 2

[0047] Such as figure 1 and figure 2 Shown:

[0048] A method for preparing a medicine crushing shaft, the medicine crushing shaft includes a crushing shaft body, a spiral crushing knife, a top bearing and a bottom bearing.

[0049] The top end bearing and the bottom end bearing are respectively arranged around the two ends of the crushing shaft body, the crushing shaft body is cylindrical, and the spiral crushing knife surrounds the crushing shaft body in a spiral downward manner and It is integrally formed with the crushing shaft body.

[0050] The surface of the spiral crushing knife close to the top bearing is the crushing knife surface (main working surface), the surface close to the bottom bearing is the crushing knife back side (secondary working surface), and the arc of the crushing knife surface is smaller than the Describe the arc of the back side of the crushing knife; the middle end of the crushing knife is the arc change node of the respective arcs of the two ...

Embodiment 3

[0066] Such as figure 1 and figure 2 Shown:

[0067] A method for preparing a medicine crushing shaft, the medicine crushing shaft includes a crushing shaft body, a spiral crushing knife, a top bearing and a bottom bearing.

[0068] The top end bearing and the bottom end bearing are respectively arranged around the two ends of the crushing shaft body, the crushing shaft body is cylindrical, and the spiral crushing knife surrounds the crushing shaft body in a spiral downward manner and It is integrally formed with the crushing shaft body.

[0069] The surface of the spiral crushing knife close to the top bearing is the crushing knife surface (main working surface), the surface close to the bottom bearing is the crushing knife back side (secondary working surface), and the arc of the crushing knife surface is smaller than the Describe the arc of the back side of the crushing knife; the middle end of the crushing knife is the arc change node of the respective arcs of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com